Preparation method for transition metal oxide nitrogen-and-phosphorus-doped catalyst applied to zinc-air battery

A transition metal, zinc-air battery technology, applied in fuel cell type half cells and primary cell type half cells, battery electrodes, circuits, etc., can solve the problems of limited resources and expensive cathode catalysts, and achieve a simple preparation process. , Conducive to large-scale development and utilization, the effect of excellent oxygen reduction activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] A method for preparing a transition metal oxide nitrogen and phosphorus doped catalyst applied to a zinc-air battery, specifically comprising the following steps:

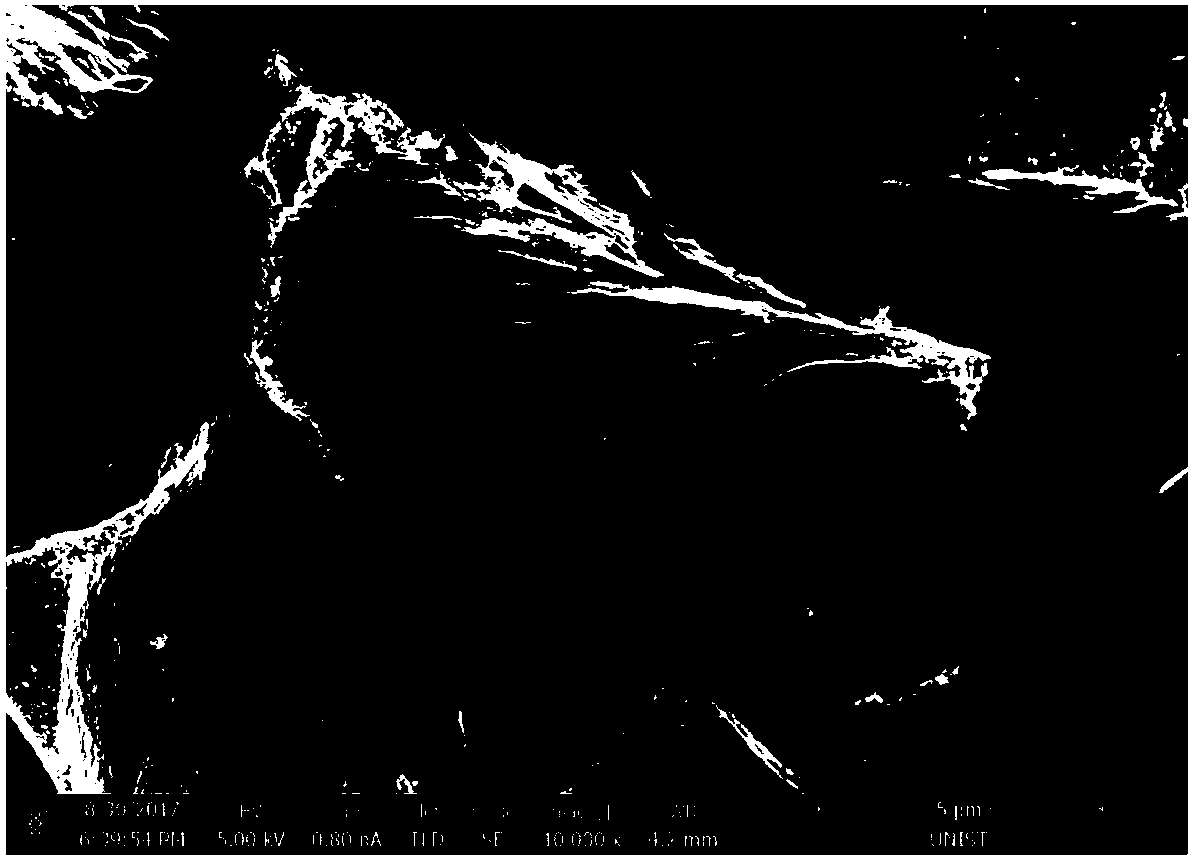

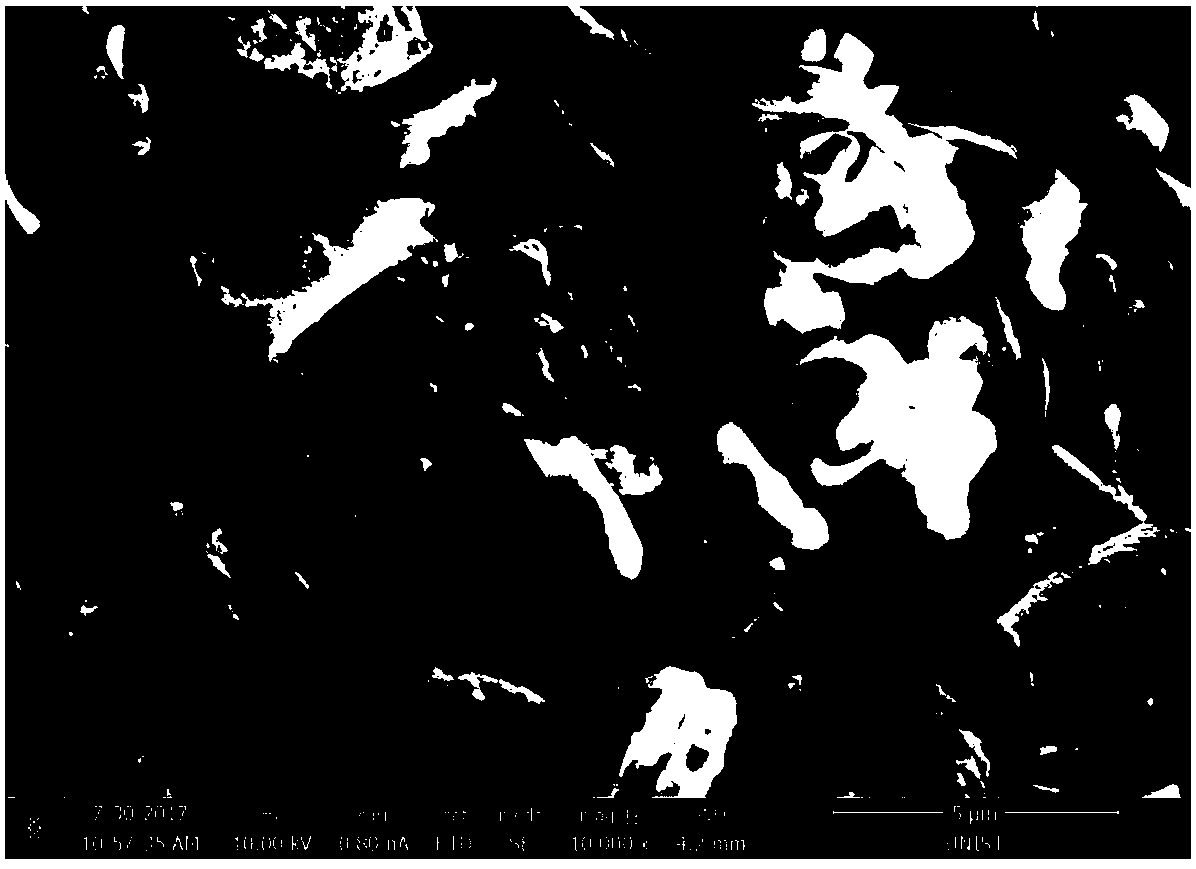

[0034] The first step, at room temperature, add 0.25g manganese acetate to quantitative phytic acid and ultrasonically for 20min to dissolve all the metal salts; then add excess acetone to the solution to produce supramolecular compound precipitation, finally pour out the solvent, and wash the supramolecular compound repeatedly with acetone Compound 3 times. In the second step, the supramolecular compound obtained in the first step was transferred to the porcelain boat of the tube furnace, and the temperature was raised to 800°C at a rate of 5°C / min under an argon atmosphere, and then kept at a constant temperature for 2 hours, and finally Cool to room temperature. In the third step, the sample obtained in the previous step is fully ground, transferred to a single-necked flask, added with excess 2M hydrochl...

Embodiment 2

[0036] A method for preparing a transition metal oxide nitrogen and phosphorus doped catalyst applied to a zinc-air battery, specifically comprising the following steps:

