Preparing method and application of silicon-based negative electrode material with SiO2 coating layer

A technology of silicon-based negative electrode materials and coating layers, applied in battery electrodes, electrical components, electrochemical generators, etc., can solve problems such as poor cycle stability, achieve improved cycle life, simple and feasible preparation process, suitable for large-scale The effect of production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] Hydrolyze 0.2g of γ-(2,3-propylene oxide)propyltrimethoxysilane in a mixed solution of ethanol and water (volume ratio 9:1, adjust the pH value to about 4.0 with acetic acid) overnight. Put 1.0g of nano-silicon powder into a three-necked flask containing 45mL of absolute ethanol and 5mL of distilled water for ultrasonic dispersion for 0.5h; mix the two, and reflux for 5h under Ar atmosphere at a temperature of 90°C and magnetic stirring. Then use distilled water / absolute ethanol to alternately centrifuge and wash 3~4 times. Under the condition of 120°C, vacuum dry for 10h.

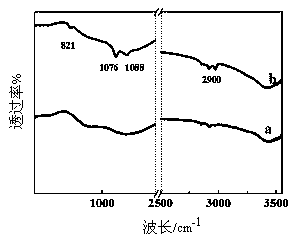

[0029] The infrared test (FTIR) was carried out on the nano-silicon before and after modification, and the comparison results are as follows: figure 1 As shown, of which 1076cm -1 The absorption peak at corresponds to the antisymmetric vibration of the Si-O-Si bond; 1088cm -1 The peak at corresponds to the asymmetric vibration peak of Si-O-C; while at 2900cm -1 The peaks appearing at , indicati...

Embodiment 2

[0031] 1.76mL of vinyltrimethoxysilane, 0.5g of nano-silica powder, 27ml of absolute ethanol and 6.6ml of distilled water were sonicated for 30min, and 3μL of ammonia water (25% by mass fraction) was added, and magnetically stirred for 2h. Then heated to 50 ° C, the reaction 1h. Then, it was centrifuged and washed three times with absolute ethanol, and dried at room temperature.

Embodiment 3

[0033] Stir and hydrolyze 1 mL of dodecyltrimethoxysilane with 100 mL of absolute ethanol solution (95% by mass, adjust the pH to 4.0-4.5 with acetic acid) for 5 min. Then add nano-silica powder, and magnetically stir the reaction for 30 minutes. After filtering, centrifuge and wash with absolute ethanol for 3 to 4 times, and dry under vacuum at 80°C.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com