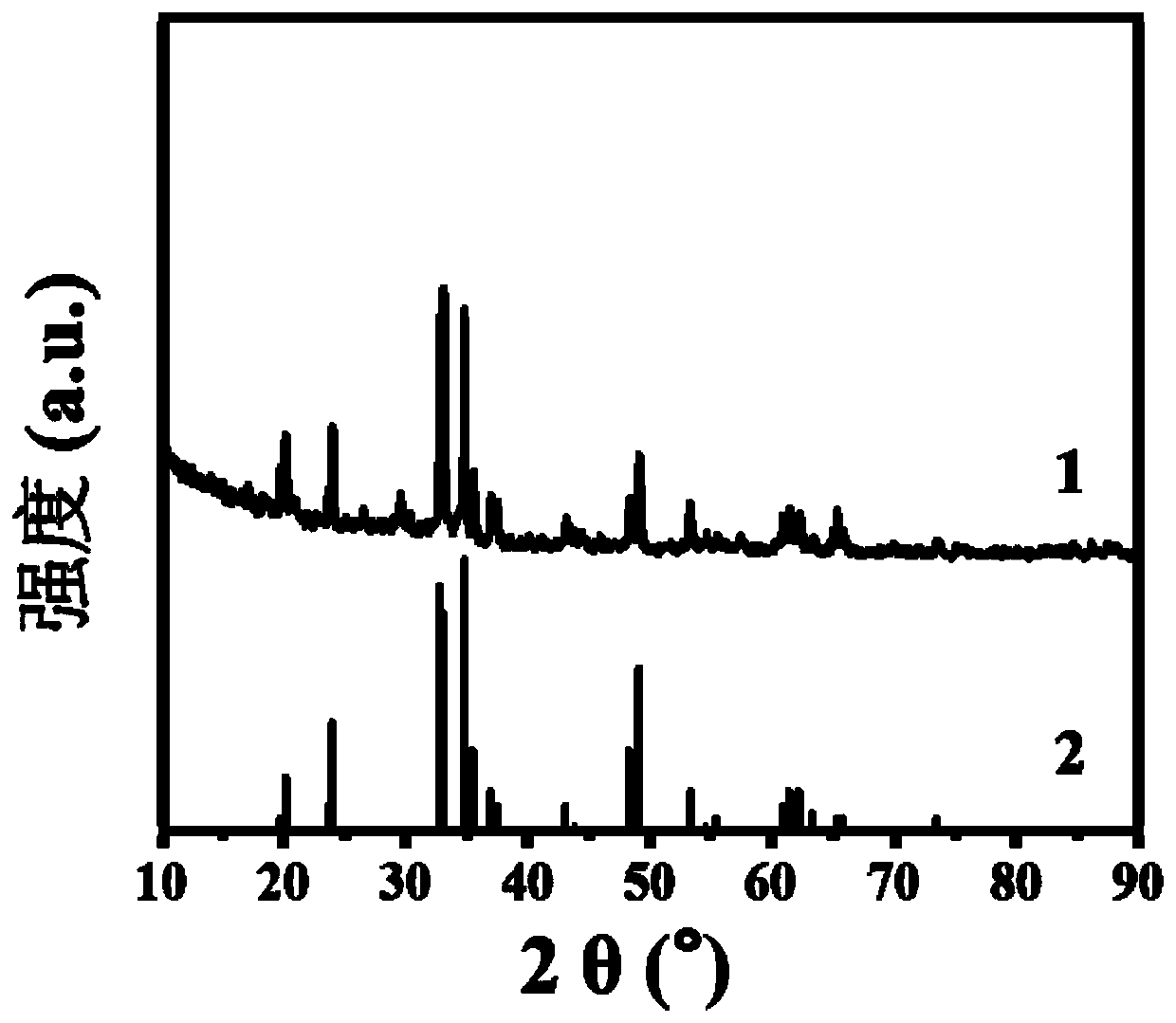

Preparation method of carbon-coated sodium iron phosphate electrode material with hollow structure

