Sodium vanadium phosphate composite electrode material as well as preparation method and application thereof

A composite electrode, sodium vanadium phosphate technology, applied in battery electrodes, circuits, electrical components, etc., can solve problems such as unsatisfactory rate performance, difficulty in reaching theoretical specific capacity, adverse effects, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0082] A kind of preparation method of sodium vanadium phosphate composite electrode material that present embodiment relates to, described preparation method is as follows:

[0083] (1) selection of raw material: present embodiment selects described vanadium source as V 2 o 5 , the phosphorus source is NH 4 h 2 PO 4 , the sodium source is Na 2 CO 3 , the organic reducing agent is ascorbic acid, the titanium source is tetrabutyl titanate C 16 h 36 o 4 Ti, the carbon source is polyethylene glycol-400 (PEG-400) and ascorbic acid;

[0084] (2) The amount of raw materials: the V 2 o 5 mass m 1 is 0.728g; the NH 4 h 2 PO 4 mass m 2 is 1.380g; the Na 2 CO 3 mass m 3 is 0.636g; the quality m of the tetrabutyl titanate 4 is 0g; the mass m of the ascorbic acid 5 Is 1.507g; The volume V of the polyethylene glycol-400 (PEG-400) 0is 6ml and the deionized water volume V is 70ml.

[0085] (3) Preparation of mixed solution: under continuous stirring conditions, first, d...

Embodiment 2

[0094] A kind of preparation method of sodium vanadium phosphate composite electrode material that present embodiment relates to, described preparation method is as follows:

[0095] (1) selection of raw material: present embodiment selects described vanadium source as V 2 o 5 , the phosphorus source is NH 4 h 2 PO 4 , the sodium source is Na 2 CO 3 , the organic reducing agent is ascorbic acid, the titanium source is tetrabutyl titanate C 16 h 36 o 4 Ti, the carbon source is polyethylene glycol-400 (PEG-400) and ascorbic acid;

[0096] (2) The amount of raw materials: the V 2 o 5 mass m 1 Is 0.709g; The NH 4 h 2 PO 4 mass m 2 is 1.380g; the Na 2 CO 3 mass m 3 is 0.636g; the quality m of the tetrabutyl titanate 4 Be 0.0680g; The quality m of described ascorbic acid 5 Is 1.507g; The volume V of the polyethylene glycol-400 (PEG-400) 0 is 6ml and the deionized water volume V is 70ml.

[0097] (3) Preparation C 16 h 36 o 4 Ti alcohol solution: first, measu...

Embodiment 3

[0108] The preparation method of a kind of sodium vanadium phosphate composite electrode material involved in this embodiment is basically the same as embodiment 2, only difference is:

[0109] Measure 8ml (tetrabutyl titanate quality m wherein) from described tetrabutyl titanate alcohol solution 4 0.136g) for the preparation of mixed solutions.

[0110] The V 2 o 5 mass m 1 It is 0.691g.

[0111] By a kind of Na of this embodiment 3 Ti x V 2-x (PO 4 ) 3 The Na obtained by the preparation method of / C composite electrode material 3 Ti x V 2-x (PO 4 ) 3 / C composite electrode material is Na 3 Ti 0.10 V 1.90 (PO 4 ) 3 / C composite electrode material.

