Cobalt-carbon porous nanocomposite oxygen reduction electrocatalyst and its preparation method and application

A nanocomposite, electrocatalyst technology, applied in circuits, electrical components, battery electrodes, etc., to achieve good methanol tolerance, easy mass production, and abundant resources.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] (a) Preparation of MOF compound [Co(O-BDC)(bbp)]

[0034] 0.120g cobalt chloride hexahydrate (0.5mmol), 0.137g 1,3-dibenzimidazolyl propane (0.5mmol), 0.092g hydroxyisophthalic acid (0.5mmol) and 0.060g sodium hydroxide (1.5mmol ) into a polytetrafluoroethylene-lined stainless steel reactor containing 10 mL of deionized water, sealed the lid, and reacted hydrothermally at 160 °C for 72 h, cooled to room temperature, filtered, washed and dried to obtain a pink MOF compound [Co(O -BDC)(bbp);

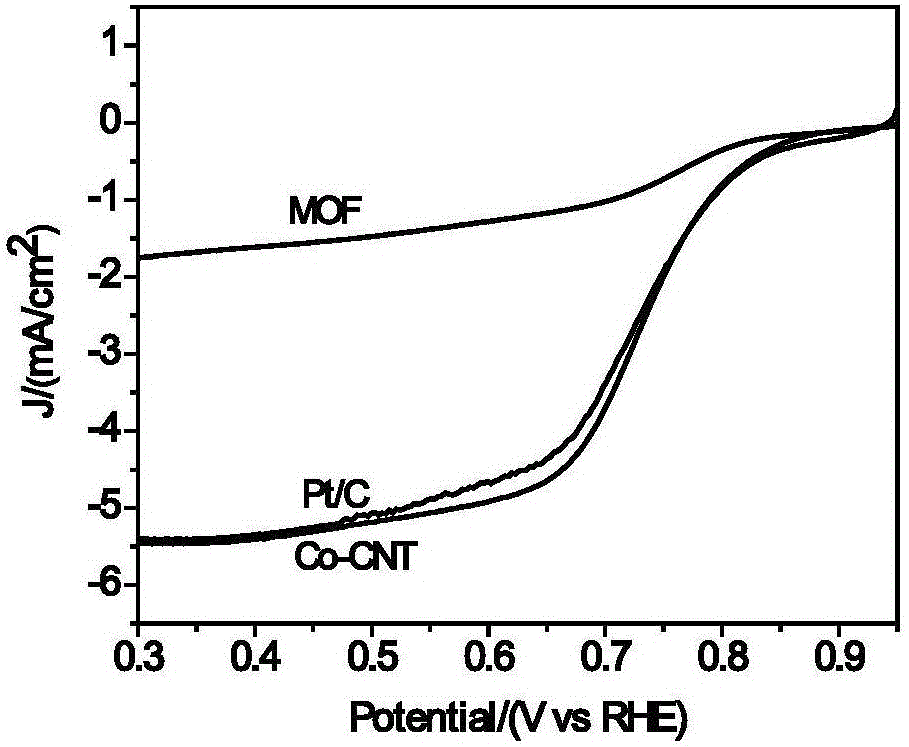

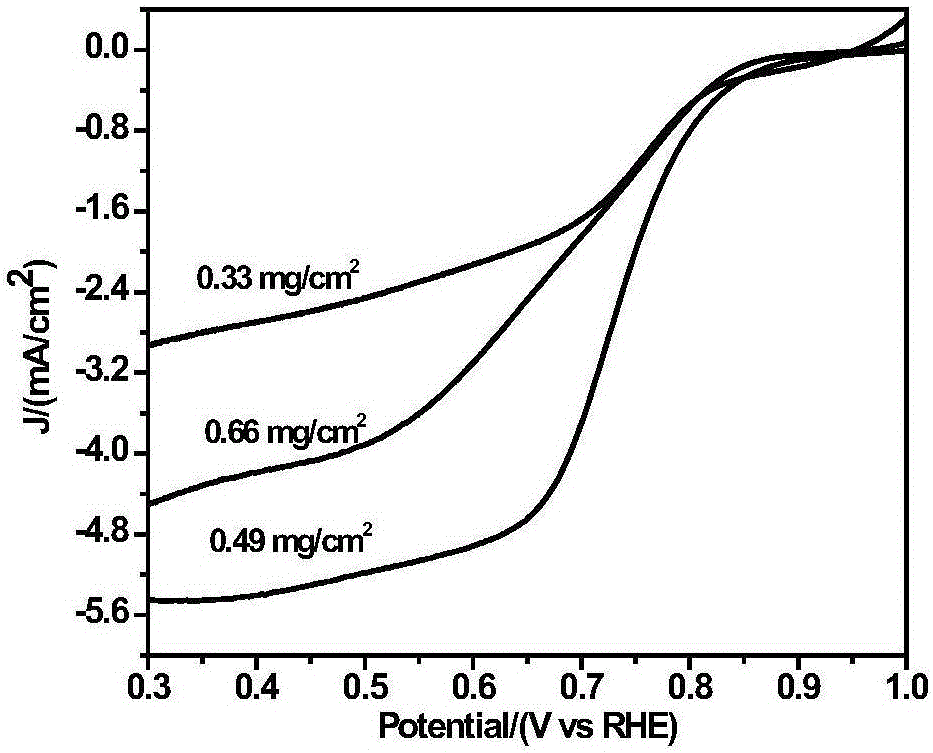

[0035] (b) Preparation of cobalt-carbon porous nanocomposite oxygen reduction electrocatalyst Co / NPCC

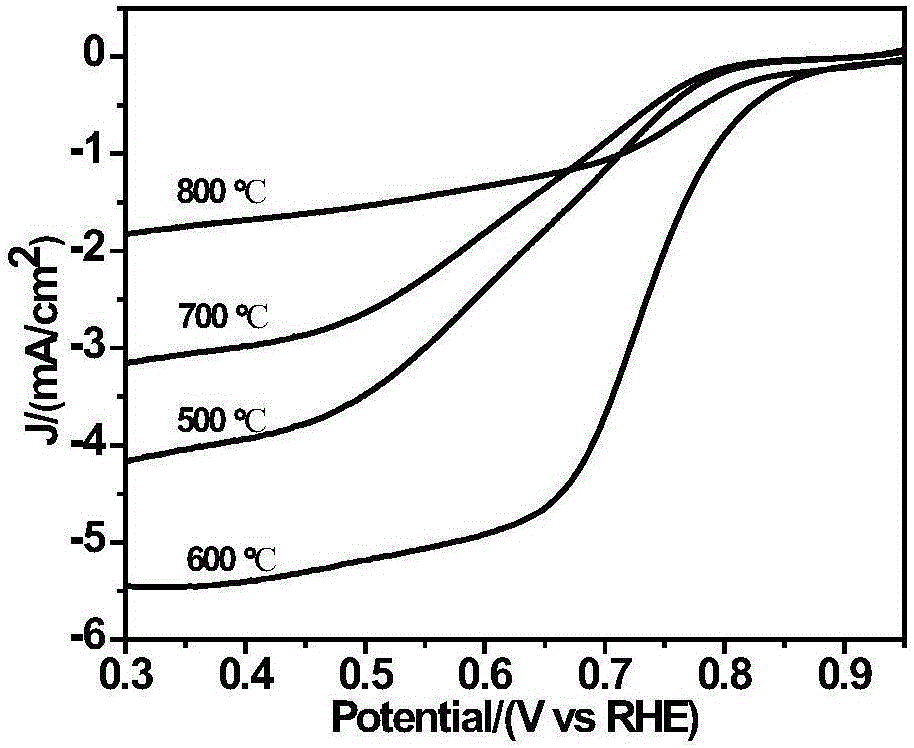

[0036] Grind the MOF compound [Co(O-BDC)(bbp)] obtained in step (a) into powder, take a certain amount and place it in a porcelain boat in a tube furnace at a rate of 5°C / min under a nitrogen atmosphere Heating, first raised to 250°C for 2 hours, then heated to 500°C for 4 hours to obtain the cobalt-carbon porous nanocomposite oxygen reduction electrocatalyst Co / NPCC with a spec...

