A kind of mos2 nanosphere bifunctional oxygen catalyst with hierarchical structure and its preparation method and application

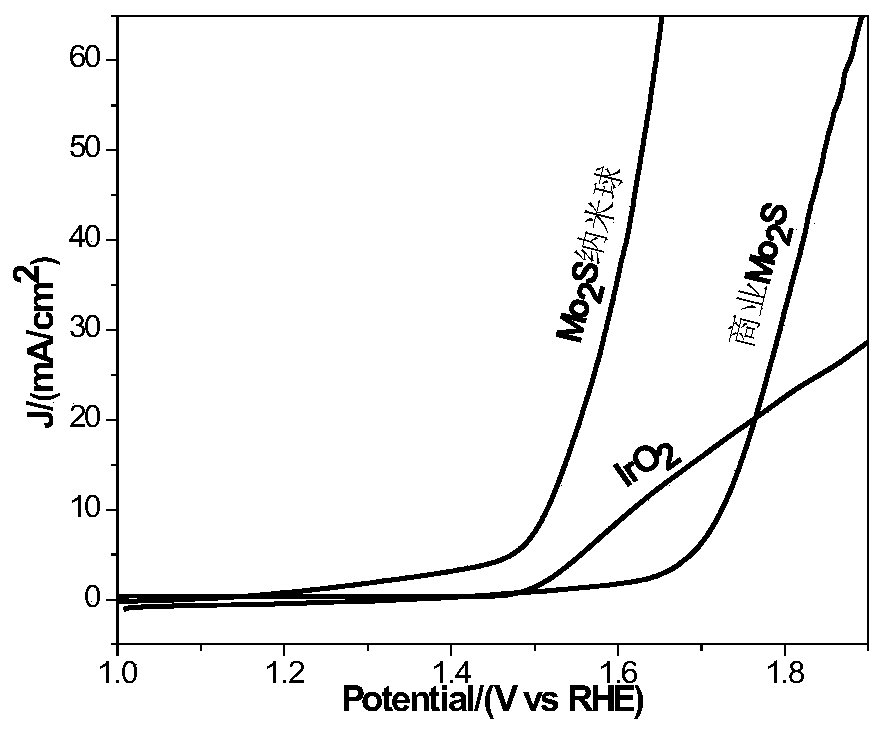

A hierarchical structure, oxygen catalyst technology, applied in catalyst activation/preparation, chemical instruments and methods, physical/chemical process catalysts, etc., to achieve the effects of superior OER and ORR bifunctional catalytic activity, low cost, and easily available and cheap raw materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

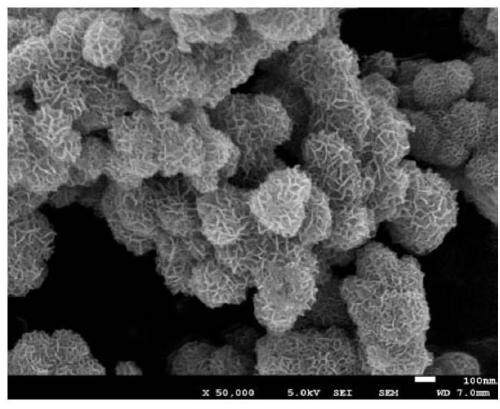

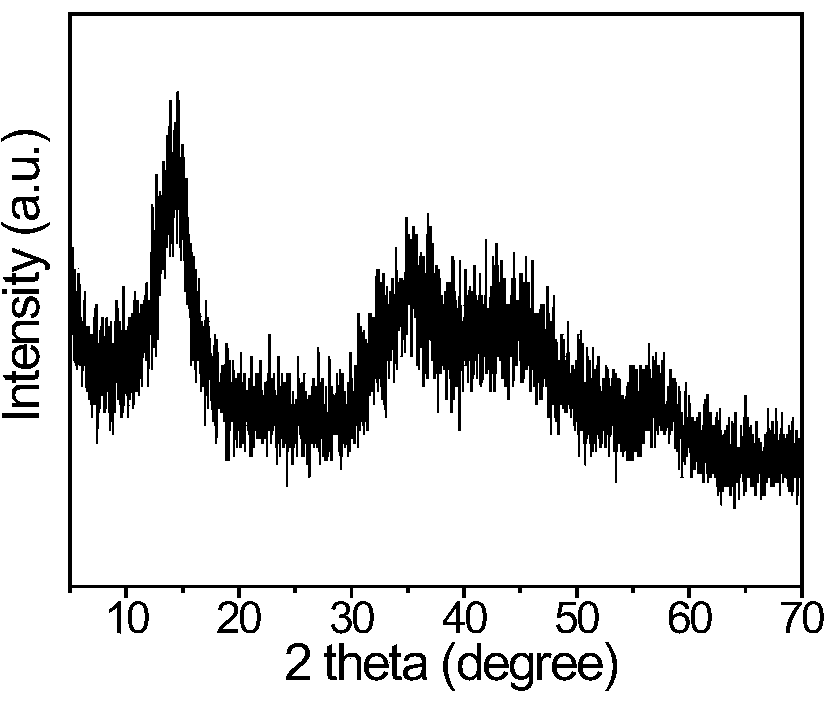

Embodiment 1

[0026] 5 mmol Na 2 MoO 4 ·2H 2 O is dissolved in 60ml of water, after fully stirring and mixing, add 15mmol KSCN to the above solution, after stirring and fully dissolving, add 8ml concentrated HCl to it, stir well, transfer into a 100ml hydrothermal reaction kettle, and seal the cover. It was hydrothermally reacted at 140 °C for 32 h, cooled to room temperature, centrifuged, washed with deionized water and anhydrous ethanol in turn, and vacuum dried at 50 °C overnight to obtain MoS with a hierarchical structure. 2 Nanosphere bifunctional oxygen catalyst with a specific surface area of 197.26m 2 / g.

Embodiment 2

[0028] 5 mmol Na 2 MoO 4 ·2H 2O is dissolved in 60ml of water, after fully stirring and mixing, add 15mmol KSCN to the above solution, after stirring and fully dissolving, add 8ml concentrated HCl to it, stir well, transfer into a 100ml hydrothermal reaction kettle, and seal the cover. It was hydrothermally reacted at 160 °C for 18 h, cooled to room temperature, centrifuged, washed with deionized water and anhydrous ethanol in turn, and vacuum dried at 50 °C overnight to obtain MoS with a hierarchical structure. 2 Nanosphere bifunctional oxygen catalyst with a specific surface area of 202.38m 2 / g.

Embodiment 3

[0030] 5 mmol Na 2 MoO 4 ·2H 2 O is dissolved in 60ml of water, after fully stirring and mixing, add 15mmol KSCN to the above solution, after stirring and fully dissolving, add 8ml concentrated HCl to it, stir well, transfer into a 100ml hydrothermal reaction kettle, and seal the cover. It was hydrothermally reacted at 180 °C for 20 h, cooled to room temperature, centrifuged, washed with deionized water and anhydrous ethanol in turn, and vacuum dried at 50 °C overnight to obtain MoS with a hierarchical structure. 2 Nanosphere bifunctional oxygen catalyst with a specific surface area of 186.46m 2 / g.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com