Rolling bearing defect detecting device based on oil spectrum analysis and magnetic flux leakage testing

A rolling bearing and spectral analysis technology, which is applied in the field of non-destructive detection of pressure-bearing rolling bearing defects, can solve the problems of large abrasive particles and cannot be detected, and achieve the effects of accurate measurement, rapid multiple measurements, strong innovation and practical value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

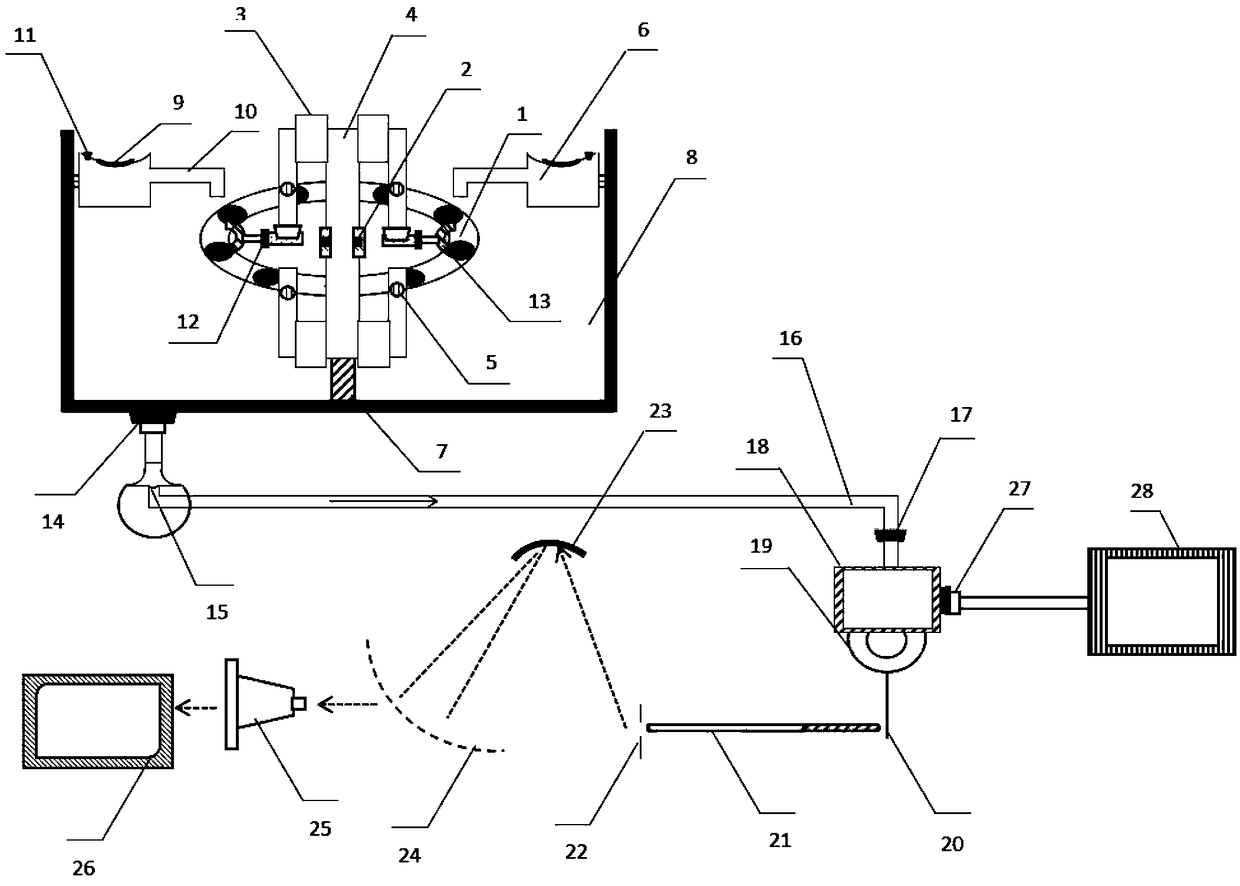

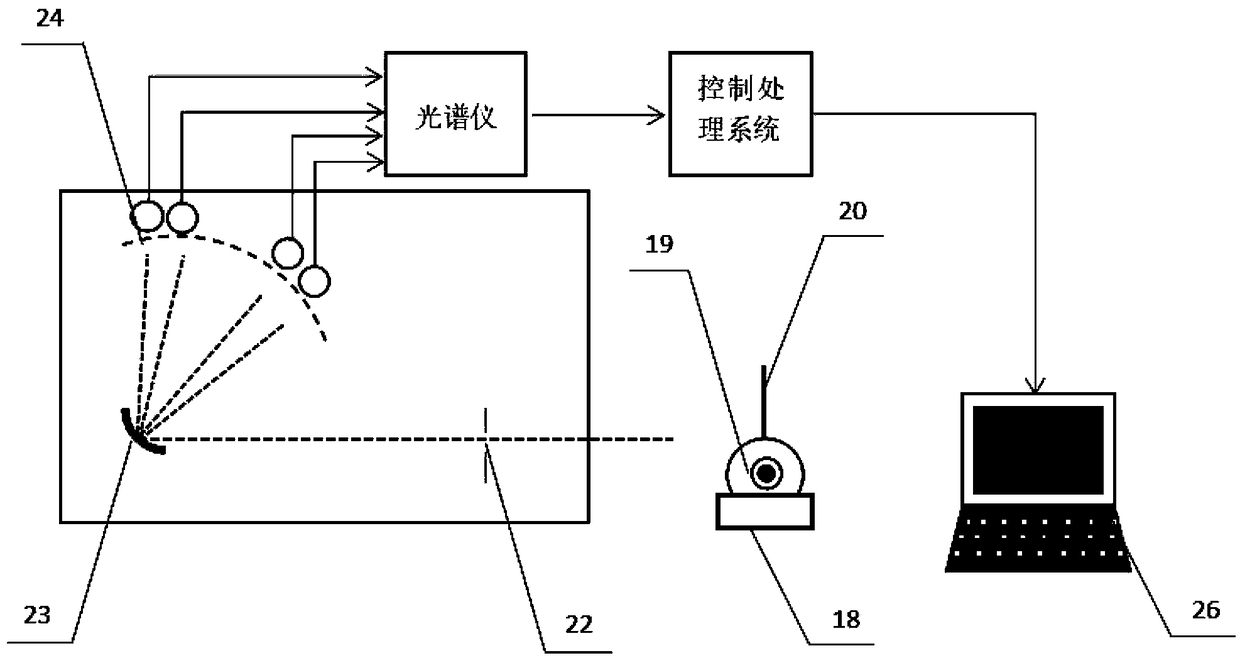

[0034] Such as figure 1 Shown: Rolling bearing defect detection device based on oil spectrum analysis and magnetic flux leakage detection, consisting of rolling bearing to be tested (1), Hall element (2), permanent magnet (3), yoke (4), magnetic concentrator (5) , fuel injection