Method for analyzing expansion extent of lithium metal cathode

A technology of lithium metal negative electrode and analysis method, applied in the direction of mechanical thickness measurement, secondary battery testing, secondary battery charging/discharging, etc., to achieve the effect of great practical significance in production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

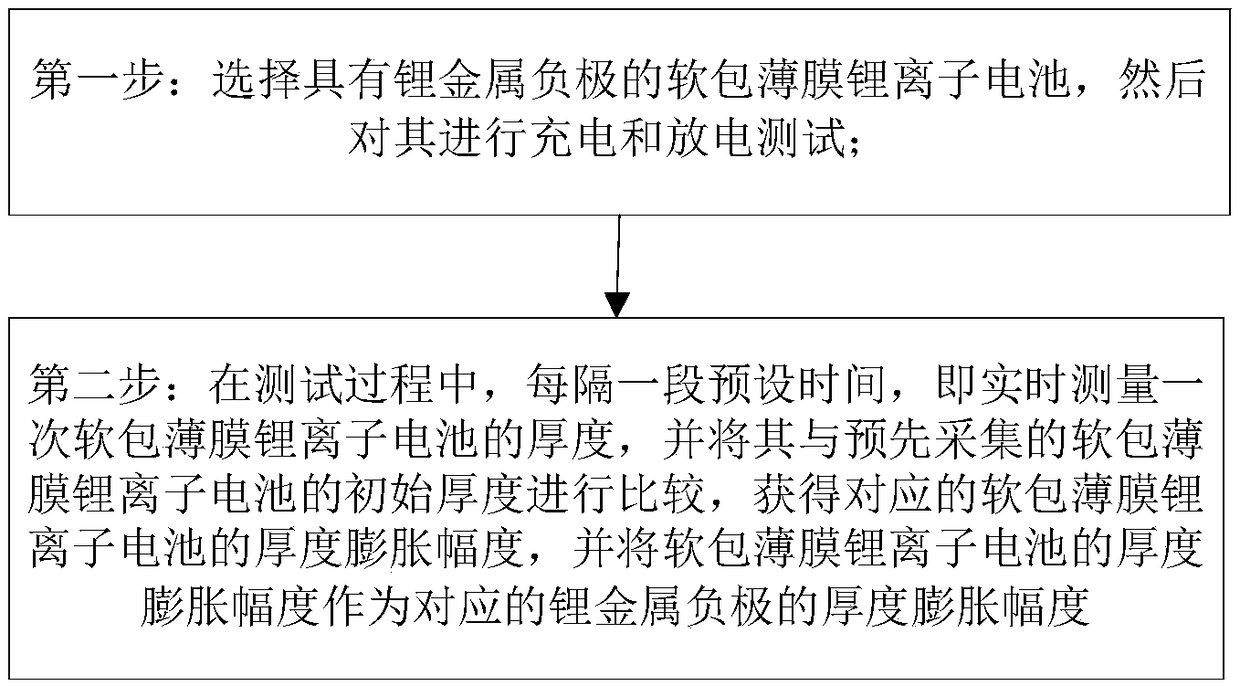

[0054] For the test method of a kind of lithium metal negative electrode expansion range provided by the present invention, the steps are as follows:

[0055] Step 1: Select a pouch thin-film lithium-ion battery with a lithium metal negative electrode, and then conduct charge and discharge tests on it;