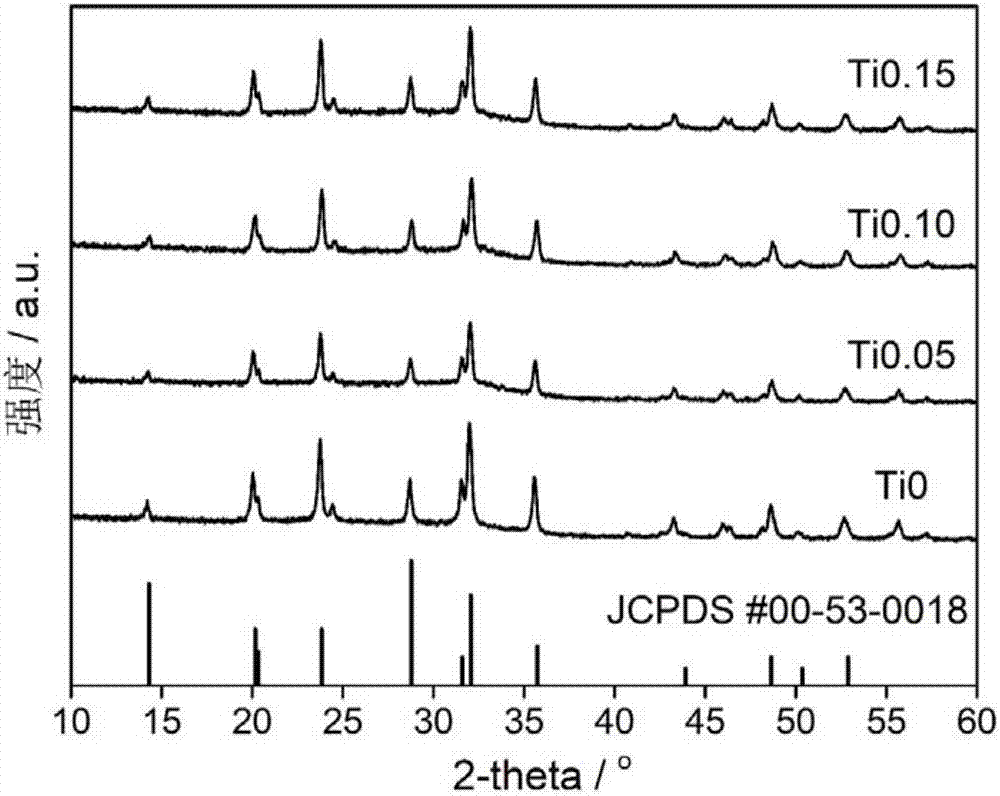

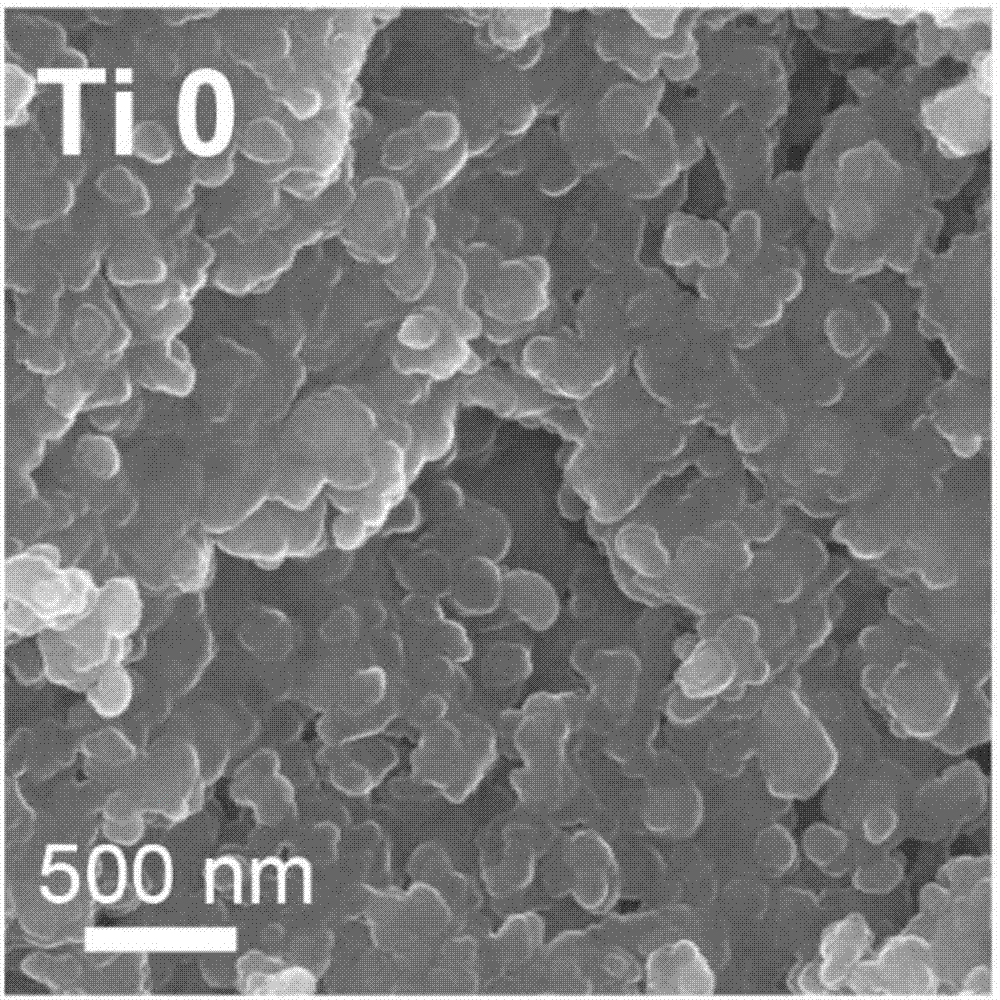

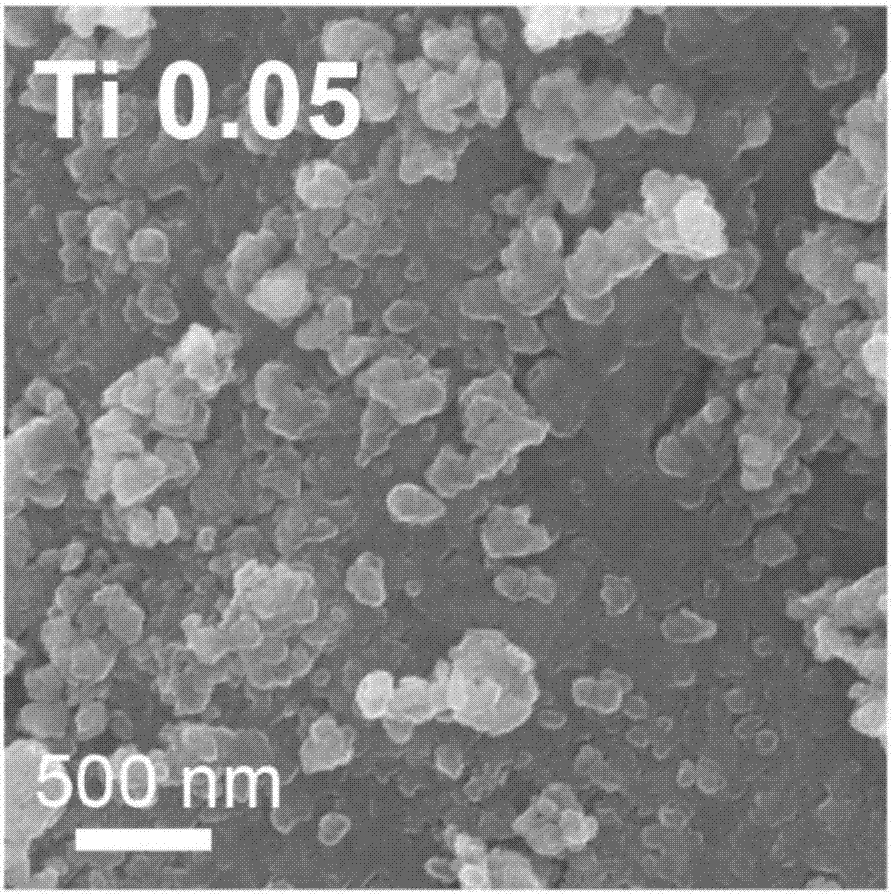

[0112] figure 1 There is Na 3 Ti 0.10 V 1.90 (PO 4 ) 3 / C composite electrode material XRD diffraction pattern. Figure 2c for Na 3 Ti 0.10 V 1.90 (PO 4 ) 3 Electron micrographs of the / C composite electrode material. Figure 3a for Na 3 Ti 0.10 V 1.90 (PO 4 ) 3 Field emission transmission elect...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| volume | aaaaa | aaaaa |

| volume | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com