Lithium molybdate coated lithium-rich manganese-based positive electrode material as well as preparation method and application thereof

A cathode material, lithium-rich manganese technology, applied in the field of materials, can solve problems such as reducing the specific capacity of the battery

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

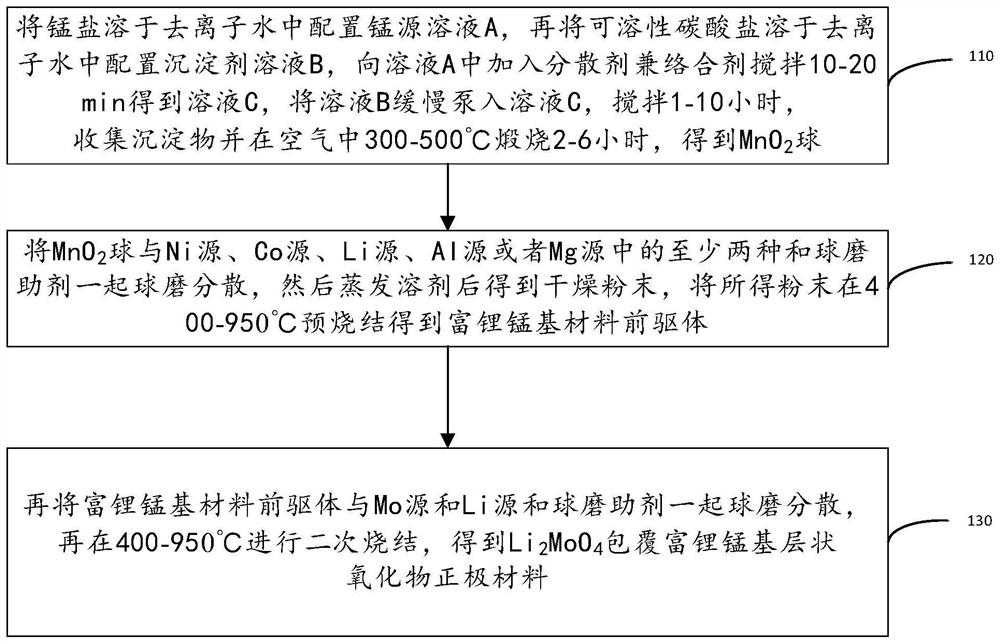

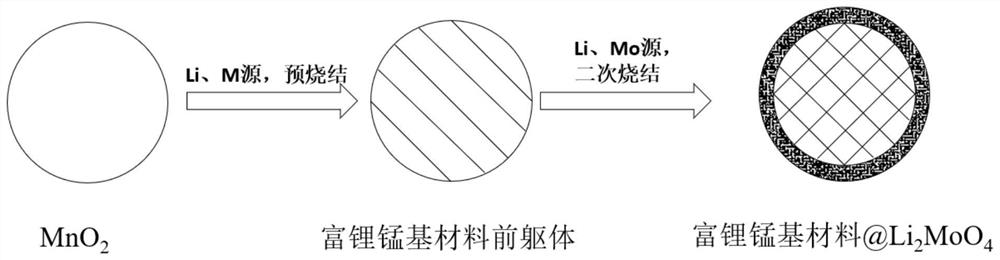

Method used

Image

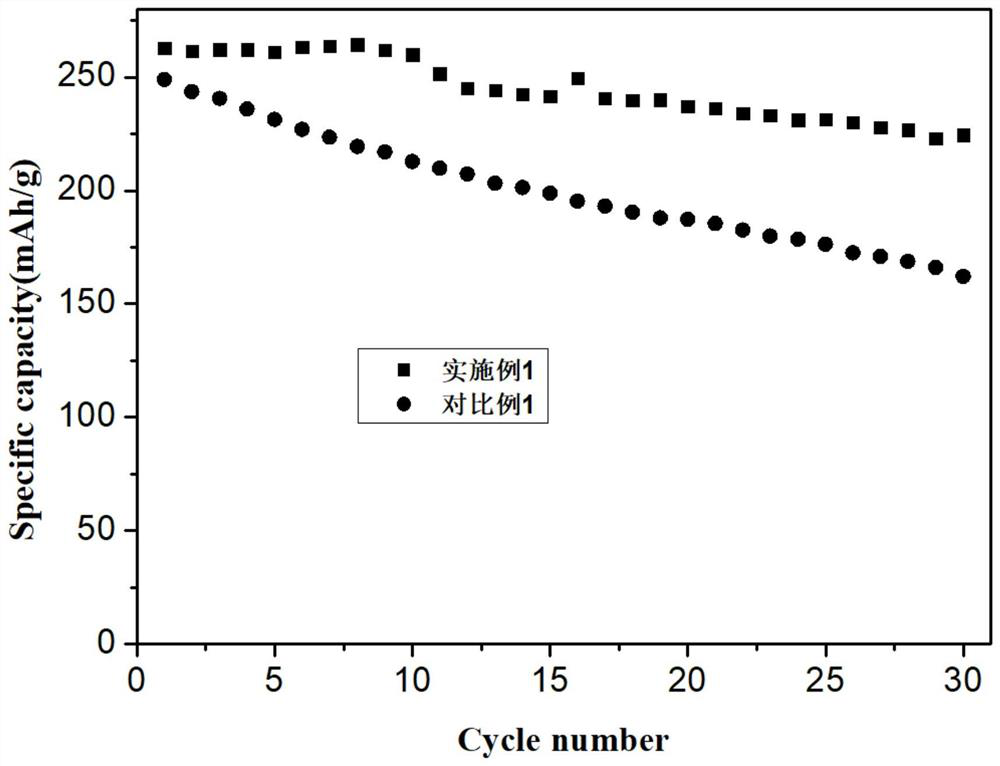

Examples

Embodiment 1

[0060] Step 1, 0.012mol of MnSO 4 Dissolved in 840ml of water to obtain liquid A, 0.12mol of NH 4 HCO 3 Dissolve in 840ml of water to obtain liquid B; add 168ml of ethanol to liquid A, stir for 20 minutes to obtain solution C; slowly pump liquid B into liquid C and stir for 2 hours, collect gray-black precipitate, and calcinate in air at 300°C 2 hours, get MnO 2 ball.

[0061] Step 2, according to the molar ratio of 0.54:0.13:0.13:1.2 MnO 2 , nickel nitrate, cobalt nitrate, lithium hydroxide are added in the mixed solution of ethanol and water (v:v=1:1), carry out ball mill mixing 12 hours with rotating speed 250r / min, carry out pre-calcination after evaporated solvent then, The pre-firing is to keep the temperature at 450°C for 6 hours, and then raise the temperature to 750°C for 10 hours. The black lithium-rich manganese-based precursor powder is obtained after pre-calcination.

[0062] Step 3, configure ammonium molybdate, lithium hydroxide, and lithium-rich manganese...

Embodiment 2

[0067] Step 1, 0.006mol of MnSO 4 Dissolved in 420ml of water to obtain liquid A, 0.06mol of NH 4 HCO 3 Dissolve in 420ml of water to obtain solution B; add 84mL of ethanol to solution A, stir for 40min to obtain solution C. After slowly pumping liquid B into liquid C and stirring for 4 hours, the precipitate was collected and calcined at 400°C in air for 3 hours to obtain MnO 2 ball.