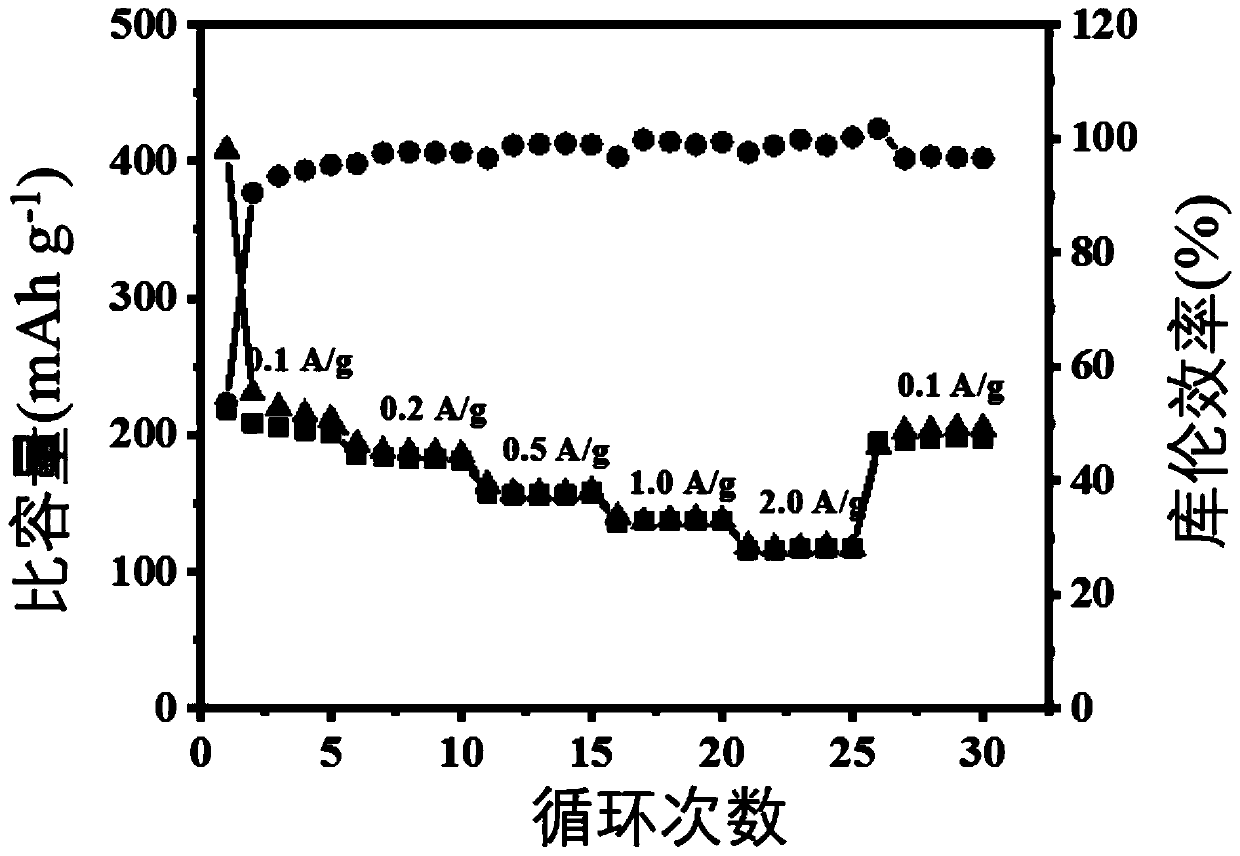

A carbon-coated sodium iron phosphate and electrode material technology, applied in positive electrodes, battery electrodes, structural parts, etc., can solve the problems of poor sodium rate performance, low electronic conductivity and ion diffusion coefficient of positive electrode materials, and achieve excellent rate Performance and cycle stability, enhanced conductivity, and the effect of promoting transport

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

[0021] Specific embodiment one: the preparation method of the carbon-coated sodium iron phosphate electrode material of a kind of hollow structure of this embodiment, it is to carry out according to the following steps:

[0022] 1. Dissolving iron source, sodium-containing phosphorus source and nitrogen-containing organic polymer compound in water to obtain a mixed solution;

[0023] The mass ratio of the iron source to the nitrogen-containing organic polymer compound is 1:(1~5); the molar ratio of the iron element in the iron source to the phosphorus element in the sodium-containing phosphorus source is 1:(1~5 ); the volume ratio of the mass of the iron source to water is 1g:(5~20)mL;

[0024] 2. Stir the mixed solution magnetically for 1h to 5h at a temperature of 10°C to 40°C to obtain a uniformly mixed solution;

[0025] 3. Use a rotary evaporator to heat the uniformly mixed solution until the water is completely evaporated at a temperature of 60°C to 120°C to obtain a un...

specific Embodiment approach 2

[0033] Specific embodiment two: this embodiment is different from specific embodiment one: the iron source described in step one is Fe(NO 3 ) 3 9H 2 O, FeCl 3 ·6H 2 O or Fe 2 (SO 4 ) 3 9H 2 O. Others are the same as in the first embodiment.

specific Embodiment approach 3

[0034] Specific embodiment three: the difference between this embodiment and specific embodiment one or two is: the sodium-containing phosphorus source described in step one is NaH 2 PO 2 ·H 2 O, Na 2 HPO 4 12H 2 O or NaH 2 PO 4 2H 2 O. Others are the same as in the first or second embodiment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com