Titanium and chromium doped iron fluoride-carbon nanometer composite positive electrode material, and preparation method and application thereof

A carbon nanocomposite, cathode material technology, applied in battery electrodes, electrochemical generators, electrical components, etc., can solve the problems of limited practical application, poor conductivity and kinetic properties of iron fluoride materials, and low material rate performance. , to achieve the effects of excellent rate characteristics and cycle performance, enhanced electrical conductivity, and improved diffusion performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0058] The invention provides a preparation method of a titanium-chromium-doped ferric fluoride-carbon nanocomposite positive electrode material, comprising the following steps:

[0059] 1) react after mixing iron hydrate, chromium hydrate, titanium salt and fluoride to obtain the doped iron fluoride precursor shown in formula I:

[0060] Fe 1-x-y Cr x Ti 0.75y f 3 (H 2 O) 0.33 Formula I;

[0061] Among them, 0.1≤x≤0.2, 0.06≤y≤0.1;

[0062] 2) mixing the doped ferric fluoride precursor with a carbon-containing conductive material and coating to obtain the titanium-chromium-doped ferric fluoride-carbon nanocomposite positive electrode material shown in formula II;

[0063] Fe 1-x-y Cr x Ti 0.75y f 3 (H 2 O) 0.33 @C Formula II;

[0064] Among them, 0.1≤x≤0.2, 0.06≤y≤0.1.

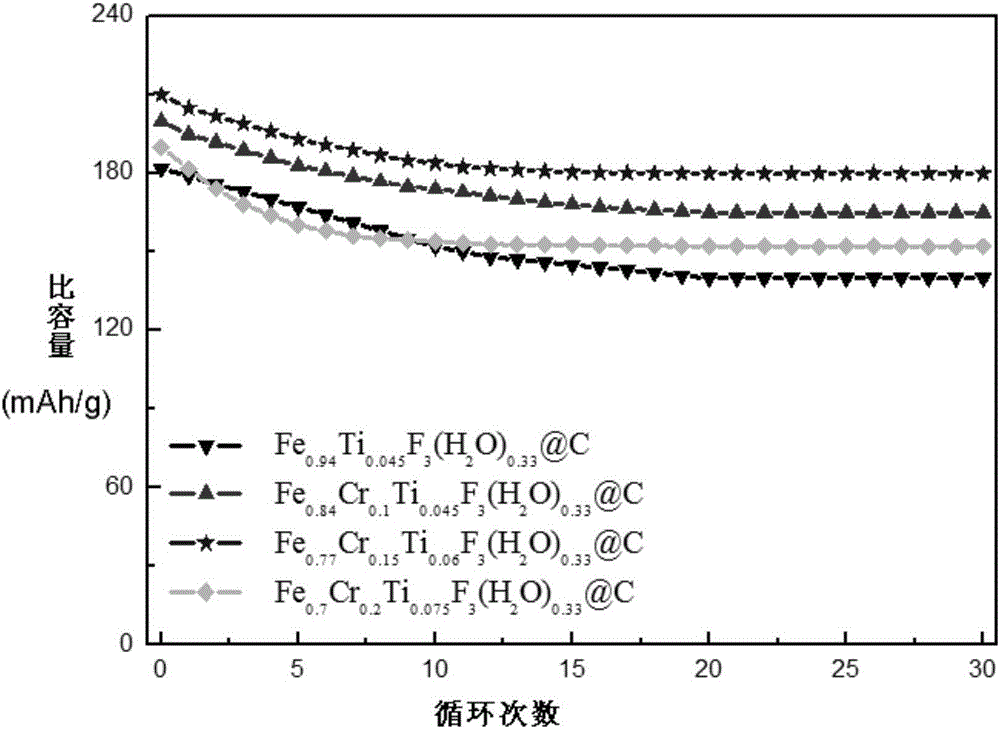

[0065] The present invention adopts a simple and feasible method to realize FeF 3 The synergistic modification of the metal ion lattice doping of the positive electrode material and the coatin...

