A method of using a pressure regulating valve connected in series in the air intake system of a test bench

A technology of pressure regulation and air intake system, which is applied in the field of pressure regulation valves, can solve the problems of increasing test cost and increasing simulation time, and achieve the effect of reducing test cost and improving test efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

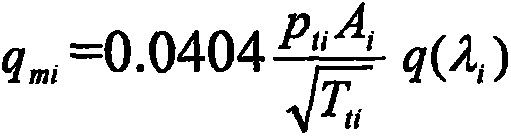

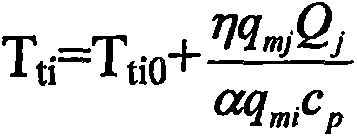

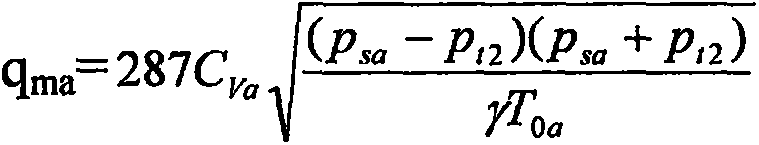

[0029] A method for using a pressure regulating valve connected in series in the air intake system of a test bench, the pressure regulating valve in series includes a primary pressure regulating valve and a secondary pressure regulating valve, the method for using the pressure regulating valve connected in series in the air intake system of the test bench , including the following steps:

[0030] 1) According to the mass flow and / or volume flow of the air intake system of the test bench through the series intake pressure regulating valve and the post-valve pressure of the secondary pressure regulating valve, determine the appropriate opening of the secondary pressure regulating valve and the secondary pressure Regulating valve front pressure;

[0031] 2), according to the mass flow and / or volume flow of the intake pressure regulating valve in series through the air intake system of the test bench and the pre-valve pressure of the secondary pressure regulating valve determined ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com