Method for in-situ preparation of minisized all-solid-state thin-film lithium-ion battery by using PLD

A lithium-ion battery and in-situ preparation technology, which is applied in the field of lithium-ion battery preparation, can solve the problems that restrict the large-scale popularization and application of all-solid-state thin-film lithium batteries, unfavorable large-scale production, and harsh packaging technology, so as to improve electrochemical performance, Avoid air and water vapor contact, fast and simple preparation method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

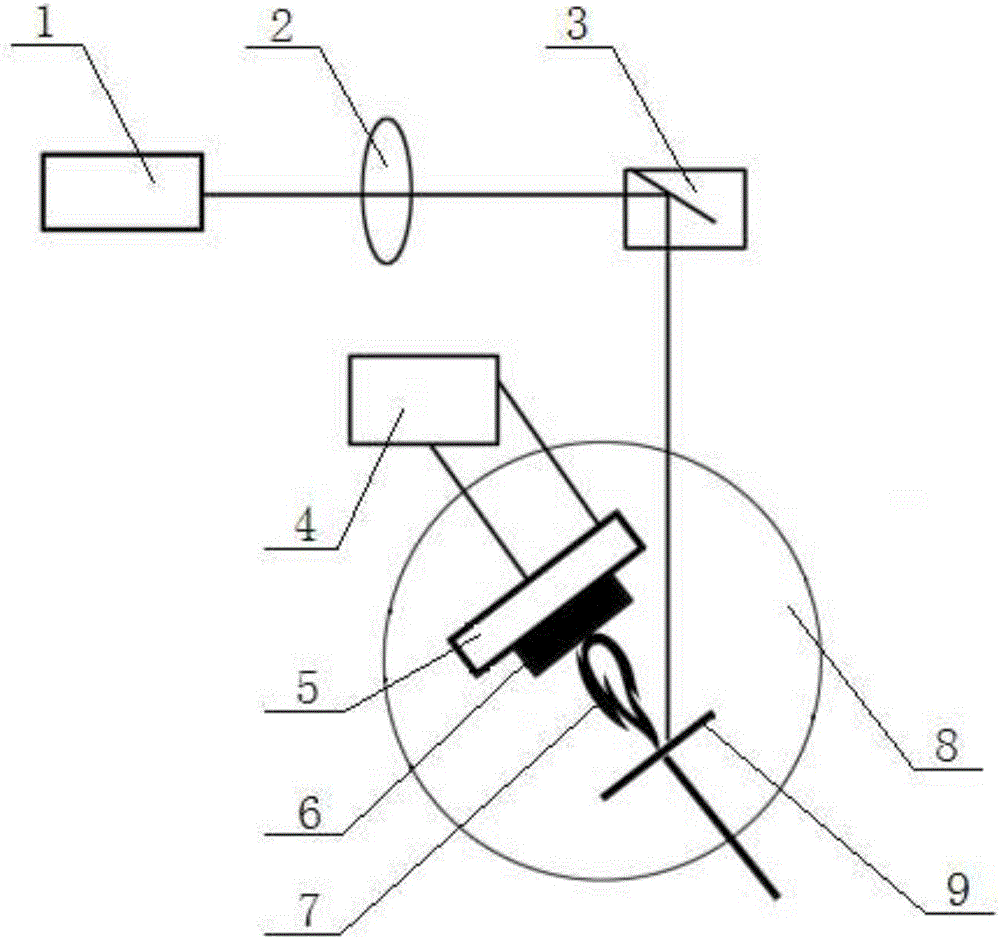

[0043] A method for preparing miniature all-solid-state thin-film lithium-ion batteries in situ with PLD, specifically comprising the following steps:

[0044] 1) Pretreatment of the substrate:

[0045] a) First, the silicon dioxide substrate 13 is ultrasonically cleaned, and the steps of cleaning are: (i) ultrasonic cleaning in acetone for 20 minutes; (ii) ultrasonic cleaning in ethanol for 20 minutes, and then cleaning several times with deionized water;

[0046] 2) Preparation of target material:

[0047] Preparation of electrolyte Li by PLD 3 PO 4-x N x (LiPON) film, the target used is made of Li 3 PO 4 The powder is pressed and sintered. For the positive electrode LiCoO 2 Thin film, electron transport layer graphene and negative electrode graphite layer, the targets used are all passed through LiCoO 2 , graphene and graphite powder pressed and sintered;

[0048] 3) In situ growth of each layer of thin film of micro battery:

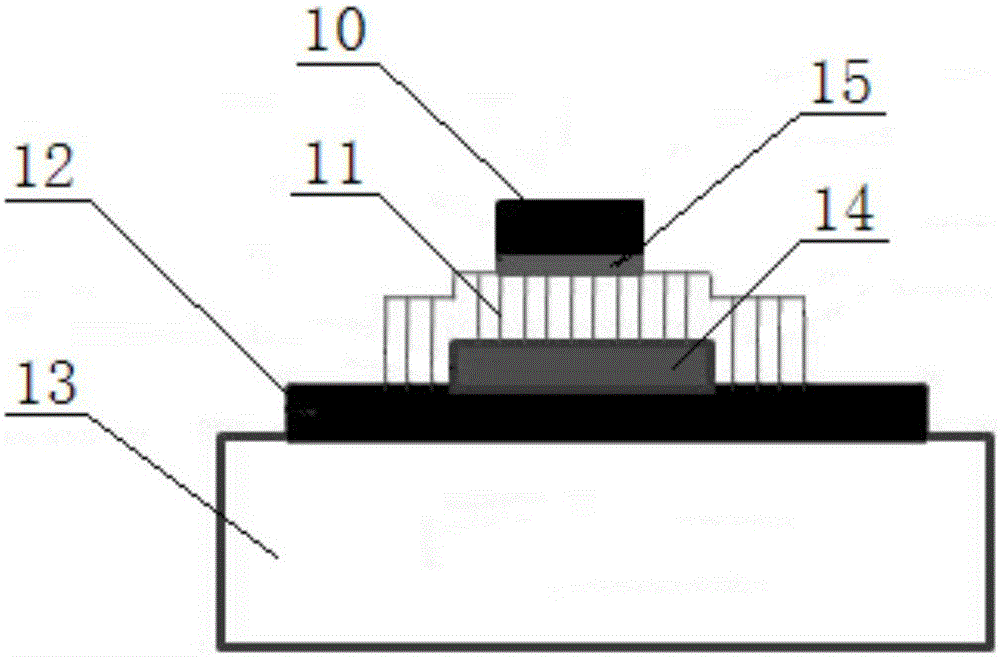

[0049] Schematic diagram of the cross...

Embodiment 2

[0060] Comparative Test. The (iv) step in Embodiment 1 is omitted, and the (v) step is adjusted as follows, and all the other steps are consistent:

[0061] (v) On the same PLD instrument, deposit the negative electrode graphite layer (600nm), the atmosphere is Ar, the air pressure is 0.1Pa, the laser frequency is 6Hz, and the laser energy density is 2.0Jcm -2 , deposited at room temperature.

Embodiment 3

[0063] Comparative Test. The (v) step in embodiment one is omitted, the (iv) step is adjusted as follows, and all the other steps are consistent:

[0064] (iv) On the same PLD instrument, deposit the negative metal lithium layer thin film (600nm). The atmosphere is Ar, the air pressure is 0.1Pa, the laser frequency is 6Hz, and the laser energy density is 2.0Jcm -2 , deposited at room temperature.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com