Rotary vane compressor with hydrofluoroolefin refrigerant gas and high speed tool steel vane

A rotary compressor, hydrofluoroolefin technology, applied in the direction of rotary piston machinery, rotary piston pump, pump combination for elastic fluid rotary piston type/oscillating piston type, etc., to achieve low cost and high reliability , the effect of preventing abrasive wear

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

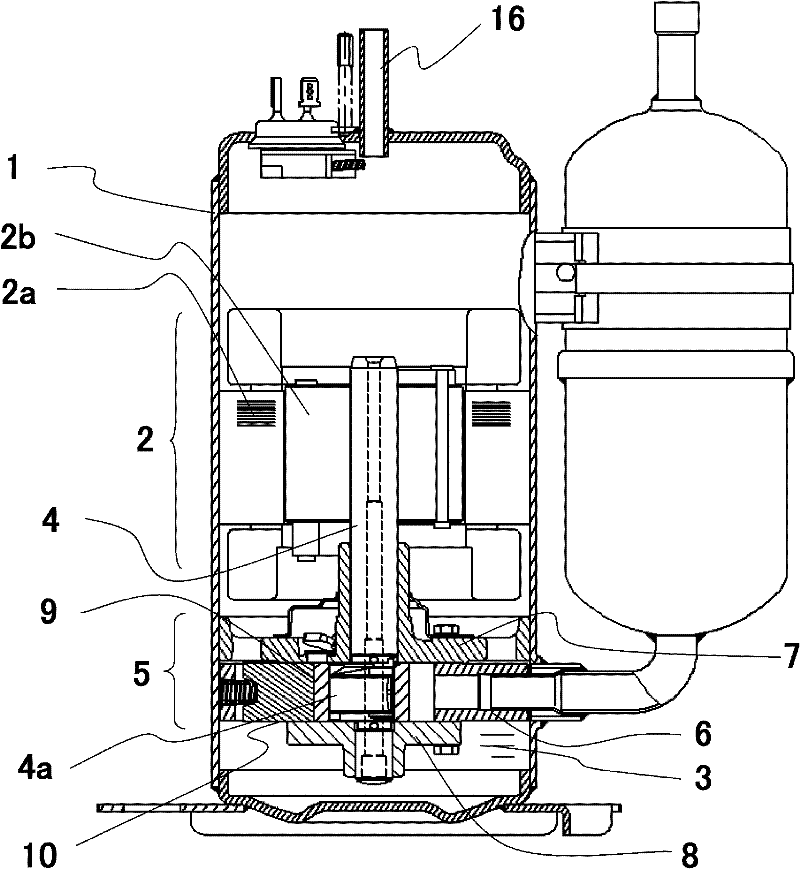

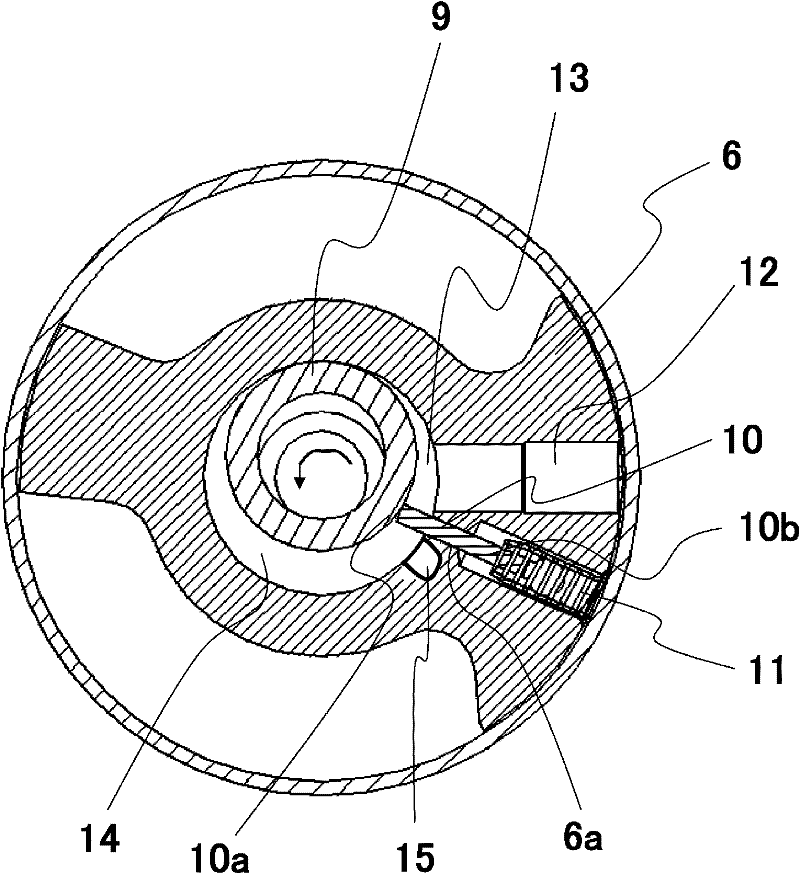

[0024] figure 1 It is a longitudinal sectional view showing the rotary compressor in Embodiment 1 of the present invention. Such as figure 1 As shown in , the stator 2a of the motor 2 is fixed to the upper area of the airtight container 1, and the compression mechanism part 5 having the shaft 4 driven by the rotor 2b is fixed to the lower area of the airtight container 1. For example, the main bearing 7 is fixed to the top surface of the cylinder 6 of the compression mechanism portion 5 and the sub-bearing 8 is fixed to the bottom surface of the cylinder 6 using bolts. In the cylinder 6, the piston 9 is placed in the eccentric region 4a of the shaft 4, so that the shaft performs an eccentric rotation.

[0025] In addition, what is stored in the bottom region of the airtight container 1 is miscible with a refrigerant (hereinafter, referred to as refrigerant R) containing a carbon-carbon double bond-containing hydrofluoroolefin (for example, HFO1234yf) as an essential co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com