Patents

Literature

89 results about "Thin film rechargeable lithium battery" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

The thin film lithium-ion battery is a form of solid-state battery. Its development is motivated by the prospect of combining the advantages of solid-state batteries with the advantages of thin-film manufacturing processes.

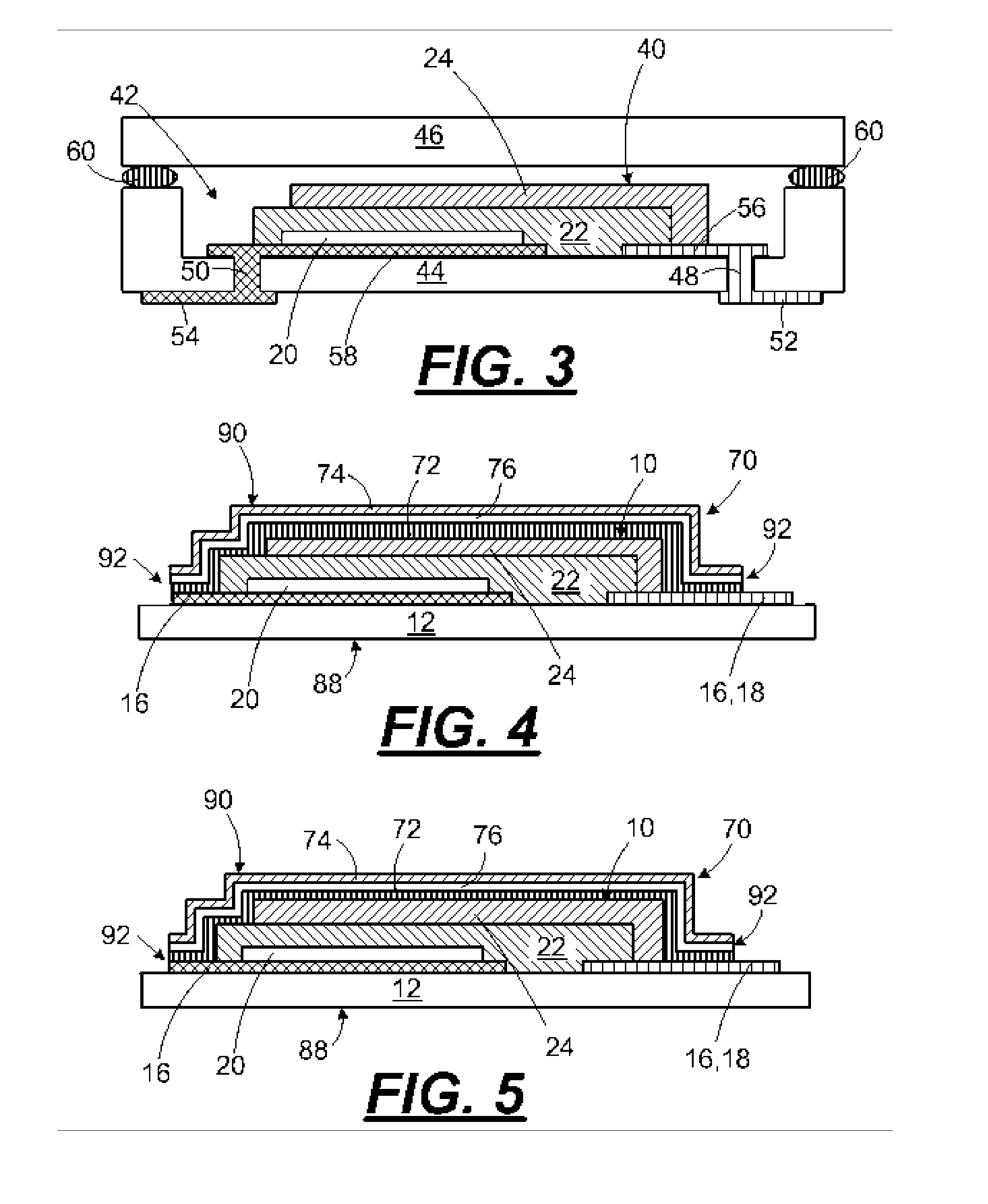

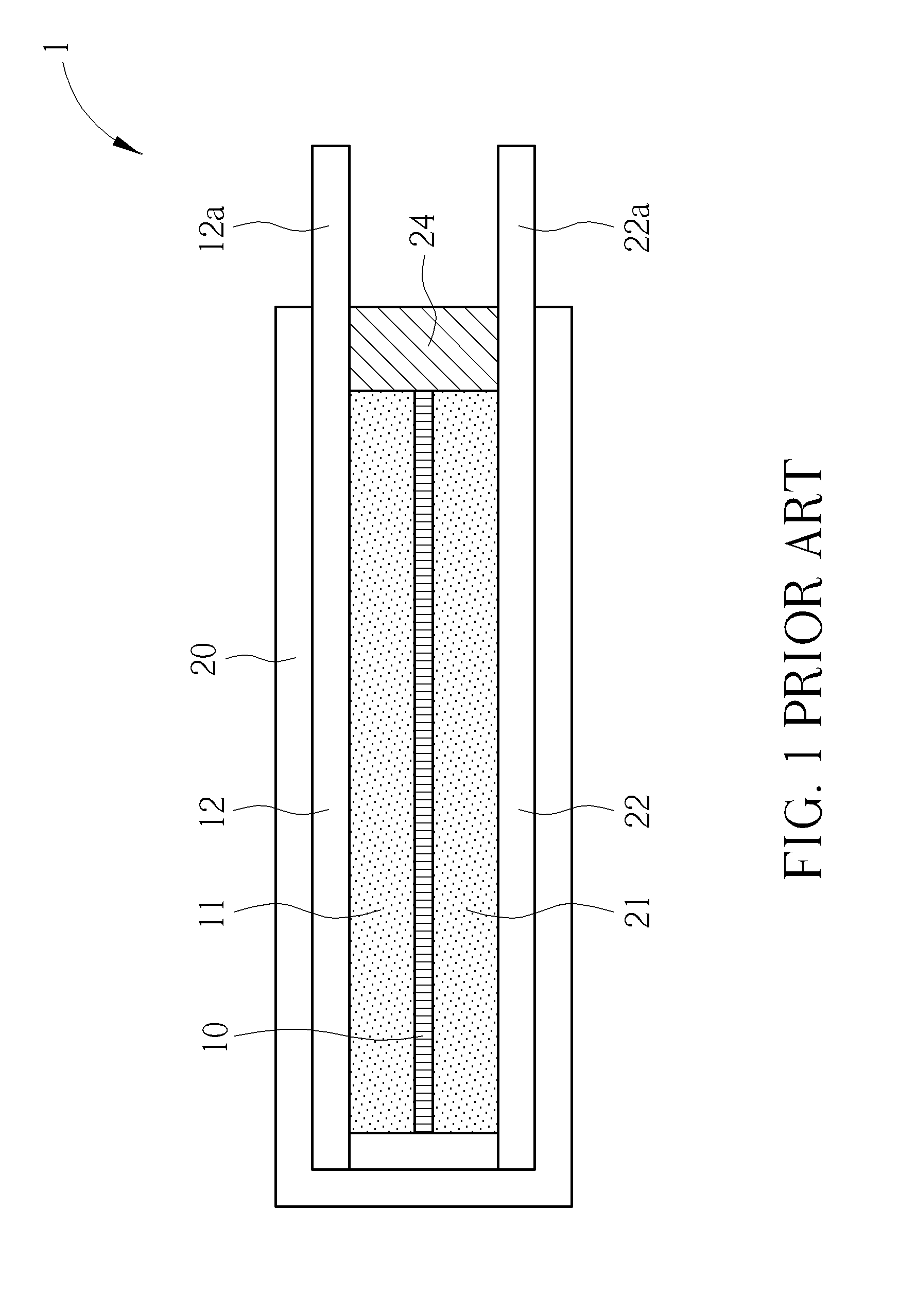

Long life thin film battery and method therefor

InactiveUS20080003492A1Improve air tightnessIncrease costSolid electrolytesFinal product manufactureEngineeringThin film rechargeable lithium battery

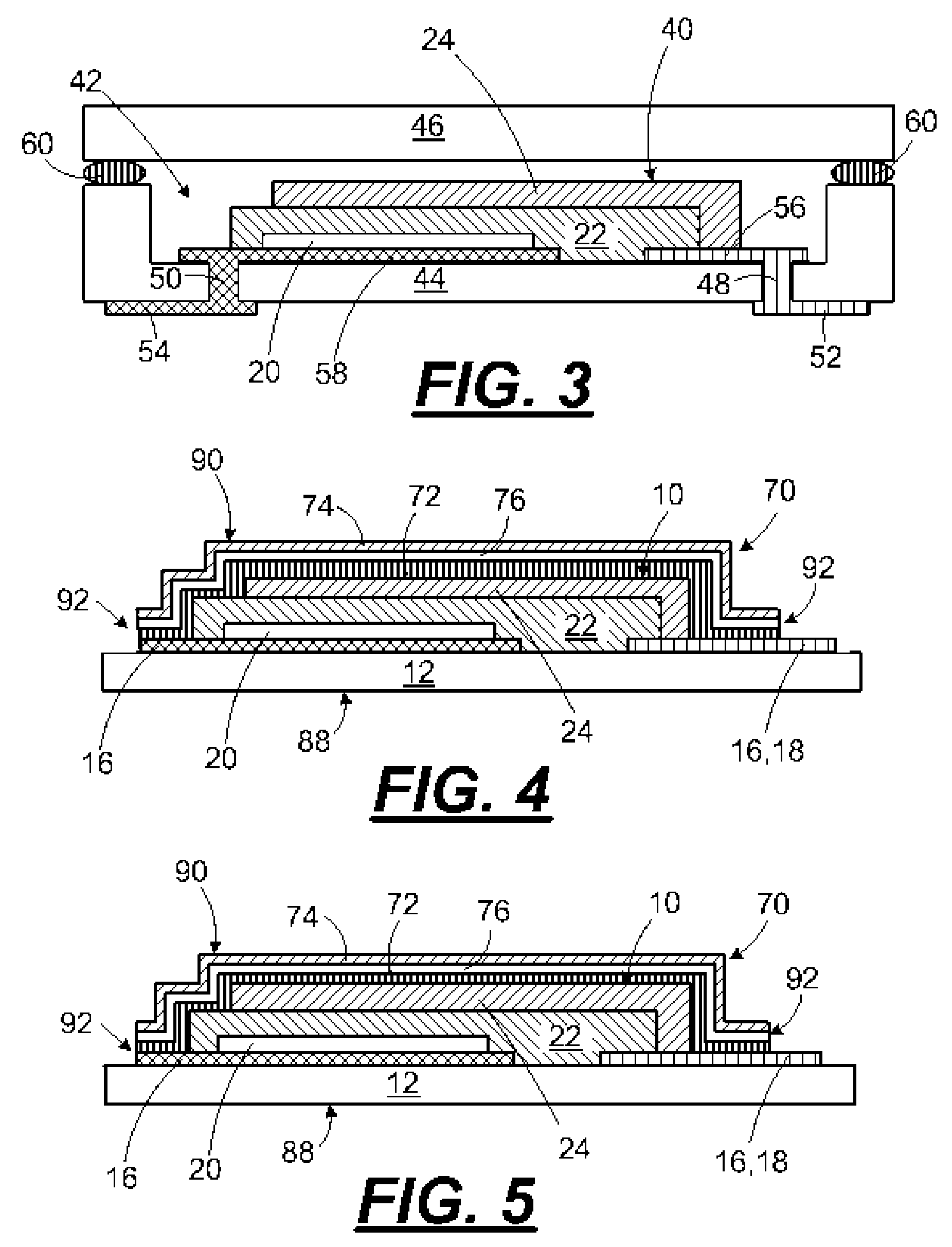

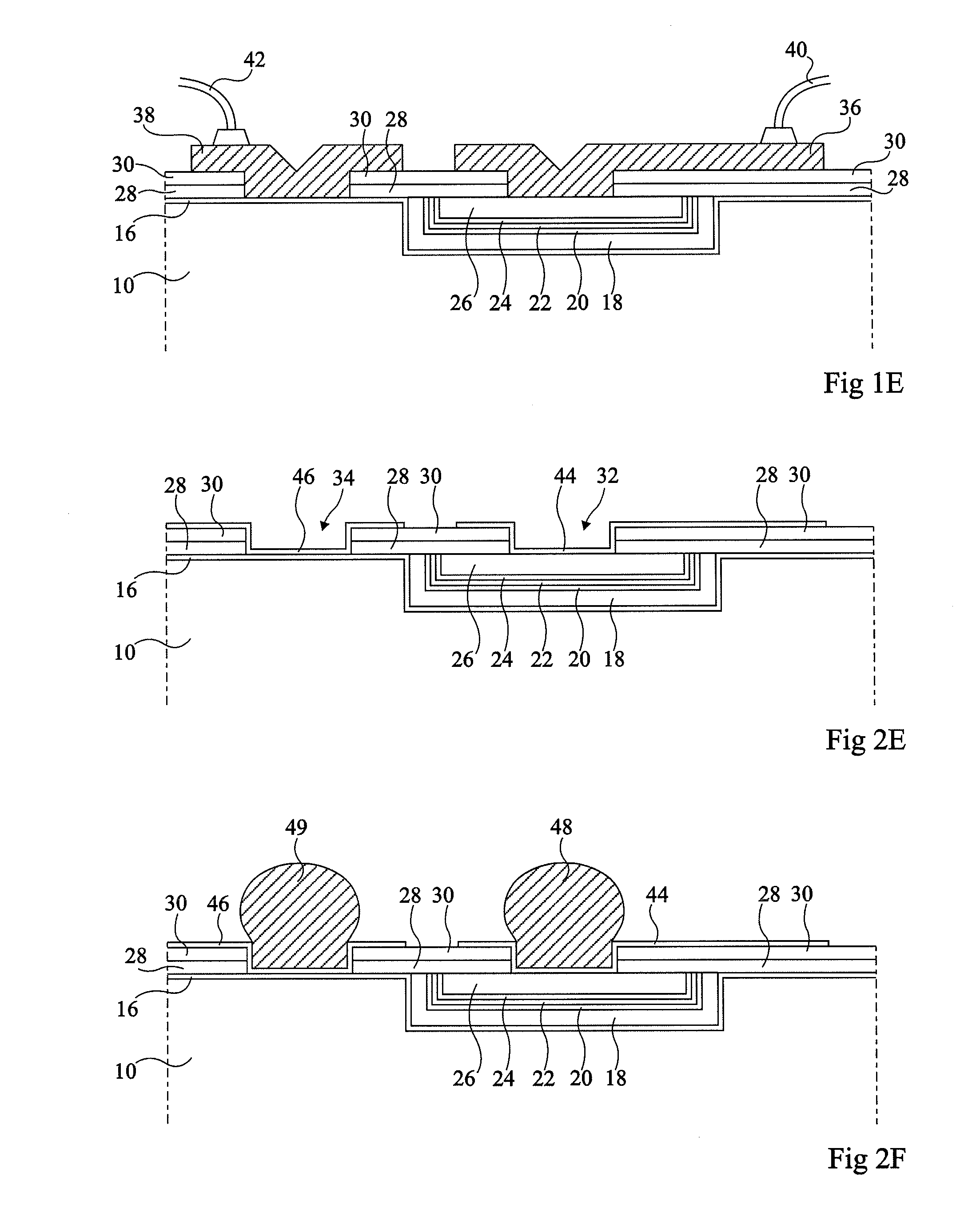

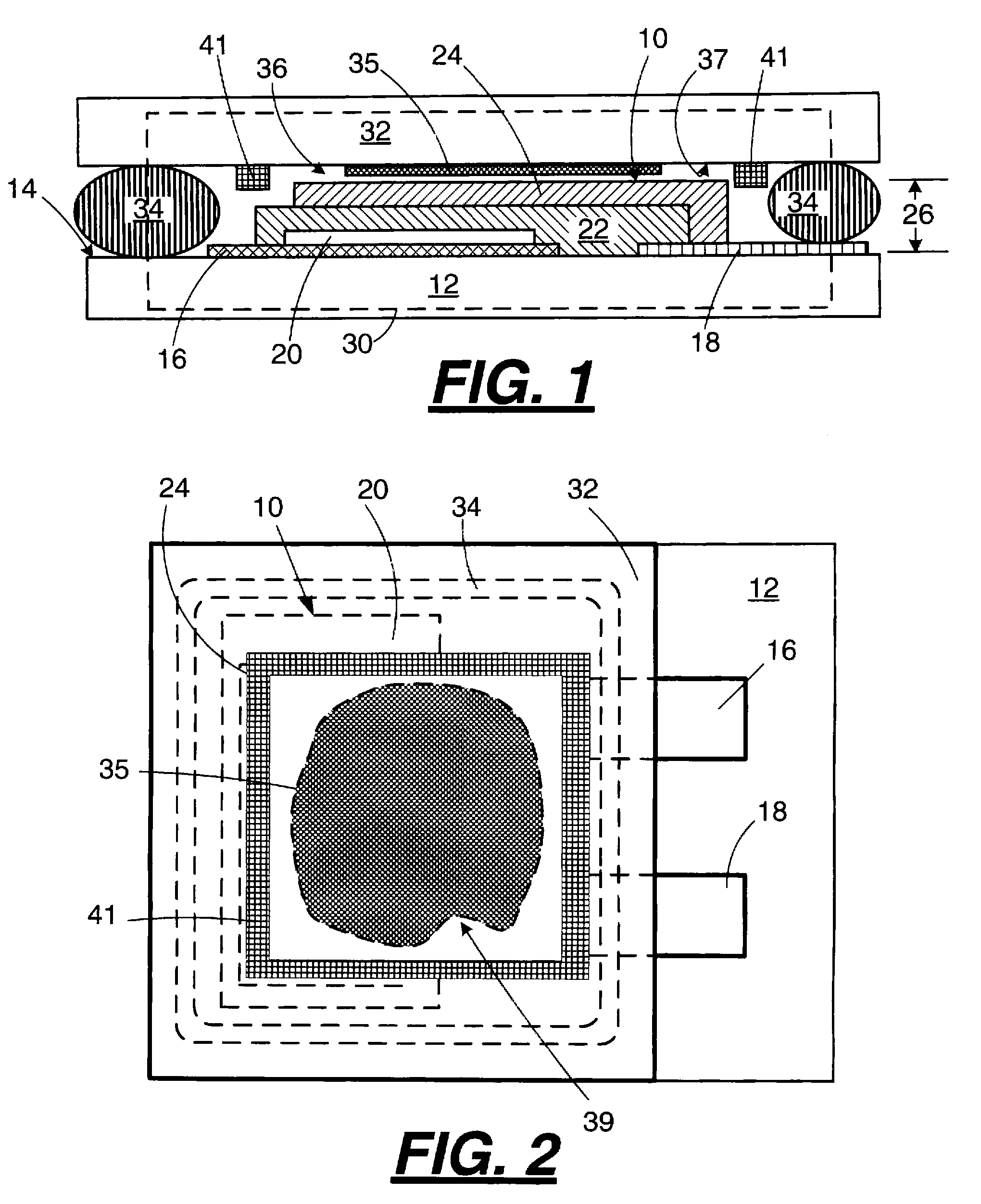

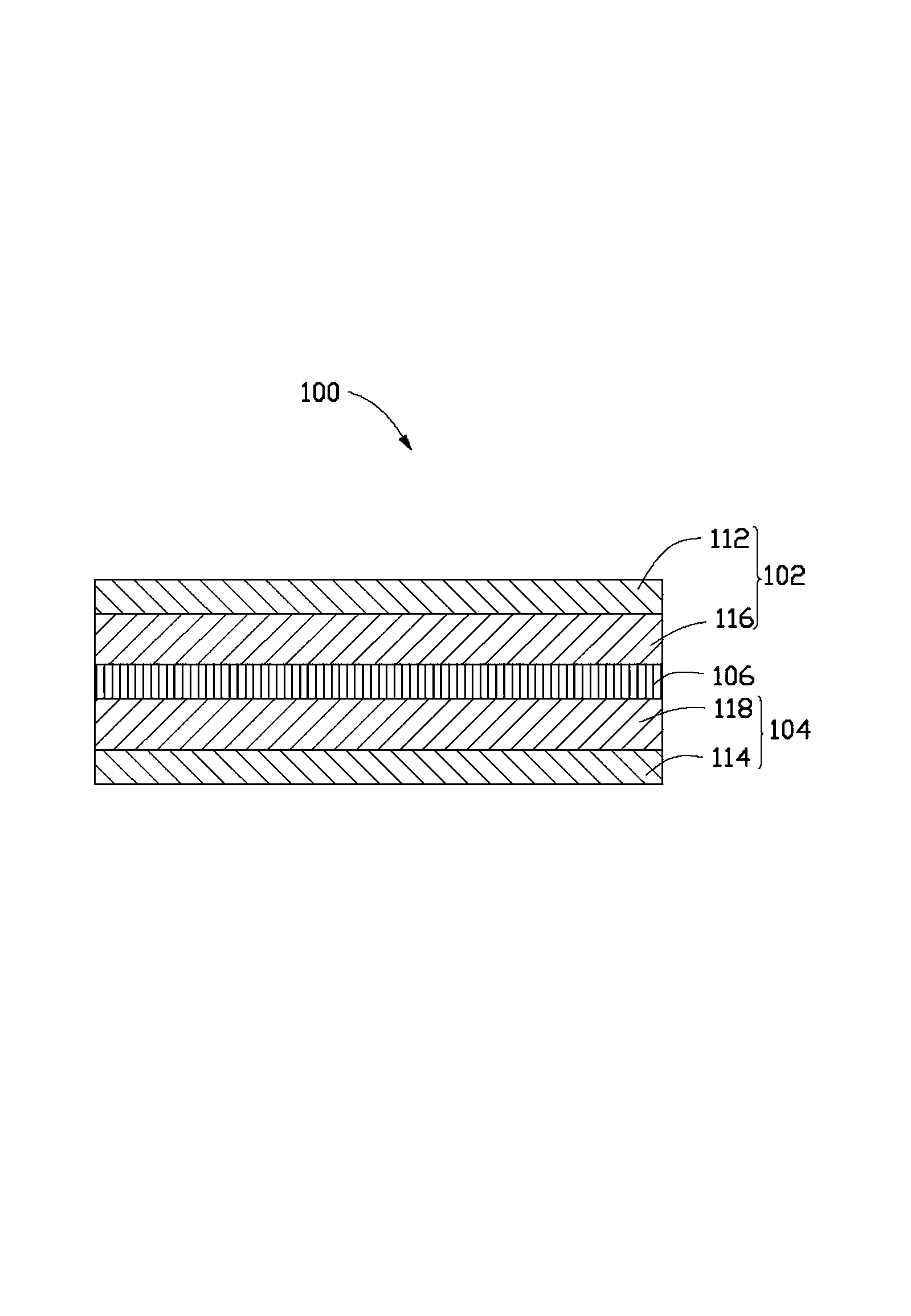

A method for improving the useful life of a thin film lithium-ion battery containing a solid electrolyte and an anode that expands on charging and long life batteries made by the method. The method includes providing a hermetic barrier package for the thin film battery that includes an anode expansion absorbing structure.