Embodiment 2

[0038] (a) Preparation of Co-MOF

[0039] Prepare according to the method and conditions of step (a) in Example 1.

[0040] (b) Preparation of cobalt-carbon porous nanocomposite oxygen reduction electrocatalyst Co / NPCC

[0041] Grind the MOF compound [Co(O-BDC)(bbp)] obtained in step (a) into powder, take a certain amount and place it in a porcelain boat in a tube furnace at a rate of 5°C / min under a nitrogen atmosphere Heating, first raised to 250°C for 2 hours, then heated to 600°C for 4 hours to obtain the cobalt-carbon porous nanocomposite oxygen reduction electrocatalyst Co / NPCC with a specific surface area of 162.27m 2 / g.

Embodiment 3

[0043] (a) Preparation of Co-MOF

[0044] Prepare according to the method and conditions of step (a) in Example 1.

[0045] (b) Preparation of cobalt-carbon porous nanocomposite oxygen reduction electrocatalyst Co / NPCC

[0046] Grind the MOF compound [Co(O-BDC)(bbp)] obtained in step (a) into powder, take a certain amount and place it in a porcelain boat in a tube furnace at a rate of 5°C / min under a nitrogen atmosphere Heating, first raised to 250°C for 2 hours, then heated to 700°C for 4 hours to obtain the cobalt-carbon porous nanocomposite oxygen reduction electrocatalyst Co / NPCC with a specific surface area of 123.63m 2 / g.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com