Flexible thin film lithium ion battery and manufacturing method thereof

A lithium-ion battery and flexible film technology, which is applied in the manufacture of electrolyte batteries, battery electrodes, secondary batteries, etc., can solve the problems of inability to bend arbitrarily, poor thickness consistency, and backward technology of intelligent products, and achieve high safety and flexibility Good performance and good thickness consistency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be further described below in conjunction with the accompanying drawings and embodiments. The shape of the flexible thin-film lithium-ion battery of the present invention can be designed according to the specific needs of electronic components, and is not limited by this embodiment.

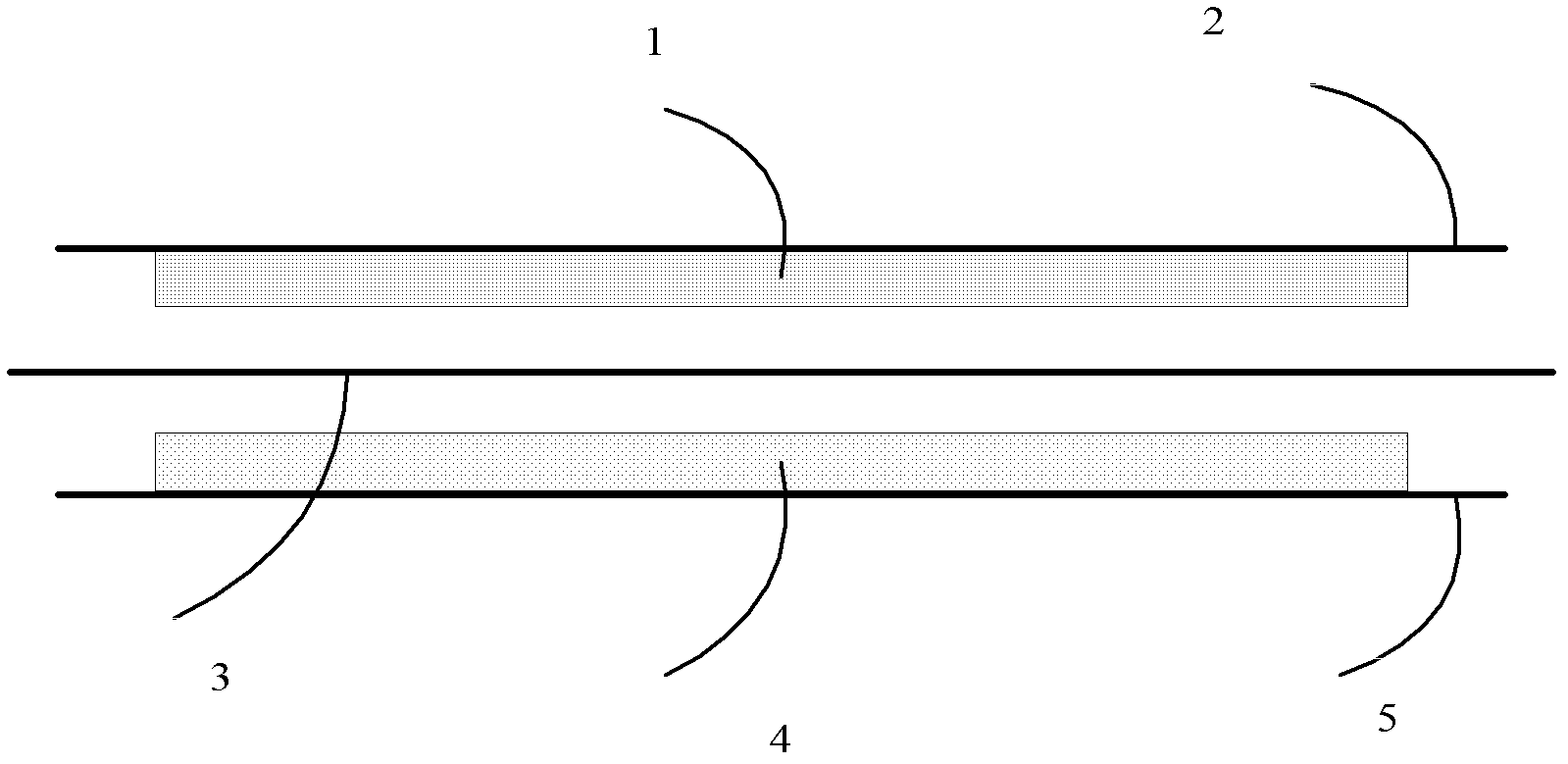

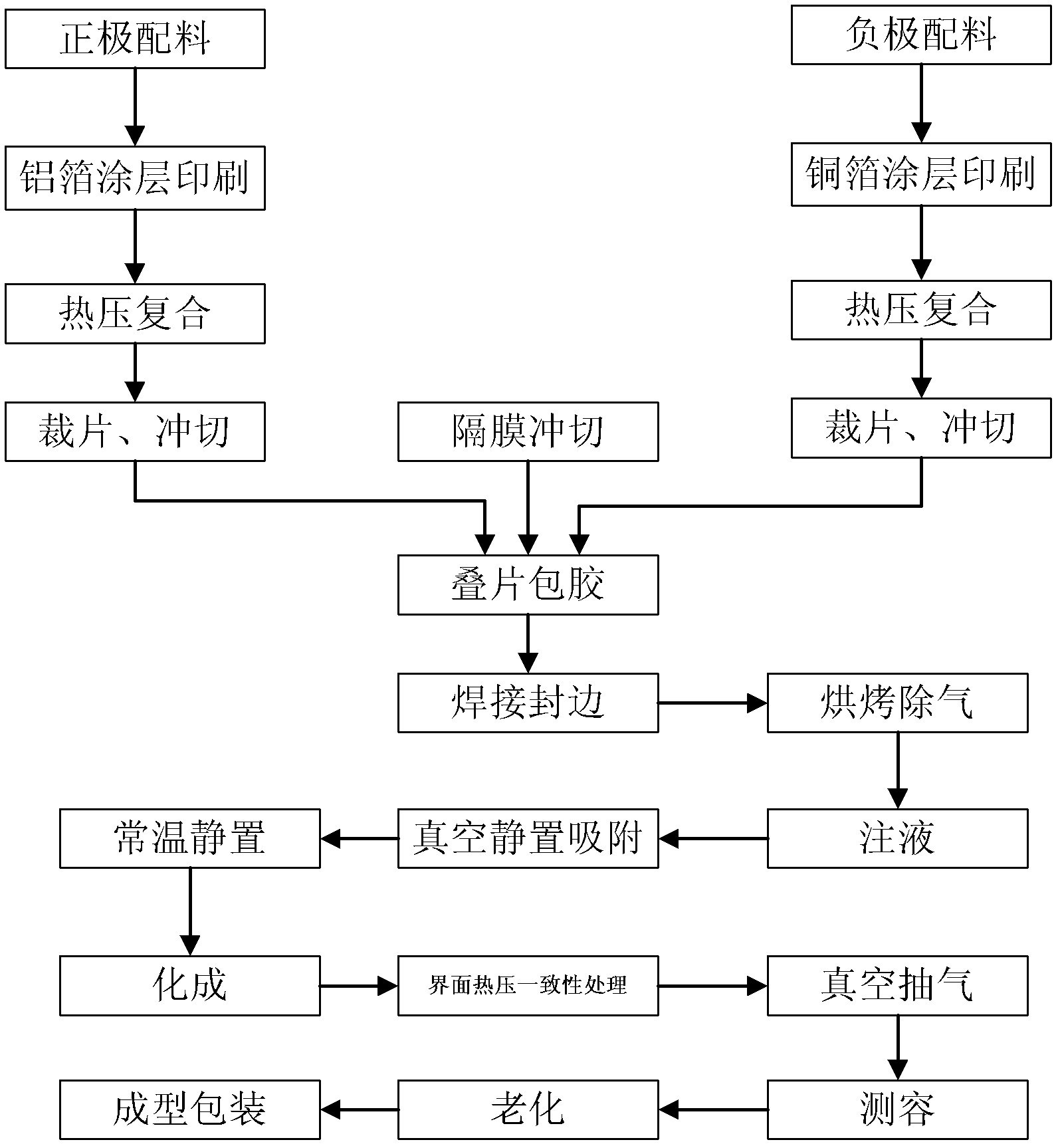

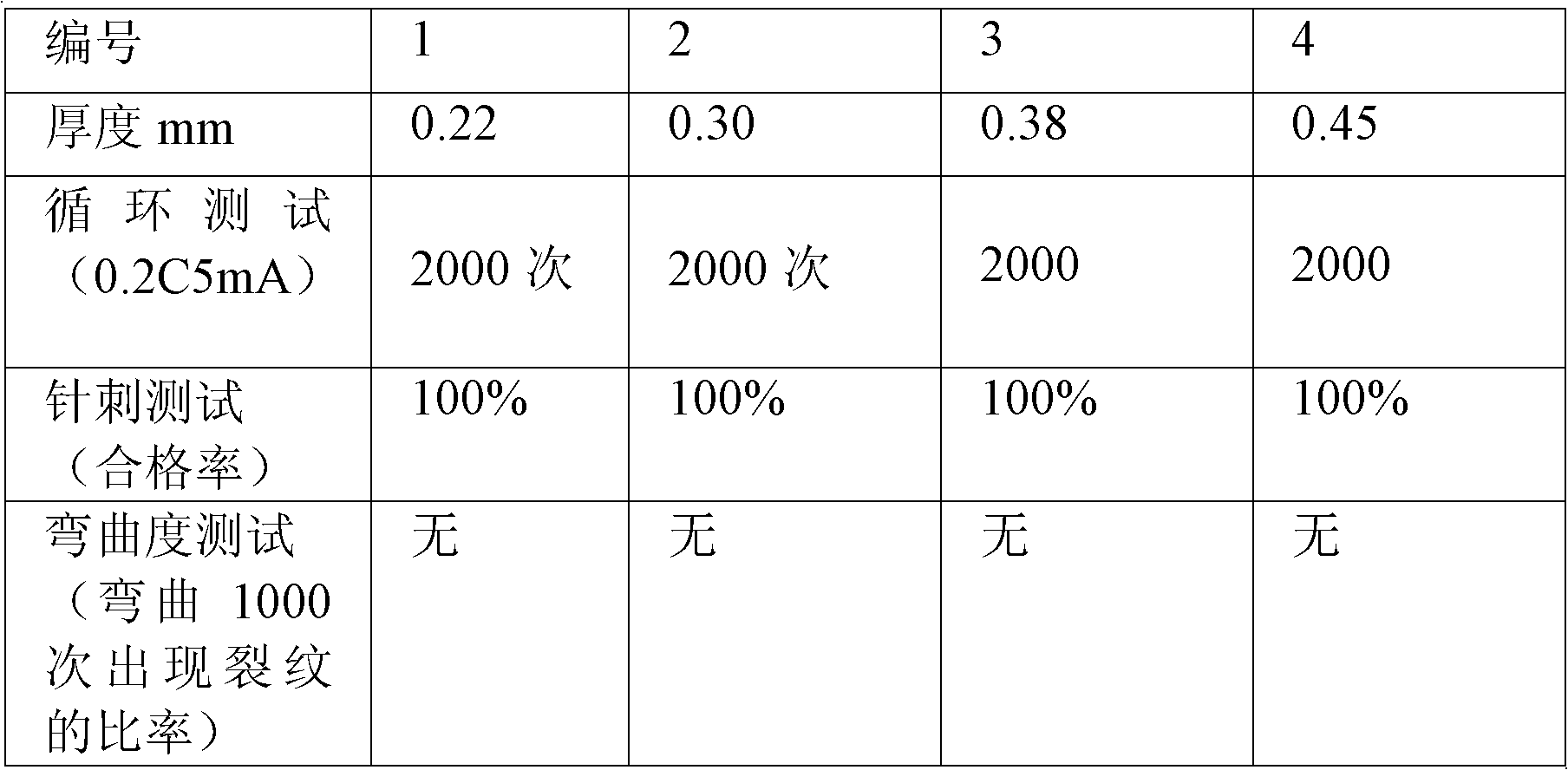

[0021] The structure of the thin film lithium battery given in this embodiment is as follows: figure 1 As shown, its battery core is composed of three layers. The positive electrode layer is composed of aluminum foil 5 and a single-sided half-layer positive electrode 4 composed of positive electrode materials. The negative electrode layer is composed of copper foil 2 and a single-sided half-layer positive electrode 1 composed of negative electrode materials. There is a separator between the positive electrode layer and the negative electrode layer. The outer surface of the copper foil and aluminum foil of the battery core is also packed with adhesive tape and pa...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com