Electrode material of lithium-ion battery and preparation method thereof

A lithium-ion battery and electrode material technology, applied in battery electrodes, secondary batteries, circuits, etc., can solve the problems that electric vehicles cannot be promoted, and achieve high safety performance, high theoretical specific capacity, and high reversible specific capacity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

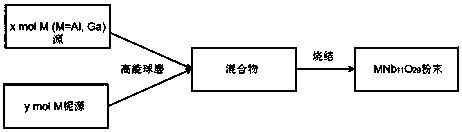

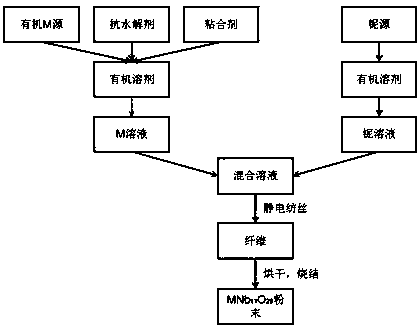

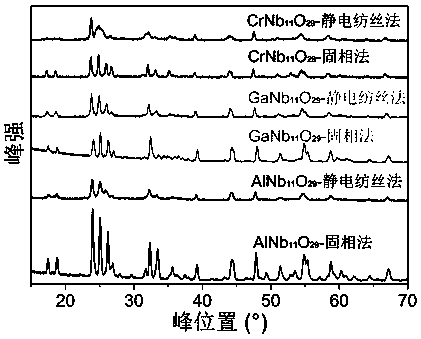

[0053] After mixing niobium pentoxide and aluminum oxide according to the ratio of element molar ratio Al:Nb=1:11, they are mixed by high-energy ball mill and sintered at 1200°C for 6 hours to obtain AlNb 11 o 29 powder.

Embodiment 2

[0055] GaNb can be obtained by mixing niobium pentoxide and gallium trioxide according to the ratio of element molar ratio Ga:Nb=1:11 by high-energy ball mill ball milling method, and sintering at 1300°C for 6 h. 11 o 29 powder.

Embodiment 3

[0057] After mixing niobium pentoxide and chromium trioxide according to the ratio of element molar ratio Cr:Nb=1:11, they are mixed by high-energy ball mill, and then sintered at 1300°C for 6 hours to obtain CrNb 11 o 29 powder.

[0058] Electrode materials were prepared by a solid phase method, and Examples 4-20 are shown in Table 1.

[0059] Table 1

[0060]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com