Owner:OAK RIDGE MICRO ENERGY

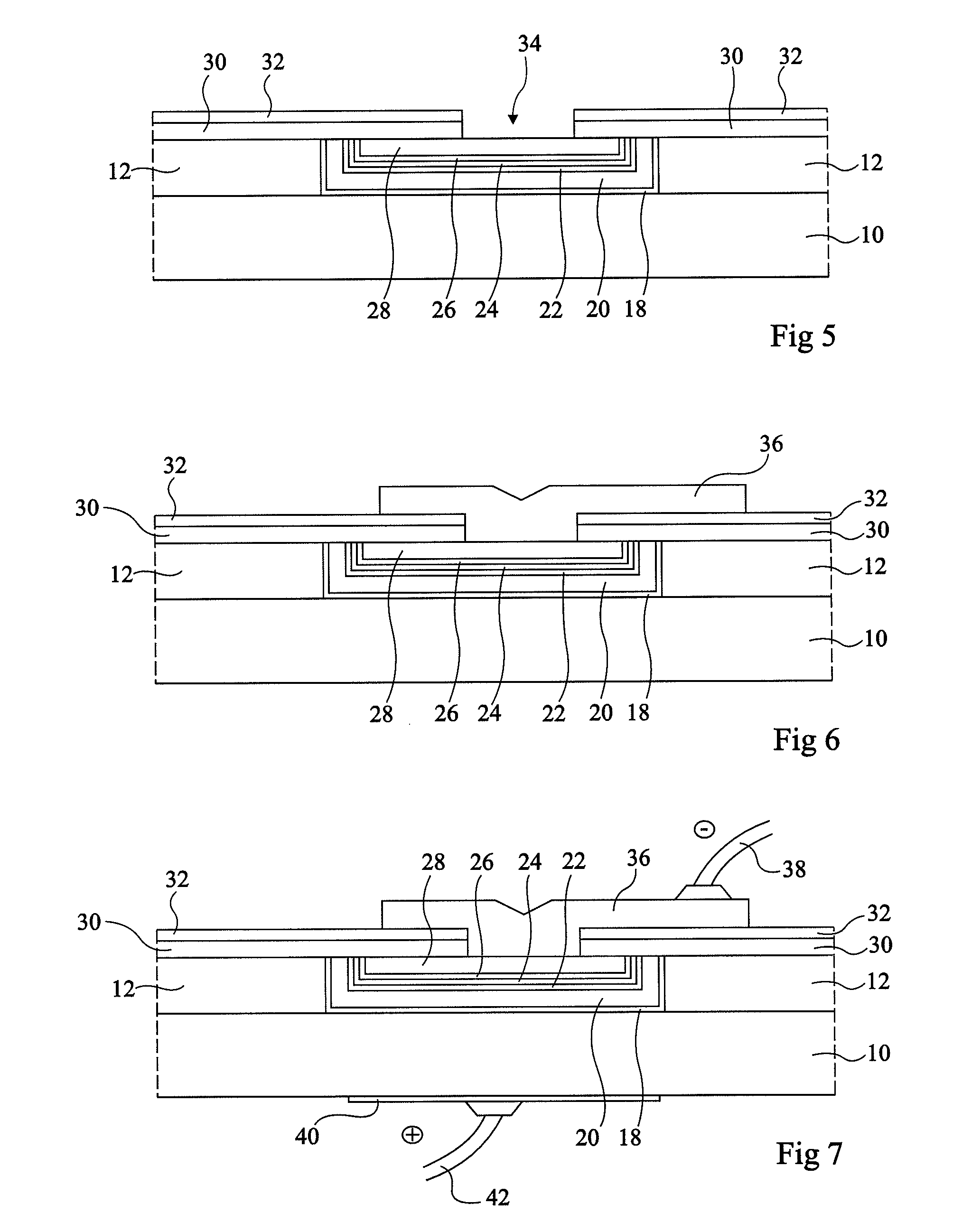

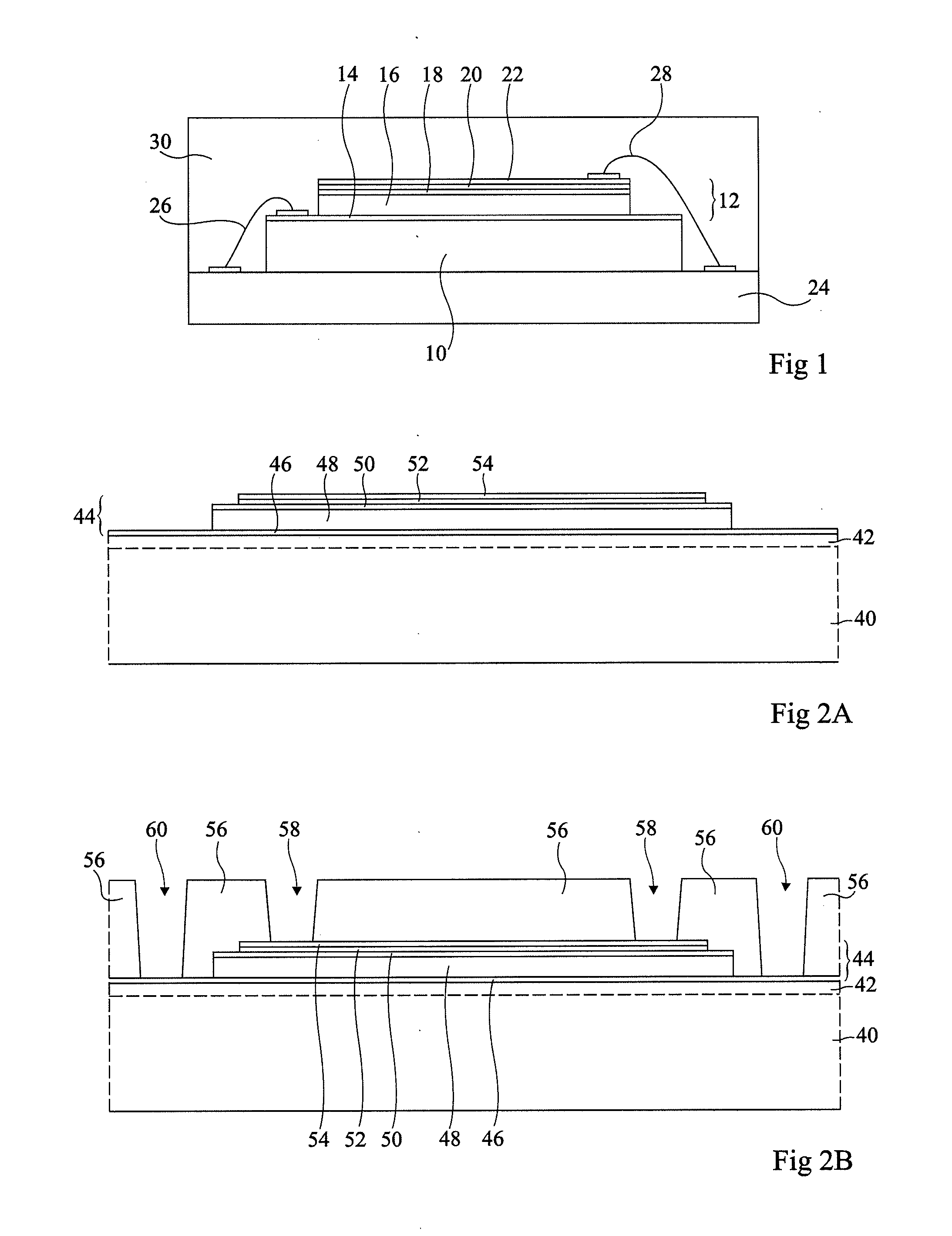

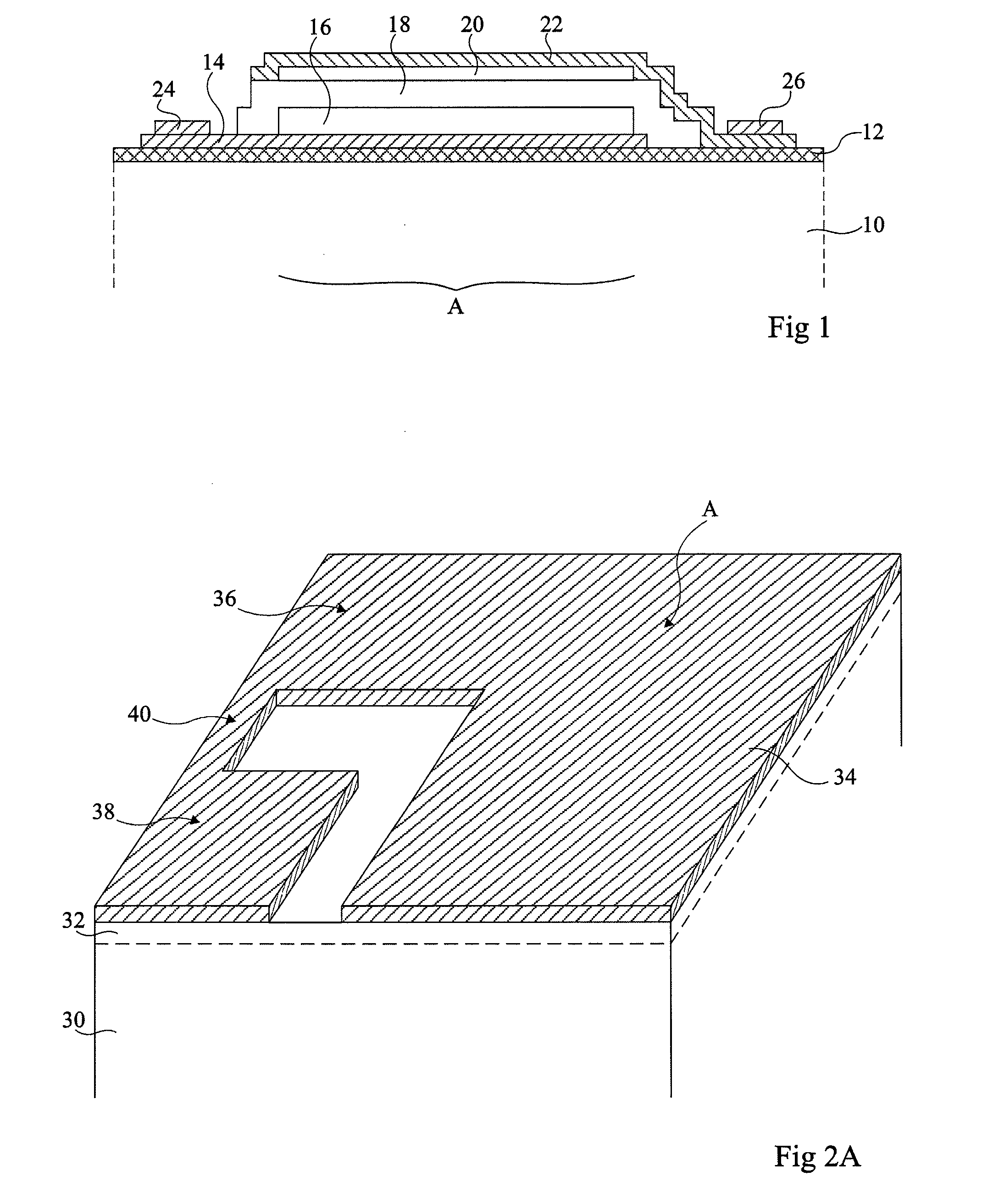

Method for forming a thin-film lithium-ion battery

InactiveUS20110076567A1Low costFinal product manufactureVacuum evaporation coatingLithiumOptoelectronics

A method for forming a lithium-ion type battery including the steps of forming, over an at least locally conductive substrate, an insulating layer having a through opening; successively and conformally depositing a stack comprising a cathode collector layer, a cathode layer, an electrolyte layer, and an anode layer, this stack having a thickness smaller than the thickness of the insulating layer; forming, over the structure, an anode collector layer filling the space remaining in the opening; and planarizing the structure to expose the upper surface of the insulating layer.

Owner:STMICROELECTRONICS (TOURS) SAS

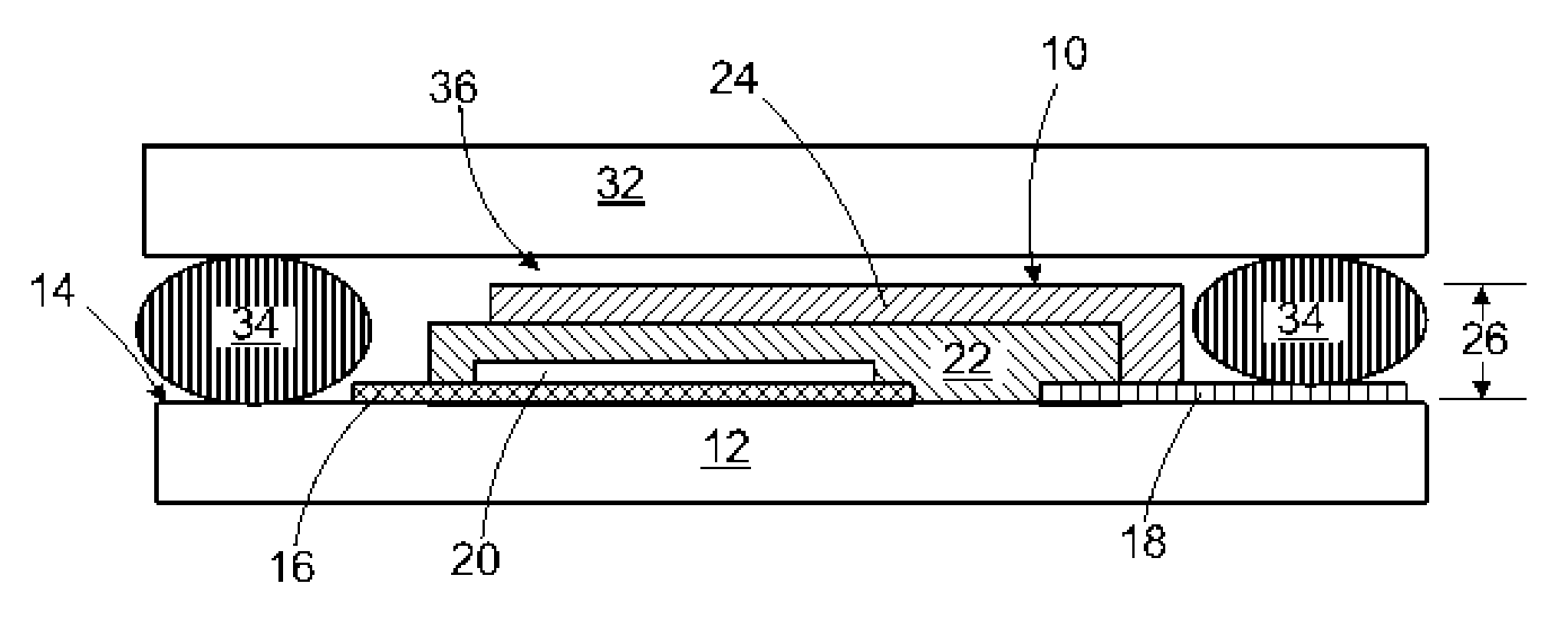

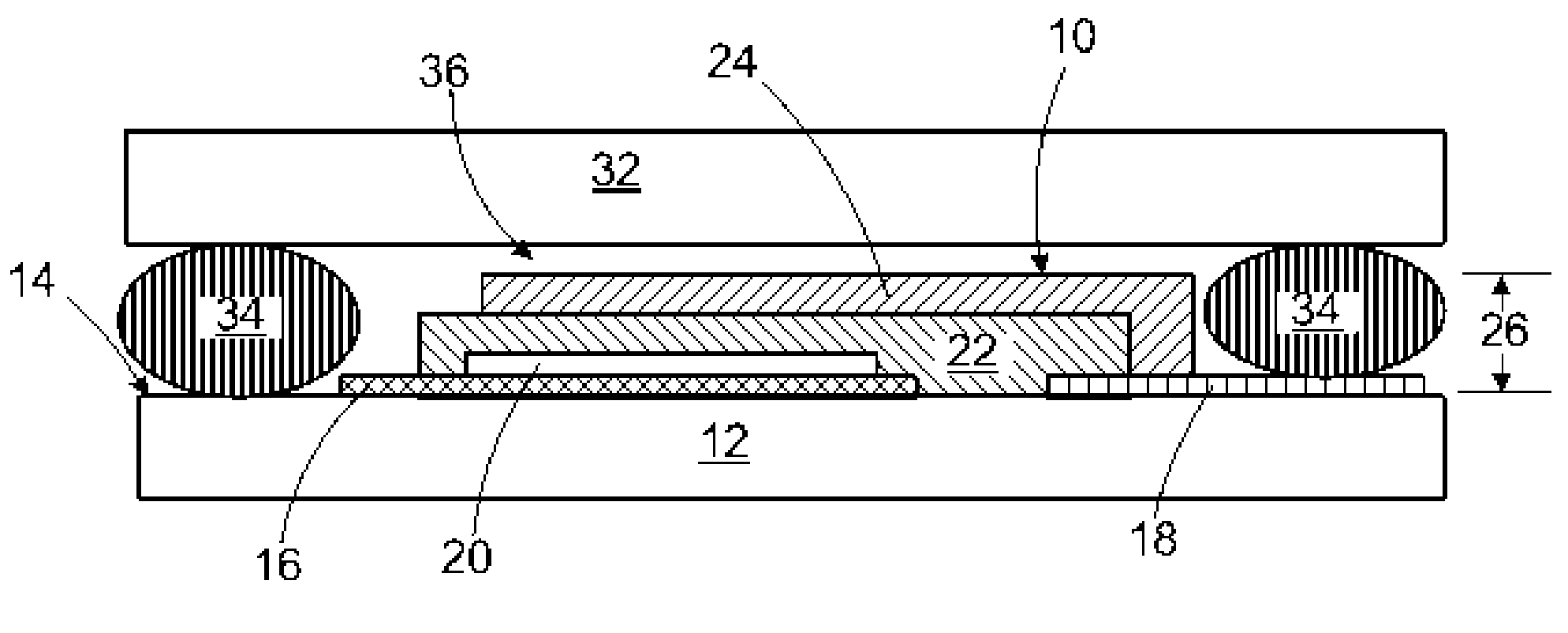

Long life thin film battery and method therefor

InactiveUS7524577B2Extended service lifeIncrease costSolid electrolytesCell electrodesEngineeringThin film rechargeable lithium battery

A method for improving the useful life of a thin film lithium-ion battery containing a solid electrolyte and an anode that expands on charging and long life batteries made by the method. The method includes providing a hermetic barrier package for the thin film battery that includes an anode expansion absorbing structure.

Owner:OAK RIDGE MICRO ENERGY

Method for making thin film lithium ion battery

InactiveUS20140013588A1Reduce power densityShortened life-spanPrimary cell manufactureFinal product manufactureOptoelectronicsThin film rechargeable lithium battery

A method for making a thin film lithium ion battery is provided. A cathode material layer and an anode material layer are provided. A cathode current collector is formed on a surface of the cathode material layer to obtain a cathode electrode. The cathode current collector includes a graphene layer. An anode current collector is applied on a surface of the anode material layer to obtain an anode electrode. A solid electrolyte layer is applied between the cathode electrode and the anode electrode, thereby forming a battery cell. Then at least one battery cell is encapsulated in an external encapsulating shell.

