Niobium-doped tin dioxide thin film lithium ion battery negative pole plate, preparation method thereof and lithium ion battery

A lithium-ion battery and tin dioxide technology, applied in the field of lithium-ion batteries, can solve the problems of poor cycle stability, many influencing factors, and low discharge capacity, and achieve the effects of enhancing electronic conductivity, uniform volume expansion, and alleviating volume expansion.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

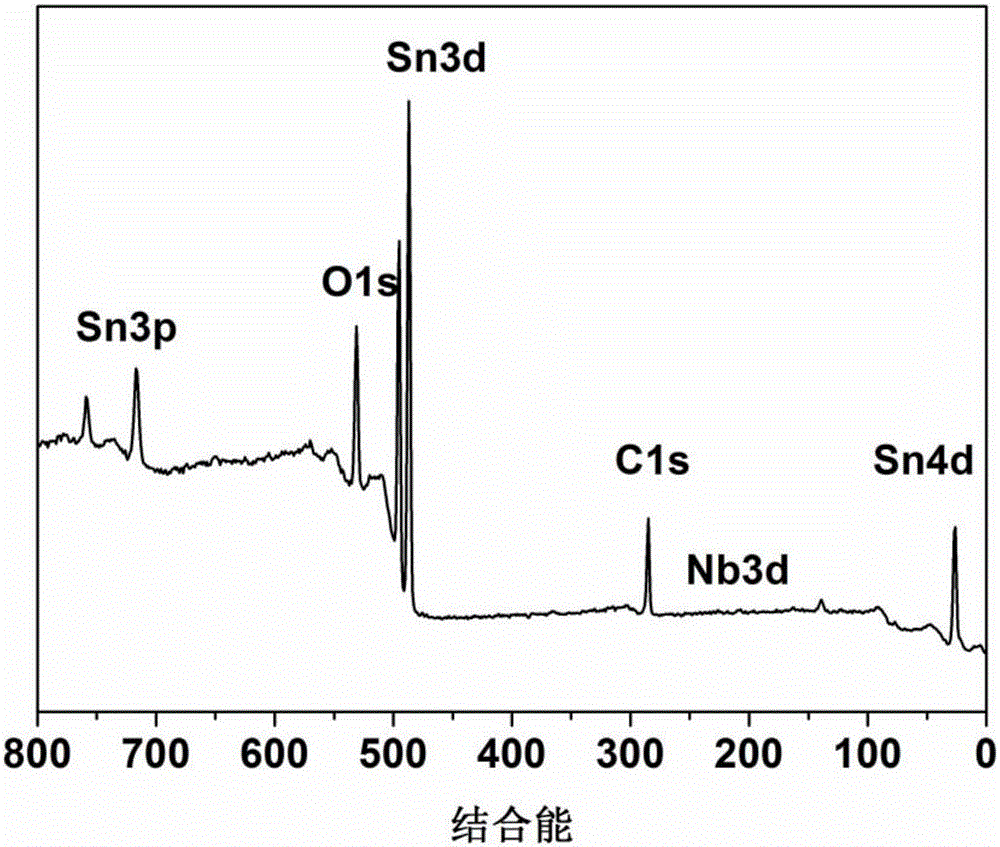

[0059] The niobium-doped tin dioxide thin film lithium-ion battery negative pole sheet of the present embodiment comprises a current collector and a niobium-doped tin dioxide thin film arranged on the current collector; the current collector is a copper foil with a matte surface and a thickness of 20 μm; the thickness of the niobium-doped tin dioxide film is 200 nm; the niobium-doped tin dioxide film is composed of the following atomic percentage components: O 75%, Sn 23.6%, Nb 1.4%.

