Method and apparatus for preparing fumed silica from coal gangue

A technology of fumed silica and coal gangue, applied in the direction of silica, silicon oxide, etc., can solve the problems of low efficiency and non-reactivity, etc., and achieve the effects of simple process flow, guaranteed operation safety, and saved operation time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

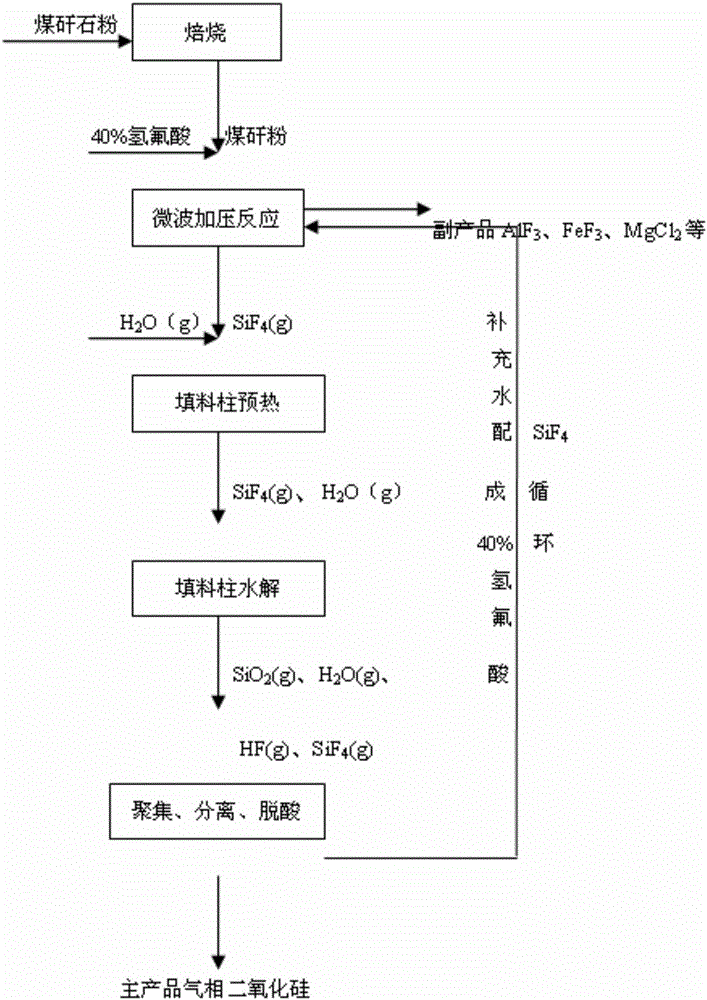

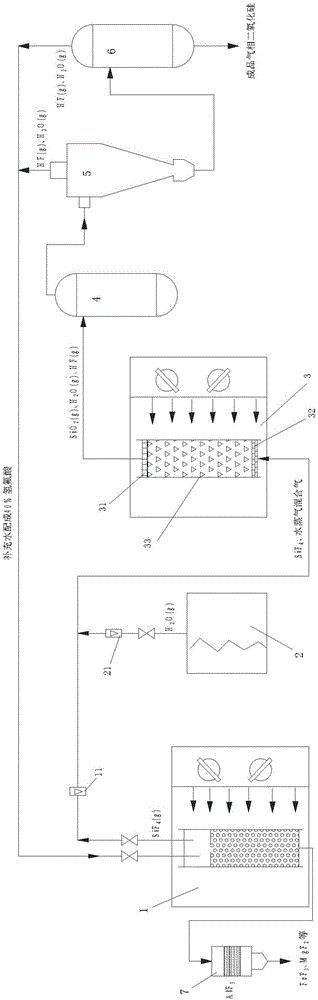

Method used

Image

Examples

Embodiment 1

[0099] (1) Preparation of wave absorbing agent

[0100] Immerse chromium trioxide with 3.0mol / L nitric acid aqueous solution for the first time in a 70°C constant temperature water bath for 8 hours, and then soak it with 2.0% ferric nitrate aqueous solution for 12 hours at 25°C for the second time, age for 18 hours, and finally Put it into a muffle furnace for calcination, first keep the temperature at 110 ℃ for 30 minutes, then calcine at 1200 ℃ for 2 hours, cool naturally, and sieve to obtain the finished product of 10-mesh wave absorbing agent.

[0101] (2) Fumed silica preparation conditions

[0102] Pass the crushed coal gangue through a 70-mesh sieve and roast it in a muffle furnace at 750°C for 1.5 hours, and then react with 40% hydrofluoric acid at a ratio of 1g:4mL in a microwave field with a gauge pressure of 0.6Mpa. The temperature was 140°C. The outlet flow rate of silicon tetrafluoride gas is controlled at 3200kg / (m 3 Absorbent﹒ h), the water vapor is in exces...

Embodiment 2

[0104] (1) Preparation of wave absorbing agent

[0105] Immerse chromium trioxide with 3.0 mol / L nitric acid aqueous solution for the first time in a constant temperature water bath at 80°C for 9 hours, and for the second time at 25°C with 2.0% ferric nitrate aqueous solution for 13 hours, age for 20 hours, and finally Put it into a muffle furnace for calcination, first keep the temperature at 110 ℃ for 30 minutes, then calcine at 1200 ℃ for 2 hours, cool naturally, and sieve to obtain the finished product of 10-mesh wave absorbing agent.

[0106] (2) Fumed silica preparation conditions

[0107] Pass the crushed coal gangue through an 80-mesh sieve and roast it in a muffle furnace at 750°C for 1.5 hours, and then react with 40% hydrofluoric acid at a ratio of 1g:4mL in a microwave field with a gauge pressure of 0.7Mpa. The temperature was 140°C. The outlet flow rate of silicon tetrafluoride gas is controlled at 3600kg / (m 3 Absorbent﹒ h), the water vapor is in excess of 1.7...

Embodiment 3

[0109] (1) Preparation of wave absorbing agent

[0110] Immerse chromium trioxide in a 90°C constant temperature water bath for 10 hours for the first time with 3.0 mol / L nitric acid aqueous solution, and for the second time at 25°C with 2.0% ferric nitrate aqueous solution for 14 hours, age for 22 hours, and finally Put it into a muffle furnace for calcination, first keep the temperature at 110 ℃ for 30 minutes, then calcine at 1200 ℃ for 2 hours, cool naturally, and sieve to obtain the finished product of 20-mesh wave absorbing agent.

[0111] (2) Fumed silica preparation conditions

[0112] Pass the crushed coal gangue through a 100-mesh sieve and roast it in a muffle furnace at 800°C for 1.5 hours, and then react with 40% hydrofluoric acid at a ratio of 1g:5mL in a microwave field with a gauge pressure of 0.8Mpa. The temperature is 150°C. The outlet flow rate of silicon tetrafluoride gas is controlled at 4000kg / (m 3 Absorbent﹒ h), the water vapor is in excess of 2.0 ac...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com