Composite iron trifluoride positive electrode material, preparation method and application

A cathode material, iron trifluoride technology, applied in the direction of positive electrode, electrode manufacturing, nanotechnology for materials and surface science, etc., can solve the problems of low lithium ion conductivity, limited rate performance, etc., to achieve a broad conductive network Structure, excellent rate capability, the effect of high rate capability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

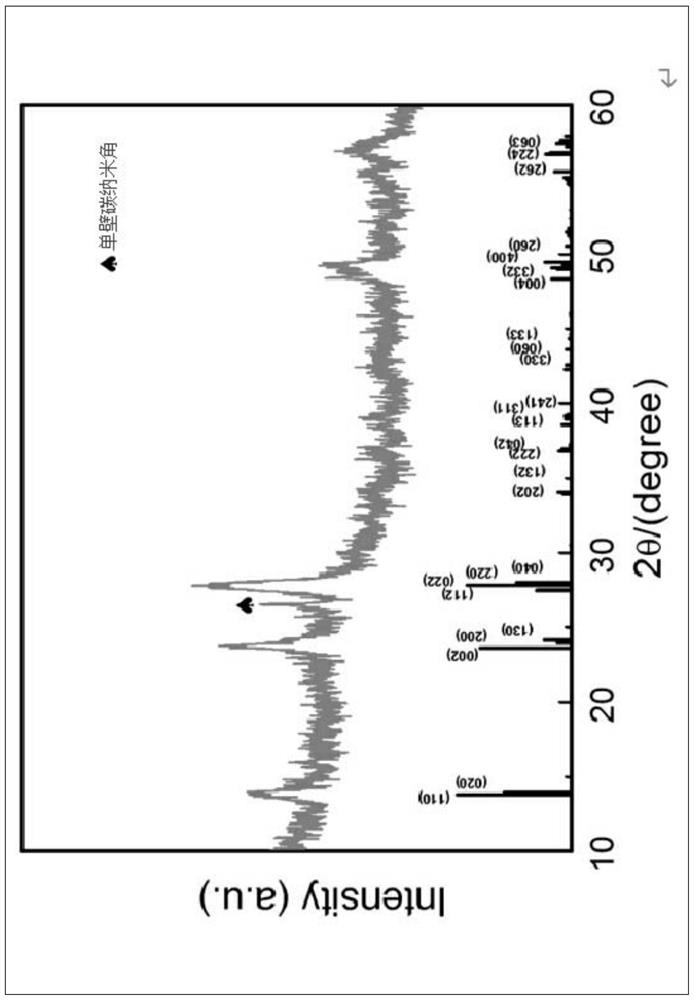

Image

Examples

Embodiment 1

[0033] This embodiment discloses a composite ferric trifluoride positive electrode material and its preparation method and application. The preparation method of the positive electrode material includes the following steps:

[0034] Step 1. Disperse 15 mg of carbon nanohorns processed through the opening oxidation process in 15 mL of [Bmim] [BF 4 ] In the ionic liquid, after 10 min of stirring and 5 min of ultrasonic treatment, the carbon nanohorns were uniformly dispersed in the ionic liquid.

[0035] Step 2, then add 100mL absolute ethanol and 1g Fe(NO 3 ) 3 9H 2 O, stirred for 30min to ensure that the reactants were well mixed.

[0036] Step 3, the reaction solution is placed in an oil bath reactor with a constant temperature of 80° C., protected by nitrogen, and continuously stirred for 6 hours to stop the reaction.

[0037] Step 4, dilute the viscous reaction product obtained with acetone, and centrifuge 8 times at a speed of 10000 rpm;

[0038] Step five, freeze the...

Embodiment 2

[0047] This embodiment discloses a composite ferric trifluoride positive electrode material and its preparation method and application. The preparation method of the positive electrode material includes the following steps:

[0048] Step 1. Disperse 10 mg of carbon nanohorns treated by the opening oxidation process in 10 mL of [Bmim] [BF 4] In the ionic liquid, after 15 min of stirring and 8 min of ultrasonic treatment, the carbon nanohorns were uniformly dispersed in the ionic liquid.

[0049] Step 2, then add 50mL absolute ethanol and 1g Fe(NO 3 ) 3 9H 2 O, stirred for 20min to ensure that the reactants were well mixed.

[0050] Step 3, the reaction solution was placed in an oil bath reactor at a constant temperature of 60° C., protected by nitrogen, and stirred continuously for 4 hours to stop the reaction.

[0051] Step 4, dilute the viscous reaction product obtained with acetone, and centrifuge 8 times at a speed of 10000 rpm;

[0052] Step five, freeze the centrifug...

Embodiment 3

[0055] This embodiment discloses a composite ferric trifluoride positive electrode material and its preparation method and application. The preparation method of the positive electrode material includes the following steps:

[0056] Step 1. Disperse 20 mg of carbon nanohorns processed through the opening oxidation process in 20 mL of [Bmim] [BF 4 ] In the ionic liquid, after 20 min of stirring and 8 min of ultrasonic treatment, the carbon nanohorns were uniformly dispersed in the ionic liquid.

[0057] Step 2, then add 200mL absolute ethanol and 1g Fe(NO 3 ) 3 9H 2 O, stirred for 40min to ensure that the reactants were well mixed.

[0058] Step 3, the reaction solution is placed in an oil bath reactor with a constant temperature of 100° C., protected by nitrogen, and continuously stirred for 8 hours to stop the reaction.

[0059] Step 4, dilute the viscous reaction product obtained with acetone, and centrifuge 8 times at a speed of 10000 rpm;

[0060] Step five, freeze th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com