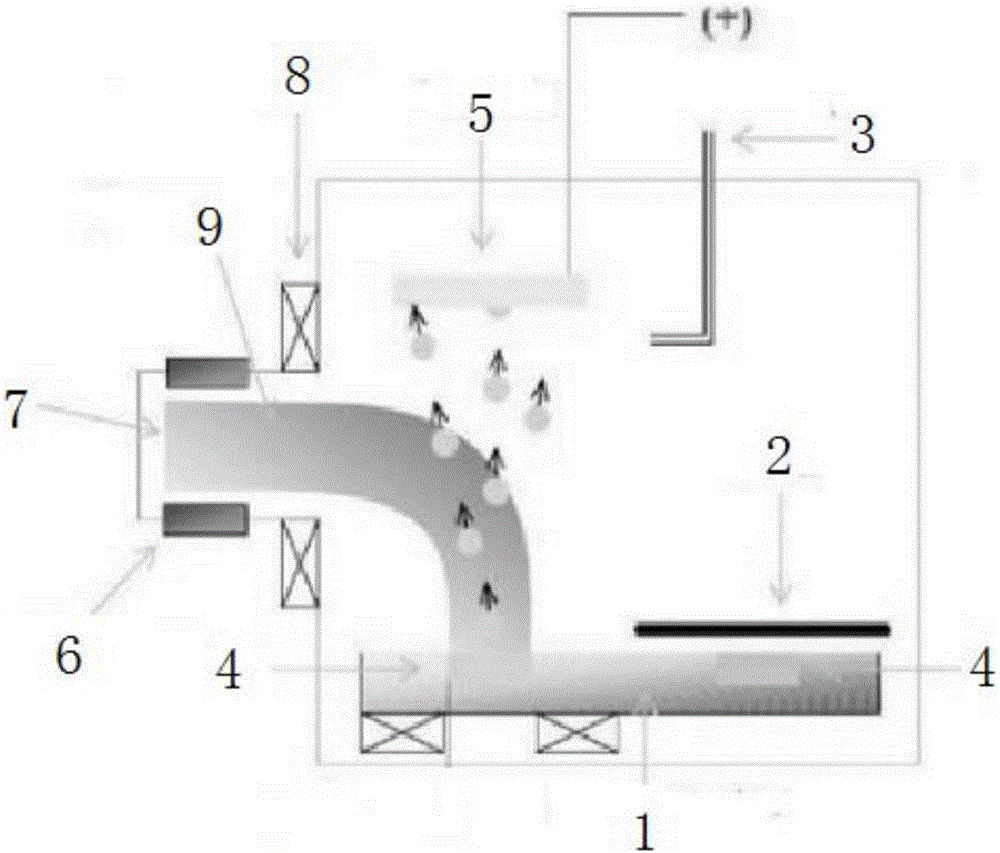

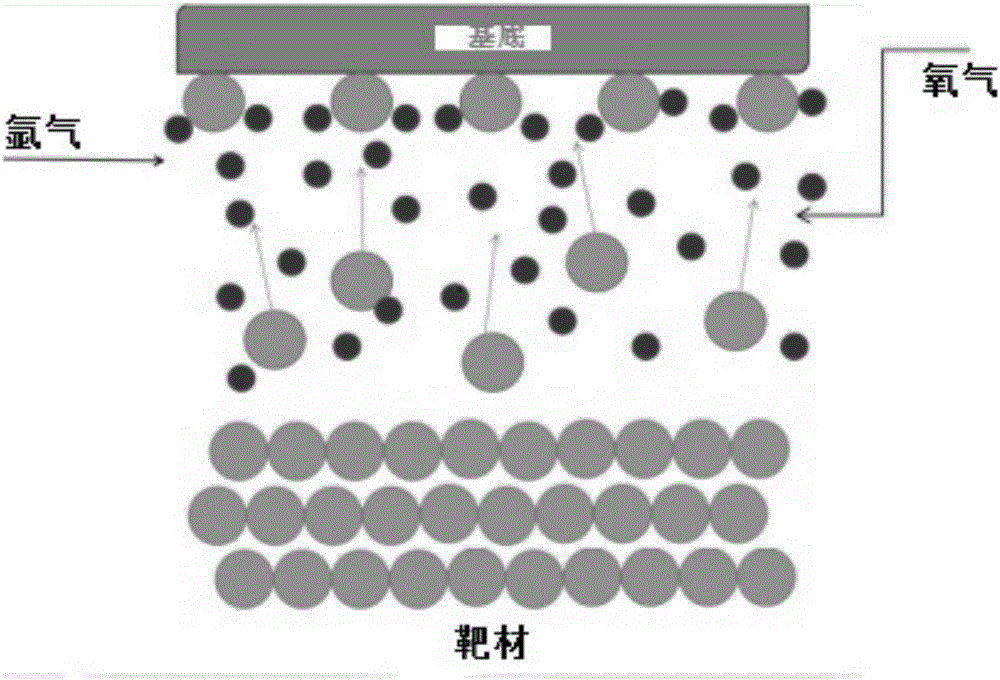

[0060] The preparation method of the niobium-doped tin dioxide thin-film lithium-ion battery negative pole piece of this embodiment includes: in an argon and oxygen atmosphere, using a current collector as a substrate, and using remote plasma sputtering technology to sputter the target On the current collector, deposit to form a thin film, that is. The specific process is as follows:

[0061] 1) Ultrasonic cleaning the copper foil in acetone, deionized water, and ethanol for 5 minutes each, and...

Embodiment 2

[0069] The niobium-doped tin dioxide thin film lithium-ion battery negative pole sheet of the present embodiment comprises a current collector and a niobium-doped tin dioxide thin film arranged on the current collector; the current collector is a copper foil with a matte surface and a thickness of 20 μm; the thickness of the niobium-doped tin dioxide film is 300 nm; the niobium-doped tin dioxide film is composed of the following atomic percentage components: O 65%, Sn 33%, Nb 2%.

[0070] The preparation method of the niobium-doped tin dioxide thin-film lithium-ion battery negative pole piece of this embodiment includes: in an argon and oxygen atmosphere, using a current collector as a substrate, and using remote plasma sputtering technology to sputter the target On the current collector, deposit to form a thin film, that is. The specific process is as follows:

[0071] 1) Ultrasonic cleaning the copper foil in acetone, deionized water, and ethanol for 5 minutes each, and the...

Embodiment 3

[0078] The niobium-doped tin dioxide thin film lithium-ion battery negative pole sheet of the present embodiment comprises a current collector and a niobium-doped tin dioxide thin film arranged on the current collector; the current collector is a copper foil with a matte surface and a thickness of 20 μm; the thickness of the niobium-doped tin dioxide film is 400nm; the niobium-doped tin dioxide film is composed of the following atomic percentage components: O 70%, Sn 28.3%, Nb 1.7%.

[0079] The preparation method of the niobium-doped tin dioxide thin-film lithium-ion battery negative pole piece of this embodiment includes: in an argon and oxygen atmosphere, using a current collector as a substrate, and using remote plasma sputtering technology to sputter the target On the current collector, deposit to form a thin film, that is. The specific process is as follows:

[0080] 1) Ultrasonic cleaning the copper foil in acetone, deionized water, and ethanol for 5 minutes each, and ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com