Owner:TSINGHUA UNIV +1

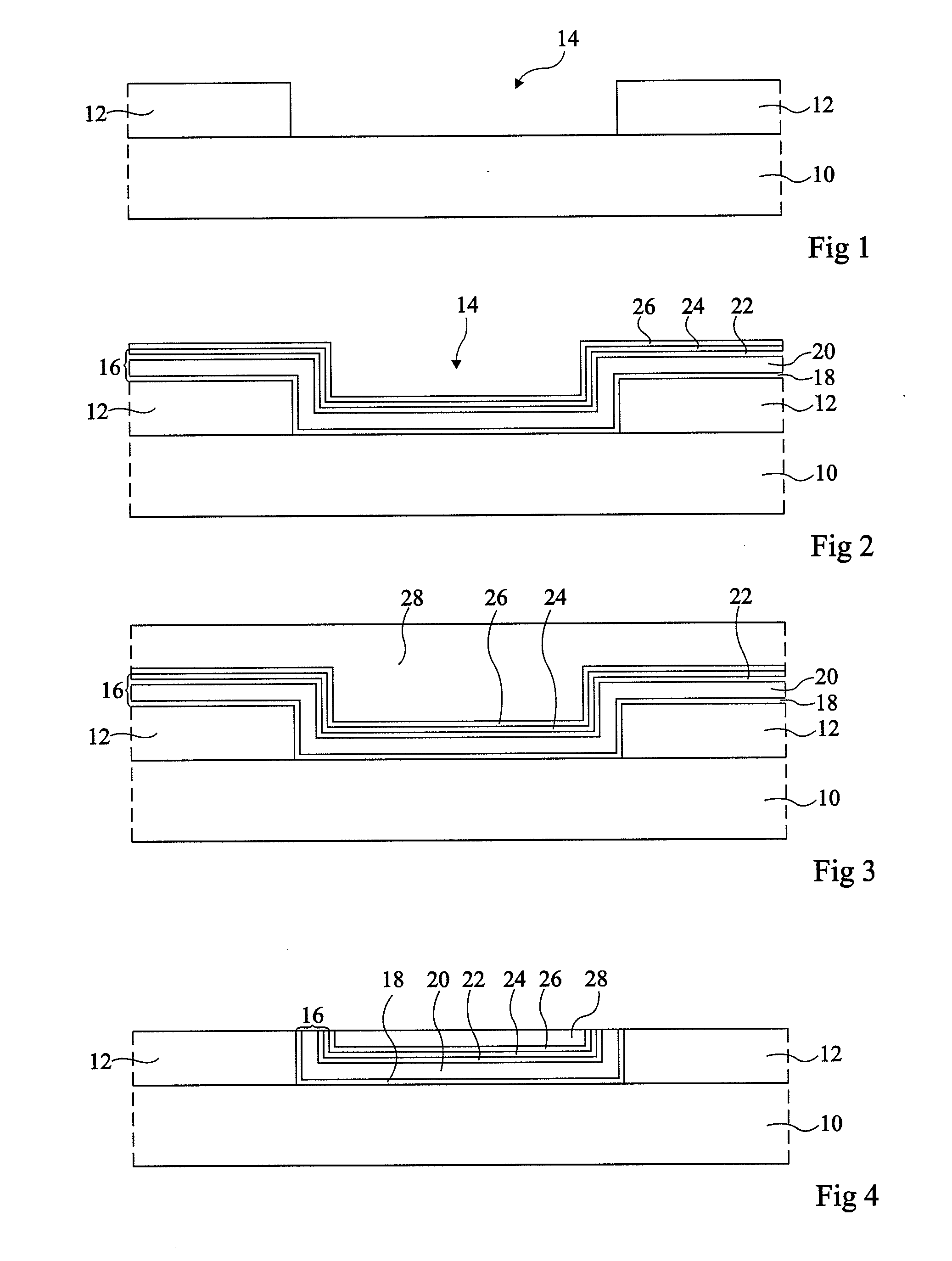

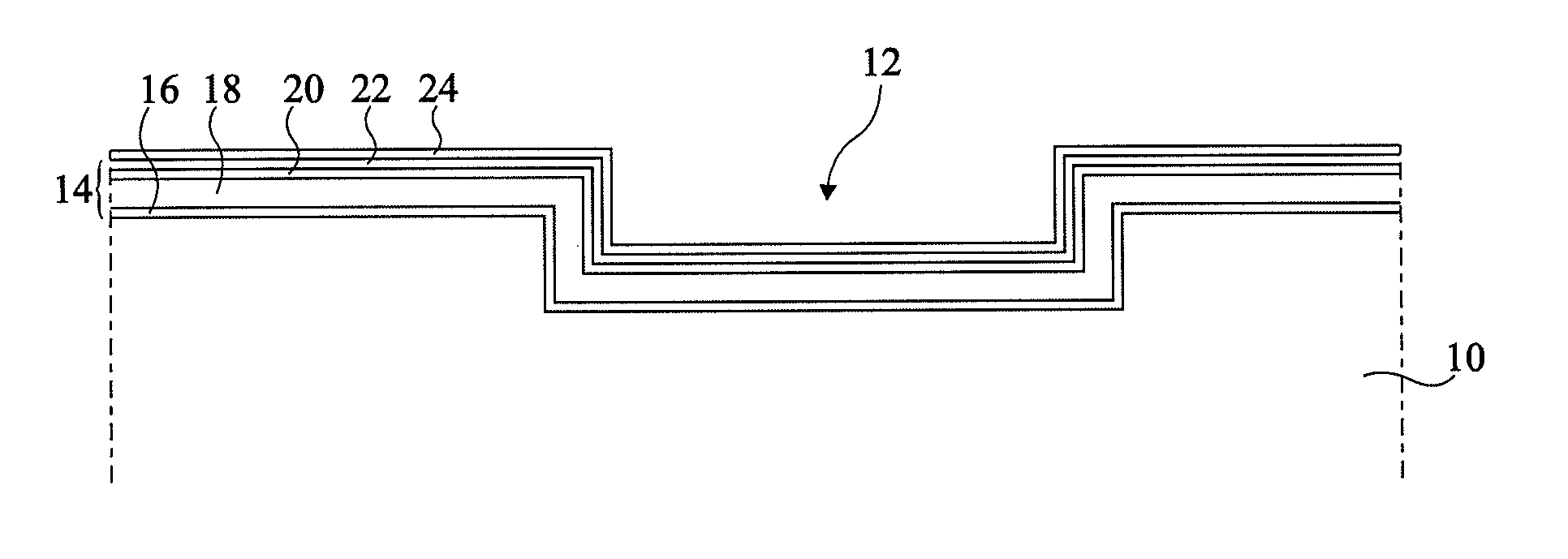

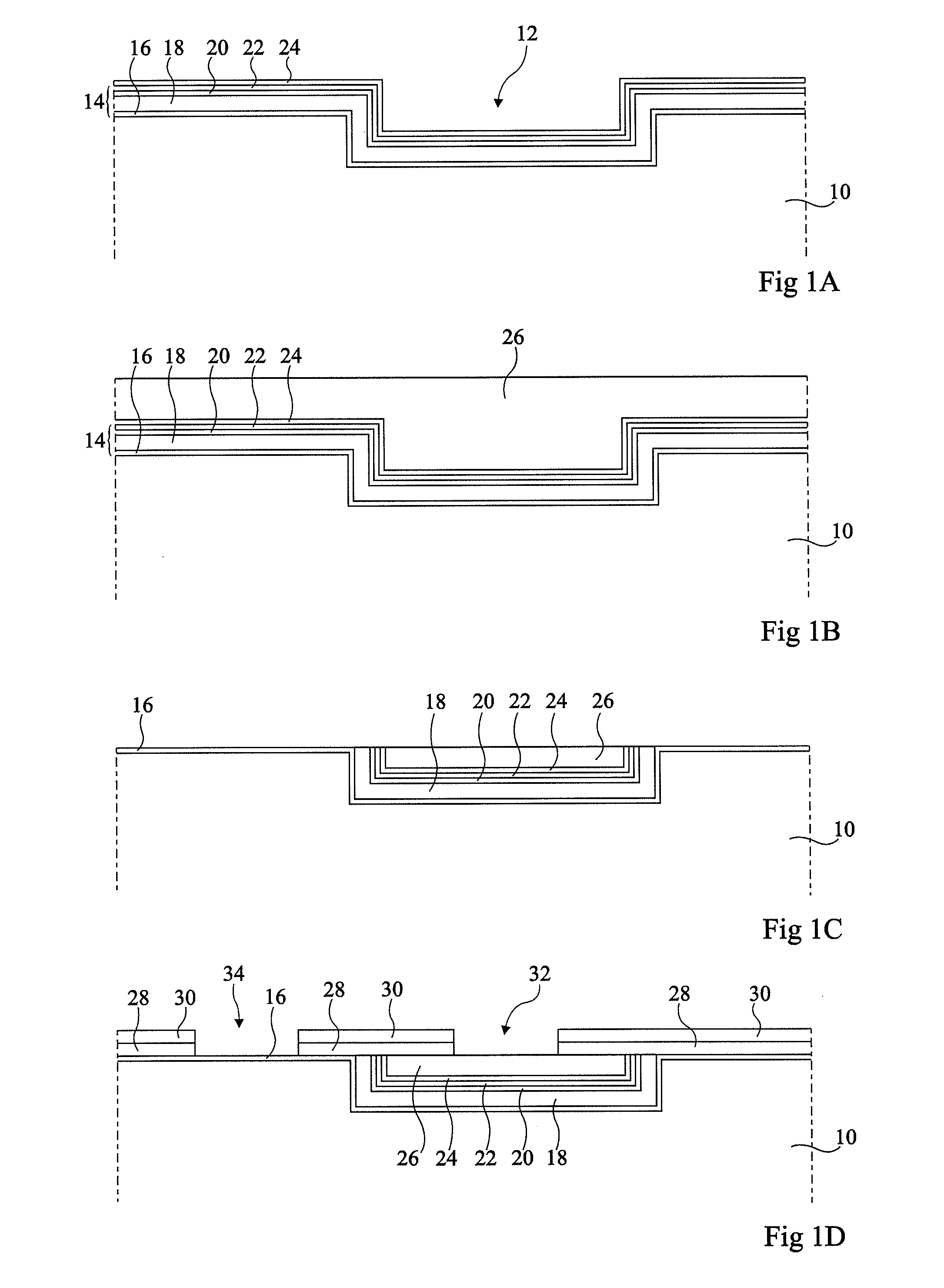

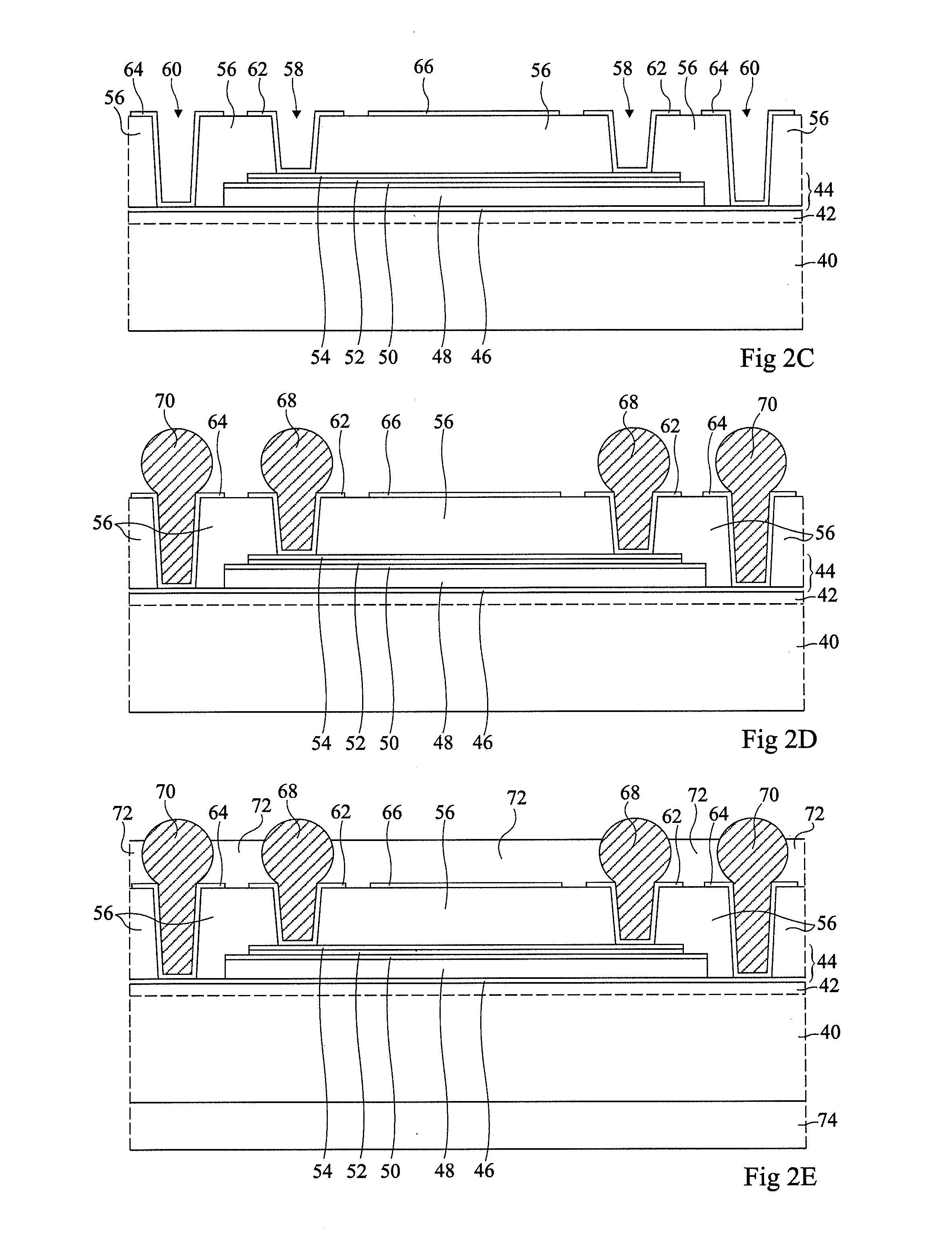

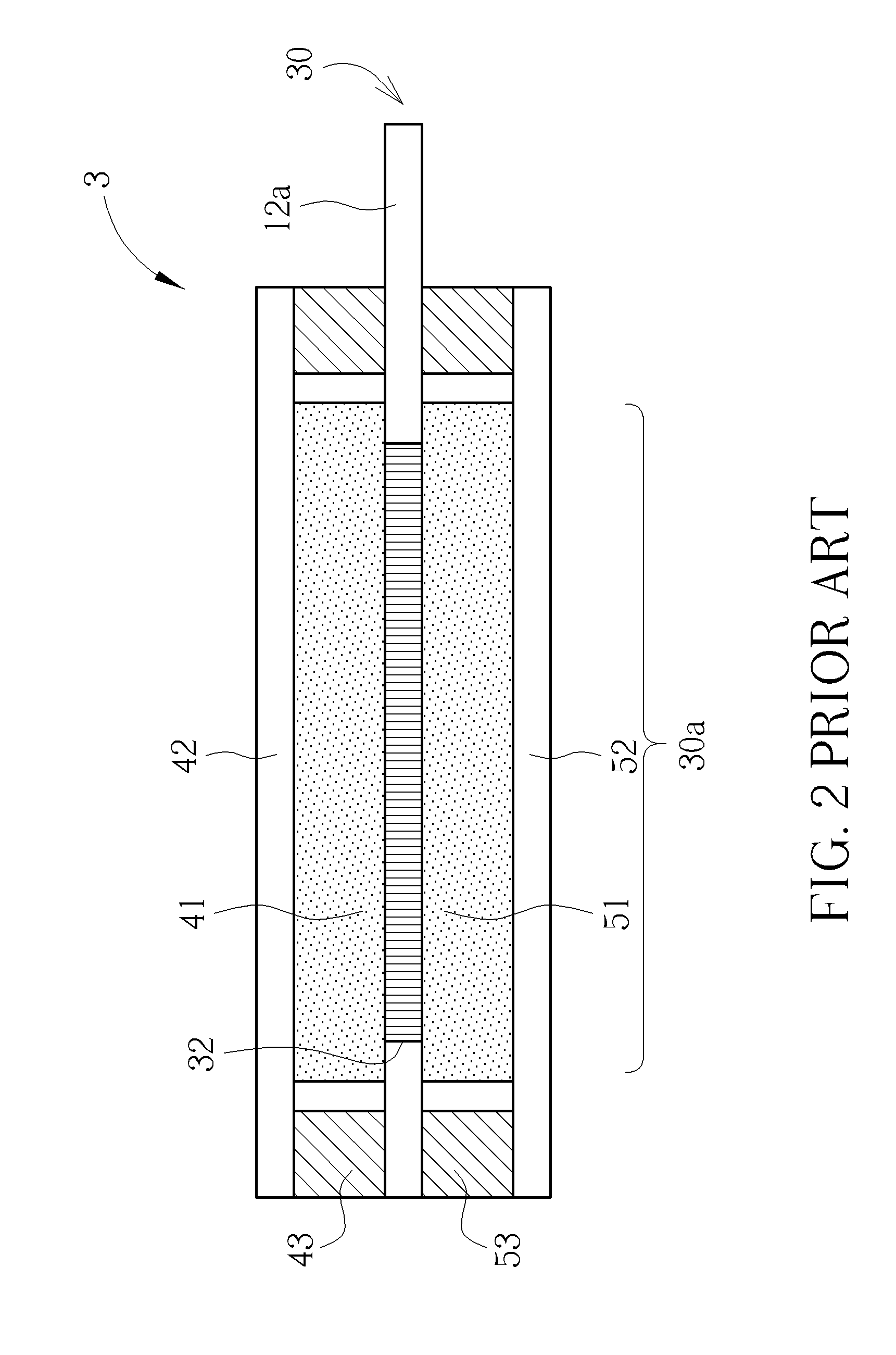

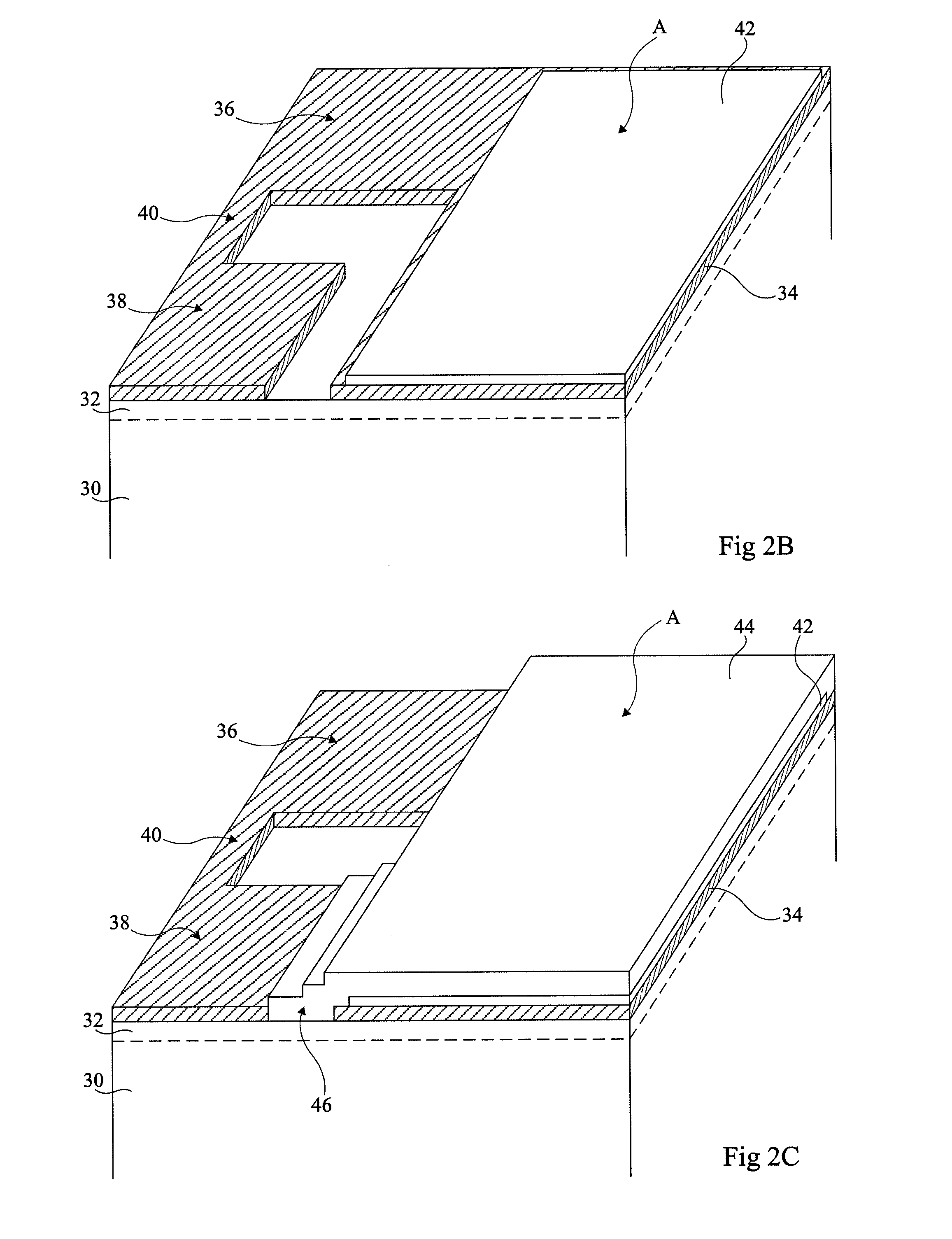

Method for forming a vertical thin-film lithium-ion battery

InactiveUS20110076568A1Low costSolid electrolytesPrimary cell maintainance/servicingLithiumOptoelectronics

A method for forming a lithium-ion type battery, including the successive steps of: forming, in a substrate, a trench; successively and conformally depositing a stack including a cathode collector layer, a cathode layer, an electrolyte layer, and an anode layer, this stack having a thickness smaller than the depth of the trench; forming, over the structure, an anode collector layer filling the space remaining in the trench; and planarizing the structure to expose the upper surface of the cathode collector layer.

Owner:STMICROELECTRONICS (TOURS) SAS

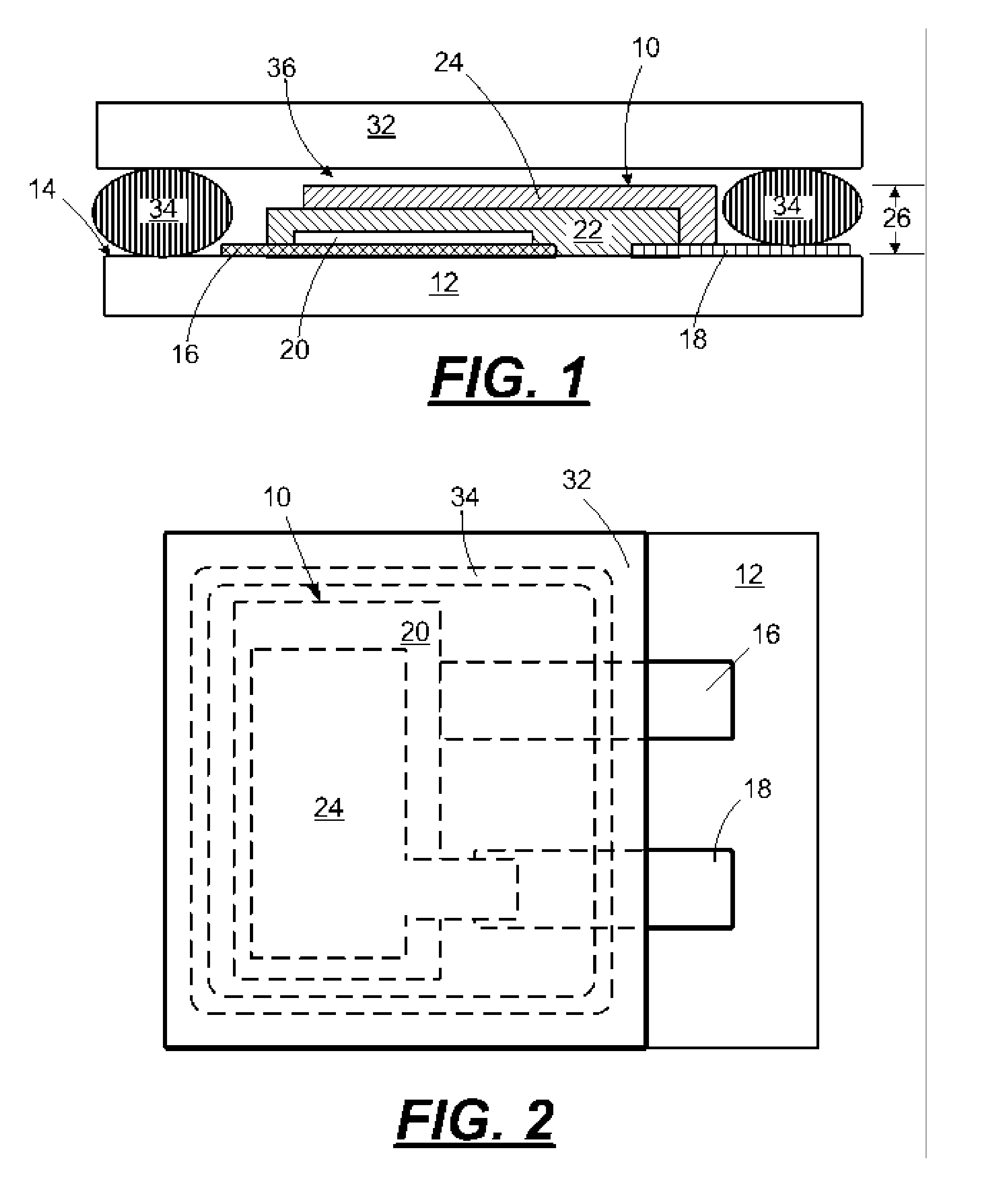

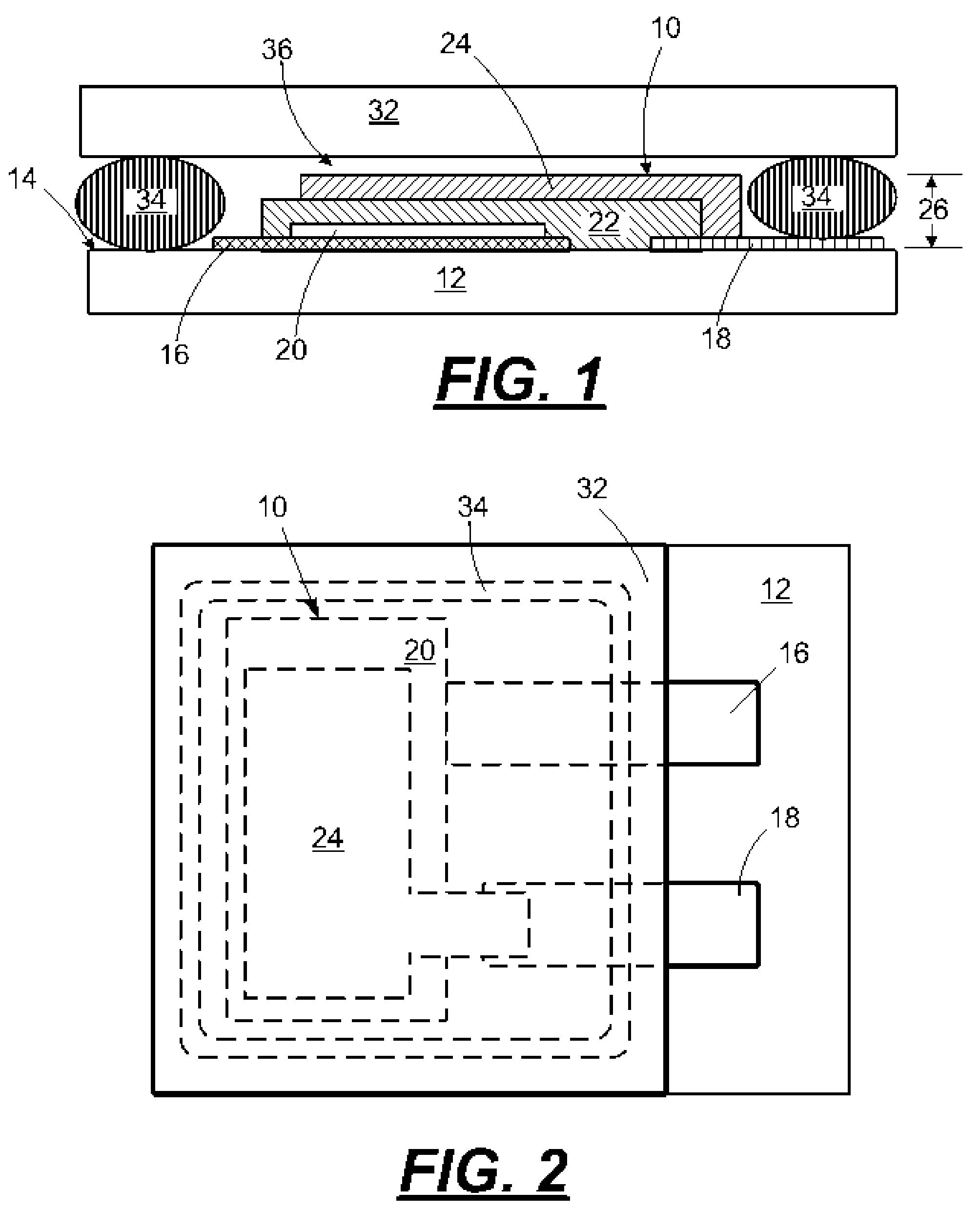

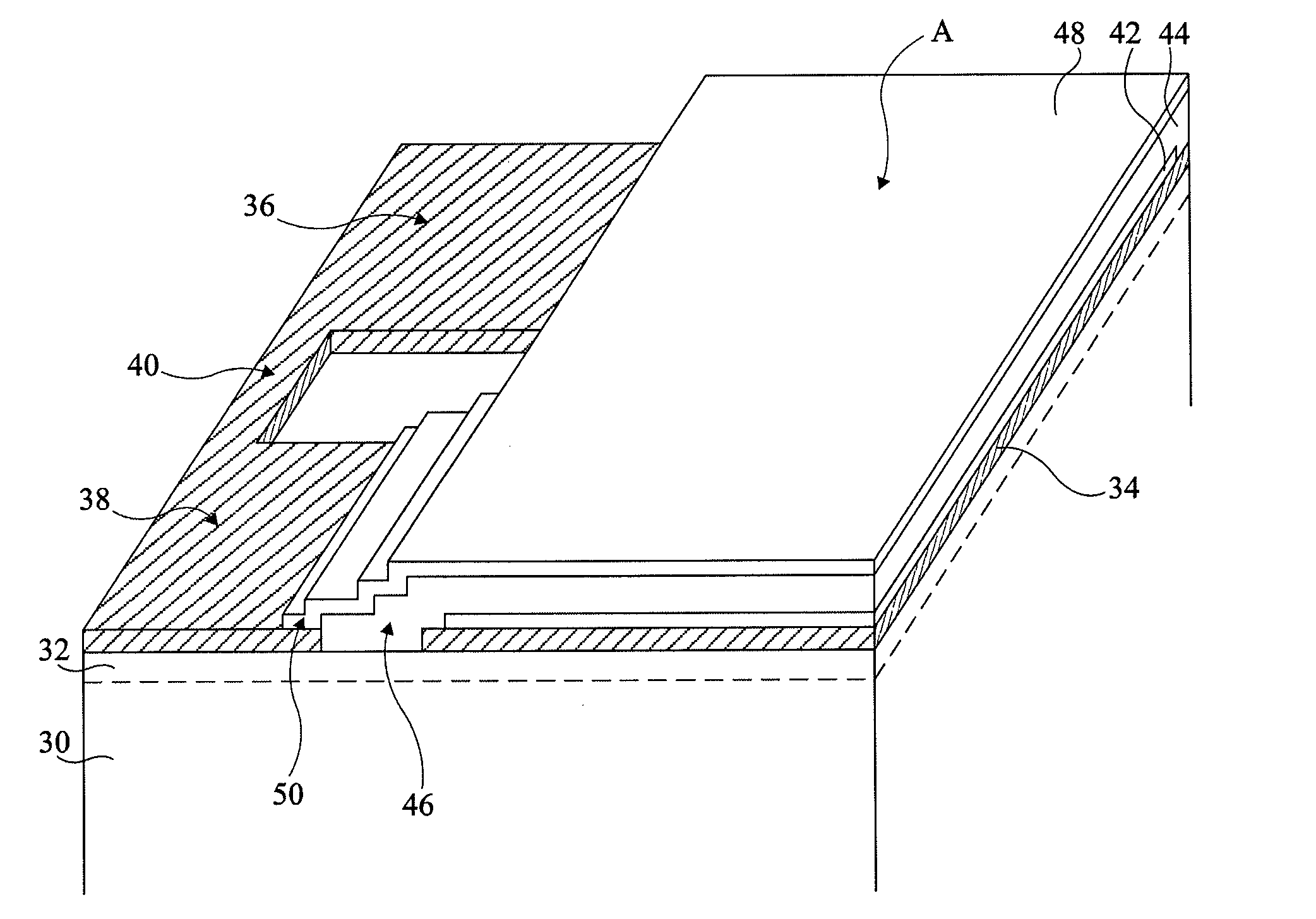

Getters for thin film battery hermetic package

InactiveUS7553582B2Improve performanceReduce adverse effectsSolid electrolytesFinal product manufactureEngineeringHermetic packaging

A method for improving the useful life of a thin film lithium-ion battery containing a solid electrolyte and an anode that expands on charging and long life batteries made by the method. The method includes providing a hermetic barrier package for the thin film battery that includes an anode expansion absorbing structure and at least one film getter.

Owner:OAK RIDGE MICRO ENERGY

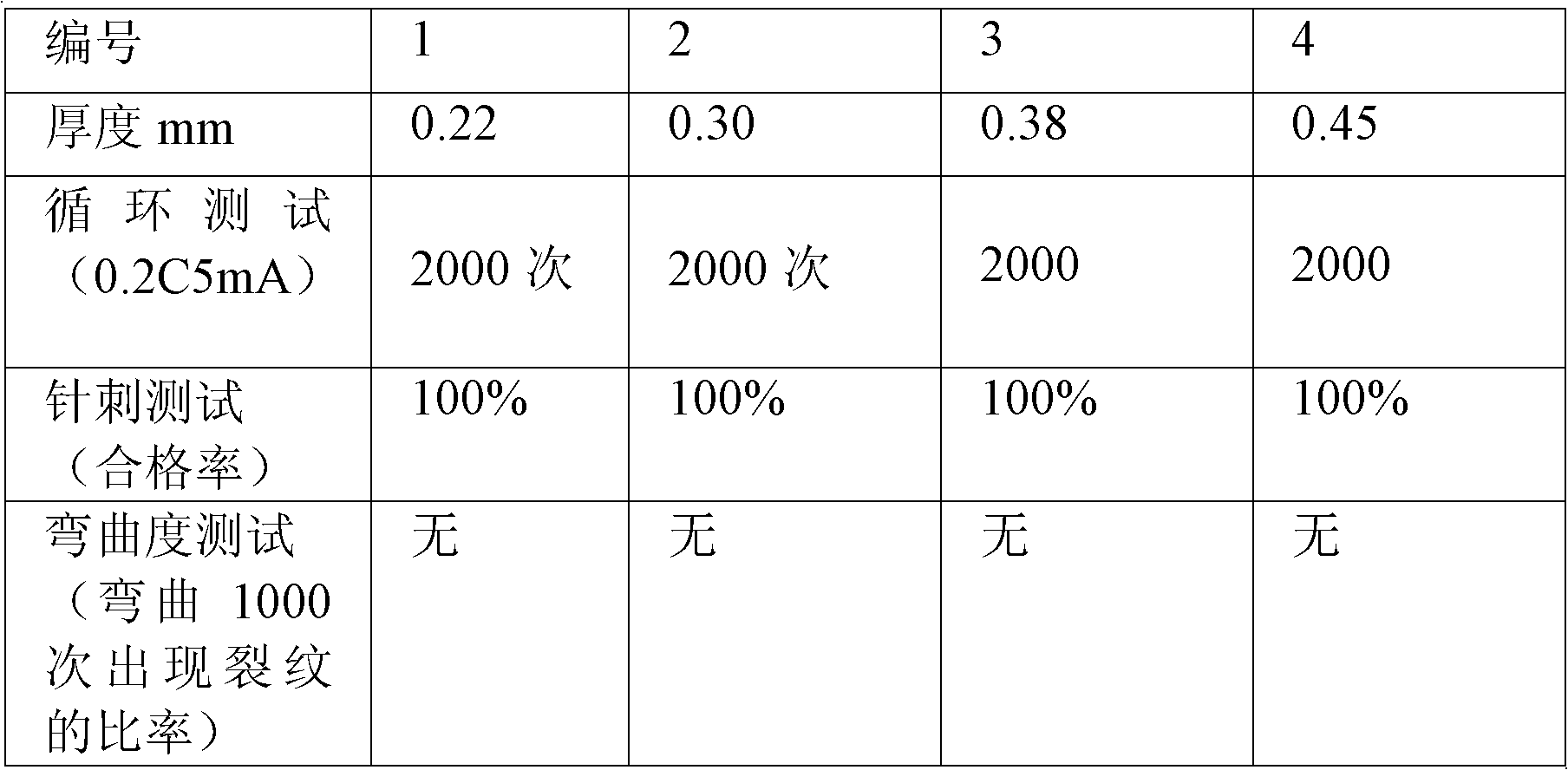

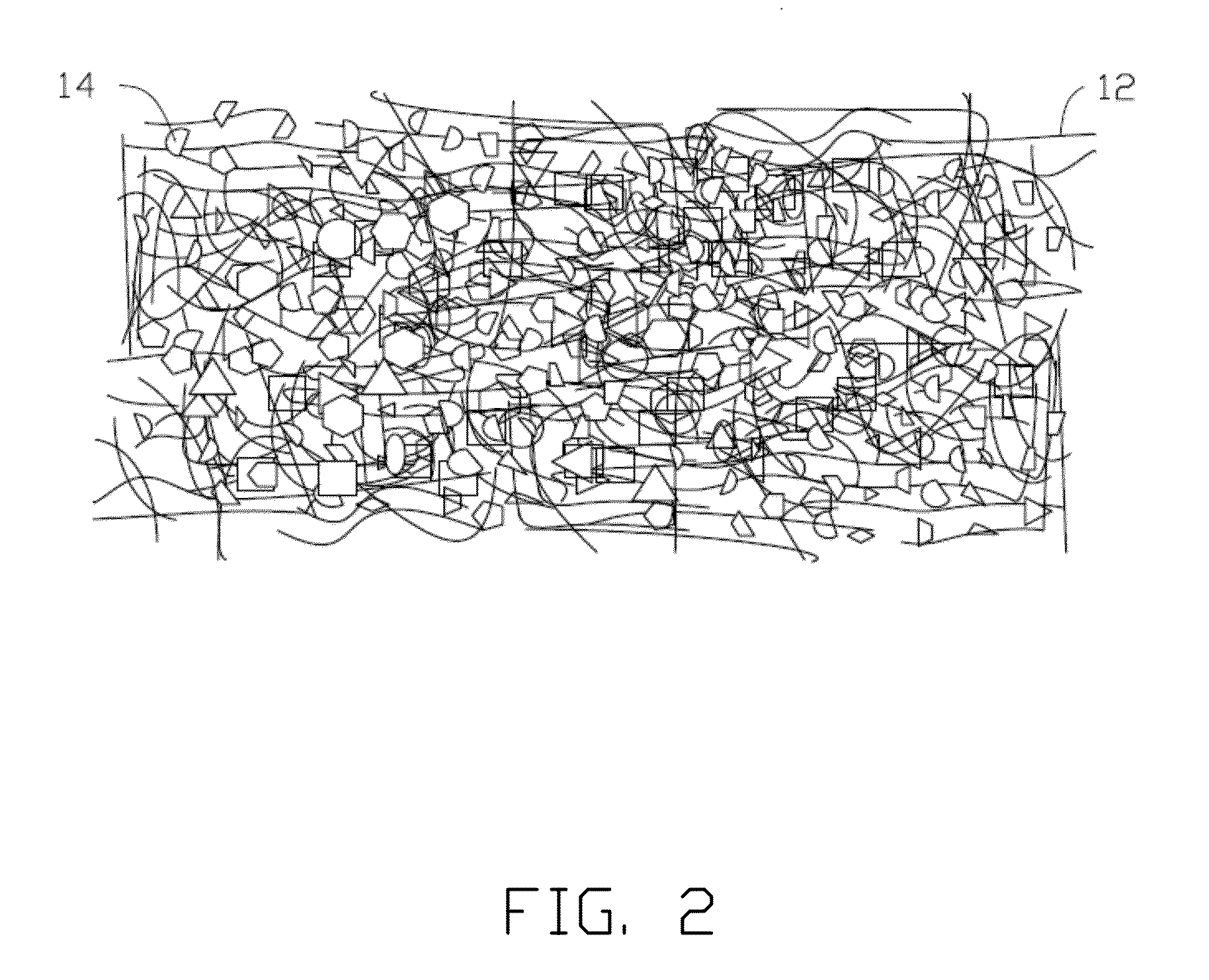

Flexible thin film lithium ion battery and manufacturing method thereof

ActiveCN102522595AImprove securityGood thickness consistencyCell electrodesFinal product manufactureFiberComposite film

