Electric flocculation device for separation and collection of industrial air-assisted microalgae water

A technology of algal water separation and electrocoagulation, applied in water/sewage treatment, chemical instruments and methods, flotation water/sewage treatment, etc., can solve problems such as low efficiency, high energy consumption, instability, etc., and achieve enhanced mass transfer , increase the electrode surface area, improve the effect of electrocoagulation efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0051] Example 1: Algae hydroelectric flocculation separation and air flotation collection of microalgae in chlorella culture solution

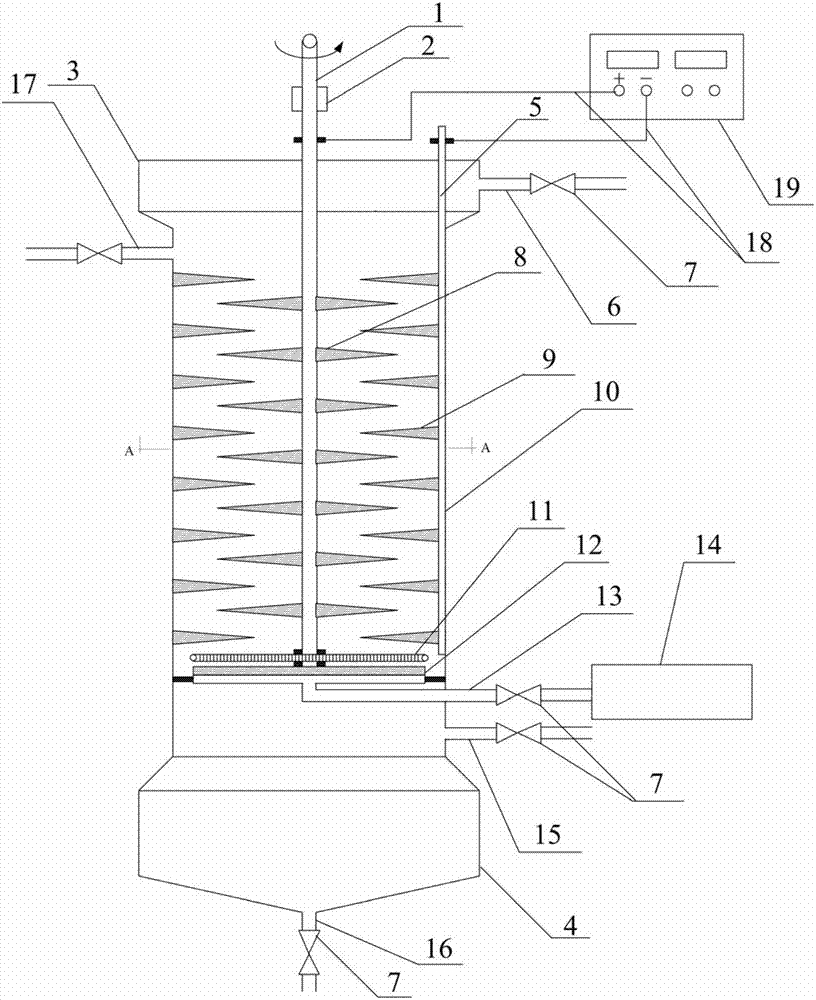

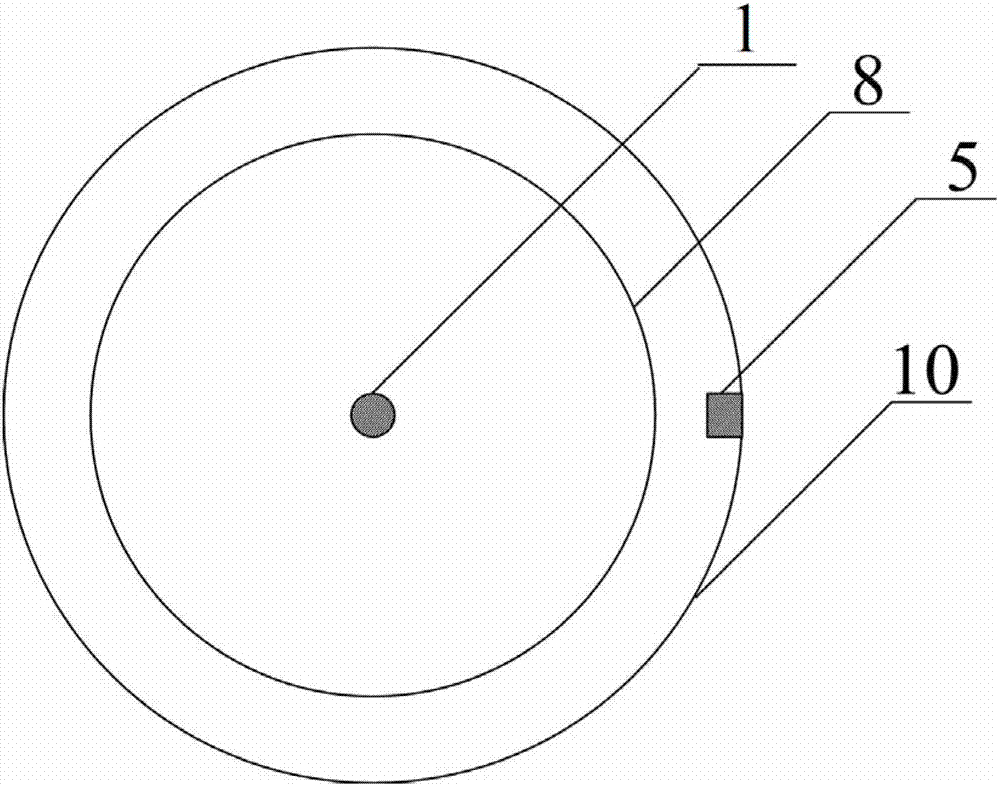

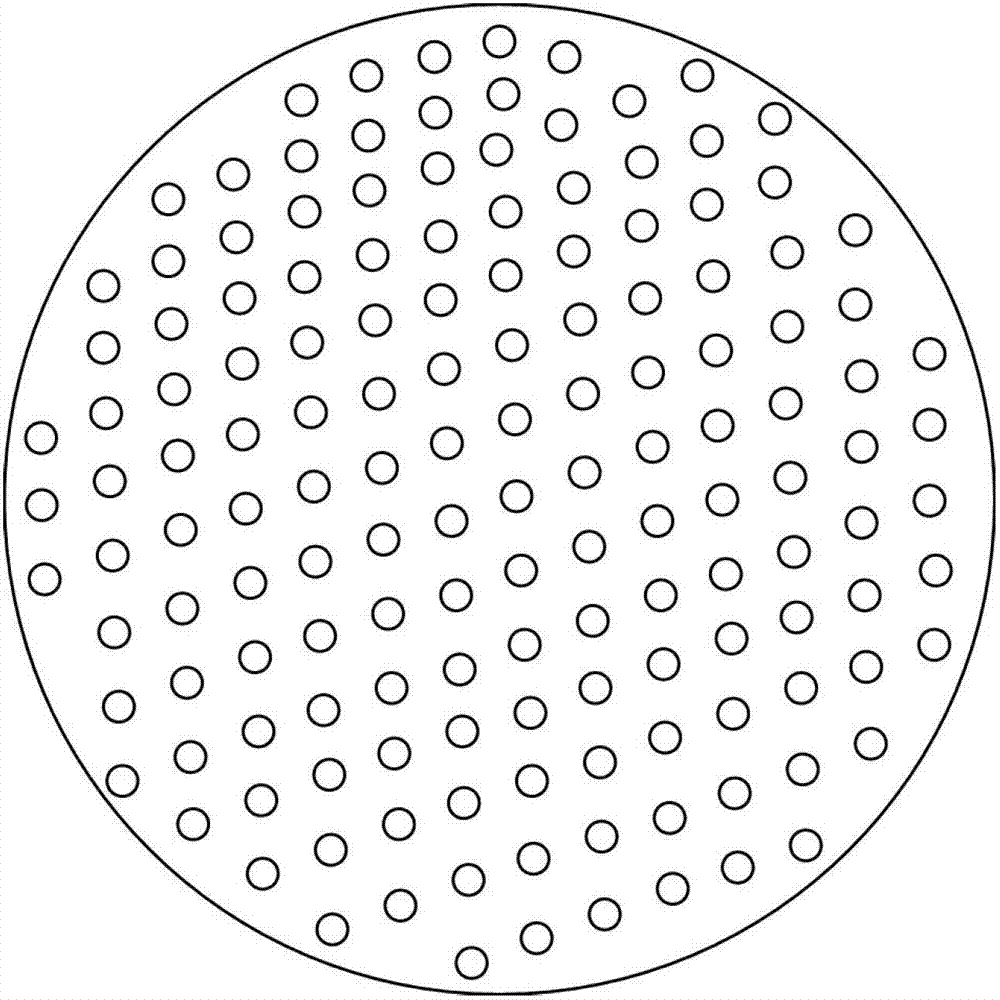

[0052] This embodiment adopts the following device: the device includes a tower body 10, a main shaft 1, a side connecting rod 5, a turntable electrode plate 8, an annular electrode plate 9, a gas distributor 12 and an air supply device 14; plate 8, the same pole annular electrode plate 9 fixed to the side connecting rod 5 adjacent to the inner wall of the tower is alternately distributed, the main shaft 1 and the turntable electrode plate 8 can rotate under the