Lithium ion cell nano complex electrode material and its preparing method

A lithium-ion battery and nanocomposite technology, applied in the field of electrochemistry, can solve the problems of insufficient mixing of Ti and LiF, large internal resistance of electrochemical reaction, small reversible specific capacity, etc. The effect of excellent performance and high specific capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0015] Put chemically pure LiF and Co powder with a molar ratio of 1:0.5 in a ball mill for 3 hours to mix LiF and Co powder thoroughly; then press the mixture powder into a target material for radio frequency magnetron sputtering A composite nano-mixture electrode thin film material was prepared by the method of irradiation. The sputtering condition is: the background pressure is 1×10 -4 Pa, the distance from the target to the substrate is 7cm, the target should be pre-sputtered for 30min before depositing the film, the sputtering atmosphere is pure argon, the flow rate is 50sccm, the working pressure is 1.5Pa, and the radio frequency power is 100W. During deposition, the substrate temperature is less than 150° C., and the deposition time is 1 hour. The particle size in the deposited film is about 10nm (attached figure 1 ), indicating that the deposited film is LiF / Co 0.5 composed of nanocomposite materials. Although, it is inevitable that there will also be CoF during th...

Embodiment 2

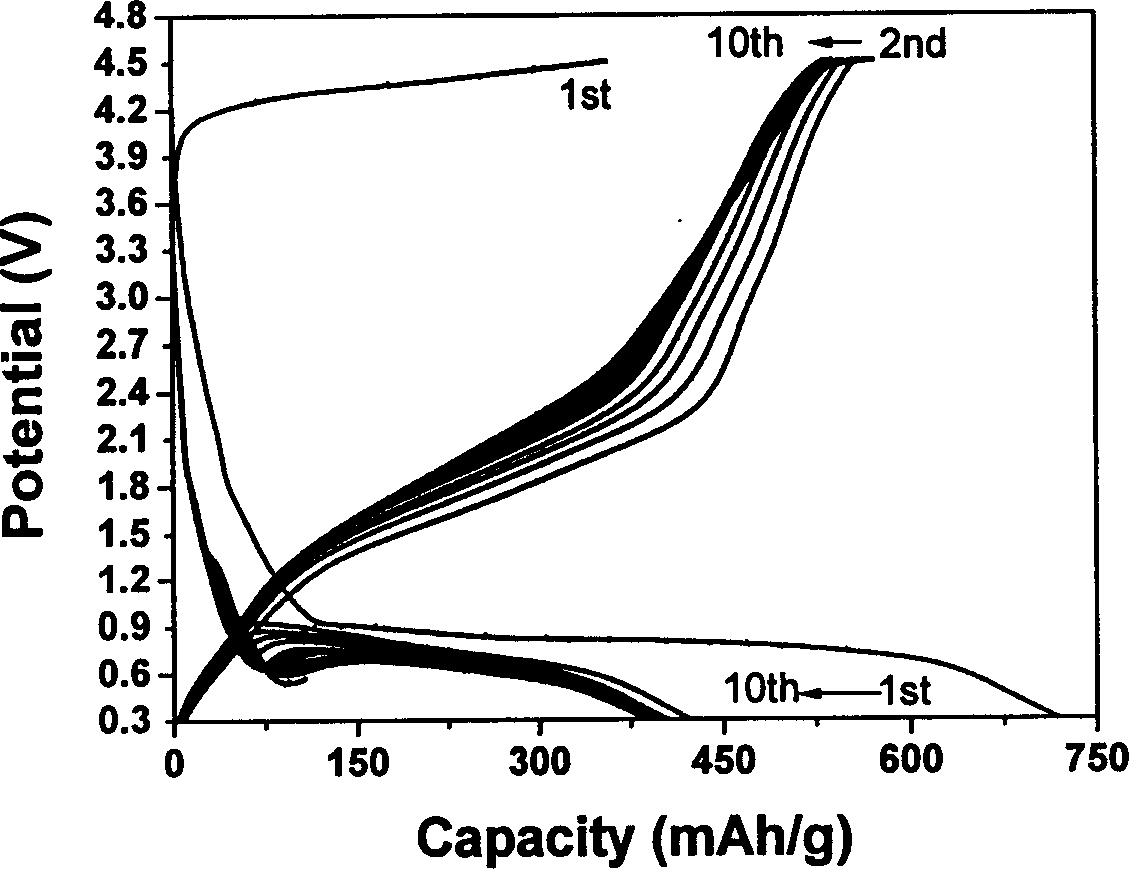

[0017] Put chemically pure LiF and Ni powder (excessive Ni powder) with a molar ratio of 1:0.6 in a ball mill for 3 hours to fully mix LiF and Ni powder; then press the mixture powder into a target material for radio frequency magnetron sputtering, The nanocomposite electrode thin film material is prepared by radio frequency magnetron sputtering. The sputtering condition is that the background pressure is 1×10 -4 Pa, the distance from the target to the substrate is 5cm, the argon flow rate is 45sccm, the working pressure is 3Pa, the radio frequency power is 30W, and the rest are the same as in Example 1. LiF / Ni deposited on a stainless steel substrate 0.6 The nanocomposite film is used as the working electrode, and the high-purity lithium sheet is used as the counter electrode to assemble a simulated battery. Battery assembly and testing are the same as in Example 1. The hybrid thin film electrode showed good electrochemical performance. The charging and discharging voltag...

Embodiment 3

[0019] Put chemically pure LiF and metal Fe powder with a molar ratio of 1:0.55 (excessive metal Fe powder) in a ball mill for 3 hours to fully mix LiF and metal Fe powder; then press the mixture powder into radio frequency magnetron sputtering The target material is prepared into a nanocomposite electrode film material by radio frequency magnetron sputtering. The sputtering condition is that the background pressure is 1×10 -4 Pa, the distance from the target to the substrate is 8cm, the argon flow rate is 55sccm, the working pressure is 0.5Pa, the radio frequency power is 80W, and the rest are the same as in Example 1. LiF / Fe deposited on stainless steel substrate 0.55 The nanocomposite film is used as the working electrode, and the high-purity lithium sheet is used as the counter electrode to assemble a simulated battery. Battery assembly and testing are the same as in Example 1. The hybrid thin film electrode showed good electrochemical performance. The charging and dis...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com