Phosphorus-doped porous carbon-coated cobalt tetroxide oxygen reduction catalyst and preparation method and application thereof

A carbon-coated tricobalt oxide and catalyst technology, which is applied to structural parts, electrical components, battery electrodes, etc., to achieve the effects of low price, good methanol tolerance, and low production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] (a) Preparation of ZIF-67

[0031] Take 450mg of Co(NO 3 ) 2 ·6H 2 O was dissolved in 4 mL of deionized water, which was called solution A; 5.5 g of 2-methylimidazole was weighed and dissolved in 20 mL of deionized water, which was called solution B. Under the condition of stirring at room temperature, solution B was dropped into solution A at a constant speed at a constant speed, and the reaction mixture was reacted in a 40°C water bath for 24 hours, then aged at room temperature for 24 hours, centrifuged at 4000rpm for 8 minutes, washed several times with deionized water and ethanol, 60 After vacuum drying at ℃ for 12 hours, the purple crystal ZIF-67 was obtained;

[0032] (b) Preparation of sodium phytate / ZIF-67 complex

[0033] Weigh 2g of ZIF-67 and disperse it in 30mL deionized water, and record it as dispersion C; weigh 2g of sodium phytate and dissolve it in 30mL deionized water, and record it as solution D; Into the dispersion C, react in a water bath at 6...

Embodiment 2

[0037] (a) Preparation of ZIF-67

[0038] Prepare according to the method and conditions of step (a) in Example 1.

[0039] (b) Preparation of sodium phytate / ZIF-67 complex

[0040] Weigh 2g of ZIF-67 and disperse it in 30mL deionized water, and record it as dispersion C; weigh 4g of sodium phytate and dissolve it in 30mL deionized water, and record it as solution D; Into the dispersion C, react in a water bath at 60°C for 8h, centrifuge at 4000rpm for 8min, wash with deionized water and ethanol several times, and dry in vacuum at 60°C for 12h to prepare the sodium phytate / ZIF-67 complex;

