Lithium battery composite electrode pole piece and preparation method and application thereof

An electrode sheet, lithium battery technology, applied in battery electrodes, non-aqueous electrolyte battery electrodes, electrolyte battery manufacturing, etc., can solve the problems of brittleness, difficult to achieve uniform and continuous coating, ion and electron transmission obstruction, and inability to obtain satisfaction, etc. Achieve the effect of avoiding adverse reactions, improving cycle performance and rate performance, and uniform interaction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0052] (1) Preparation of polylactic acid solution: dry and weighed polylactic acid (PLA) is dissolved in dichloromethane, accompanied by magnetic stirring, to obtain a uniform polylactic acid solution with a mass fraction of 1%; the molecular weight of polylactic acid is 120,000 , and dried in a vacuum oven at 40-140°C for 4-48 hours;

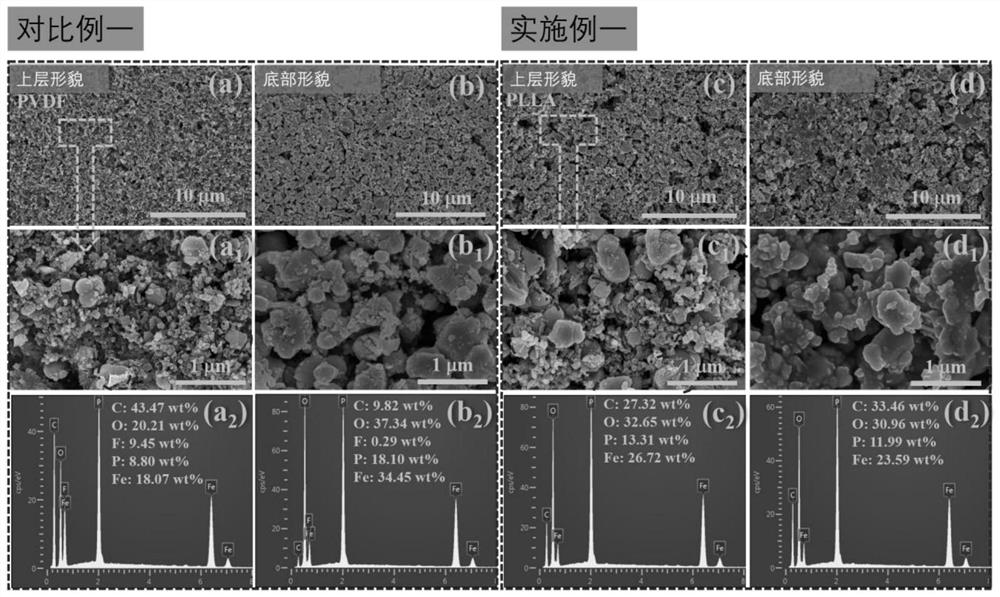

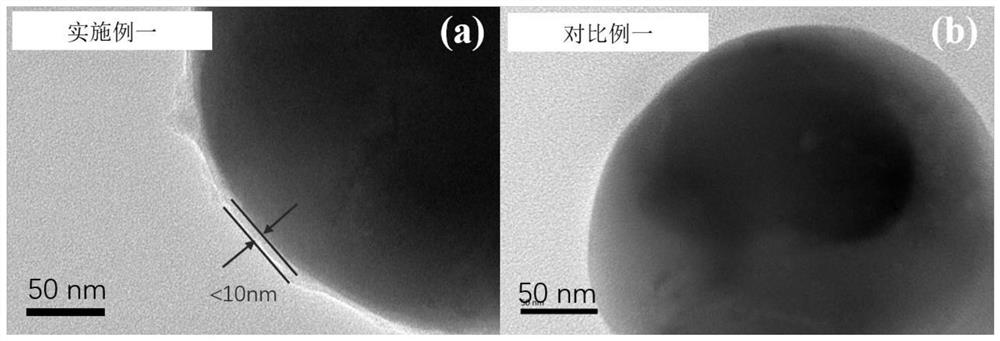

[0053] (2) Preparation of composite slurry (functional slurry): a certain amount of the above-mentioned solution is added to weighed lithium iron phosphate (LFP) and conductive carbon black, and the mass ratio of active material / conducting agent / polymer is 80:10:10, adding the raw materials into a planetary ball mill and mixing for 1 hour at a speed of 350 rpm to obtain a uniformly mixed slurry;

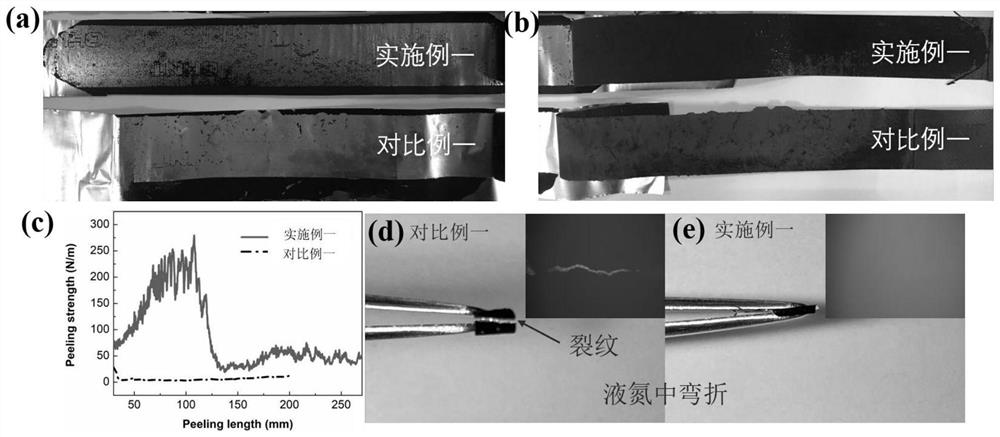

[0054] (3) Preparation of composite electrode: Coat the uniformly mixed slurry obtained above with a certain thickness (about 100um) on the surface of aluminum foil, dry at 40°C for 1h (to ensure that the solvent is completely removed), and the solve...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com