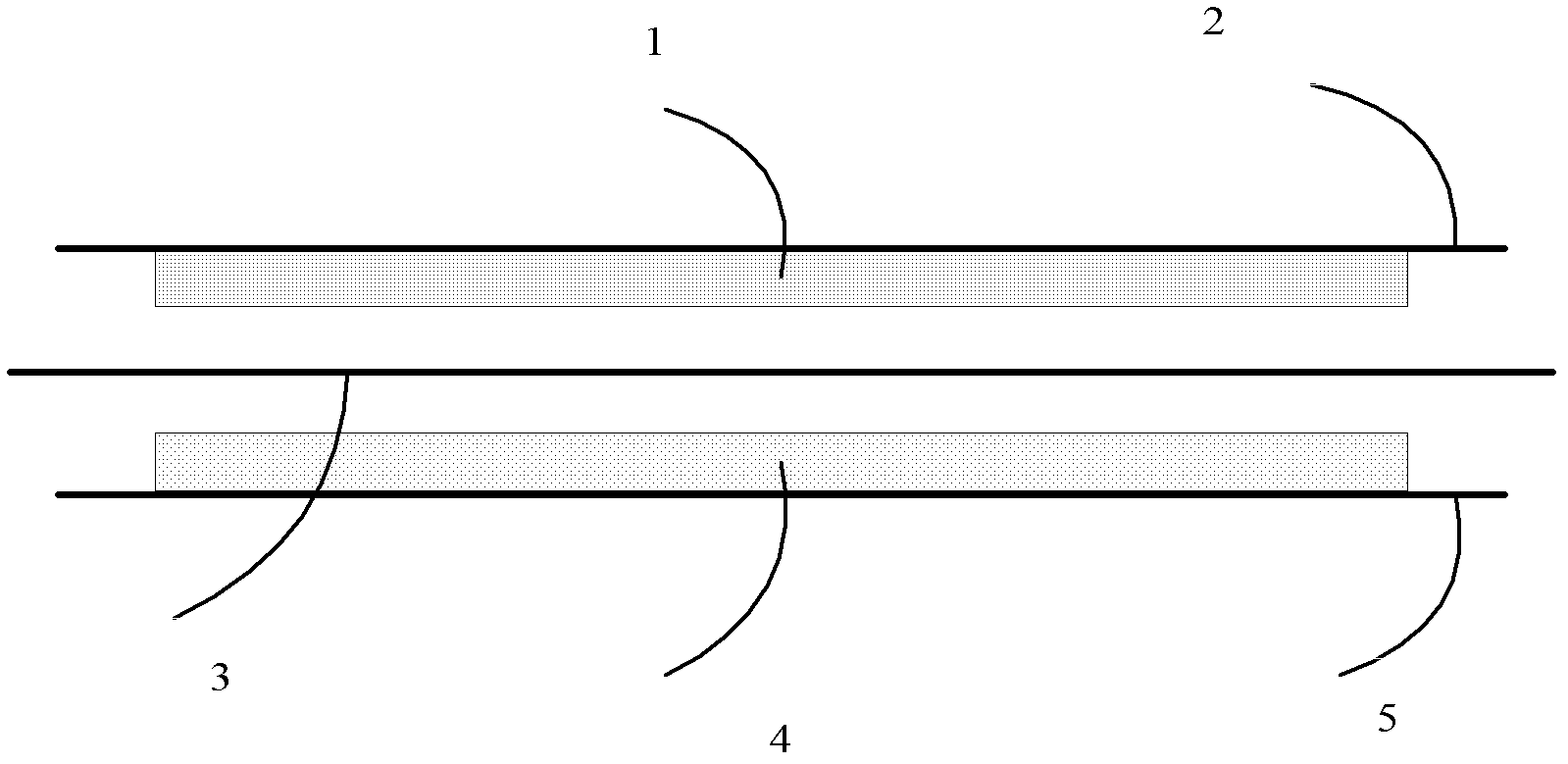

The utility model discloses a flexible thin film lithium ion battery and a manufacturing method thereof. The flexible thin film lithium ion battery is composed of a positive layer, a diaphragm, a negative layer and an external packing layer; the positive layer is composed of aluminum foil with a thickness of 16-30 microns and a positive material printed on one surface of the aluminum foil by adopting intaglio printing technology; the negative layer is composed of copper foil with a thickness of 10-30 microns and a negative material printed on one surface of the copper foil by adopting the intaglio printing technology; the external packing layer is an aluminum plastic composite film; the positive material of the battery comprises dispersant Hypermer KD-1; and the negative material of the battery comprises conductive agent vapor-grown carbon fiber. The flexible thin film lithium ion battery provided by the invention has the benefits that the safety is high, the thickness consistency is good, and the thickness of the battery can be controlled and lowered to 0.25MM, besides, the flexibility is good, the performance and the shape of the battery can not be affected even though the flexible thin film lithium ion battery is bent for several times.

Owner:江苏百特福新能源科技有限责任公司

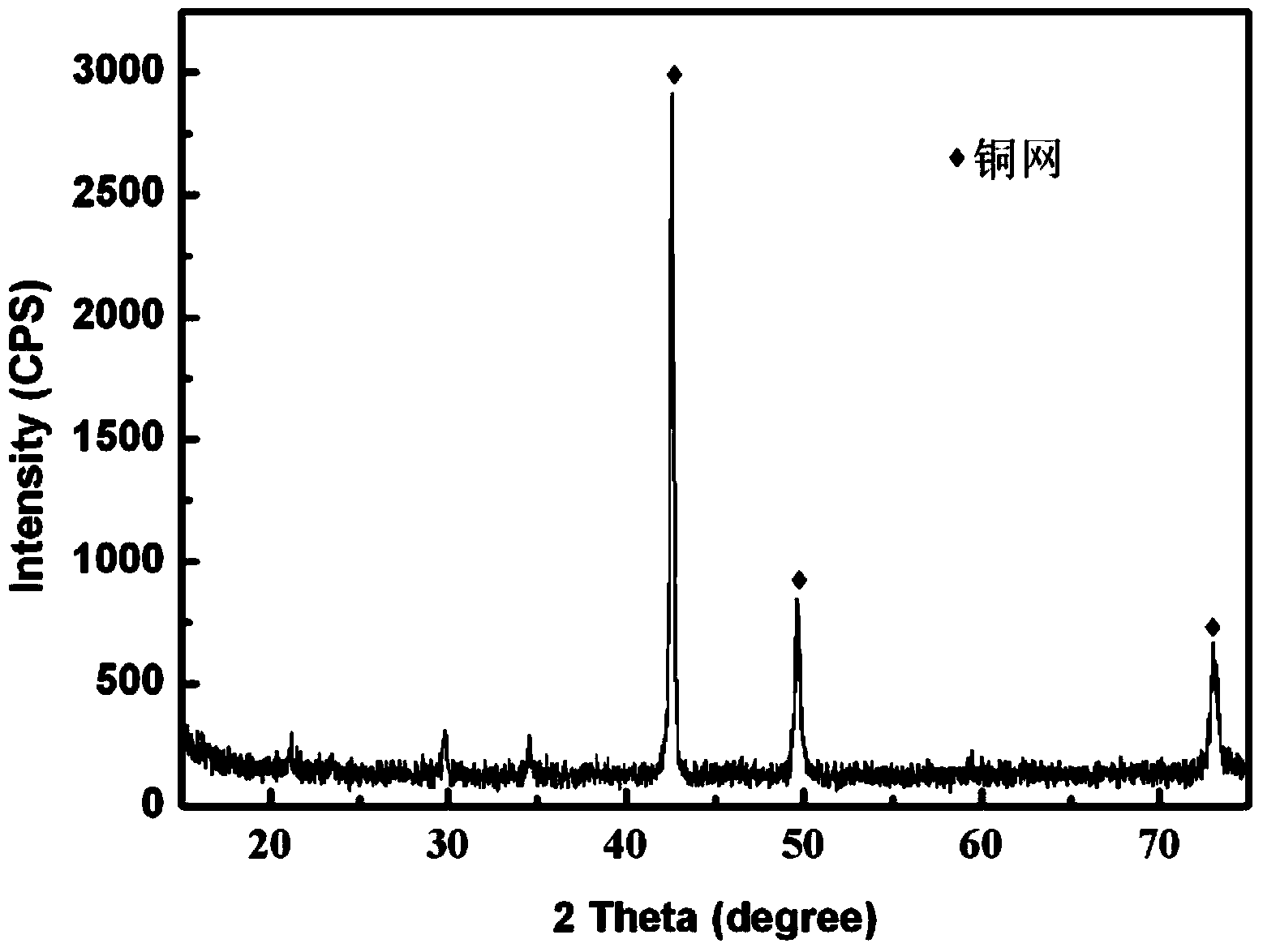

Method for preparing cathode of lithium ion battery with lithium-silicon film through pulse electrodeposition

InactiveCN104064732AEliminate Concentration PolarizationQuality improvementCell electrodesAluminium-ion batterySodium-ion battery

The invention relates to a method for preparing a cathode of a lithium ion battery with a lithium-silicon film through pulse electrodeposition, belonging to the technical field of lithium ion batteries. The method for preparing the cathode of the lithium ion battery with the lithium-silicon film through pulse electrodeposition comprises the following process steps of: (1) electrolyte preparation: adding lithium salt and silicon tetrachloride into an anhydrous organic solvent under the protection of insert gases, and dissolving by stirring to obtain electrolyte; (2) pulse electrodeposition: carrying out lithium and silicon co-electrodeposition on the prepared electrolyte under the protection of inert gases and at the temperature of 20-30 DEG C, wherein a platinum sheet is used as an anode, a platinum wire is used as a reference electrode, and a cathode is a planar metal current collector or meshy metal current collector; carrying out electrodeposition in a constant-current pulse or constant-voltage pulse way; then, flushing by using an anhydrous aprotic organic solvent to obtain the cathode provided by the invention. The method has the advantages of uniform deposition layer, tight combination between the lithium and silicon film and the metal current collector, high lithium storage quantity, controllable circulation capacity and first circulation efficiency, good circulation stability and the like.

Owner:盐城市新能源化学储能与动力电源研究中心

Cathode material of thin film lithium ion battery and method for producing the same

InactiveCN101222047AIncrease contact interfaceLower transfer resistanceElectrode manufacturing processesElectrode carriers/collectorsHigh rateLithium-ion battery

The invention discloses cathode material for a membrane lithium ion battery, which is a foaming nickel load NiO / Ag nano composite porous membrane, NiO with a mass percent of 75 percent to 95 percent, and nano metal Ag of 5 percent to 25 percent. The preparation method for the cathode material comprises the following steps: firstly, a foaming nickel substrate is laid into mixture of NiSO4 solution, K2S2O8 solution, strong aqua ammonia and water for sedimentation and then calcined in argon gas; secondly, the substrate after calcinations is laid into mixture of silver-ammonia solution and polyvinylpyrrolidone ethanol solution for continuous sedimentation. Compared with the prior NiO membrane cathode, a cathode of the foaming nickel load NiO / Ag nano composite porous membrane contains more active materials, and contact interface between an electrode and electrolytes is larger and lithium ion battery diffusion path is shorter. Moreover, the cathode still has high area specific capacity and superior cyclicity even under the condition of high rate.

Owner:ZHEJIANG UNIV

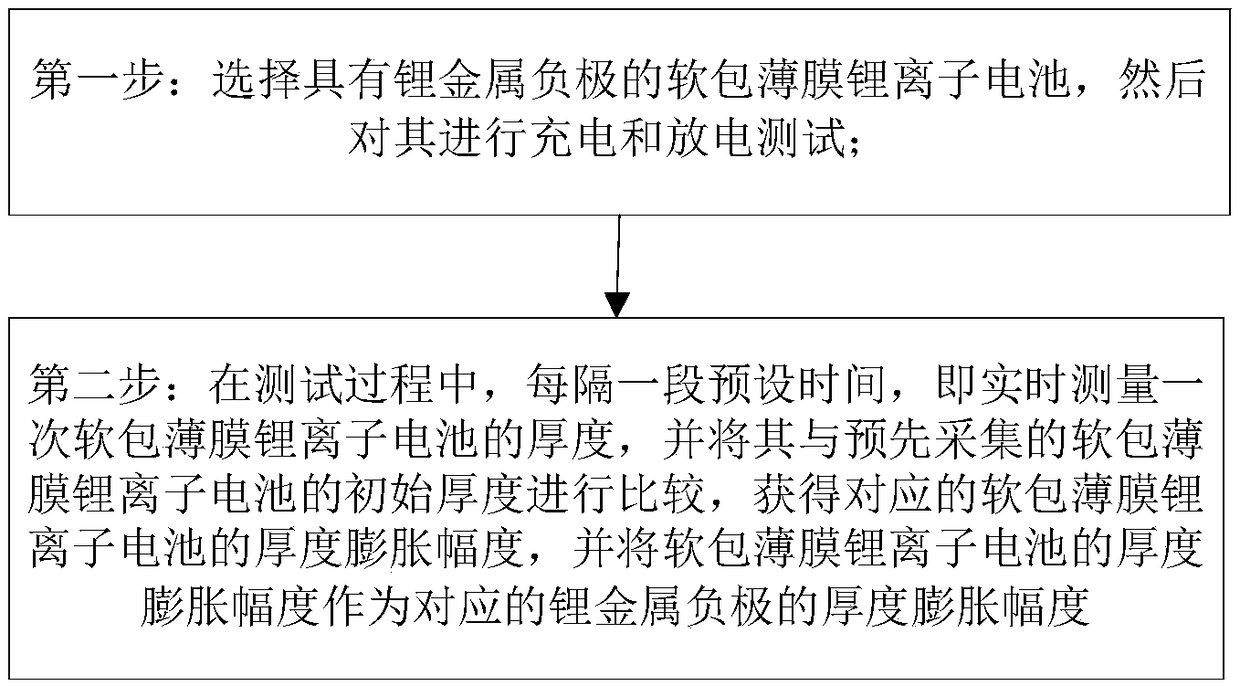

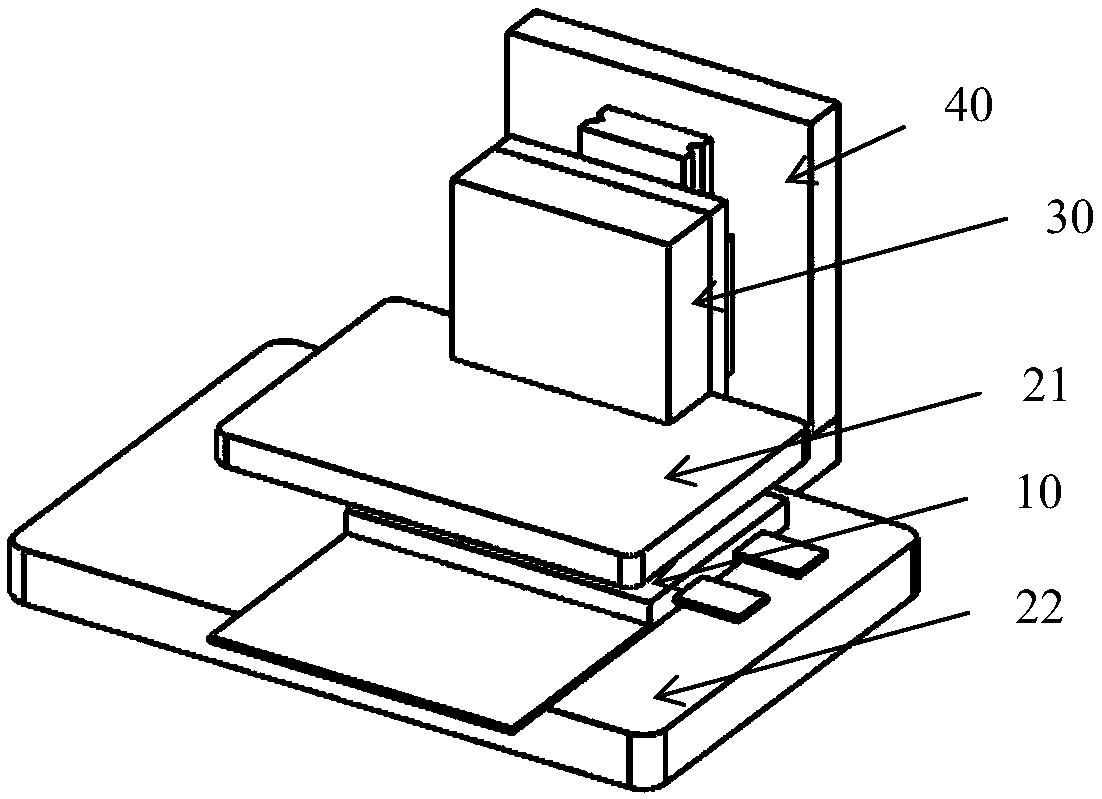

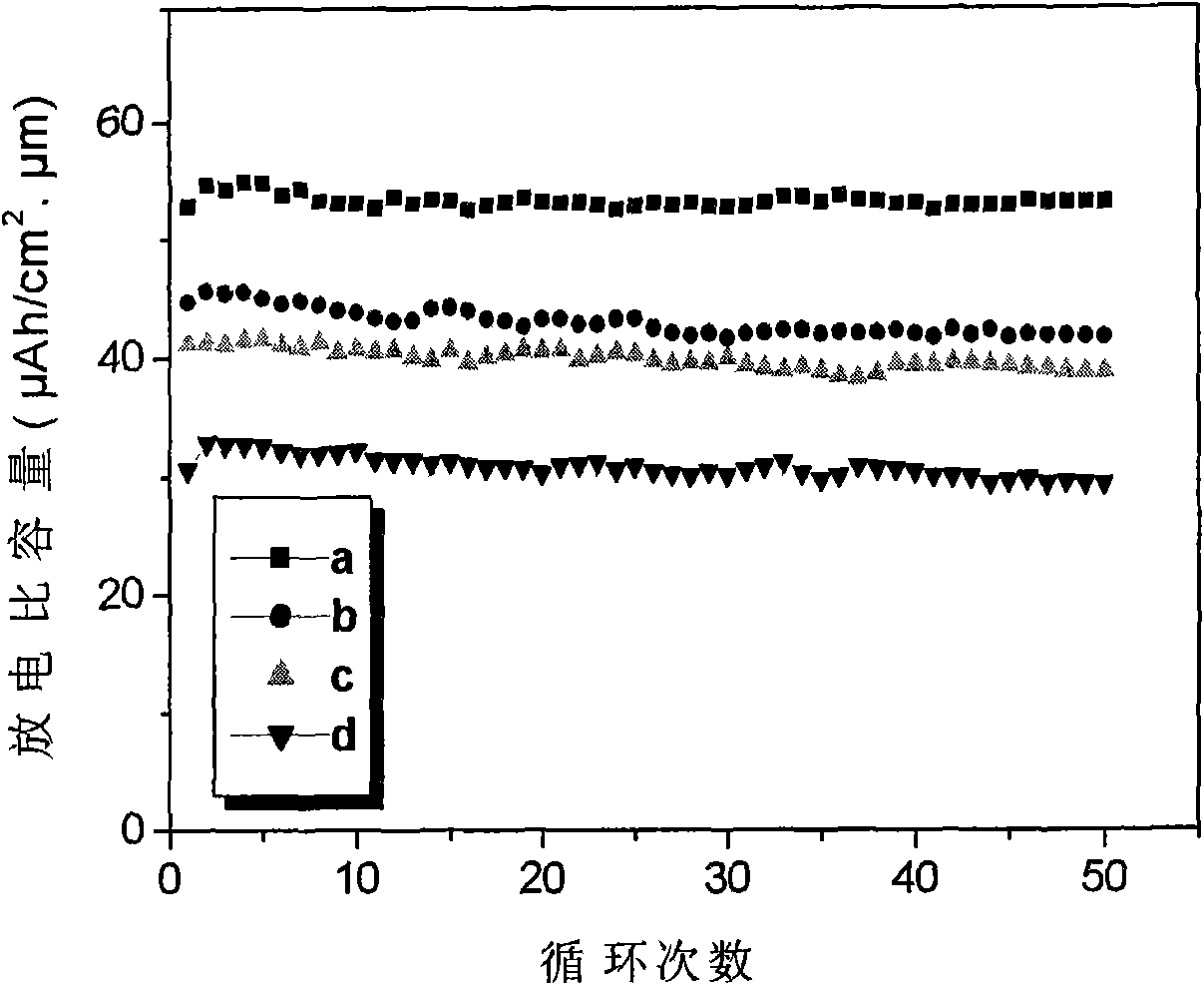

Method for analyzing expansion extent of lithium metal cathode

ActiveCN108899594AMaster the expansionMaster performanceElectrical testingSecondary cells testingLithium metalLithium-ion battery

The invention discloses a method for analyzing the expansion extent of a lithium metal cathode. The method comprises the following steps: (1) selecting a soft-package thin film lithium ion battery with a lithium metal cathode, and carrying out charging and discharging tests on the soft-package thin film lithium ion battery; and (2) measuring the thickness of the soft-package thin film lithium ionbattery once in real time at set intervals in the testing process, and carrying out comparison on the thickness measured in real time and the pre-collected original thickness of the soft-package thinfilm lithium ion battery so as to obtain the corresponding thickness expansion extent of the soft-package thin film lithium ion battery, wherein the thickness expansion extent of the soft-package thinfilm lithium ion battery is taken as the thickness expansion extent of the corresponding lithium metal cathode. According to the method disclosed by the invention, the expansion condition of the large-area lithium metal cathode can be accurately and reliably grasped and can be tested and analyzed.

Owner:TIANJIN LISHEN BATTERY +1

Preparation method of nano-silver particle dispersed Li*Ti*O* thin film lithium ion battery negative electrode

InactiveCN101609883AStoichiometric composition controllableGood dispersionElectrode manufacturing processesDecompositionHYDROSOL

The invention discloses a preparation method of an all solid-state film lithium ion battery negative electrode-a nano-silver particle dispersed Li4Ti5O12 negative electrode thin film, which belongs to the technical field of electrochemistry. The process is as follows: material preparation: dissolving compounds of titanium and the compounds of lithium in an organic solvent for obtaining solution A and mixing water, complexing agent and silver nitrate for obtaining solution B; preparation of precursor solution as follows: stirring and mixing the solution A and the solution B to a stable sol; and the preparation of the thin film: preparing a gel thin film on a substrate through the sol-gel method, carrying out preheating decomposition at 200-400 DEG C, annealing in an H2 atmosphere at 600-800 DEG C and further preparing the Ag / Li4Ti5O12 thin film. The thin film provided by the invention has the advantages of controllable stoichiometric composition, simple preparation method, process and equipment and easy preparation of the negative electrode thin film with large area. Compared with the traditional Li4Ti5O12 thin film negative electrode, the lithium ion battery negative electrode of the invention has high area specific capacity and excellent cycle performance in case of high multiplying power discharge.