drive of the motor; the main shaft 1 and the side connecting rod 5 pass through copper The wire 18 is connected to the positive and negative poles of the DC power supply 19; the gas distributor 12 is arranged under the concentric cylinder at the lower part of the tower body 10, and is connected to the bottom of the main shaft 1; gas; the side of the upper enlarged section 3 of the tow...

Embodiment 2

[0054] Example 2: Separation of algae by hydroelectric flocculation of algae in spirulina culture solution Hydroelectric flocculation separation of algae

[0055] The device used in this embodiment is the same as in Embodiment 1.

[0056] The experimental process is as follows: the culture solution containing spirulina enters from the feed liquid inlet 17, and the turntable electrode plate 8 fixedly connected to the main shaft 1 is driven by external power, relative to the annular electrode plate 9 fixedly connected to the side connecting rod 5. Rotating motion; after electrification, the spirulina in the feed liquid produces flocculation, agglomeration and sedimentation under the action of the electric field; the air supply device 14 sends air through the gas distributor 12 at the lower part of the tower body 10 to generate air bubbles; the rising bubble surface absorbs the flocculated spirulina and carries the spirulina The algae moves to the top of the tower body 10; the re...

Embodiment 3

[0057] Example 3: Separation of algal hydroelectric flocculation and air flotation collection of cyanobacteria in Kunming Dianchi Lake

[0058] The device used in this embodiment is the same as in Embodiment 1.

[0059] The experiment process is as follows: Dianchi Lake water containing cyanobacteria enters from the feed liquid inlet 17, and the rotating disk electrode plate 8 fixedly connected to the main shaft 1 is driven by external power relative to the annular electrode plate 9 fixedly connected to the side connecting rod 5. Rotational movement; after electrification, the cyanobacteria in the water produce flocculation, agglomeration and settlement under the action of the electric field; the air supply device 14 supplies air through the gas distributor 12 at the lower part of the tower body 10 to generate air bubbles; Movement; the reunited cyanobacteria are brought to the liquid surface at the upper part of the tower body 10 by the air bubbles; the liquid level at the up...

PUM

| Property | Measurement | Unit |

|---|---|---|

| recovery rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com