Method for preparing outer wall-fluorinated multi-walled carbon nanotube containing iron fluoride intercalated substance

A multi-walled carbon nanotube and fluorination technology, applied in electrical components, battery electrodes, non-aqueous electrolyte batteries, etc., can solve the problems of volume expansion and low electronic conductivity, and achieve the effect of increasing output voltage and theoretical specific capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

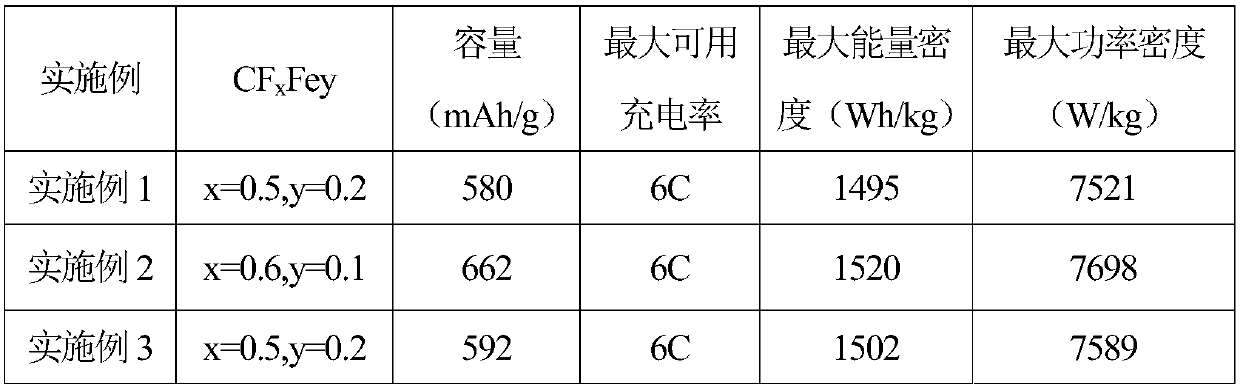

Embodiment 1

[0034] In this embodiment, the preparation method of the outer wall fluorinated multi-walled carbon nanotubes containing iron fluoride intercalation comprises the following steps:

[0035] 1. Mix the dry multi-walled carbon nanotubes with KOH evenly, and react in a tube furnace at 700°C for 4 hours under a nitrogen atmosphere, then cool to room temperature, wash with water, and then dry. After drying, it is mixed with concentrated nitric acid (concentration: 68wt%) of 40 times the mass ratio, refluxed at 80° C. for 2 hours, and then washed with water until neutrally dried.

[0036] 2. Place the high-purity multi-walled carbon nanotubes with the end caps opened in a dry, vacuumable heating reactor, and feed ferric chloride vapor with a mass ratio of 2:1 to the multi-walled carbon nanotubes at 330°C React for 6 hours, so that ferric chloride intercalates into the multi-walled carbon nanotubes. After the reaction, the temperature is lowered to 310° C., and the process pressure is...

Embodiment 2

[0042] In this embodiment, the preparation method of the outer wall fluorinated multi-walled carbon nanotubes containing iron fluoride intercalation comprises the following steps:

[0043] 1. Mix the dried multi-walled carbon nanotubes with NaOH evenly, react in a tube furnace at 750°C for 4 hours under a nitrogen atmosphere, then cool to room temperature, wash with water and then dry. After drying, mix with 30 times mass ratio fuming concentrated nitric acid (concentration 85wt%), reflux at 90°C for 2 hours, then wash with water until neutral drying.

[0044] 2. Place the high-purity multi-walled carbon nanotubes with the end caps opened in a dry, vacuumable heating reactor, and feed ferric chloride vapor with a mass ratio of 2:1 to the multi-walled carbon nanotubes at 320°C React for 6 hours, so that ferric chloride intercalates into the multi-walled carbon nanotubes. After the reaction, the temperature is lowered to 310° C., and the process pressure is maintained at 0.3 MPa...

Embodiment 3

[0049] In this embodiment, the preparation method of the outer wall fluorinated multi-walled carbon nanotubes containing iron fluoride intercalation comprises the following steps:

[0050] 1. Mix the dry multi-walled carbon nanotubes with KOH evenly, react in a tube furnace at 730°C for 5 hours under a nitrogen atmosphere, then cool to room temperature, wash with water and then dry. After drying, it is mixed with concentrated hydrochloric acid (concentration 35wt%) of 80 times the mass ratio, refluxed at 80° C. for 3 hours, and then washed with water until neutrally dried.

[0051] 2. Place the high-purity multi-walled carbon nanotubes with the end caps opened in a dry, vacuumable heating reactor, and feed ferric chloride vapor with a mass ratio of 2:1 to the multi-walled carbon nanotubes at 315°C React for 6 hours, so that ferric chloride intercalates into the multi-walled carbon nanotubes. After the reaction, the temperature is lowered to 310° C., and the process pressure is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com