Owner:大连德润达实业有限公司

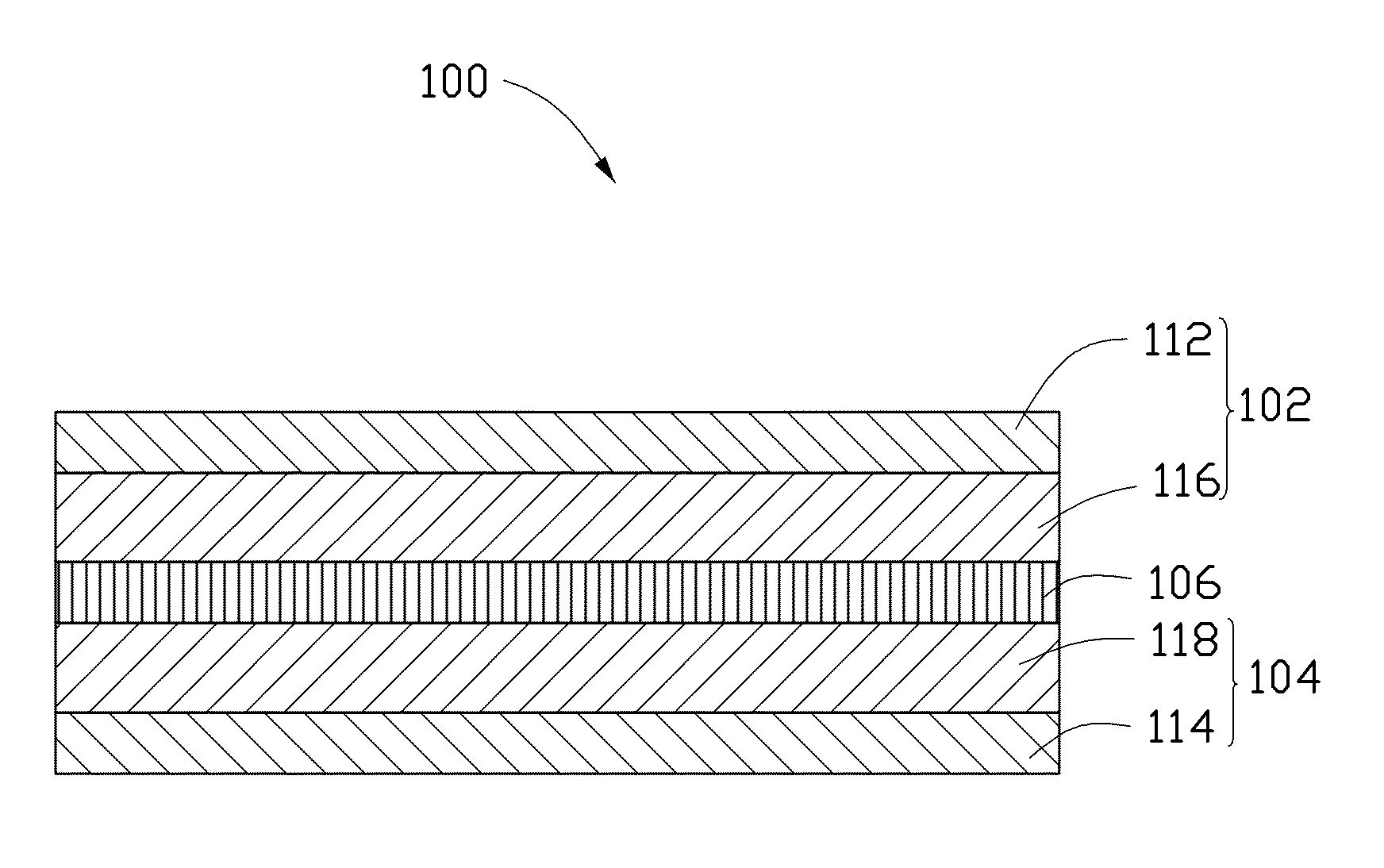

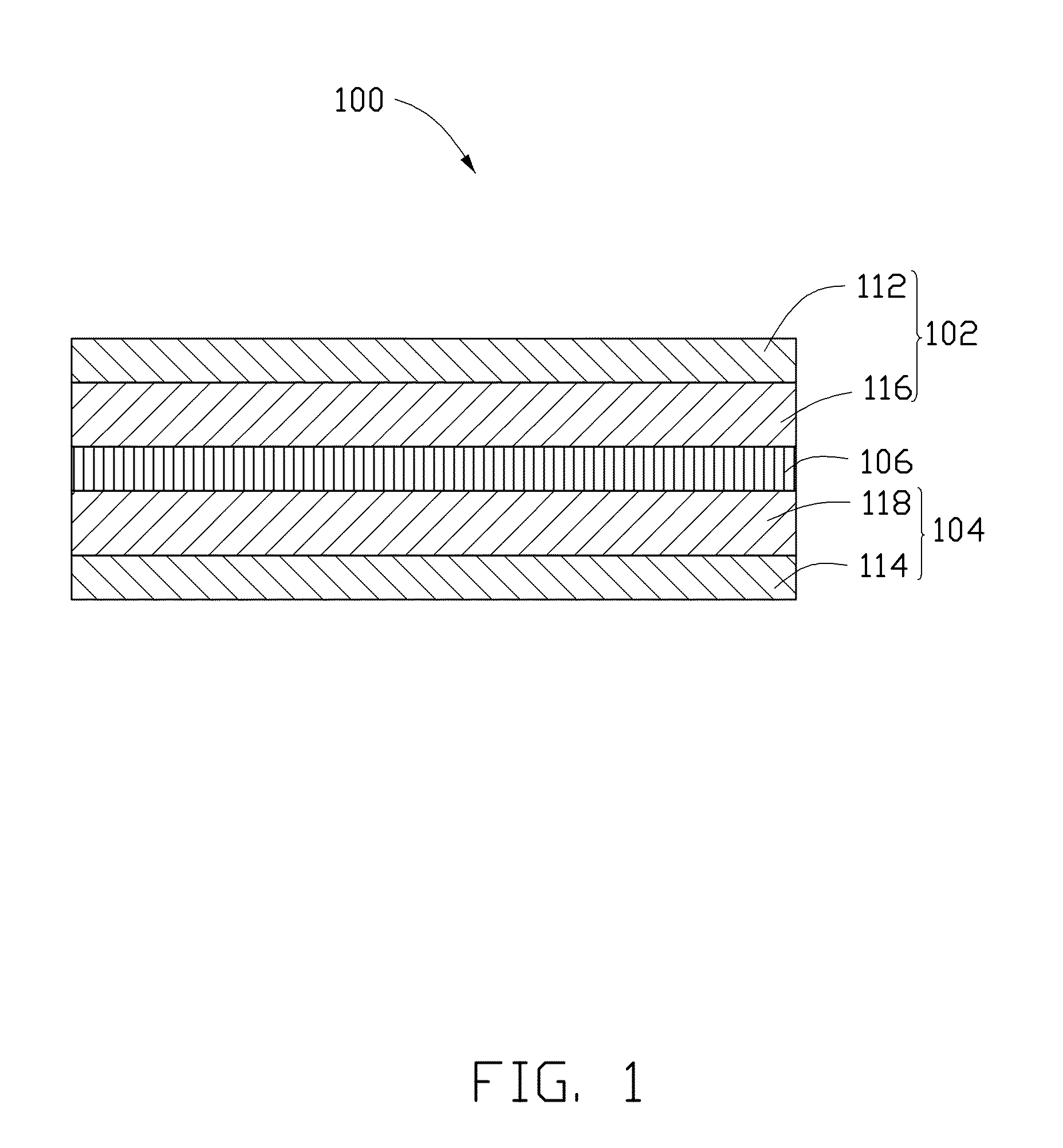

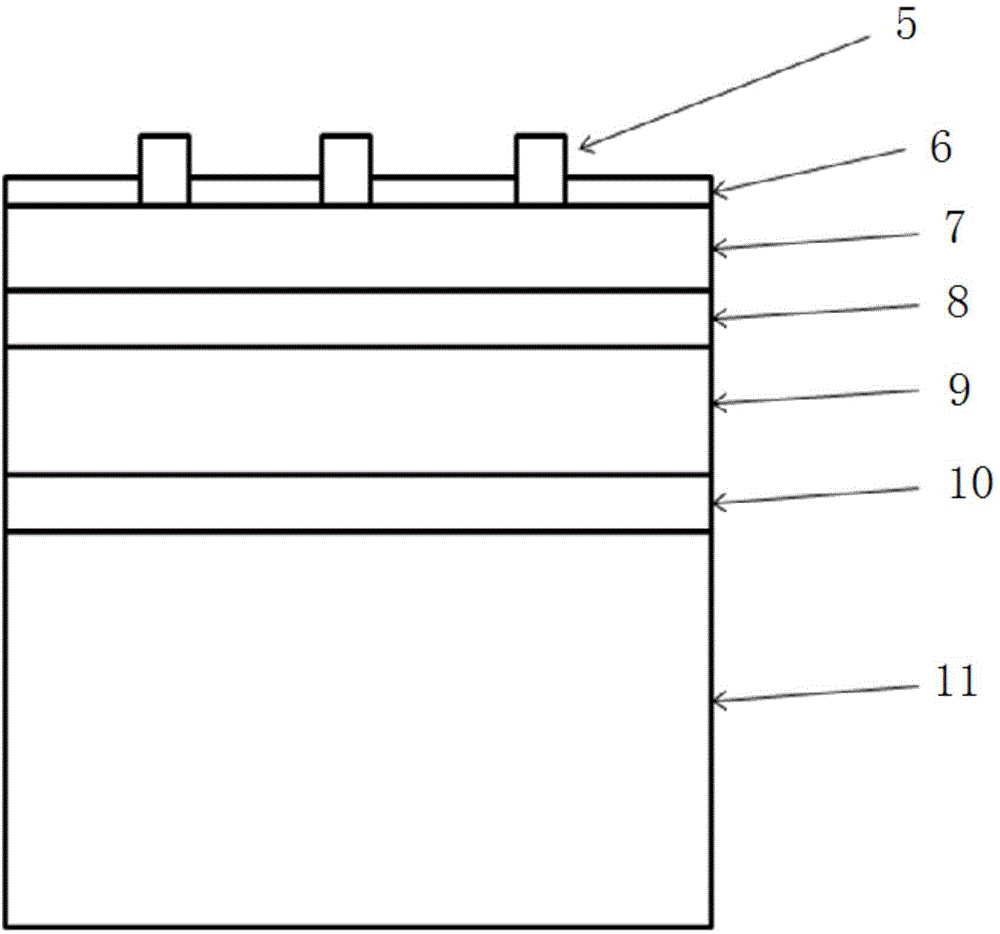

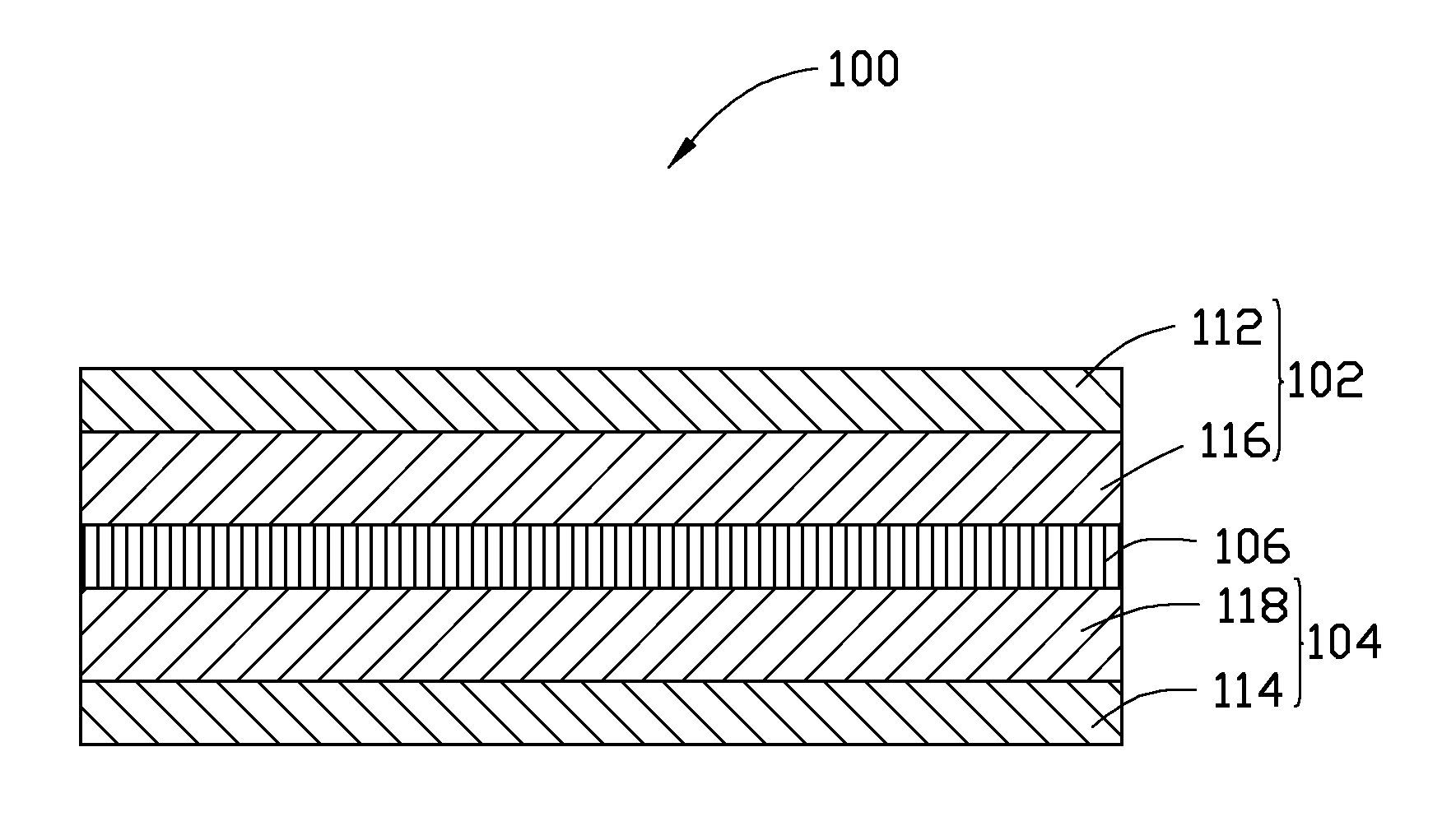

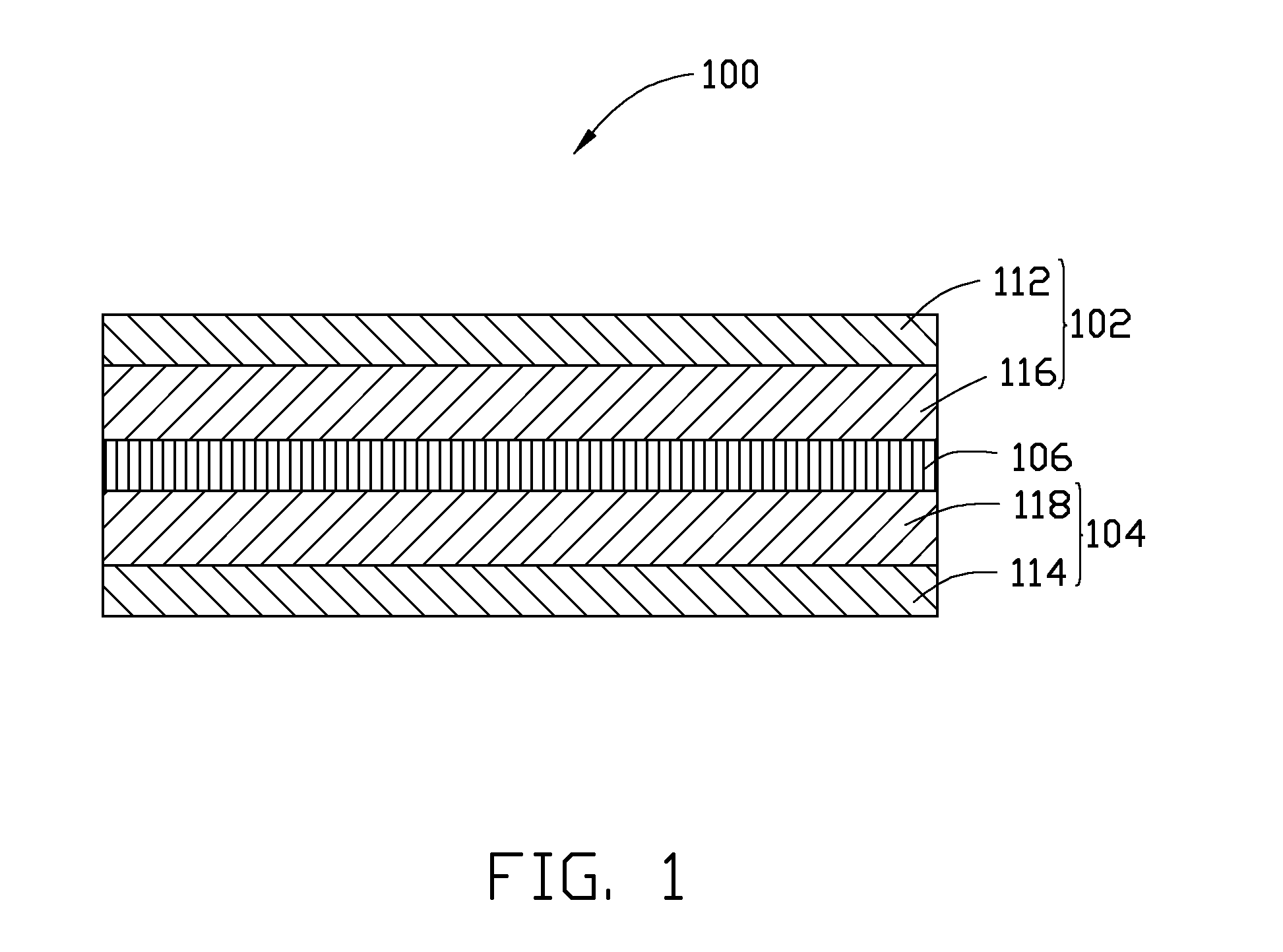

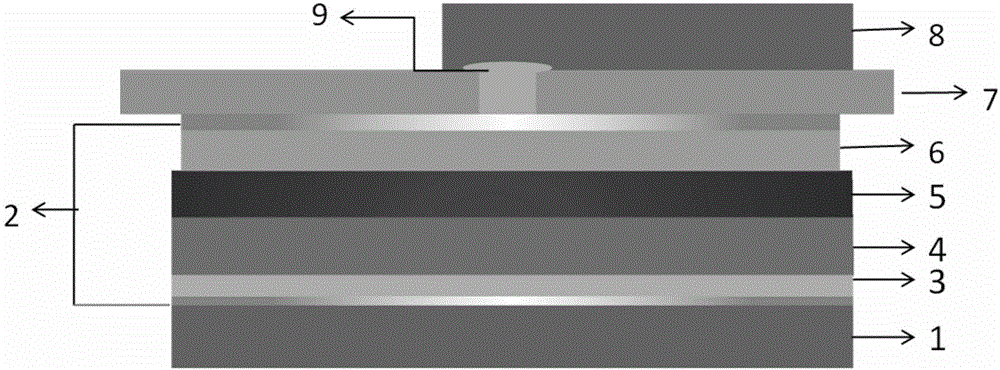

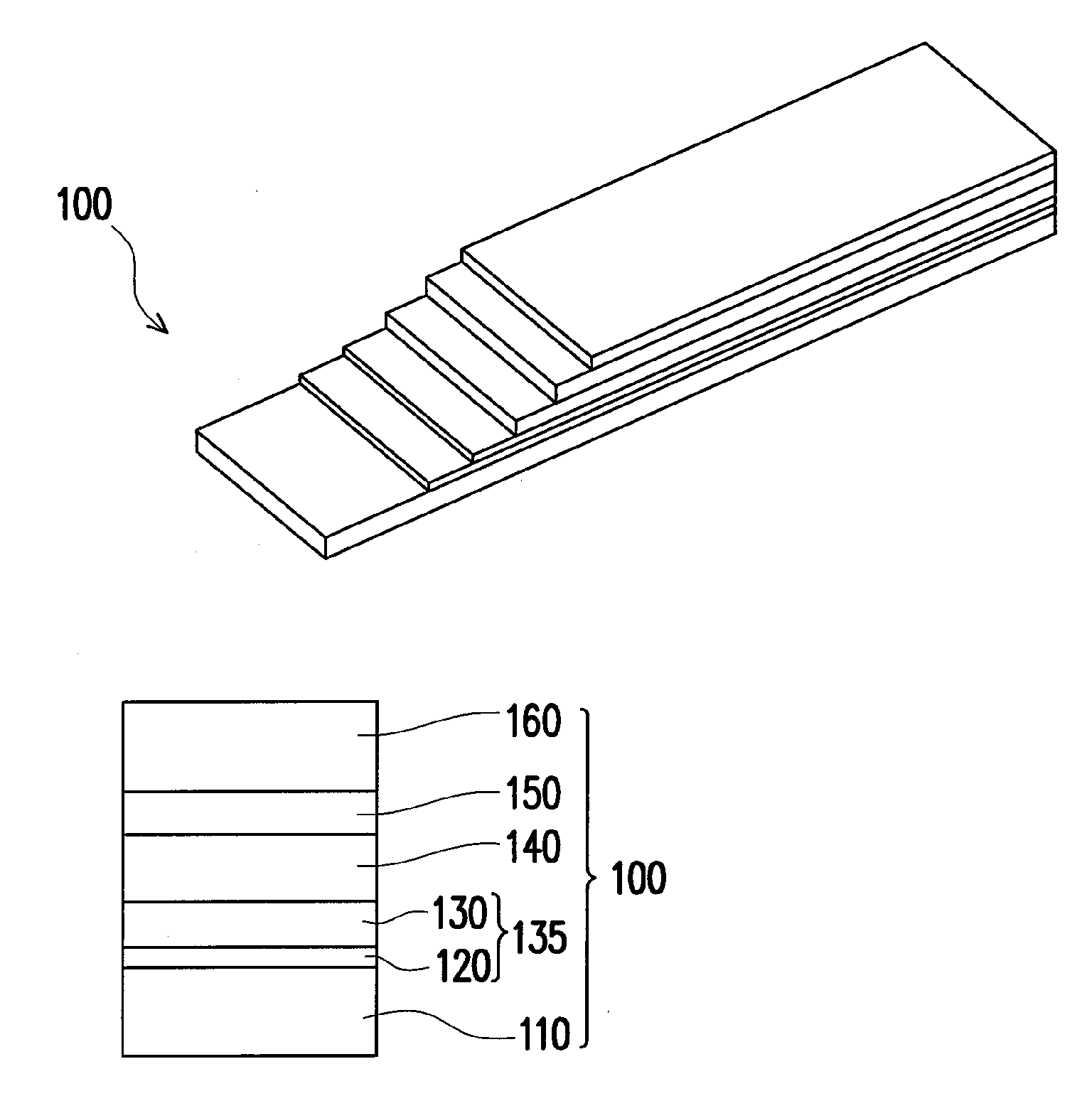

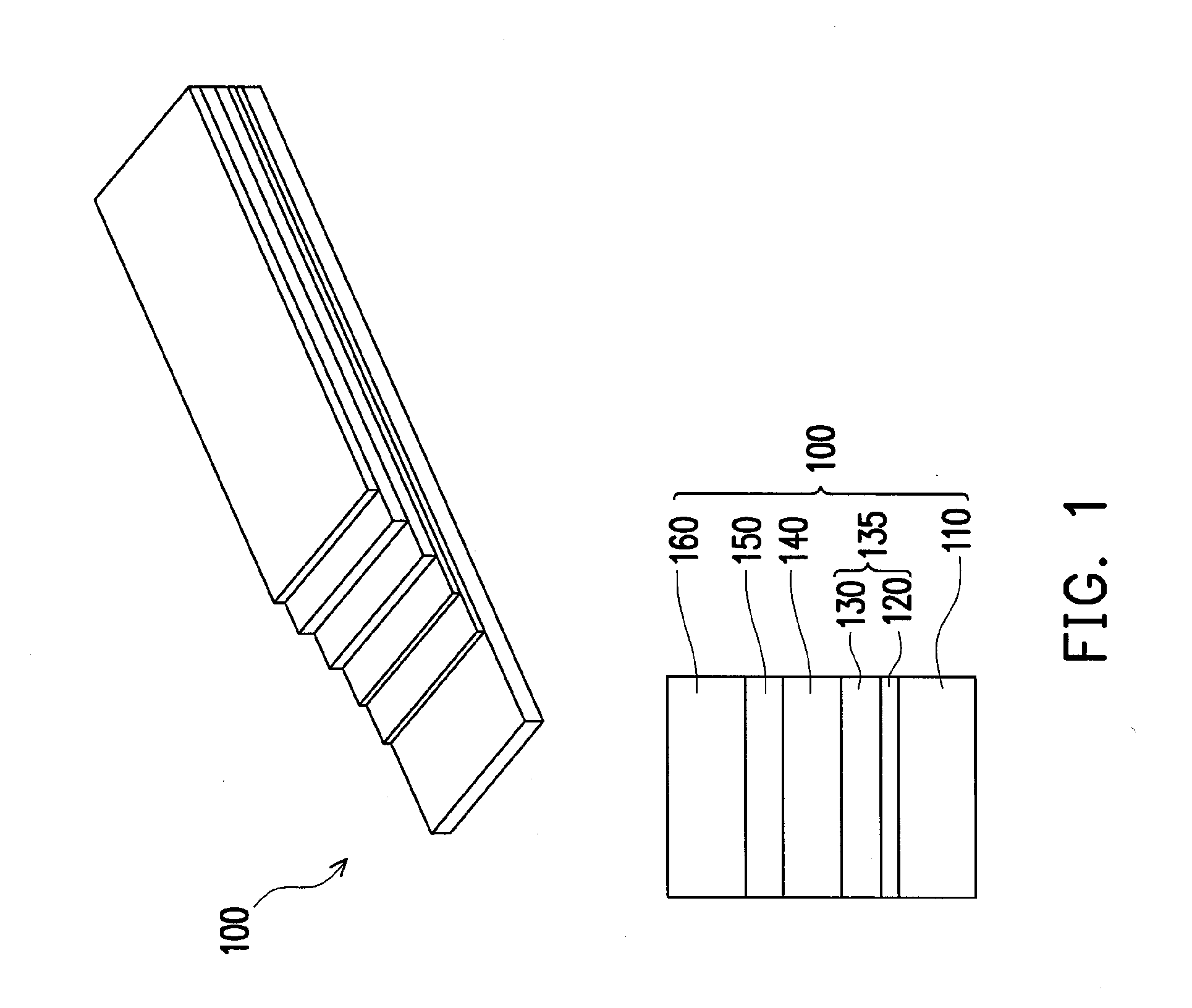

Thin film lithium ion battery

ActiveUS20140017552A1Reduce power densityShortened life-spanMaterial nanotechnologyFinal product manufactureCarbon nanotubeThin film rechargeable lithium battery

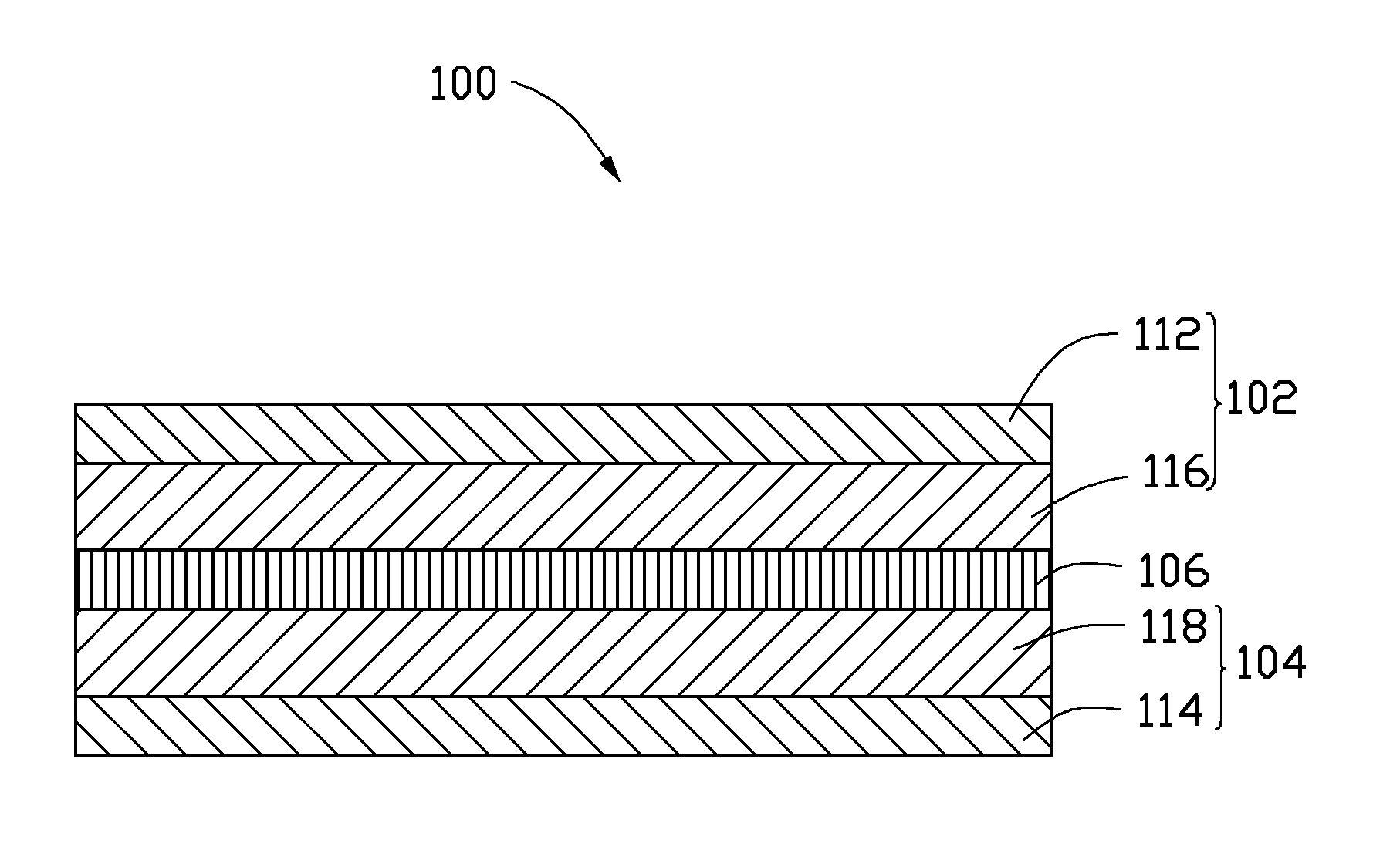

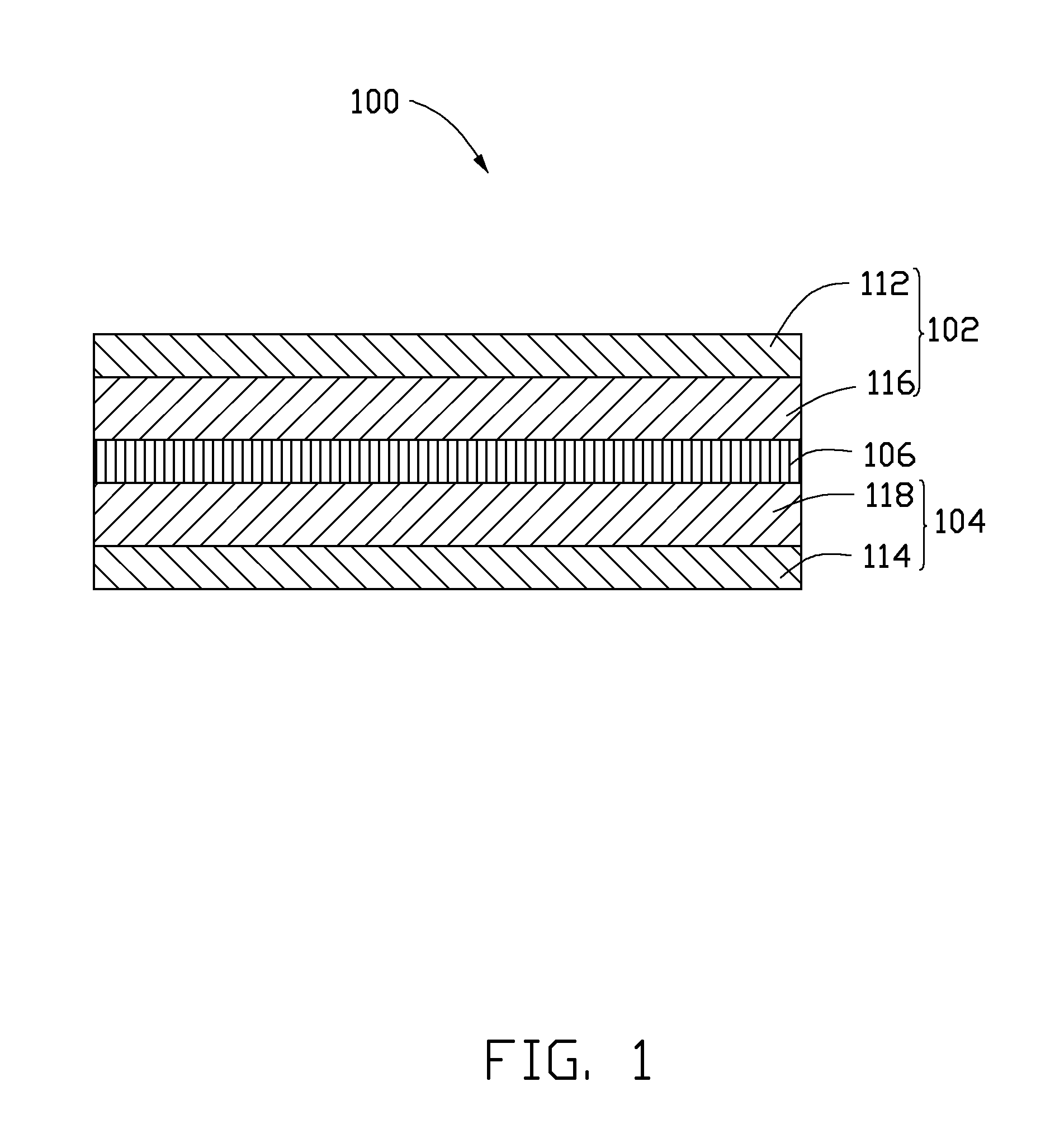

A thin film lithium ion battery includes a cathode electrode, an anode electrode, and a solid electrolyte layer. The solid electrolyte layer is sandwiched between the cathode electrode and the anode electrode. At least one of the cathode electrode and the anode electrode includes a current collector. The current collector is a carbon nanotube layer consisting of a plurality of carbon nanotubes.