[0068] Step 2, according to the molar ratio of 0.52:0.2:0.08:1.2 MnO 2 , nickel oxalate, cobalt acetate, and lithium hydroxide are added to the mixed solution of ethanol and water (v:v=2:1), and the ball milling is carried out at a speed of 270r / min for 14 hours, and then the solvent is evaporated to dryness for pre-calcination. In order to firstly keep the temperature at 450°C for 4 hours, then raise the temperature to 750°C for 8 hours, and obtain black lithium-rich manganese-based precursor powder after pre-calcination.

[0069] Step 3, configure ammonium molybdate, lithium hydroxide, a...

Embodiment 3

[0071] Step 1, 0.012mol of MnSO 4 Dissolved in 420ml of water to obtain liquid A, 0.06mol of NaHCO 3 Dissolve in 420ml of water to obtain solution B, add 84mL of ethanol to solution A, stir for 60min to obtain solution C. Slowly pump liquid B into liquid C and stir for 6 hours, collect the precipitate and calcinate it in air at 450°C for 6 hours to obtain MnO 2 ball.

[0072] Step 2, according to the molar ratio of 0.6:0.2:1.2 MnO 2 , nickel acetate, and lithium hydroxide were added to the mixture of ethanol and water (v:v=1:2), ball milled and mixed for 16 hours at a speed of 240r / min, and then evaporated to dryness for pre-calcination. Keep the temperature at 450°C for 3 hours, and then raise the temperature to 750°C for 6 hours. After pre-calcination, black lithium-rich manganese-based precursor powder is obtained.

[0073] Step 3: Prepare molybdenum trioxide, lithium hydroxide, and lithium-rich manganese-based precursor powder according to the theoretical mass ratio of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com