A Debugging Method for the State Parameters of a Test Bench

A technology of state parameters and debugging methods, applied in engine testing, machine/structural component testing, measuring devices, etc., can solve problems such as inability to master the performance of the test bench as a whole, no debugging methods, and increased simulation time.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0056] A method for debugging state parameters of a test bench, wherein the type of debugging includes no-load debugging, on-load debugging, and hot-running, and the on-load debugging and hot-running include the following steps:

[0057] 1), debug the intake system;

[0058] 2), debug the heater;

[0059] 3) Debug thrust measuring equipment;

[0060] 4), debug ejector;

[0061] 5) Jointly debug the intake system, heater, thrust measuring equipment and ejector.

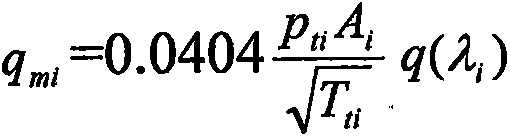

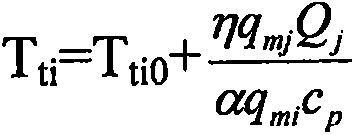

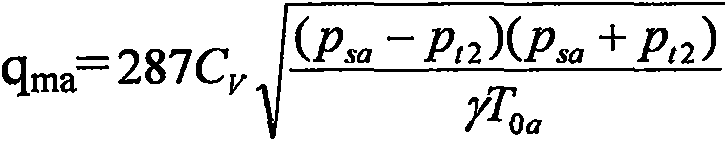

[0062] When debugging the intake system, the predictive control method is used to debug the intake state parameters of the test bench, which includes the following steps:

[0063] 1), according to the control amount of a single parameter obtained by the predictive control method, debug the intake pressure regulating valve;

[0064] 2) According to the control amount of a single parameter obtained by the predictive control method, debug the fuel proportional regulating valve of the heater

[0065] 3) According to t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com