Owner:TSINGHUA UNIV +1

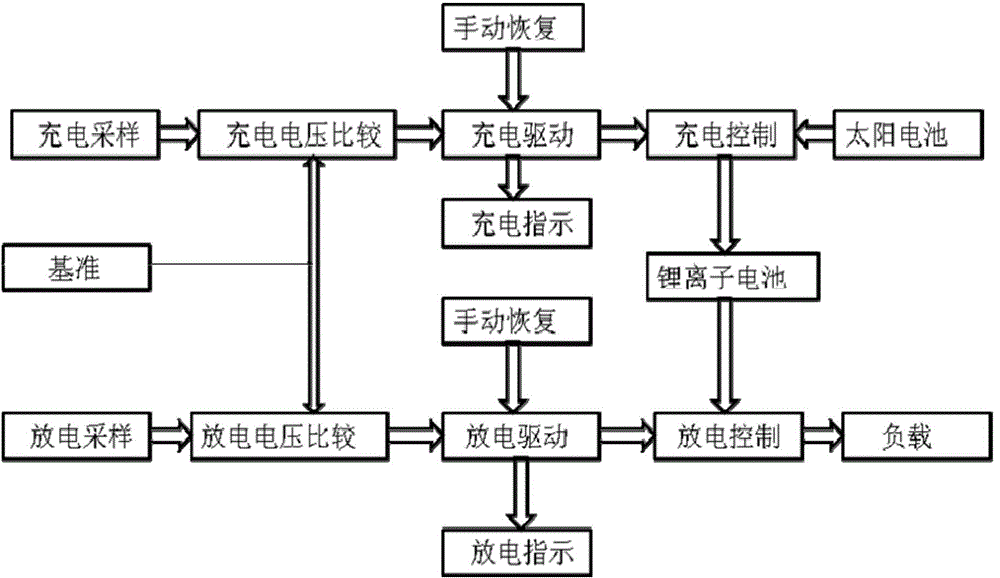

Preparation method of flexible integral solar battery/lithium-ion battery thin-film composite battery

InactiveCN105789372ARealize self-charging functionEasy to bendFinal product manufactureSecondary cellsComposite filmWhole body

The invention relates to a preparation method of a flexible integral solar battery / lithium-ion battery thin-film composite battery, and belongs to the technical field of electric energy. According to the preparation method of the flexible integral solar battery / lithium-ion battery thin-film composite battery, a same flexible thin-film substrate is adopted; a solar battery and a lithium-ion battery are located at the front surface and the back surface of the flexible thin-film substrate respectively; and the method comprises the following preparation processes: (1) preparing a flexible thin-film solar battery; and (2) preparing a flexible thin-film solar battery / lithium-ion battery integrated battery, protecting one side of the solar battery with a mask, integrally sputtering an aluminum film on the other side and coating the other side with a positive electrode material layer; coating a PI / Cu composite thin-film with a negative electrode material layer and forming a whole body in a hot pressing manner; and adding a flexible lithium-ion battery to an electrolyte, integrally encapsulating the battery and connecting the flexible thin-film solar battery and the flexible thin-film lithium-ion battery to a flexible power controller respectively. The preparation method has the advantages of being stable in process, convenient to operate and the like; and the product is a real flexible integral battery, is light in weight, convenient to carry and high specific energy, and can adapt to different installation surfaces.

Owner:CHINA ELECTRONIC TECH GRP CORP NO 18 RES INST

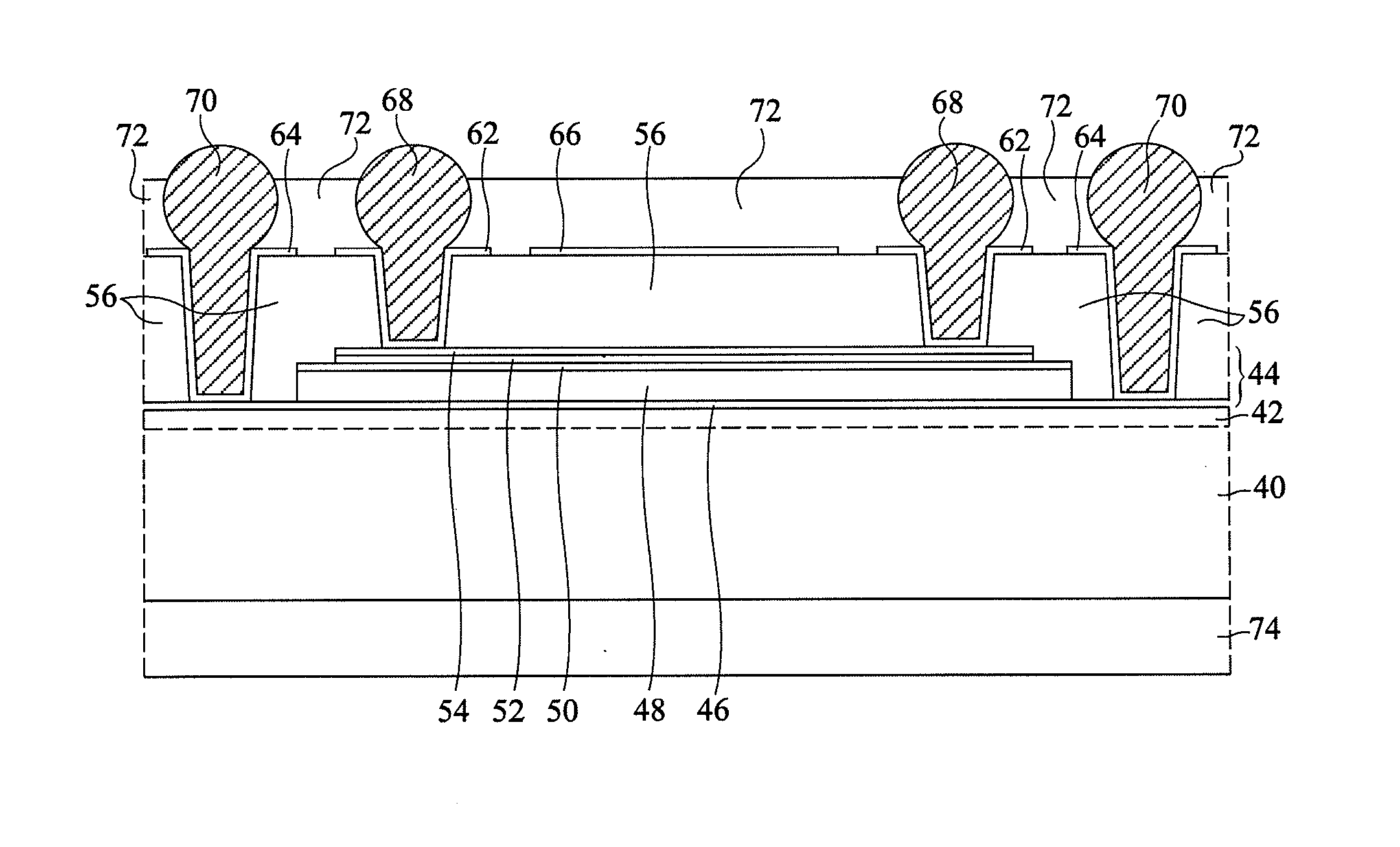

Method of direct encapsulation of a thin-film lithium-ion type battery on the substrate

A method for encapsulating a thin-film lithium-ion type battery, including the steps of: forming, on a substrate, an active stack having as a lower layer a cathode collector layer extending over a surface area larger than the surface area of the other layers; forming, over the structure, a passivation layer including through openings at locations intended to receive anode collector and cathode collector contacts; forming first and second separate portions of an under-bump metallization, the first portions being located on the walls and the bottom of the openings, the second portions covering the passivation layer; and forming an encapsulation layer over the entire structure.

Owner:STMICROELECTRONICS (TOURS) SAS

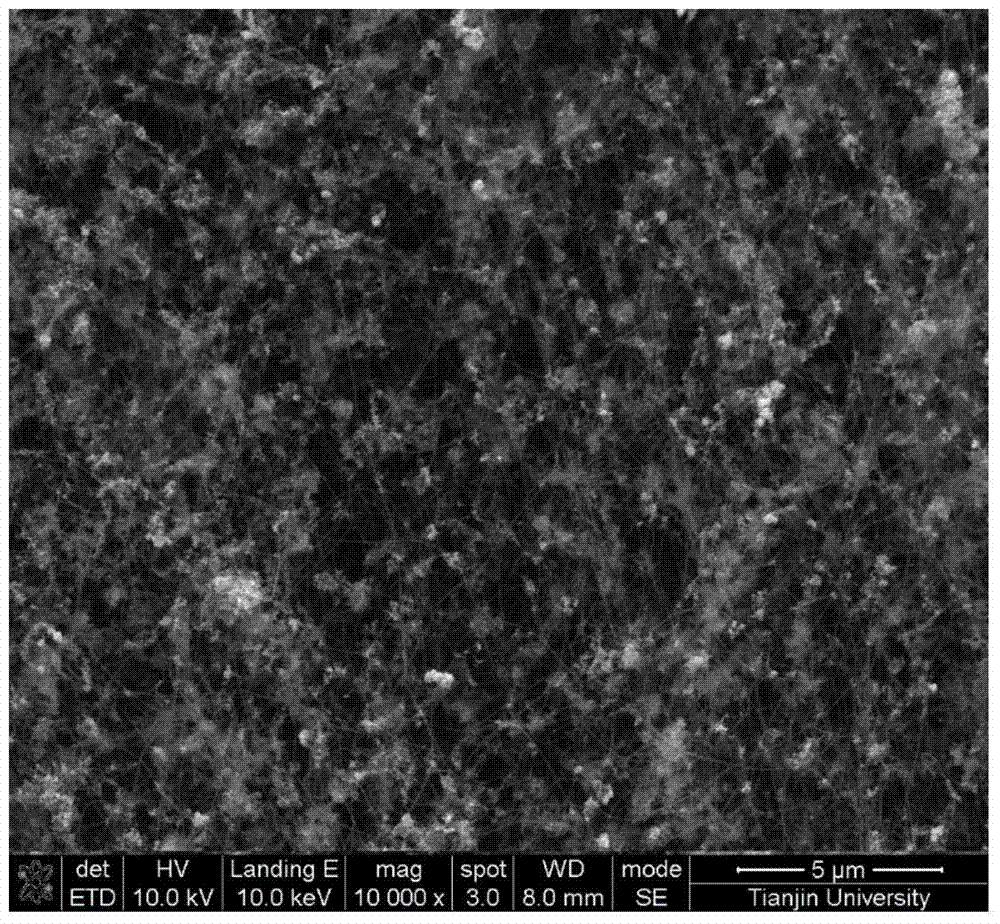

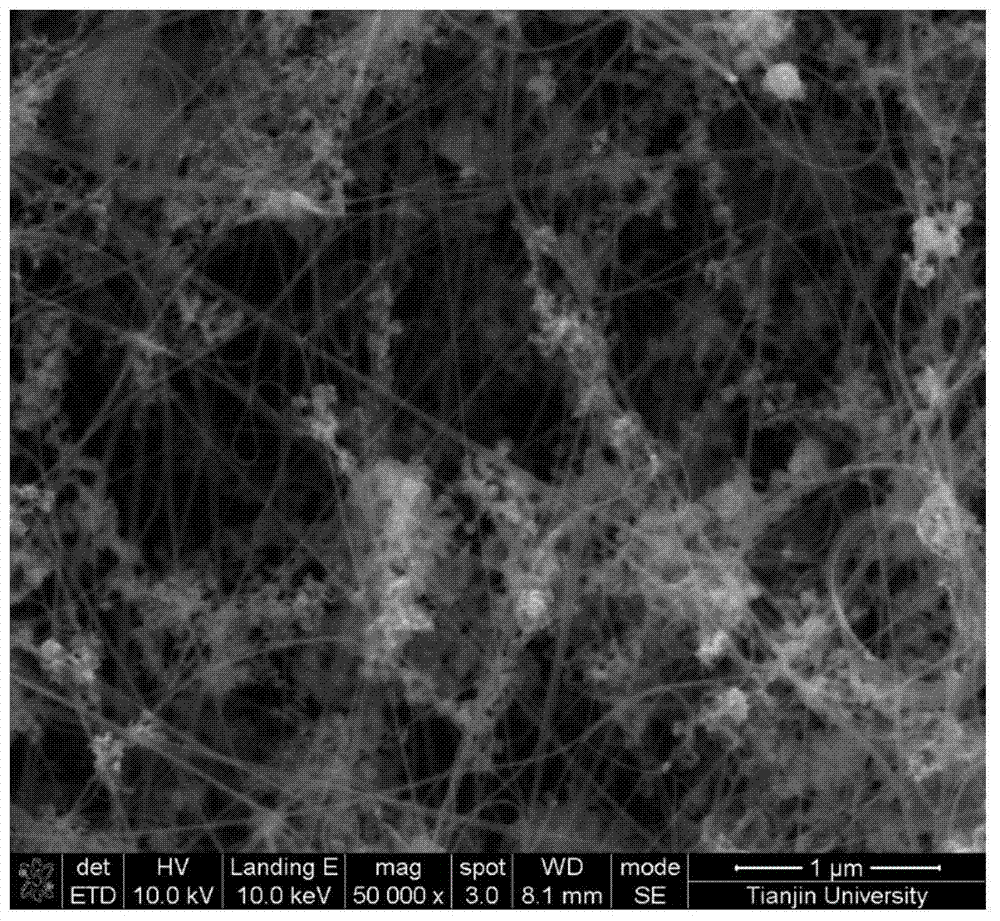

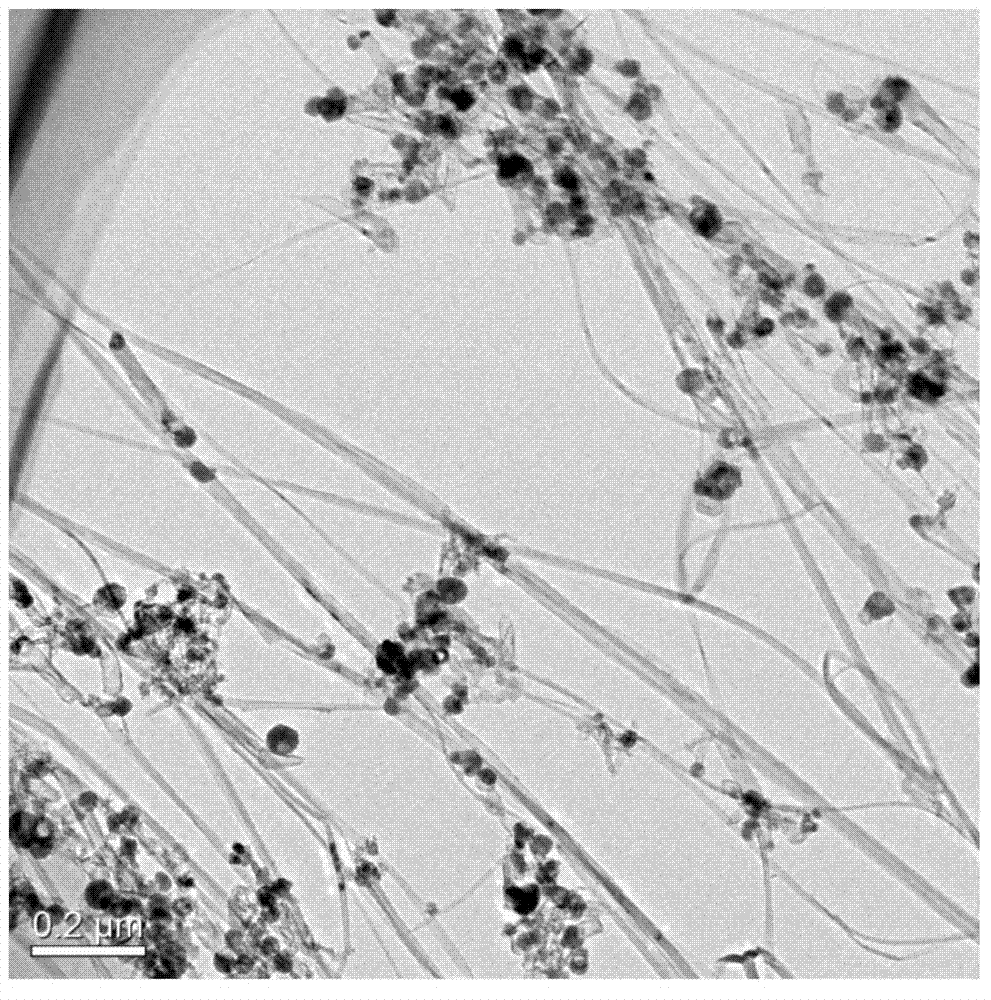

Preparation method of ferric oxide/carbon nanotube lithium ion battery anode material

InactiveCN104505498AGood application effectImprove conductivityCell electrodesComposite filmCarbon nanotube

The invention discloses a preparation method of a ferric oxide / carbon nanotube lithium ion battery anode material, which adopts a floating-catalyst chemical vapor deposition process and comprises the following steps: mixing a liquid-phase carbon source, a catalyst and an accelerator, and carrying out ultrasonic dispersion to obtain a uniform precursor solution; heating a reactor to 900-1200 DEG C in an argon environment, and keeping the temperature constant; under the driving action of a carrier gas (hydrogen or hydrogen-argon gas mixture), injecting the precursor solution into the reactor at the rate of 2-12 mL / hour to obtain a uniform and continuous composite film; and carrying out heat treatment on the composite film at 300-600 DEG C under air conditions for 1-4 hours to obtain the Fe2O3 / carbon nanotube composite film lithium ion battery anode material. The method has the advantages of simple technique and lower energy consumption, further improves the properties of the composite material, and can be widely used in the aspect of lithium ion battery electrode materials.

Owner:TIANJIN UNIV

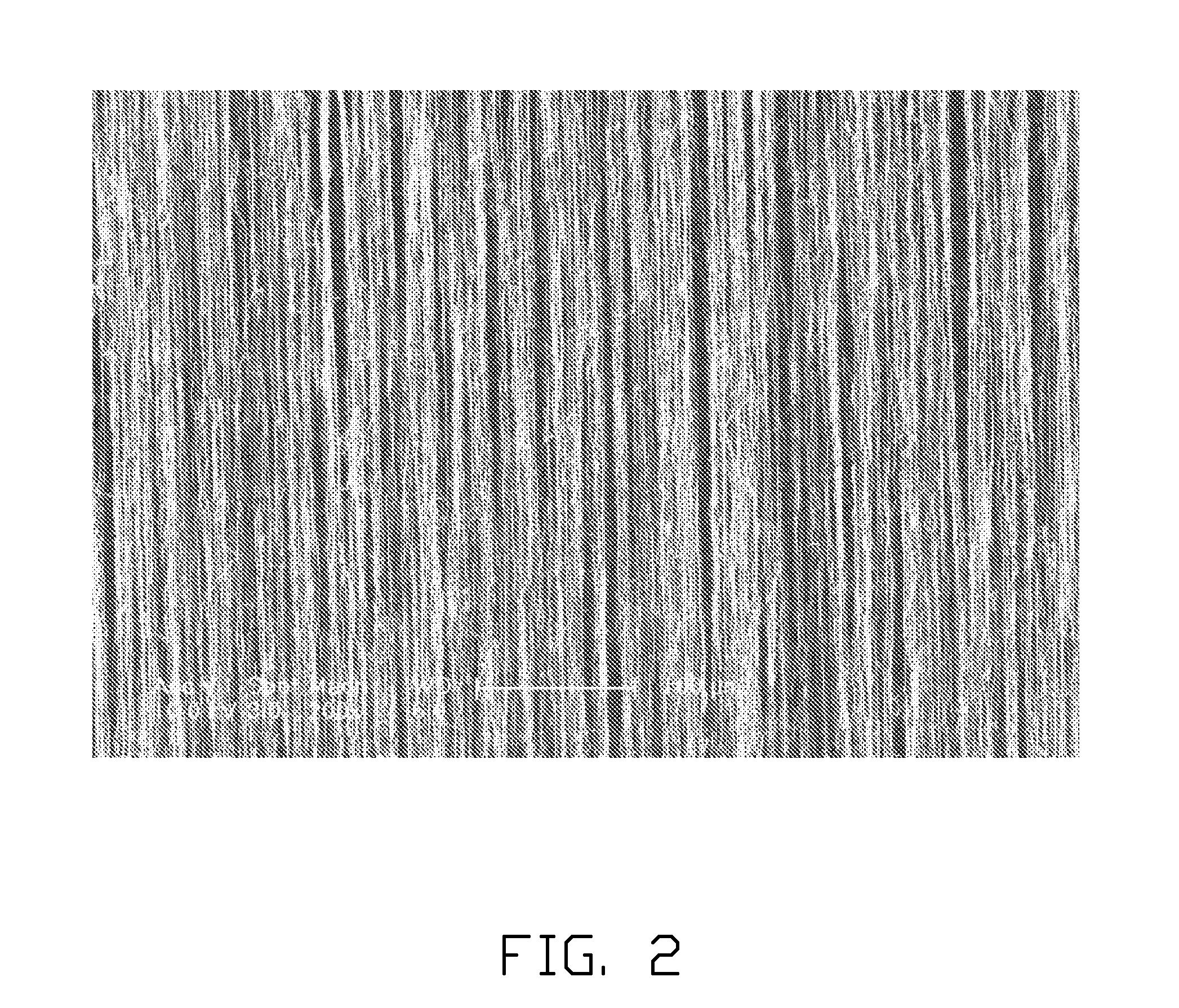

Lithium battery electrode material Li2S/Co nanometer compound film and its preparation method

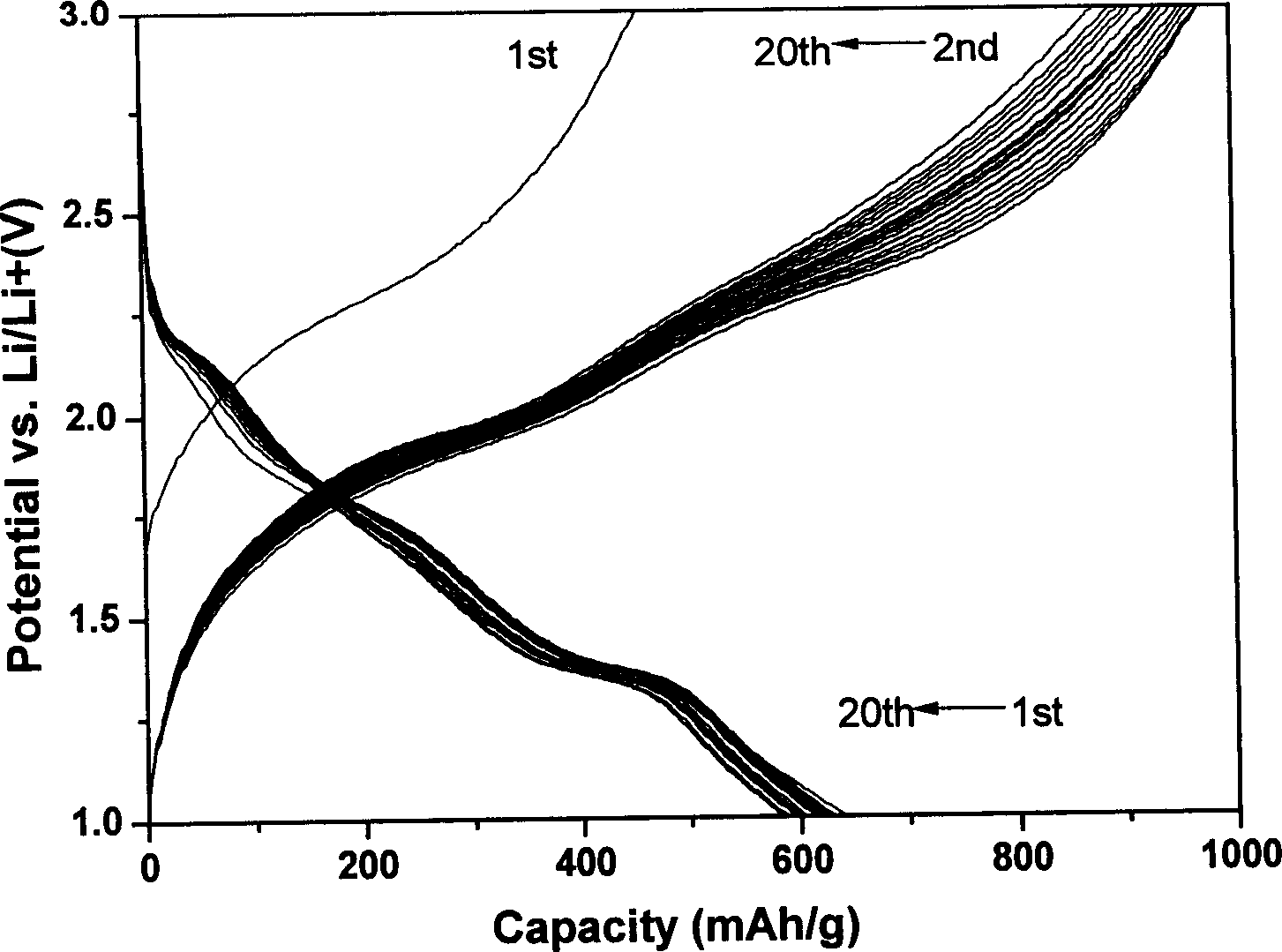

InactiveCN1794495AGood charge and discharge cycle performanceHigh specific capacityCell electrodesVacuum evaporation coatingSpecific volumePulsed laser deposition

This invention relates to an electrode active material used in Li ionic batteries and its preparation method, in which, the material is prepared by depositing a nm compound film made up of Li2S and a transition metal element Co with pulse laser and the size of the compound is smaller than 50nm, the specific volume is varied in the sphere of 400-650mAh / g along with the difference of Co and presents very good stability in the repeated charge / discharge process.

