High-capacity all-solid-state lithium-sulfur battery

A lithium-sulfur battery, all-solid-state technology, applied in battery electrodes, secondary batteries, circuits, etc., can solve the problems of battery life decay, reduced safety and stability of lithium-sulfur batteries, low Coulomb efficiency, etc., and achieves high conductivity. , High specific capacity, high theoretical effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

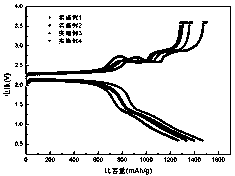

Embodiment 1

[0020] A high-capacity all-solid-state lithium-sulfur battery, the battery includes a positive electrode, a negative electrode and a solid electrolyte. The positive electrode active material is a solid solution of lithium sulfide and lithium bromide obtained by a ball milling process. The molar ratio of lithium sulfide to lithium bromide is 0.8:0.2, the ball mill tank is zirconia, 90 4mm zirconia balls, and the ball milling time is 10hrs. The cathode material is made of Li 2 S-LiBr solid solution, conductive agent Super P and LGPS solid electrolyte are obtained by ball milling, and the mass ratio is 5:1:4. The ball mill jar is made of zirconia, 90 4mm zirconia balls, and the milling time is 10hrs. The positive electrode material is 5 mg, the solid electrolyte LGPS 70 mg is pressed into tablets, and the negative electrode is made of lithium indium alloy.

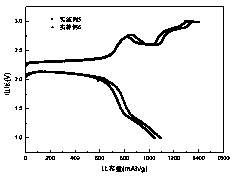

Embodiment 2

[0022] A high-capacity all-solid-state lithium-sulfur battery, the battery includes a positive electrode, a negative electrode and a solid electrolyte. The positive active material is a solid solution of lithium sulfide and lithium iodide obtained by a ball milling process. The molar ratio of lithium sulfide to lithium iodide is 0.8:0.2, the ball milling tank is zirconia, 90 4mm zirconia balls, and the ball milling time is 12hrs. The cathode material is made of Li 2 S-LiI solid solution, conductive agent VGCF and LGPS solid electrolyte are obtained by ball milling, and the mass ratio is 5:1:4. The ball mill jar is zirconia, 90 4mm zirconia balls, and the ball milling time is 12hrs. The positive electrode material is 5 mg, the solid electrolyte LGPS 70 mg is pressed into tablets, and the negative electrode is made of lithium indium alloy.

Embodiment 3

[0024] A high-capacity all-solid-state lithium-sulfur battery, the battery includes a positive electrode, a negative electrode and a solid electrolyte. The positive active material is a solid solution of lithium sulfide and lithium iodide obtained by a ball milling process. The molar ratio of lithium sulfide to lithium iodide is 0.7:0.3, the ball milling tank is zirconia, 90 4mm zirconia balls, and the milling time is 15hrs. The cathode material is made of Li 2 S-LiI solid solution, conductive agent VGCF and LGPS solid electrolyte are obtained by ball milling, and the mass ratio is 4:2:4. The ball mill jar is zirconia, 90 4mm zirconia balls, and the ball milling time is 15hrs. The positive electrode material is 5mg, the LGPS solid electrolyte is 55mg pressed into tablets, and the negative electrode is made of lithium indium alloy.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com