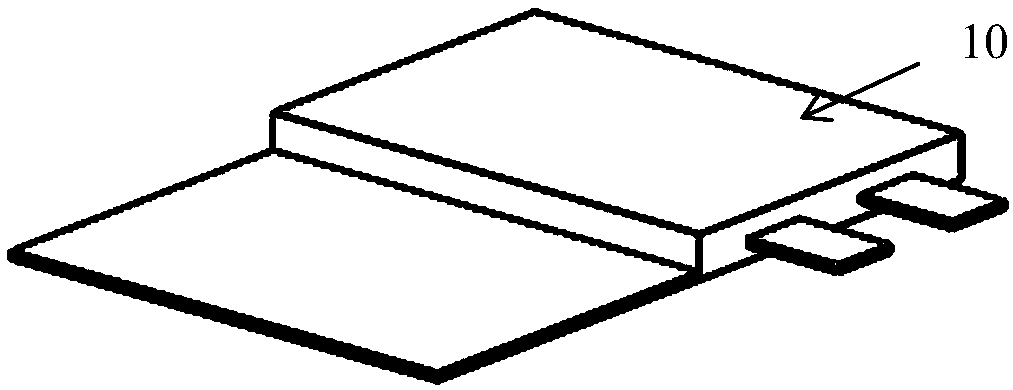

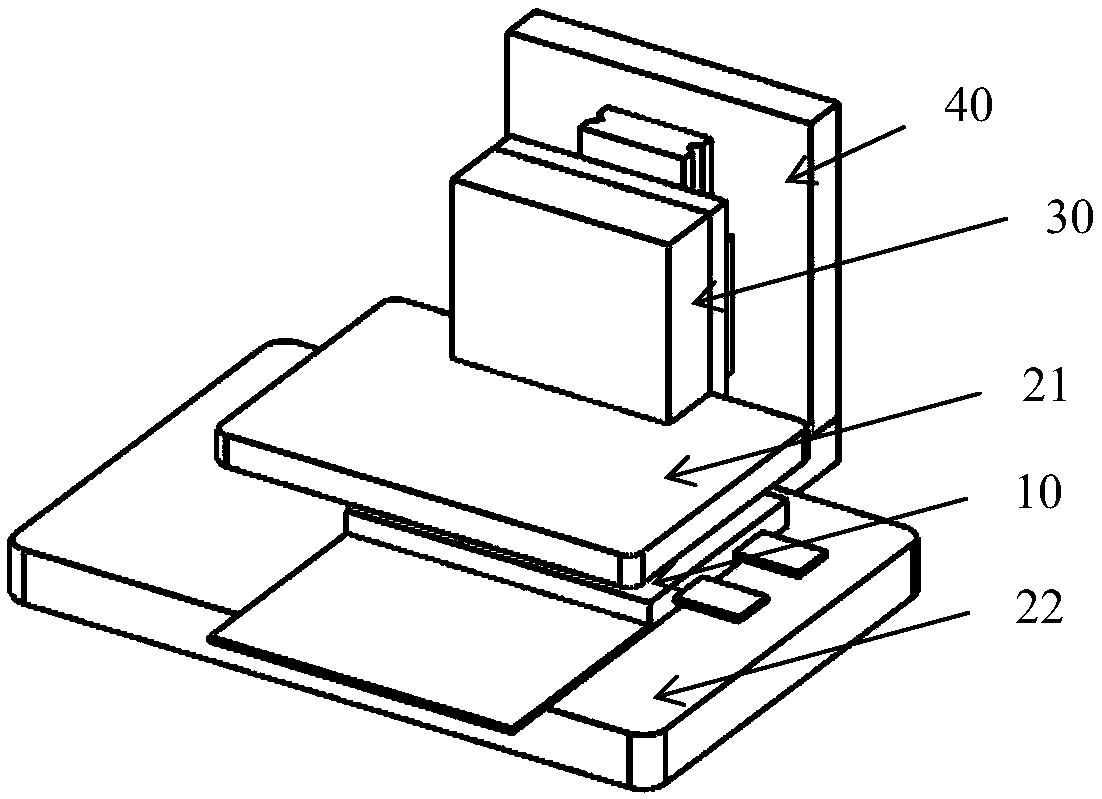

[0056] In terms of specific implementation, the preparation of soft-packed thin-film batteries for thickness expansion testing: prepare battery components such as positive electrodes, large-area lithium metal negative electrodes, tabs, diaphragms, electro-hydraulics, and soft-packed battery cases according to the traditional laminated battery technology, and assemble large-scale Area lithium metal negative electrode thickness expansion special soft pack thin film battery (such as figure 1 shown). Among them, the lithium metal negative electrode is an independently supported negative electrode with a length of 5 cm, a width of 5 cm, and a thickness of 40 μm. Among them, the t...

Embodiment 2

[0064] For the test method of a kind of lithium metal negative electrode expansion range provided by the present invention, the steps are as follows:

[0065] Step 1: Select a pouch thin-film lithium-ion battery with a lithium metal negative electrode, and then conduct charge and discharge tests on it;

[0066] In terms of specific implementation, the preparation of soft-packed thin-film batteries for thickness expansion testing: prepare battery components such as positive electrodes, large-area lithium metal negative electrodes, tabs, diaphragms, electro-hydraulics, and soft-packed battery cases according to the traditional laminated battery technology, and assemble large-scale Area lithium metal negative electrode thickness expansion special soft pack thin film battery (such as figure 1 shown). Among them, the lithium metal negative electrode is an independently supported negative electrode with a length of 5 cm, a width of 5 cm, and a thickness of 40 μm. Among them, the t...

Embodiment 3

[0074] For the test method of a kind of lithium metal negative electrode expansion range provided by the present invention, by embodiment 1 and 2, can analyze and obtain following conclusion:

[0075] In the first cycle, when charging, lithium is released from the positive electrode and deposited on the negative electrode. The theoretical thickness is 9 microns, and the actual thickness is 11 microns. The difference in thickness is caused by the non-dense deposition of lithium metal. During the first cycle, when discharging, lithium is extracted from the negative electrode, and lithium is intercalated in the positive electrode, and the thickness of lithium metal is finally reduced to 1 micron. It shows that the lithium metal deposited in the first cycle charging is active, and can basically return to the positive electrode through lithium intercalation.

[0076] After five cycles, when charging, the thickness of the pole piece increases to 17 microns. When discharging, the min...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| Width | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com