Embodiment 1

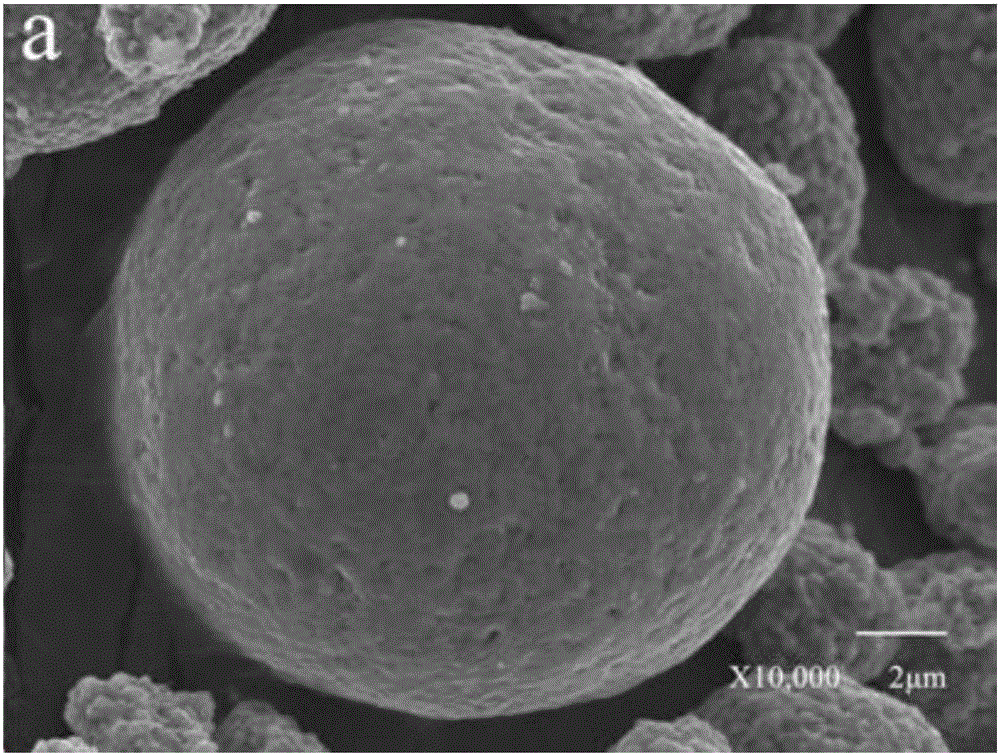

[0083] According to Fe 0.84 Cr 0.1 Ti 0.045 f 3 (H 2 O) 0.33 The molar weights of Fe, Cr, Ti and F in the chemical formula are taken by weighing ferric nitrate (Fe(NO 3 ) 3 9H 2 O), chromium chloride (CrCl 3 ·6H 2 O), titanium nitrate and ammonium fluoride, carry out batching, add appropriate amount of water and ethanol immersion mixture, SiC is auxiliary agent, and its mass ratio with mixture is 0.05:1, at room temperature, under nitrogen protection, in high-energy ball mill with rotating speed 250r / min, ball milling for 10 hours. Take out the ball-milled material, put it into a vacuum tube-type atmosphere furnace protected by argon, raise the temperature to 300°C, keep the temperature constant for 8 hours, and then cool it down to obtain Ti 4+ 、Cr 3+ Doped ferric fluoride precursor.

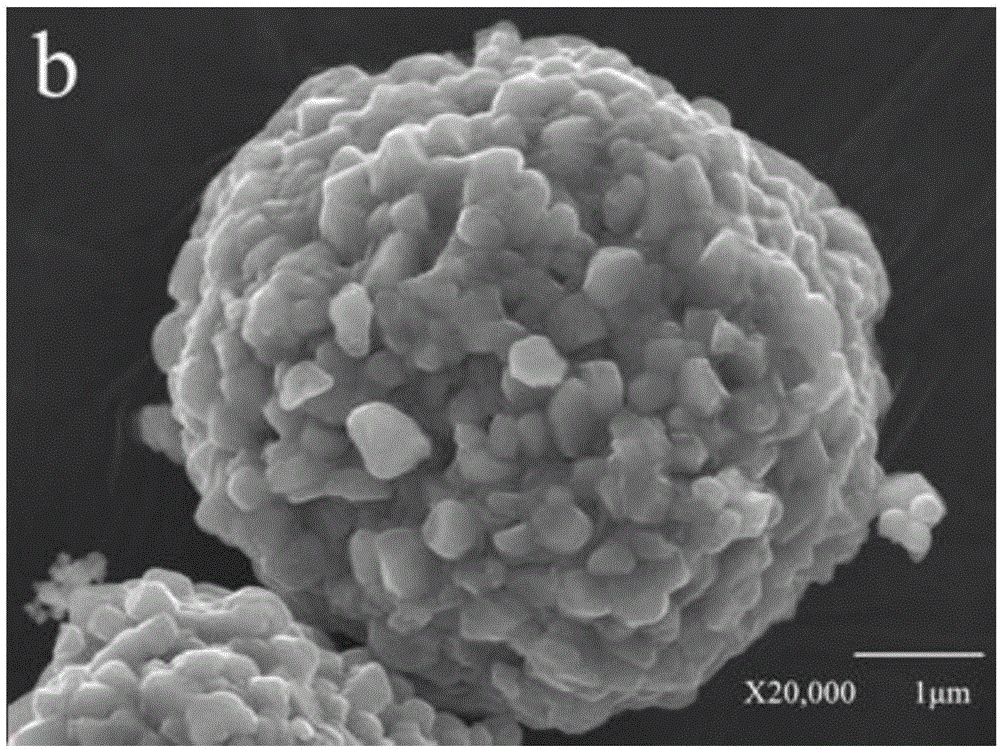

[0084] Conductive carbon black is mixed with ethylene glycol in a mass ratio of 1:1, and ultrasonically dispersed in ethanol to form a conductive carbon dispersion; the Ti 4+ 、Cr ...

Embodiment 2

[0087] According to Fe 0.77 Cr 0.15 Ti 0.06 f 3 (H 2 O) 0.33 The molar weights of Fe, Cr, Ti and F in the chemical formula are taken by weighing ferric nitrate (Fe(NO 3 ) 3 9H 2 O), chromium chloride (CrCl 3 ·6H 2 O), titanium nitrate and ammonium fluoride, carry out batching, add appropriate amount of water and ethanol immersion mixture, SiC is auxiliary agent, and its mass ratio with mixture is 0.05:1, at room temperature, under nitrogen protection, in high-energy ball mill with rotating speed 350r / min, ball milling for 15 hours. Take out the ball-milled material, put it into a vacuum tube-type atmosphere furnace protected by argon, raise the temperature to 400 ° C, keep the temperature for 10 hours, and then cool it to obtain Ti 4+ 、Cr 3+ Doped ferric fluoride precursor.

[0088] Conductive carbon black is mixed with ethylene glycol in a mass ratio of 1:2, and ultrasonically dispersed in ethanol to form a conductive carbon dispersion; the Ti 4+ 、Cr 3+ The dope...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com