Lithium ion hybrid super capacitor and preparation method thereof

A supercapacitor, lithium-ion technology, applied in the field of lithium-ion hybrid supercapacitor and its preparation, can solve the problems of low theoretical capacity, large labor and equipment investment, limited active sites, etc., to improve energy density and theoretical specific capacity, The effect of reducing production cost and simplifying production process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0093] In a preferred embodiment, the preparation method comprises the following steps:

[0094] a) Preparing the negative electrode: the metal, alloy or metal composite material of the required size is used as the negative electrode after surface treatment;

[0095] b) Prepare the electrolyte: dissolve the lithium salt in the solvent, and fully stir to obtain the electrolyte;

[0096] c) Preparing a diaphragm: using a porous polymer film, an inorganic porous film or an organic / inorganic composite film of a required size as a diaphragm;

[0097] d) Preparation of positive electrode: positive electrode active material, conductive agent and binder are made into positive electrode slurry or positive electrode sheet material; then the positive electrode slurry is coated on the surface of the positive electrode current collector or the positive electrode sheet material is pressed on the positive electrode current collector surface, dried to obtain a positive electrode of the desir...

Embodiment 1

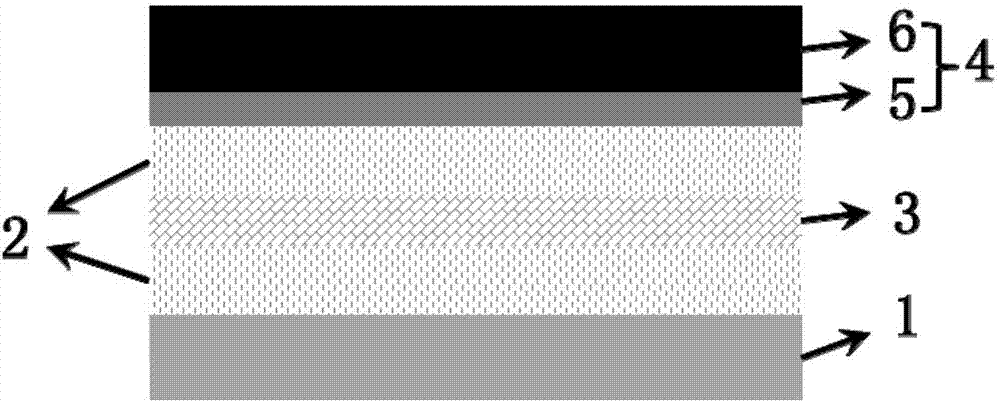

[0103] A lithium-ion hybrid supercapacitor includes a positive electrode, a negative electrode, an electrolyte, a diaphragm, and a casing.

[0104] Prepare the positive electrode of the capacitor: add 0.8g of activated carbon (AC), 0.1g of conductive carbon black, and 0.1g of polyvinylidene fluoride to 2mL of nitrogen methyl pyrrolidone solvent, grind thoroughly to obtain a uniform slurry; then evenly coat the slurry on aluminum foil The surface was vacuum-dried at 80°C for 12 hours; the dried electrode sheets were cut into discs with a diameter of 10mm, compacted with a hydraulic press (10MPa, 10s), and placed in a glove box as a battery positive electrode for later use;

[0105] Prepare the negative electrode of the capacitor: take an aluminum foil with a thickness of 20 μm, cut it into a disc with a diameter of 12 mm, clean it with ethanol, dry it, and place it in a glove box as the negative electrode for later use;

[0106] Preparation of electrolyte: Weigh 3g of lithium h...