Owner:FUDAN UNIV

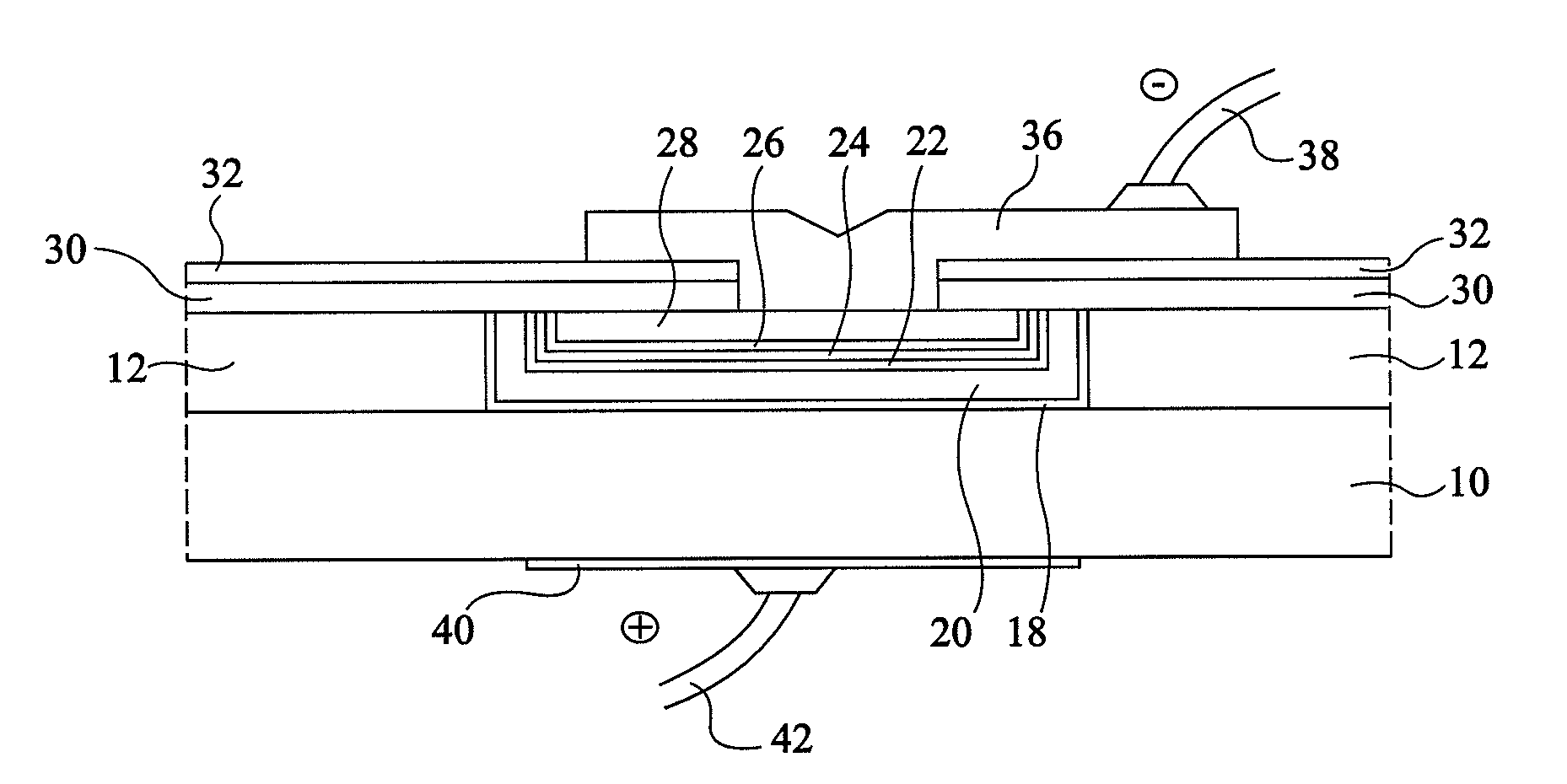

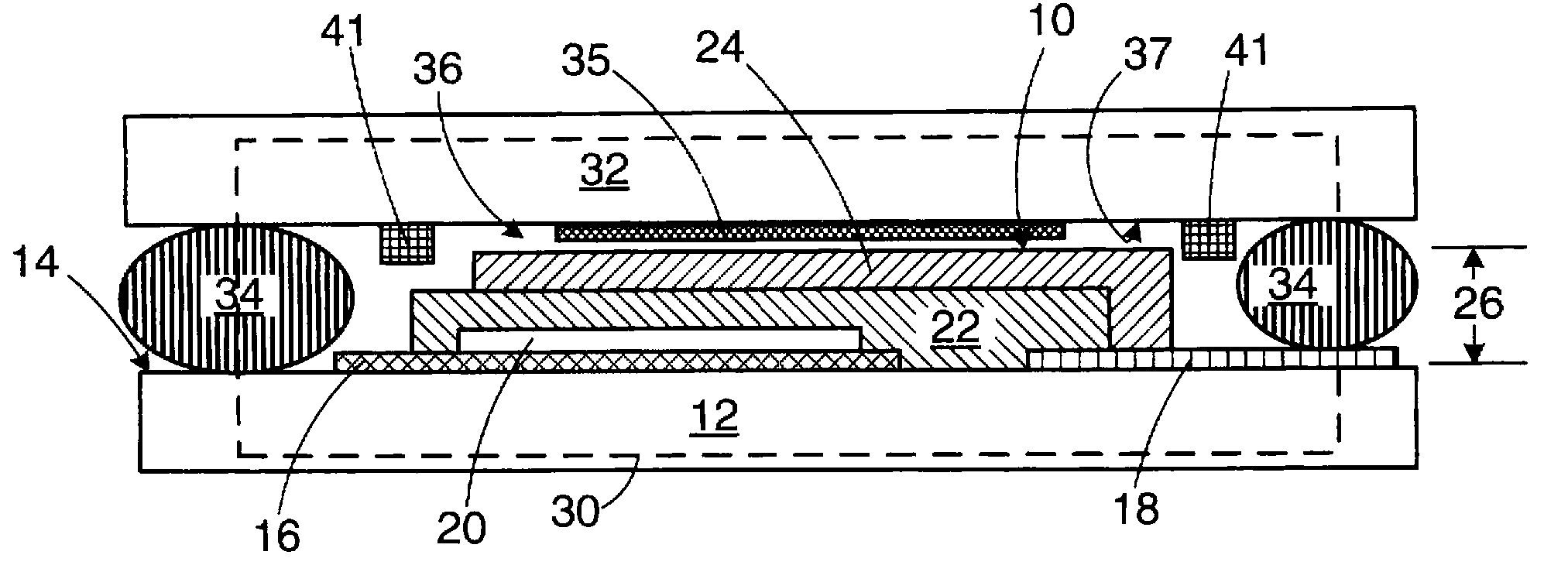

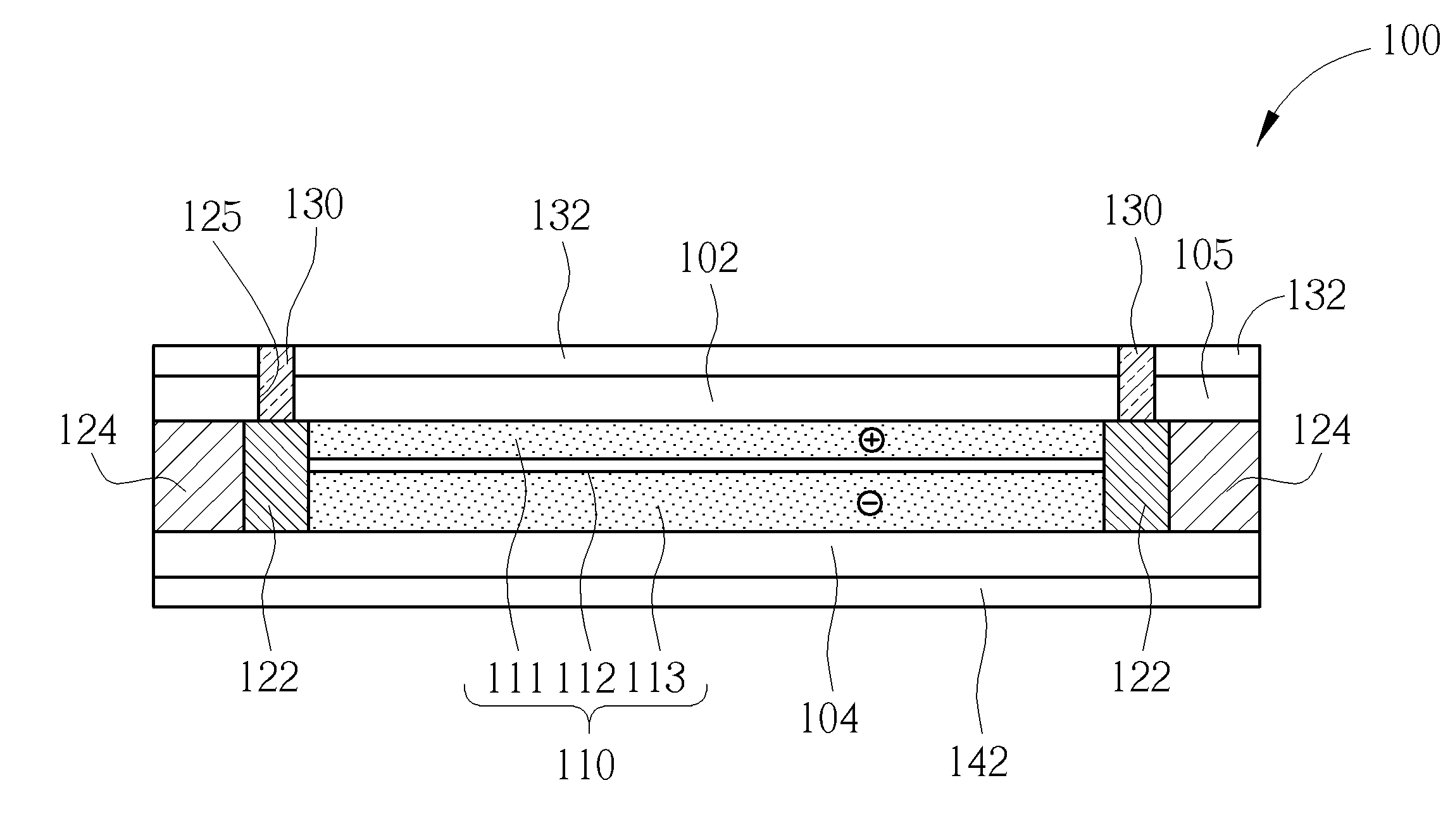

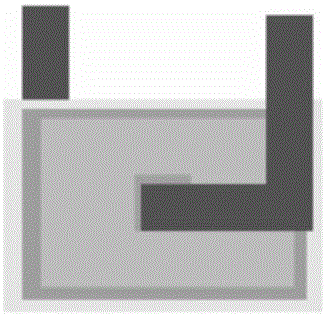

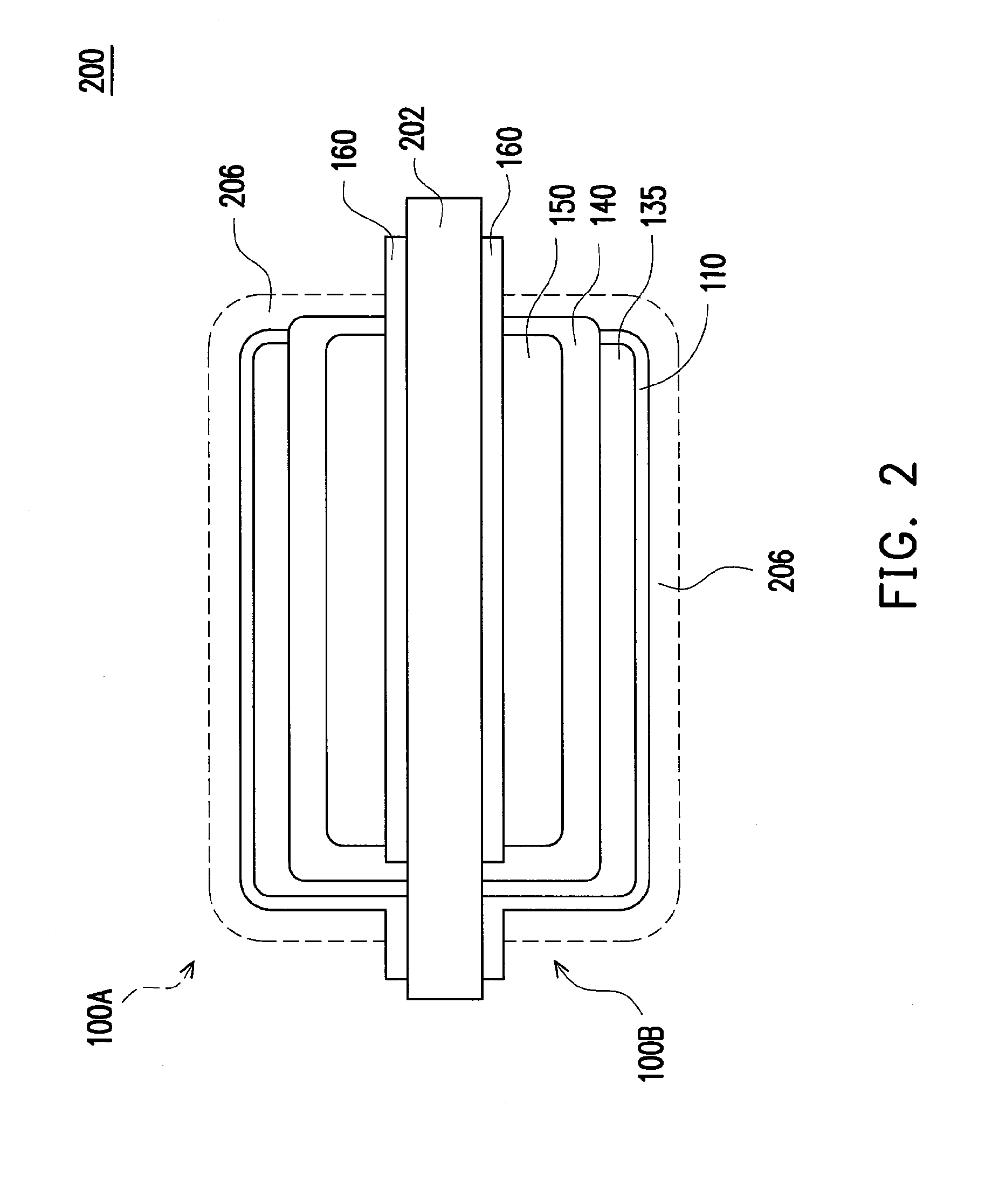

Thin film lithium-ion battery

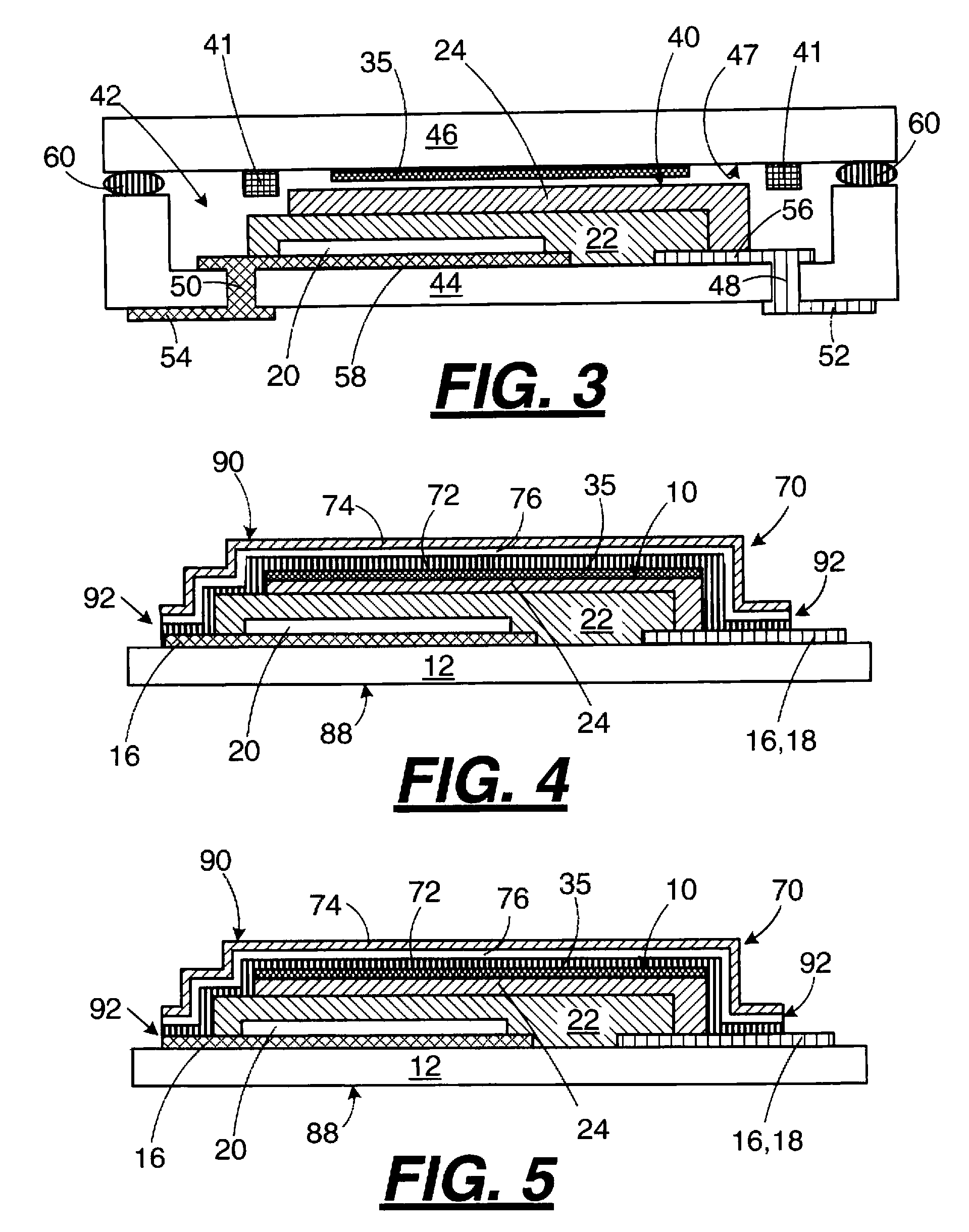

ActiveUS20140377624A1Simple structureLarge capacityCurrent conducting connectionsFinal product manufactureEngineeringPositive current

A thin film lithium-ion battery unit includes a positive current collecting substrate, a positive electrode active material layer on an inner surface of the positive current collecting substrate, a negative current collecting substrate, a negative electrode active material layer on an inner surface of the negative current collecting substrate, a separator between the positive electrode active material layer and the negative electrode active material layer, and electrolyte retained at least in the separator. The positive electrode active material layer, the separator and the negative electrode active material layer constitute a laminated electric core. An outer conductive frame is spaced apart from the positive current collecting substrate and encompasses the positive current collecting substrate.

Owner:LIN YING TSUN

Thin film lithium ion battery

ActiveUS20130171496A1Material nanotechnologyFinal product manufactureCarbon nanotubeLithium-ion battery

A thin film lithium ion battery includes a cathode electrode, an anode electrode, and a solid electrolyte layer. The solid electrolyte layer is sandwiched between the cathode electrode and the anode electrode. At least one of the cathode electrode and the anode electrode includes a current collector. The current collector is a carbon nanotube layer consisting of a plurality of carbon nanotubes.

Owner:TSINGHUA UNIV +1

Production method for nickel oxide anode thin film used for full solid-state thin-film lithium ion battery

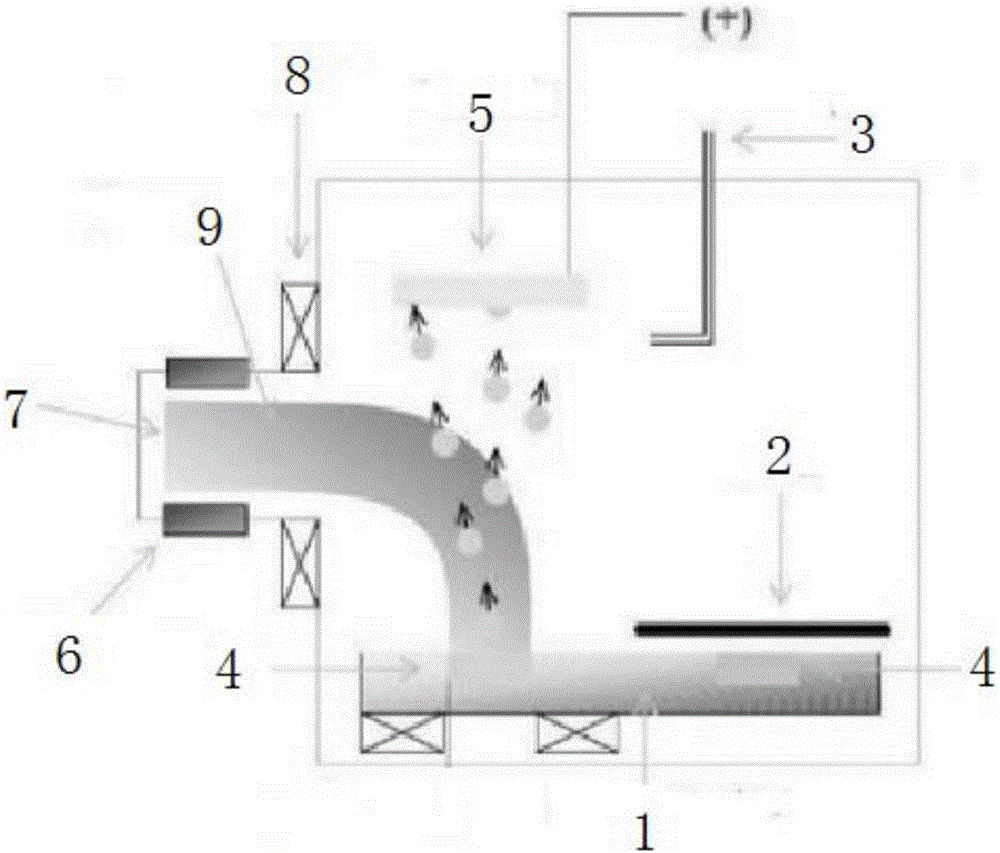

InactiveCN101174687AComplete structureUniform size distributionElectrode manufacturing processesVacuum evaporation coatingOxygenLithium-ion battery

The present invention provides a preparation method of a nickel oxide anode film used for the solid film lithium-ion battery, which adopts the vacuum vapor deposition method to deposit a Ni film on a substrate, and then adopts the heat oxidation method combining with the oxygen generator to prepare a NiO film material. The oxidation temperature for the preparation method of the nickel oxide anode film of the solid film lithium-ion battery provided by the present invention is low, the cost is low, the process and the equipments are simple, the deposition speed is higher than that of the traditional method, and a nano nickel oxide film with uniform granular size and complete structure is easy to obtain, which has good chemical performance, and can be used as the anode material of the solid film lithium-ion battery.

Owner:HENAN UNIV OF SCI & TECH

Nano combination electrode material Li3N/Si used for lithium ion battery and its preparation method

InactiveCN101222041ALower electrochemical internal resistanceHigh electrochemical capacityElectrode manufacturing processesChemical vapor deposition coatingComposite electrodeSodium-ion battery

The invention belongs to the lithium ion membrane battery technical field, in particular relates to a nano composite electrode material Li3N / Si used for a lithium ion battery and a preparation method thereof. The material of the invention is a nano membrane which consists of Li3N and an IVA group element Si and can be prepared and obtained by means of pulse laser sedimentation, and grain diameter of Li3N / Si nano compounds is lower than 50 nanometers. Specific capacity of membrane electrode changes within the range of 400 to 650 mAh / g along with different proportions of Li3N and Si in the membrane, and superior electrochemistry performance is shown during the process of repeated charging and discharging. The specific capacity of the membrane electrode material of the invention is high; cyclicity is good; preparation method is simple. The invention is suitable for a lithium ion membrane battery.

Owner:FUDAN UNIV

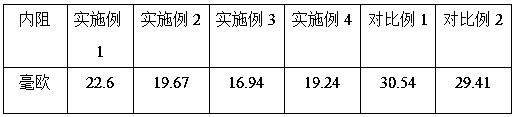

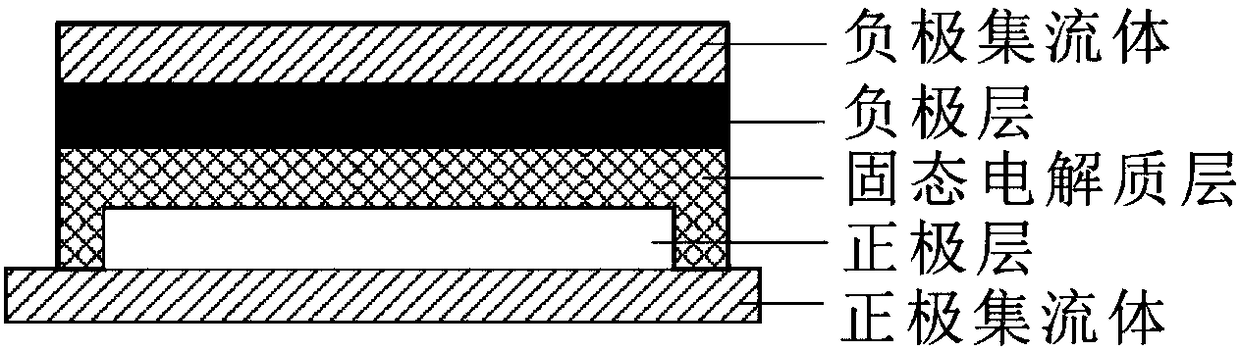

Preparation method of film lithium ion battery

ActiveCN103545556AIncrease energy densityExtended service lifePrimary cell manufactureFinal product manufactureExternal encapsulating structurePole piece

The invention provides a preparation method of a film lithium ion battery, which comprises the following steps: providing a positive pole material layer; arranging a positive pole current collector on the surface of the positive pole material layer to form a positive pole piece, wherein the positive pole current collector comprises a graphene layer; providing a negative pole material layer; arranging a negative pole current collector on the surface of the negative pole material layer to form a negative pole piece; and arranging a solid electrolyte film between the positive pole piece and the negative pole piece, and packaging the positive pole piece, solid electrolyte film and negative pole piece in an external packaging structure.

Owner:TSINGHUA UNIV +1

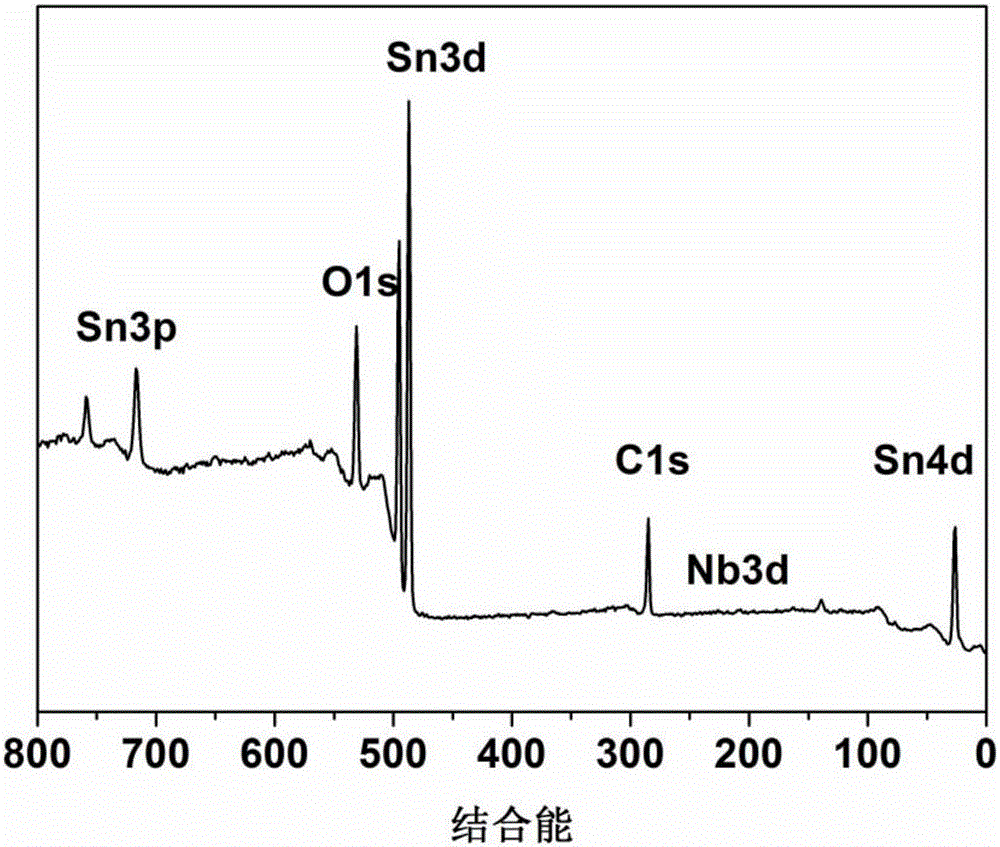

Niobium-doped tin dioxide thin film lithium ion battery negative pole plate, preparation method thereof and lithium ion battery

InactiveCN106684325AImprove cycle performanceImprove electronic conductivitySecondary cellsVapour deposition manufacturingTin dioxideHigh rate

The invention relates to a niobium-doped tin dioxide thin film lithium ion battery negative pole plate, a preparation method thereof and a lithium ion battery, and belongs to the technical field of a lithium ion battery negative electrode material. The niobium-doped tin dioxide thin film lithium ion battery negative pole plate comprises a current collector and a niobium-doped tin dioxide thin film arranged on the current collector. In the niobium-doped tin dioxide thin film lithium ion battery negative pole plate, the volume expansion is more uniform, the niobium-doped tin dioxide thin film lithium ion battery negative pole plate has relatively high lithium ion diffusion rate and electrical conductivity, the phenomena that the volume of an electrode material is expanded and a structure is pulverized, broken and separated from the current collector under high-rate charging and discharging can be effectively reduced, the discharging capacity is improved, and the cycle lifetime is prolonged. Moreover, the niobium-doped tin dioxide thin film lithium ion battery negative pole plate is high in discharging capacity, small in initial irreversible capacity and long in cycle lifetime, is safe and environment-friendly, and has a wide application prospect in the field of the lithium ion battery.

