Use method of parallel test bed air intake system pressure regulating valves

A technology of pressure regulation and air intake system, which is applied in the direction of engine testing, machine/structural component testing, measuring devices, etc. It can solve problems such as lack of mature use methods, increase simulation time, and increase test costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

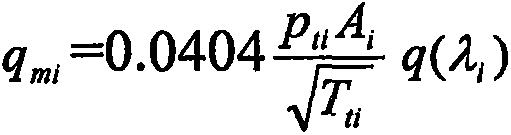

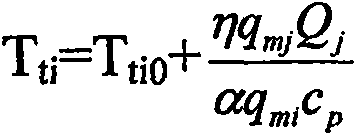

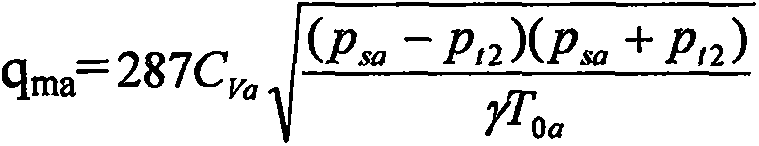

[0026] A method for using the pressure regulating valve of the air intake system of a parallel test bench, when using the pressure regulating valve of the air intake system of the parallel test bench, any one of the pressure regulating valves of the air intake system of the parallel test bench can be used independently , or use the pressure regulating valve of the air intake system of the parallel test bench in combination, when using the pressure regulating valve of the air intake system of the parallel test bench in combination, adjust the pressure After the opening of the pressure regulating valve with a larger range is fixed at 50% or 100%, the control system controls the opening of the pressure regulating valve with a smaller pressure regulating range according to the control amount of the parameters obtained by the predictive control method.

[0027] The predictive control method comprises the steps of:

[0028] 1) According to the total intake pressure, intake air flow ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com