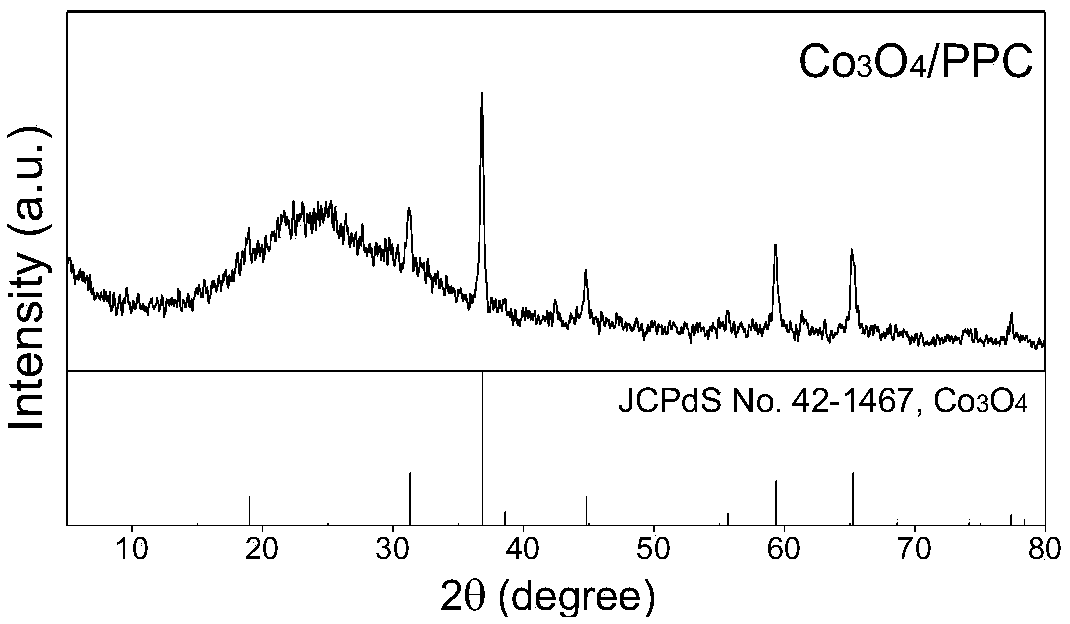

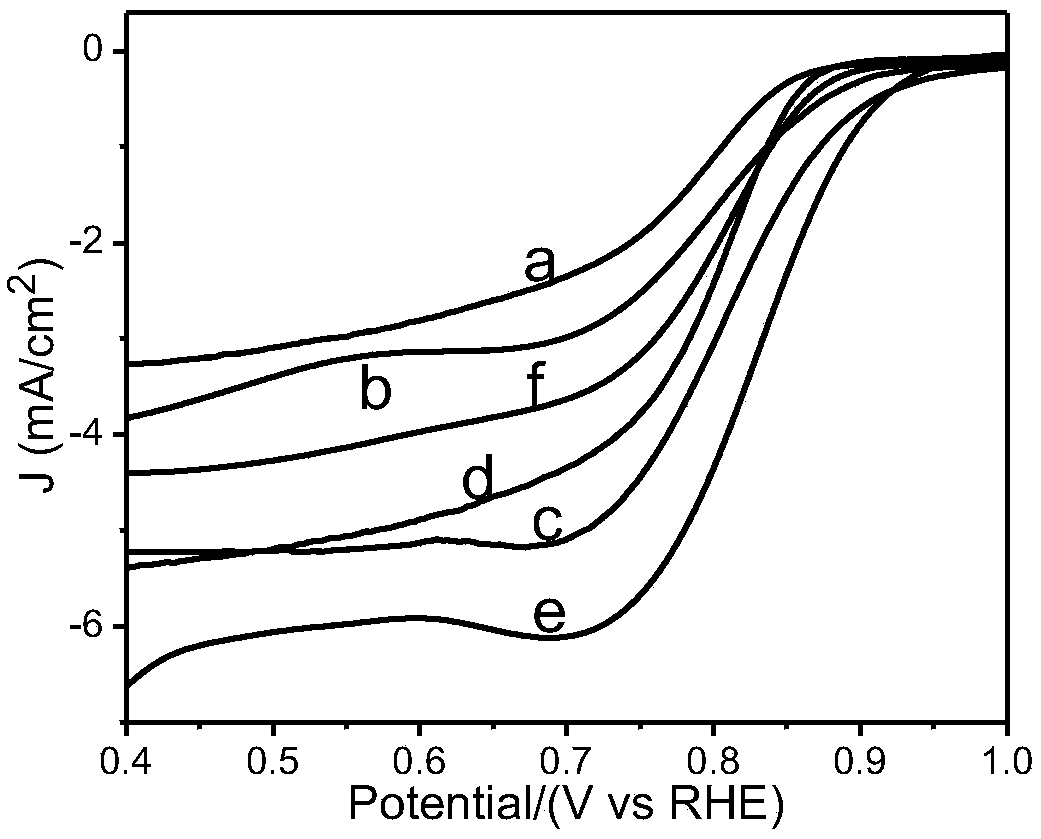

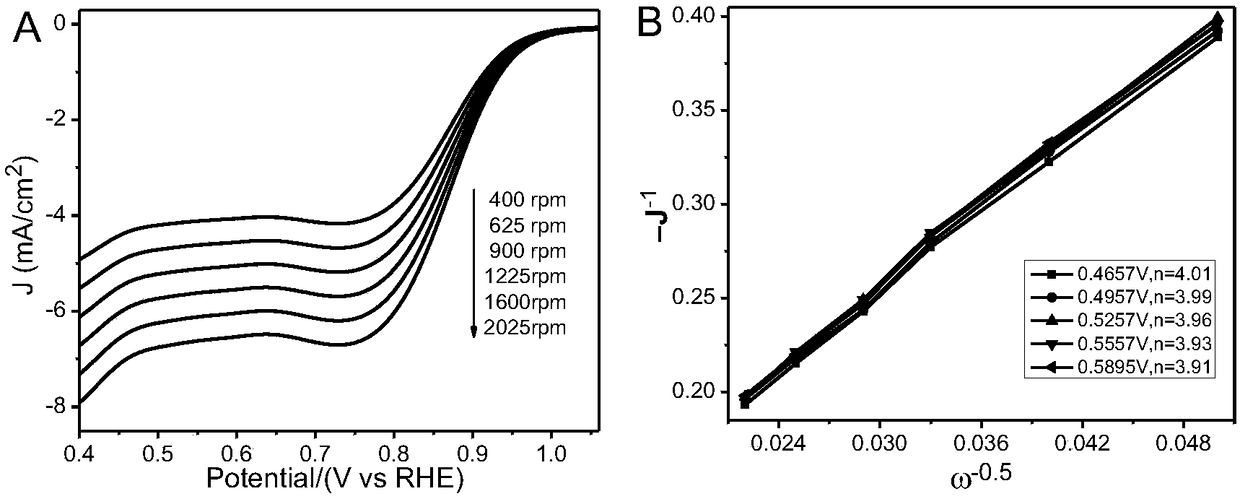

[0041] (c)Co 3 o 4 / PPC Catalyst Preparation

[0042] Grind the sodium phytate / ZIF-67 compound obtained in step (b) into powder, take a certain amount and put it in a porcelain boat, place the porcelain boat in a tube furnace, and liter High temperature to 250 ° C, after constant temperature treatment for 2 hours, the temperature was raised to 700 ° C for 4 hours at the same heating ra...

Embodiment 3

[0044] (a) Preparation of ZIF-67

[0045] Prepare according to the method and conditions of step (a) in Example 1.

[0046] (b) Preparation of sodium phytate / ZIF-67 complex

[0047] Weigh 2g of ZIF-67 and dissolve it in 30mL deionized water, and record it as solution C; weigh 6g of sodium phytate and dissolve it in 30mL deionized water, record it as solution D; under stirring at room temperature, slowly add solution D dropwise to In solution C, react in a water bath at 60°C for 8h, centrifuge at 4000rpm for 8min, wash with deionized water and ethanol several times, and dry in vacuum at 60°C for 12h to prepare the sodium phytate / ZIF-67 complex;

[0048] (c)Co 3 o 4 / PPC Catalyst Preparation

[0049] Grind the sodium phytate / ZIF-67 compound obtained in step (b) into powder, take a certain amount and put it in a porcelain boat, place the porcelain boat in a tube furnace, and liter High temperature to 250 ° C, after constant temperature treatment for 2 hours, the temperature ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| The average particle size | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

| The average particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com