Owner:ZHENGZHOU UNIV +1

Method for forming a thin-film lithium-ion battery

InactiveUS20110111281A1Final product manufactureElectrode carriers/collectorsLithiumElectrical battery

A method for forming an integrated lithium-ion type battery, including the successive steps of: forming, on a substrate, a stack of a cathode layer made of a material capable of receiving lithium ions, an electrolyte layer, and an anode layer of the battery; forming a short-circuit between the anode and cathode layers; performing a thermal evaporation of lithium; and opening the short-circuit between the anode and cathode layers.

Owner:STMICROELECTRONICS (TOURS) SAS

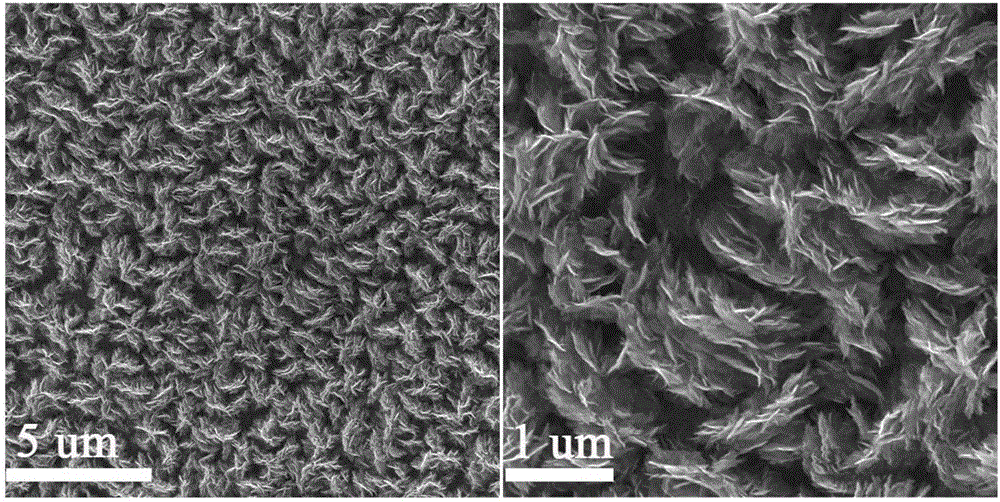

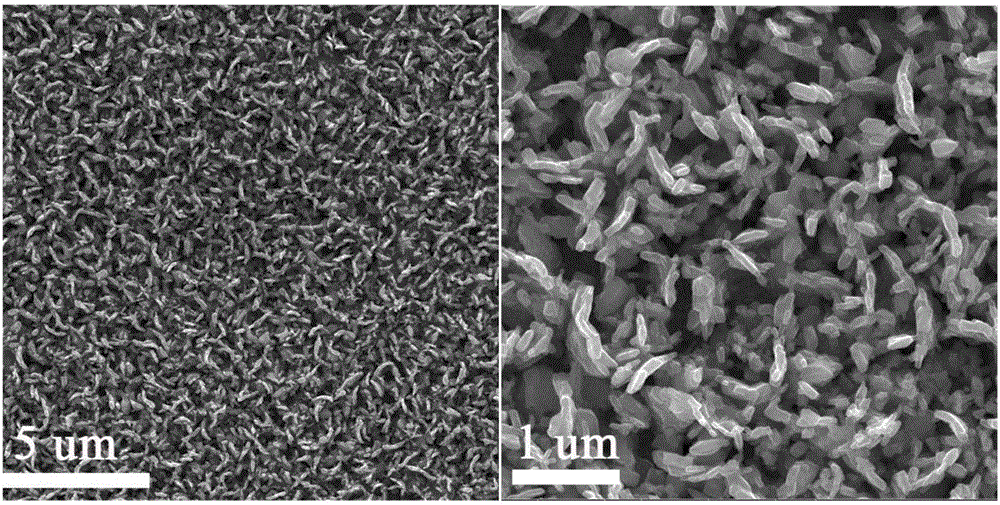

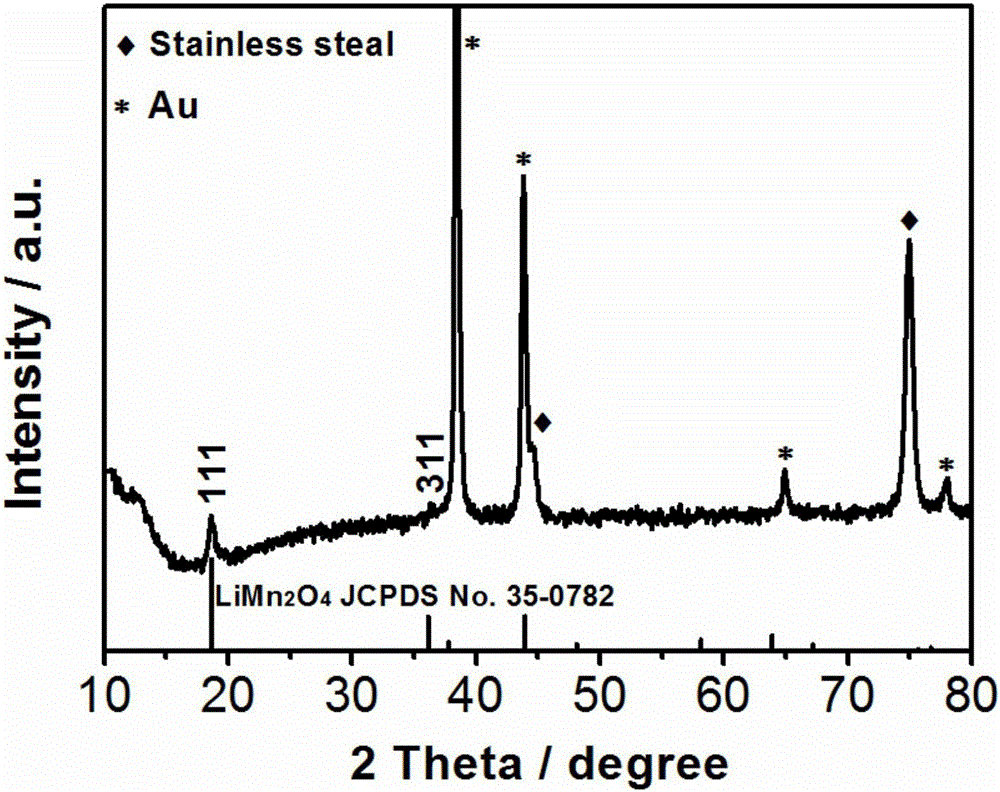

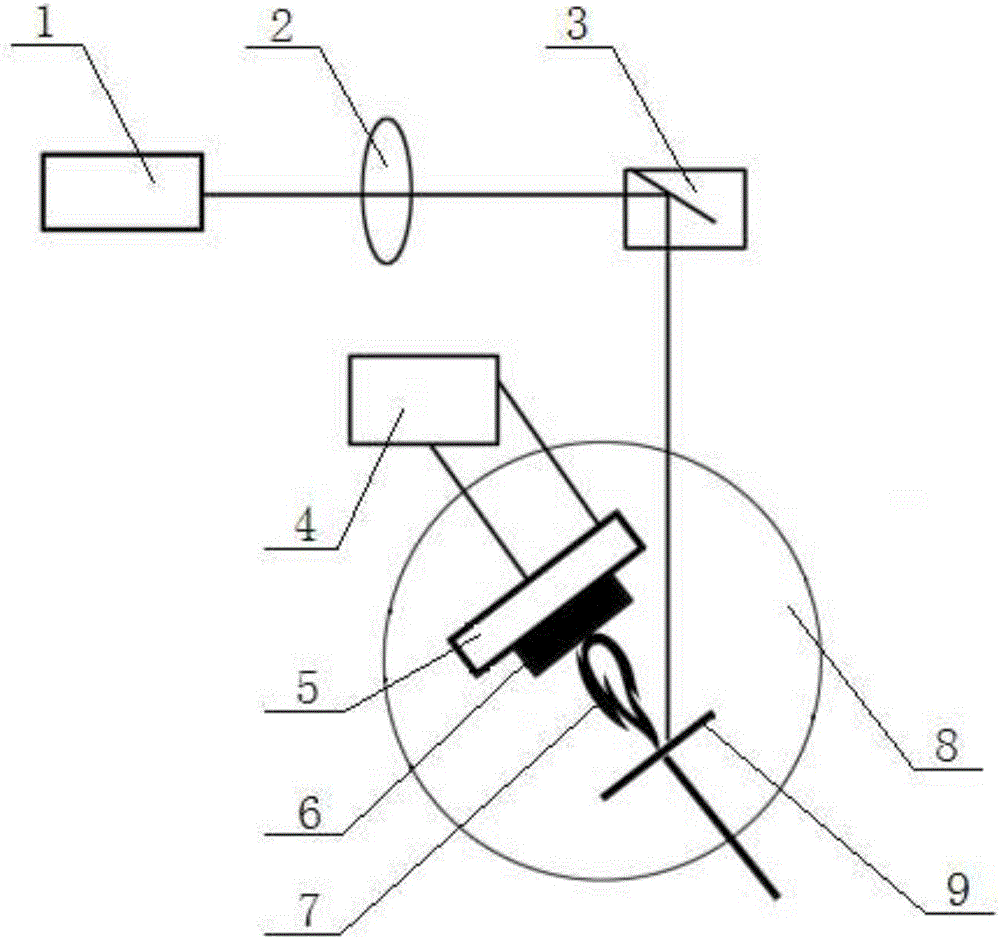

Preparation methods of three-dimensional LiMn2O4 thin film positive electrode and three-dimensional all-solid-state thin film lithium ion battery

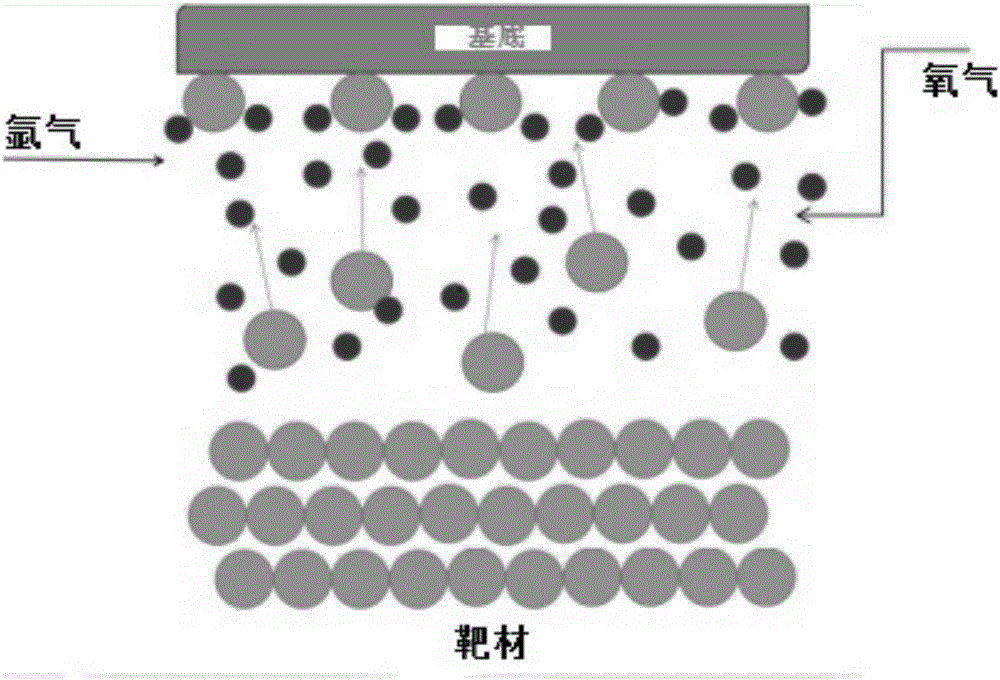

ActiveCN106207099AHigh specific surface areaImproved magnification performanceFinal product manufactureVacuum evaporation coatingSolid state electrolyteHigh rate

The invention discloses preparation methods of a three-dimensional LiMn2O4 thin film positive electrode and a three-dimensional all-solid-state thin film lithium ion battery. The preparation method of the three-dimensional LiMn2O4 thin film positive electrode comprises the following steps: using a LiMn2O4 material with excessive Li as a target, vacuumizing a chamber, heating a substrate, introducing argon and oxygen and regulating the pressures of the gases in the chamber; obtaining a three-dimensional LiMn2O4 thin film on the substrate; carrying out annealing treatment on the obtained three-dimensional LiMn2O4 thin film. The preparation method of the three-dimensional all-solid-state thin film lithium ion battery is characterized by plating the three-dimensional positive electrode thin film with a solid-state electrolyte thin film, a negative electrode thin film and a negative electrode current collector in sequence. The preparation methods have the beneficial effects that templates are unnecessary to be utilized to prepare the thin film positive electrode; a three-dimensional structure is directly obtained through DC power supply magnetron sputtering; the method is simple, is low in cost and easily achieves industrialization; the new electrode has the effects of increasing the specific surface area of the LiMn2O4 material, reducing the contact resistance and obtaining the high rate performance; the three-dimensional all-solid-state thin film battery prepared from the three-dimensional thin film electrode has excellent rate and cycling stability and has the effect of improving the power density while improving the energy density in unit area.

Owner:THE NORTHERN RES INST OF NJUST

Method for in-situ preparation of minisized all-solid-state thin-film lithium-ion battery by using PLD

ActiveCN106058305AImprove stabilityAvoid reactionFinal product manufactureVacuum evaporation coatingHeat stabilityOxygen

The invention discloses a method for in-situ preparation of a minisized all-solid-state thin-film lithium-ion battery by using PLD, belonging to the technical field of lithium-ion batteries. The method comprises the following steps: 1) pretreatment of a substrate: cleaning a silica substrate and drying the substrate for subsequent usage; and 2) preparation of the battery: successively depositing metal platinum used as a current collector, lithium cobalt oxide used as a positive electrode, lithium phosphorus oxynitride used as an electrolyte, graphene used as an electron penetration and transition layer and graphite as a negative electrode film on the cleaned silica substrate in the step 1) by using PLD. The structure of the minisized all-solid-state thin-film lithium-ion battery employs PLD in-situ deposition and introduces graphene as the electron penetration and transition layer between the negative electrode graphite and the solid electrolyte, so the performance and cycle index of the battery can be effectively improved, heat stability of the battery is guaranteed, and heatproof requirements of welding are met.

Owner:HEFEI GUOXUAN HIGH TECH POWER ENERGY

Preparation method of electro-deposition graphene thin film lithium ion battery negative electrode plate

ActiveCN108448062AIncrease productivityElectrodeposition time is shortElectrode manufacturing processesLithiumComposite film

The invention discloses a preparation method of an electro-deposition graphene thin film lithium ion battery negative electrode plate. The preparation method comprises the following steps of (1) configuring a polyacid solution at pH of 1-2, and enabling graphene oxide to be dissolved into the configured polyacid solution to obtain a dispersion system used as an electro deposition liquid; (2) putting a copper foil into the electro deposition liquid for performing deposition on the surface of the copper foil to obtain a polyacid-graphene composite film; (3) enabling the prepared polyacid-graphene composite film to be soaked in a LiOH solution to enable hydrogen ions and hydroxide ions to be fully reacted to complete exchange of hydrogen ions and hydroxide ions to obtain a polyacid lithium salt-graphene composite film; and (4) performing cleaning and drying on the prepared polyacid lithium salt-graphene composite film. The negative electrode plate prepared in the method is high in compaction and uniformity, short in electro deposition time and capable of facilitating improvement of production efficiency.

Owner:中国东方电气集团有限公司

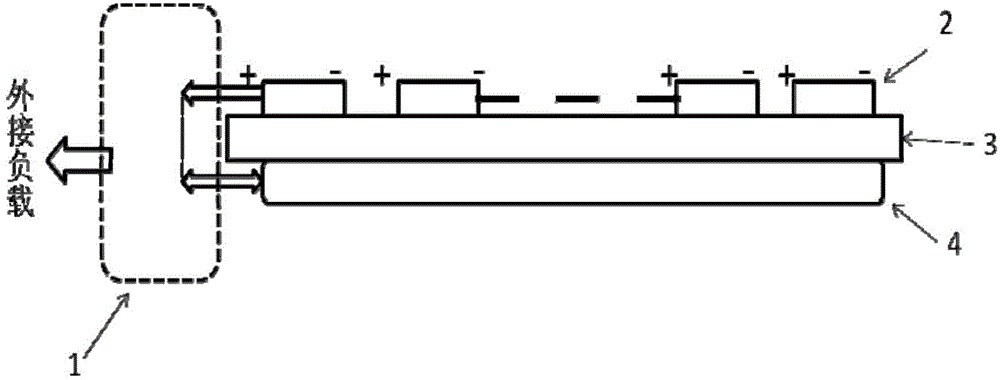

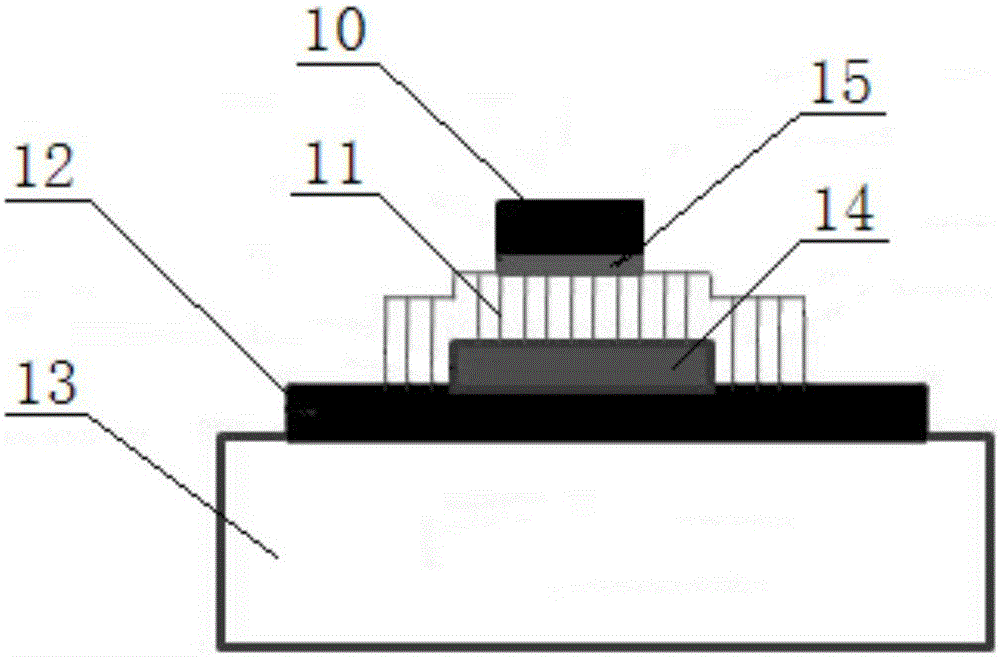

Tab extraction method for all-solid-state thin film lithium ion battery with vertical structure

ActiveCN106531949AMaximize space utilizationSave space utilizationFinal product manufactureCell component detailsContact formationSputtering

The invention discloses a tab extraction method for an all-solid-state thin film lithium ion battery with a vertical structure. The tab extraction method comprises the steps of plating a substrate with a positive electrode tab with an adhesion layer, a positive electrode current collector, a positive electrode film, an electrolyte film, a negative electrode film and a negative electrode current collector through magnetron sputtering in sequence; and enabling a negative electrode tab with the positive electrode tab on the negative electrode current collector through an insulating thin film material and conductive adhesion glue or micro connection. The tab extraction method has the beneficial effects as follows: the problem in tab extraction of the battery on different substrates is solved, and the maximum space utilization of the battery can be realized by the structure; a die is not required in the film plating of the adhesion layer, the positive electrode current collector and the electrolyte film; the negative electrode and the negative electrode current collector only require one die, so that the method is simple, and industrial production can be realized easily; the positive electrode and the negative electrode can be blocked directly by the insulating film to prevent edge contact between positive and negative electrode active materials and the current collector thin films thereof to form short circuit; and in addition, the thickness of the electrode material of the all-solid-state thin film battery can be not limited, so that the safety of the battery is ensured while the battery capacity of the single thin film lithium ion battery is greatly increased.

Owner:THE NORTHERN RES INST OF NJUST

Preparation method of all-solid-state thin film lithium ion battery

InactiveCN108400387ASimple preparation processReduce manufacturing costFinal product manufactureElectrolyte accumulators manufactureSolid state electrolyteElectrical battery

The invention belongs to the technical field of preparation of lithium ion batteries and provides a preparation method of all-solid-state thin film lithium ions, which overcomes the problems of high equipment requirements, high cost and difficulty in mass production and application in the existing preparation process. According to the preparation method, a metal plate is selected as a positive electrode current collector plate and a negative electrode current collector plate of the battery; and the positive electrode material slurry, the solid electrolyte slurry and the negative electrode material slurry are sequentially atomized into small particles to be printed by adopting an atomizer, so as to form the all-solid-state thin film lithium ion battery laminated with the positive electrodecurrent collector plate, a positive electrode thin-film layer, a solid electrolyte thin-film layer, a negative electrode thin-film layer and a negative electrode current collector plate. The preparation method in the invention adopts an atomization printing technology, the preparation process is simple, and the preparation cost is low; at the same time, the composition of each layer material can be controlled by controlling the composition of the slurry, and the all-solid-state thin film lithium ion batteries in different shapes, sizes and thickness are generated through movement control of aprinting nozzle and mask design printing; and industrial production and application is facilitated.

Owner:UNIV OF ELECTRONICS SCI & TECH OF CHINA

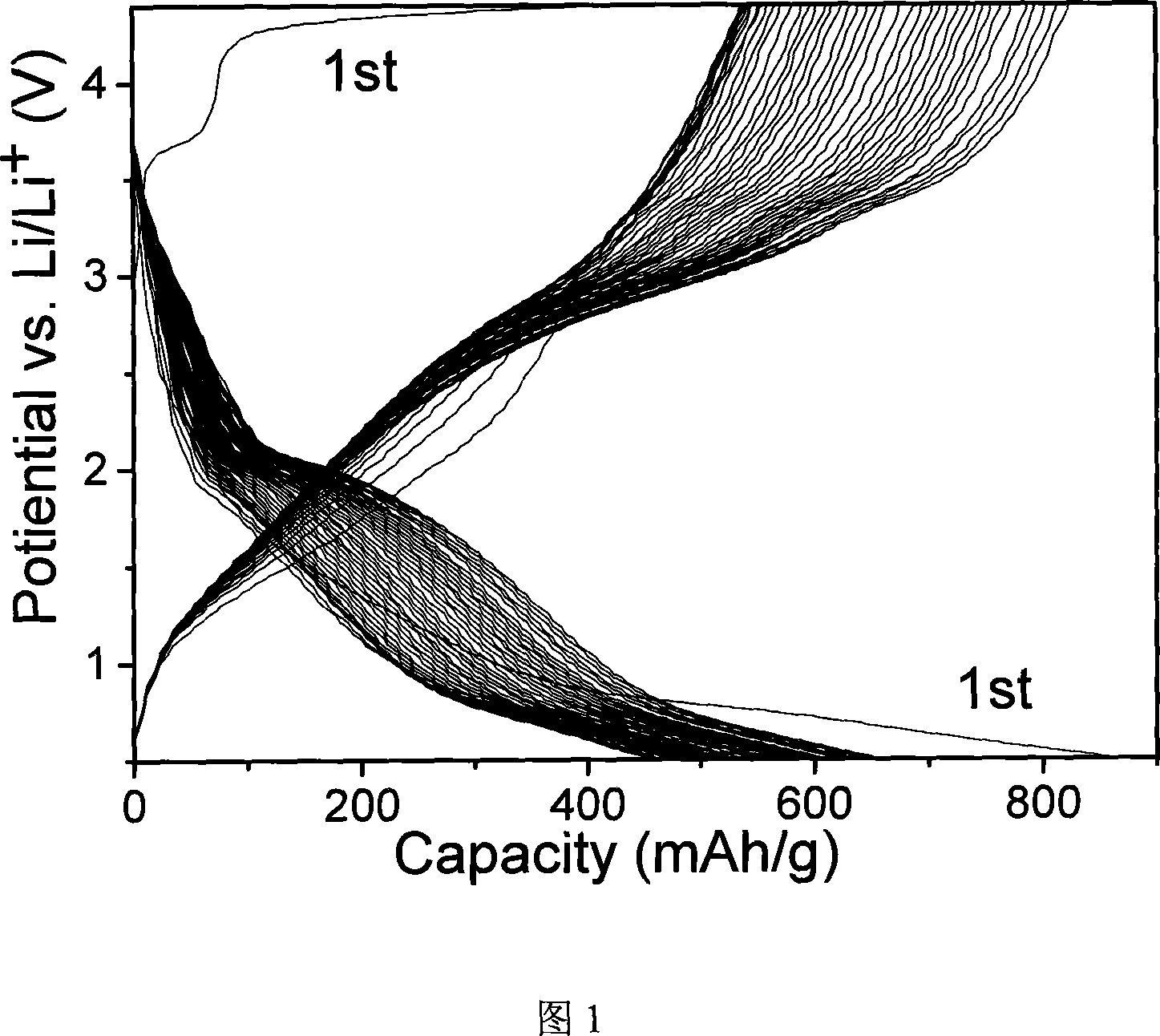

Thin film lithium-ion battery

ActiveUS20130115507A1Large capacityImprove cycle performanceFinal product manufactureCell electrodesLithiumEngineering

The present invention is directed to a thin film lithium-ion battery having at least a laminate structure therein. The laminate structure includes a bottom current collector layer, an anode consisting of a superlattice layer and a silicon based layer, an electrolyte and separator, a cathode and a top current collector layer sequentially stacked together. The electrolyte and separator of the laminate structure contains lithium ions.

Owner:WANG CHIA GEE

Film lithium ion battery and application thereof

InactiveCN101908655AEasy to operateLow costSmall-sized cells cases/jacketsElectrode carriers/collectorsCombustionEngineering

The invention belongs to the technical field of battery and relates to a film lithium ion battery and application thereof. The electrode sheet of the film lithium ion battery comprises a metal layer and an outside non-metal layer. Electrode active materials are coated on the metal layer. The film lithium ion battery has the advantages of good safety and high volume density, and can prevent gas expansion, explosion and combustion. The invention has strong operation, lower cost when compared with the prior art, and good reproducibility, and the prepared product has stable quality and high volume density, and can be applied to IC cards, bank cards and other miniature electronic devices.

Owner:FUDAN UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com