Method for preparing cathode of lithium ion battery with lithium-silicon film through pulse electrodeposition

A lithium-ion battery, pulse electrodeposition technology, applied in the direction of battery electrodes, circuits, electrical components, etc., can solve the problems of poor conductivity, difficult to thicken silicon films, etc., to improve quality, eliminate concentration polarization, and tightly bonded Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

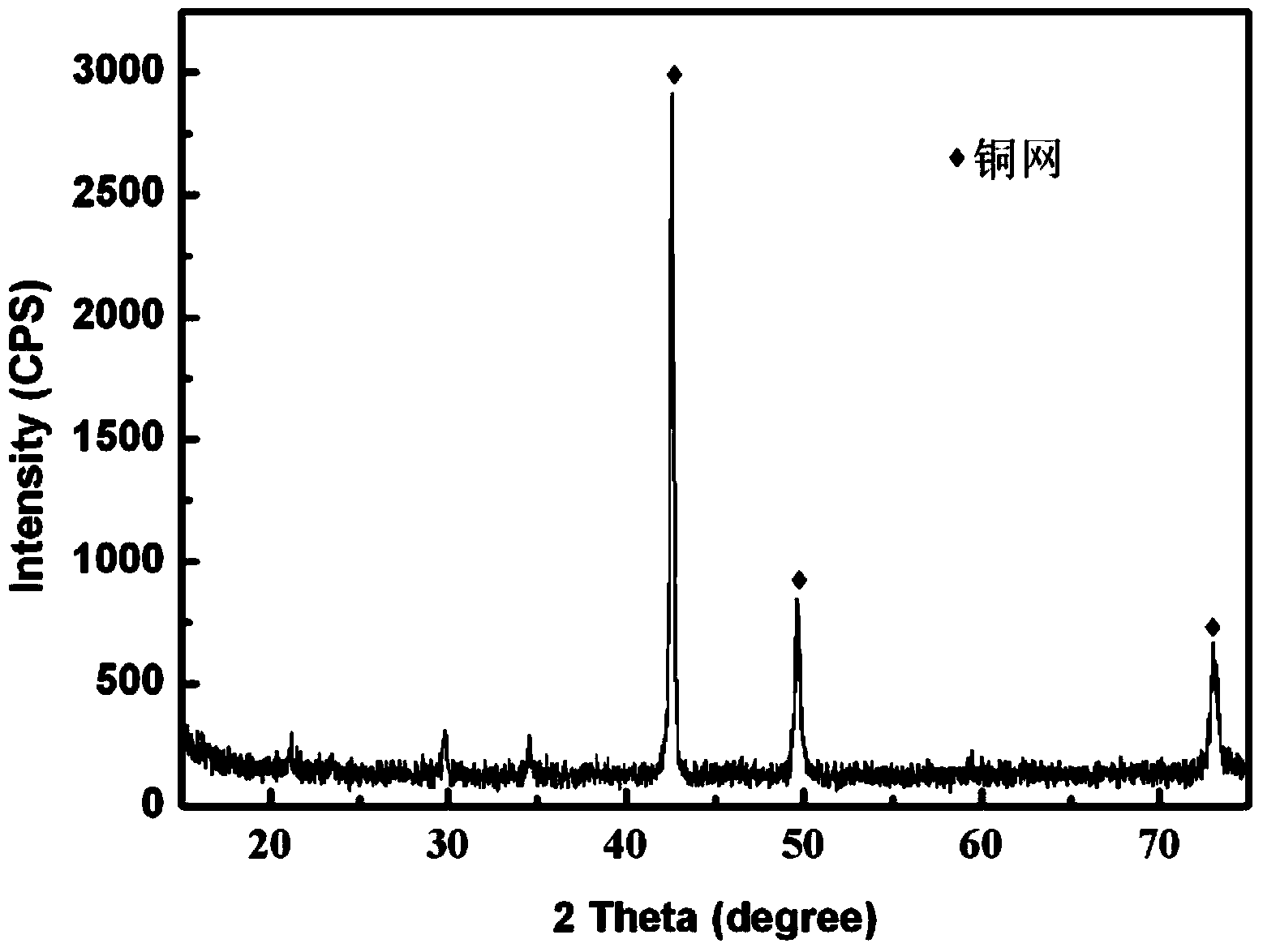

Embodiment 1

[0036] A method for preparing lithium-silicon thin-film lithium-ion battery negative electrodes by pulse electrodeposition, the preparation process comprising the following process steps:

[0037] 1. Electrolyte Preparation

[0038] Under the protection of argon, lithium perchlorate and silicon tetrachloride were added to the propylene carbonate solvent, stirred and dissolved to obtain an electrolyte, and the molar concentration of silicon tetrachloride in the electrolyte was 0.5mol L -1 , the molar concentration of lithium perchlorate is 0.6mol L -1 ;

[0039] 2. Pulse Electrodeposition

[0040] Place the above electrolytic solution in a three-chamber electrolytic cell with a constant temperature jacket at a constant temperature of 30°C, and conduct co-electrodeposition of lithium and silicon under the protection of argon: the platinum sheet is the anode, the platinum wire is the quasi-reference electrode, and the cathode is the Copper net collector, 100 mesh; electrodepos...

Embodiment 2

[0044] A method for preparing lithium-silicon thin-film lithium-ion battery negative electrodes by pulse electrodeposition, the preparation process comprising the following process steps:

[0045] 1. Electrolyte Preparation

[0046] Under the protection of argon, lithium perchlorate and silicon tetrachloride were added to the propylene carbonate solvent, stirred and dissolved to obtain an electrolyte, and the molar concentration of silicon tetrachloride in the electrolyte was 0.5mol L -1 , the molar concentration of lithium perchlorate is 0.6mol L -1 ;

[0047] 2. Pulse Electrodeposition

[0048] Place the above electrolytic solution in a three-chamber electrolytic cell with a constant temperature jacket at a constant temperature of 30°C, and conduct co-electrodeposition of lithium and silicon under the protection of argon: the platinum sheet is the anode, the platinum wire is the quasi-reference electrode, and the cathode is the Copper foil current collector with a thickne...

Embodiment 3

[0051] A method for preparing lithium-silicon thin-film lithium-ion battery negative electrodes by pulse electrodeposition, the preparation process comprising the following process steps:

[0052] 1. Electrolyte Preparation

[0053] Under the protection of nitrogen, add lithium dioxalate borate and silicon tetrachloride into the dichloromethane solvent, stir and dissolve to obtain an electrolyte, and the molar concentration of silicon tetrachloride in the electrolyte is 0.4mol L -1 , the molar concentration of lithium dioxalate borate is 0.3mol L -1 ;

[0054] 2. Pulse Electrodeposition

[0055] Place the above electrolyte in a three-chamber electrolytic cell with a constant temperature jacket, at a constant temperature of 25°C, and conduct co-electrodeposition of lithium and silicon under nitrogen protection: the platinum sheet is the anode, the platinum wire is the quasi-reference electrode, and the cathode is nickel Foil current collector with a thickness of 0.03mm; the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com