[0037] The first step is to add 0.25g of copper acetate to 2ml of phytic acid at room temperature and ultrasonically for 20 minutes to dissolve all the metal salts; then add excess acetone to the solution to produce supramolecular compound precipitation, and finally pour out the solvent and wash the supramolecular compound repeatedly with acetone Compound 3 times. In the second step, the supramolecular compound obtained in the first step was transferred to the porcelain boat of the tube furnace, and the temperature was raised to 800°C at a rate of 5°C / min under an argon atmosphere, and then kept at a constant temperature for 2 hours, and finally Cool to room temperature. The third step is to fully grind the sample obtained in the previous step, transfer it to a single-necked flask, add excess 2M hydrochlori...

Embodiment 3

[0039] A method for preparing a transition metal oxide nitrogen and phosphorus doped catalyst applied to a zinc-air battery, specifically comprising the following steps:

[0040]The first step is to add 0.25g of cobalt acetate to 2ml of phytic acid at room temperature and ultrasonically for 20 minutes to dissolve all metal salts; then add excess acetone to the solution to produce supramolecular compound precipitation, and finally pour out the solvent and wash the supramolecular compound repeatedly with acetone Compound 3 times. In the second step, the supramolecular compound obtained in the first step was transferred to the porcelain boat of the tube furnace, and the temperature was raised to 800°C at a rate of 5°C / min under an argon atmosphere, and then kept at a constant temperature for 2 hours, and finally Cool to room temperature. The third step is to fully grind the sample obtained in the previous step, transfer it to a single-necked flask, add excess 2m hydrochloric aci...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com