cavity (6), rotating base (7), collection tank (8), piezoelectric fuel injector (9), fuel injection port (10), fuel injection port (11), telescopic bracket (12), adjustable Bayonet (13), first valve (14), filter chamber (15), latex tube (16), second valve (17), detection chamber (18), turntable electrode (19), graphite rod electrode (20) , an optical fiber (21), an entrance slit (22), a grating (23), an exit slit (24), a spectrometer (25), a computer workstation (26), a third valve (27) and a recovery cavity (28).

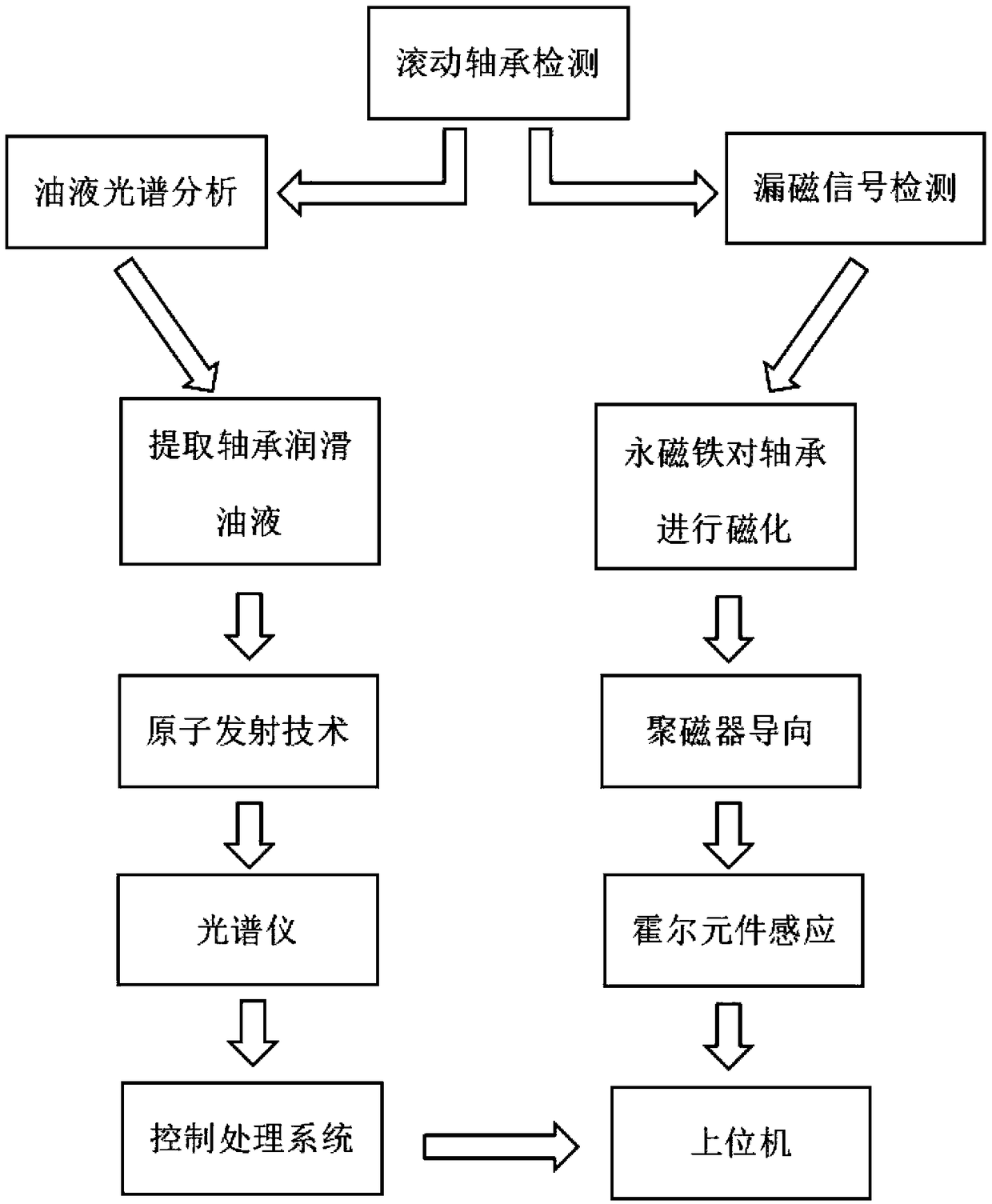

[0035] Rolling bearing defect detection device based on oil spectrum analysis and magnetic flux leakage detection, its working process is as follows figure 2As shown in the system block...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

| wavelength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com