A direct synthesis of g-c 3 no 4 Method for supporting cerium oxide nanocomposite material

A nanocomposite material, g-c3n4 technology, applied in the direction of chemical instruments and methods, nanotechnology, nanotechnology, etc., to achieve the effect of controllable synthesis

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

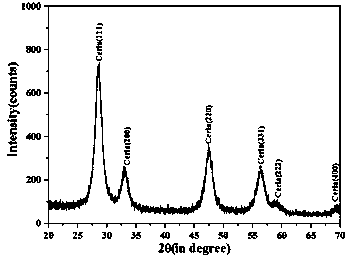

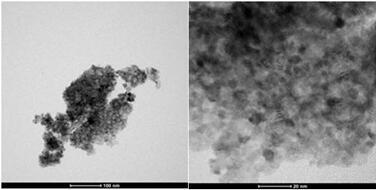

[0030] Use cerium nitrate as raw material, dissolve it in deionized water to prepare 100 ml, 0.45 mol / L cerium nitrate solution, then add 0.0675 mol of citric acid, stir to dissolve, add ammonium nitrate, adjust the actual oxygen supply and the required oxygen amount of the system The ratio is 0.50; after it is completely dissolved, adjust the pH to 0.5 with 28wt% ammonia water; the obtained solution is heated and stirred in a water bath, and after evaporating part of the water, add melamine designed to synthesize 10% of the mass of cerium oxide, and continue heating and stirring until it solidifies Gelling, to obtain a beige gel, the resulting gel is placed in a vacuum oven at 80 o C is dried to constant weight, obtains xerogel; Gained xerogel is placed in quartz beaker, through 400 o C for about 1 minute to induce combustion, and the combustion products are collected and ground to obtain the final product. The resulting product is dark gray, and the X-ray spectrum of the pr...

Embodiment 2

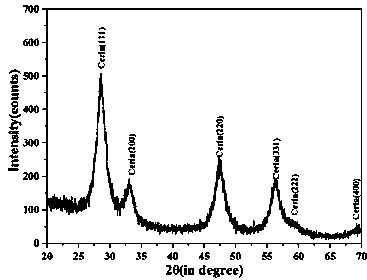

[0032] Use cerium nitrate as raw material, dissolve it in deionized water to prepare 100 ml, 0.25 mol / L cerium nitrate solution, then add 0.0375 mol of citric acid, stir to dissolve, add ammonium nitrate, adjust the actual oxygen supply and the required oxygen amount of the system The ratio is 0.50; after it is completely dissolved, adjust the pH to 0.9 with 28wt% ammonia water; the obtained solution is heated and stirred in a water bath, and after evaporating part of the water, add melamine designed to synthesize 40% of the mass of cerium oxide, and continue heating and stirring until it solidifies Gelling to obtain a beige gel, the resulting gel is placed in a vacuum oven for 60 o C is dried to constant weight, obtains xerogel; Gained xerogel is placed in quartz beaker, through 400 o C for about 1 minute to induce combustion, and the combustion products are collected and ground to obtain the final product. The resulting product is dark gray, and the X-ray spectrum of the pr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| quality score | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com