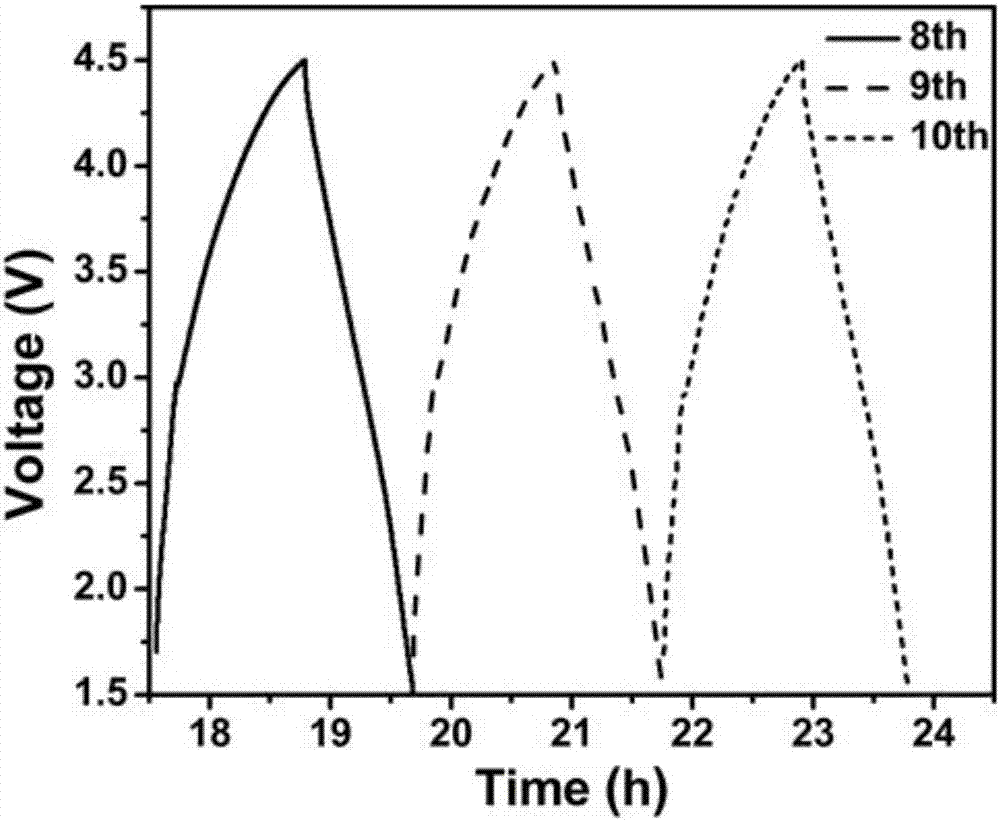

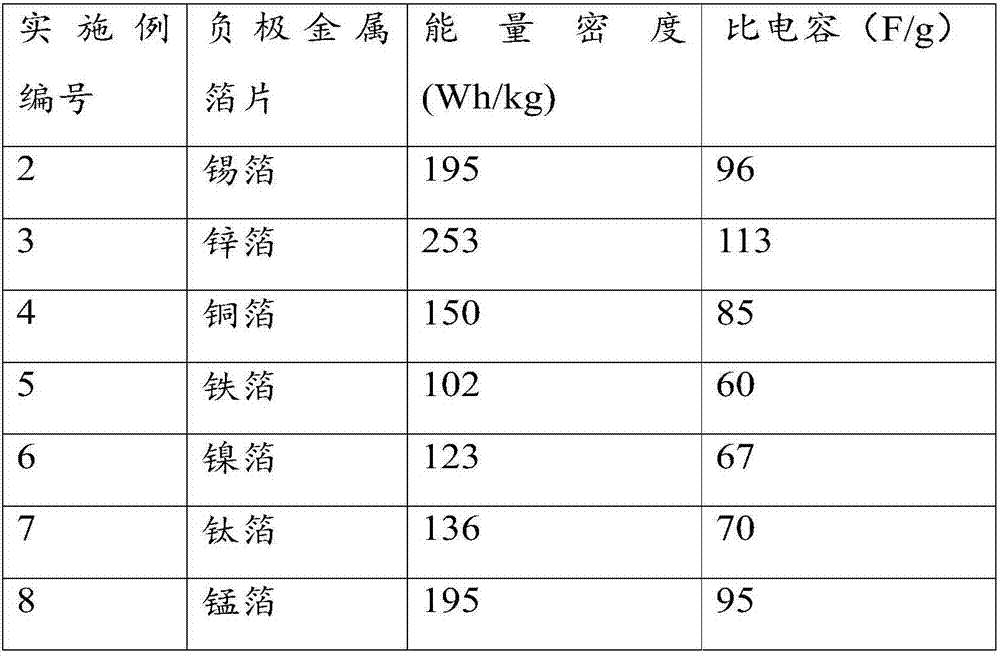

Embodiment 2-12

[0111] Example 2-12 and the lithium ion hybrid supercapacitor preparation process of Example 1 are different except that the metal foil used when preparing the negative electrode is different, and all other steps and materials used are the same. The energy storage performance of the supercapacitor was tested and compared with the performance of Example 1 of the present invention. For the negative electrode materials used in Examples 1-12 and their energy storage performance, see Table 1 for details.

[0112] Table 1: The performance parameter table of the lithium-ion hybrid supercapacitor of embodiment 1-12

[0113]

[0114]

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com