Tab extraction method for all-solid-state thin film lithium ion battery with vertical structure

A lithium-ion battery, all-solid-state technology, applied in the direction of structural parts, battery pack parts, non-aqueous electrolyte storage batteries, etc., can solve the problems of low space utilization of the substrate, difficulty in leading out the negative electrode tab, short circuit, etc., and save the process , strong binding force and excellent electrical conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

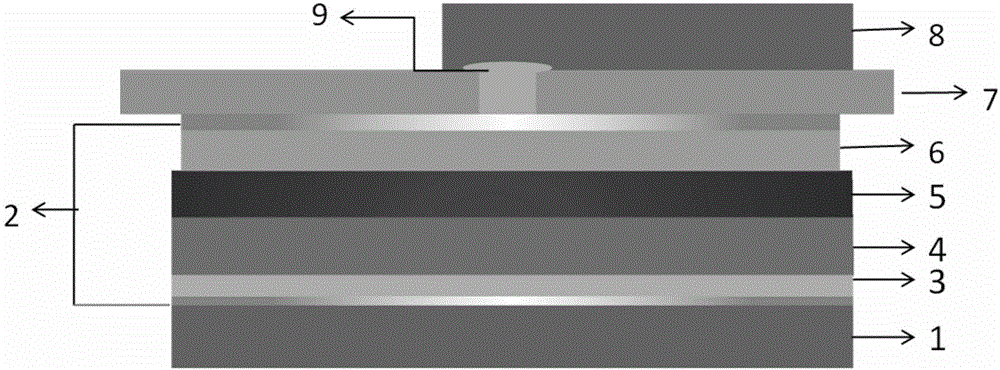

[0028] figure 1 is a cross-sectional view of the all-solid-state thin-film battery of the present invention, such as figure 1 As shown, the method for leading out the tabs of the all-solid-state thin-film lithium-ion battery of the present invention includes a stainless steel foil substrate 1, a Ti adhesion layer 2, a Pt positive electrode current collector 3, and a LiMn 2 o 4 Positive electrode 4, LiPON electrolyte 5,, TiO 2 Negative electrode 6, Pt negative electrode current collector 2, negative electrode tab 8, PE insulating film material 7, silver paste 9.

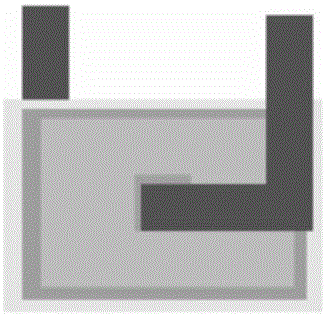

[0029] Figure 2a to Figure 2i It is the flow chart of battery tab extraction in the present invention, as shown in the figure,

[0030] Figure 2a is a stainless steel foil substrate with a positive tab;

[0031] Figure 2b A Ti adhesion layer is plated on a stainless steel foil substrate using a magnetron sputtering DC power supply;

[0032] Figure 2c Pt positive current collector is plated on the adhesion...

Embodiment 2

[0040] In embodiment 2 and embodiment 1 Figure 2a to Figure 2g The process is exactly the same and will not be repeated here. The difference is that Figure 2h , 2i , Fix the stainless steel foil negative electrode tab with the positive electrode tab on the negative electrode current collector by using PE insulating film material and copper conductive glue.

[0041] Finally, the tab part of the negative electrode must be isolated from the positive electrode and its current collector through an insulating film. Among them, the cathode material LiMn 2 o 4 After the film is coated, it needs to be annealed in the air at 700°C for 30 minutes, and the thickness is about 1 μm. The performance of the all-solid-state thin film battery made by this method can reach 45 μAh cm -2 , which is basically consistent with the test results of other methods.

Embodiment 3

[0043] In embodiment 3 and embodiment 1 Figure 2a to Figure 2g The process is exactly the same and will not be repeated here. The difference is that Figure 2h , 2i , The stainless steel foil negative electrode tab with positive electrode tab is fixed on the negative electrode current collector by using PE insulating film material and micro-welding technology.

[0044] Finally, the tab part of the negative electrode must be isolated from the positive electrode and its current collector through an insulating film. Among them, the cathode material LiMn 2 o 4 After the film is coated, it needs to be annealed in the air at 700°C for 30 minutes, and the thickness is about 1 μm. The performance of the all-solid-state thin film battery made by this method can reach 45 μAh cm -2 , which is basically consistent with the test results of other methods.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com