Lithium battery electrode material Li2S/Co nanometer compound film and its preparation method

A technology of nanocomposite and electrode active material, applied in the field of Li2S/Co nanocomposite film and its preparation, can solve problems such as fast decay, and achieve the effects of high specific capacity, excellent electrochemical performance and simple preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0013] Chemically pure Li with a molar ratio of 1:1 2 S is fully mixed with Co powder; then the mixture powder is pressed into a target material for pulse laser deposition, and a composite nano-mixture electrode film material is prepared by pulse laser deposition. Preparation conditions: the substrate is a stainless steel sheet, the distance between the substrate and the target is 40mm; the deposition process is carried out in argon, and the pressure is kept at 10Pa; the deposition temperature is room temperature; the laser wavelength is 355nm, the pulse frequency is 10Hz, the pulse width is 10ns, and the energy The density is 2J / cm -2 ; The deposition time was 0.5 hours.

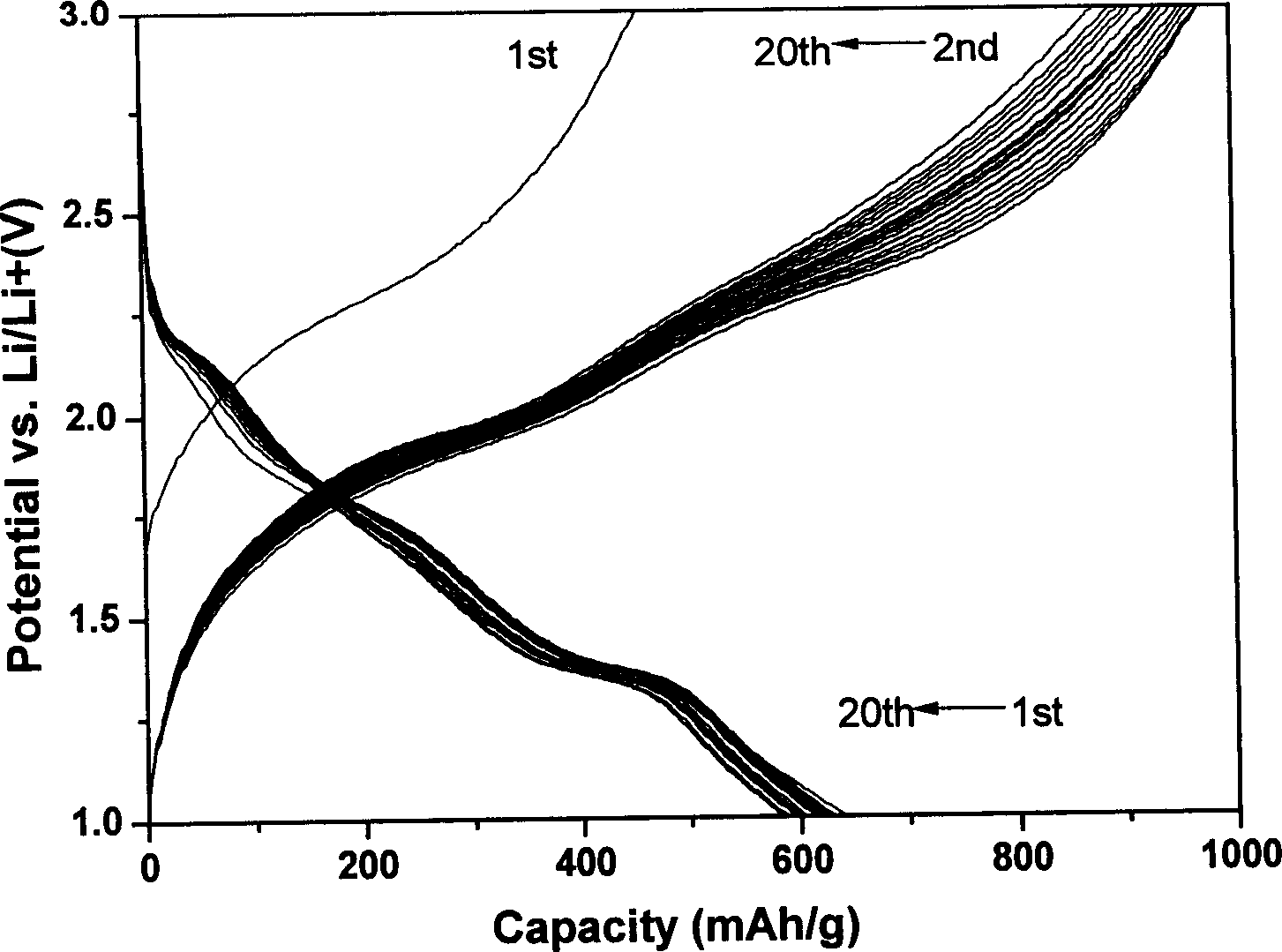

[0014] According to SEM, the particle size in the deposited film is about 20nm. Indicating that the deposited film is Li 2 S / Co nanocomposite material composition. It was determined by TEM electron diffraction that the deposited film was Li 2 S / Co nano-hybrid, where Li 2 S is a face-centered cubic str...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| energy density | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com