Experiment research system for electrolytic copper foil and using method thereof

An electrolytic copper foil, experimental research technology, applied in the electrolytic process, electrolytic components, electroforming, etc., can solve the problems of loose electrolytic copper foil deposition structure, inability to maintain stable electrolyte composition, cathode concentration polarization, etc., to achieve Reduce the cost of new product development and production, meet the actual production auxiliary requirements, and eliminate the effect of concentration polarization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

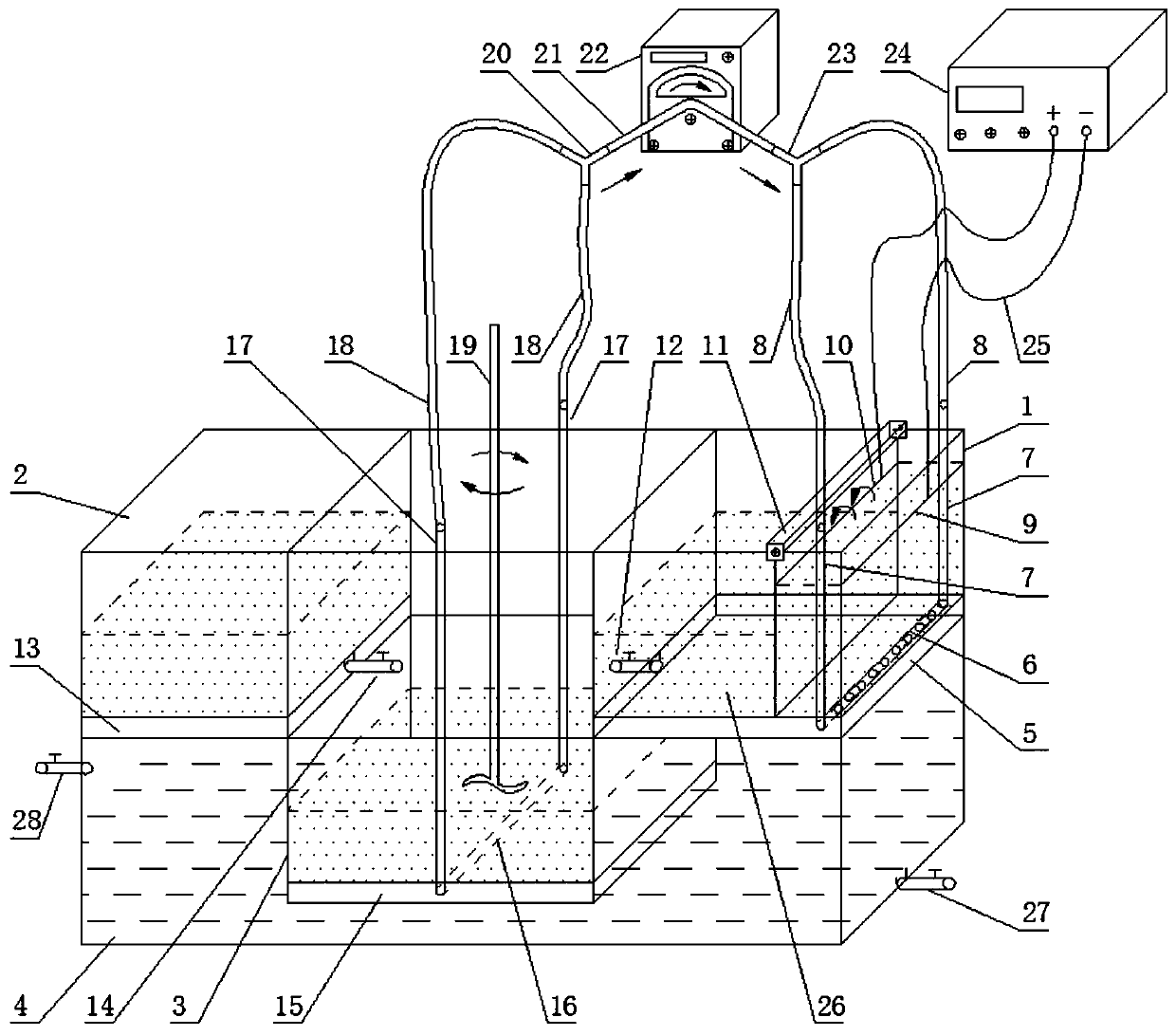

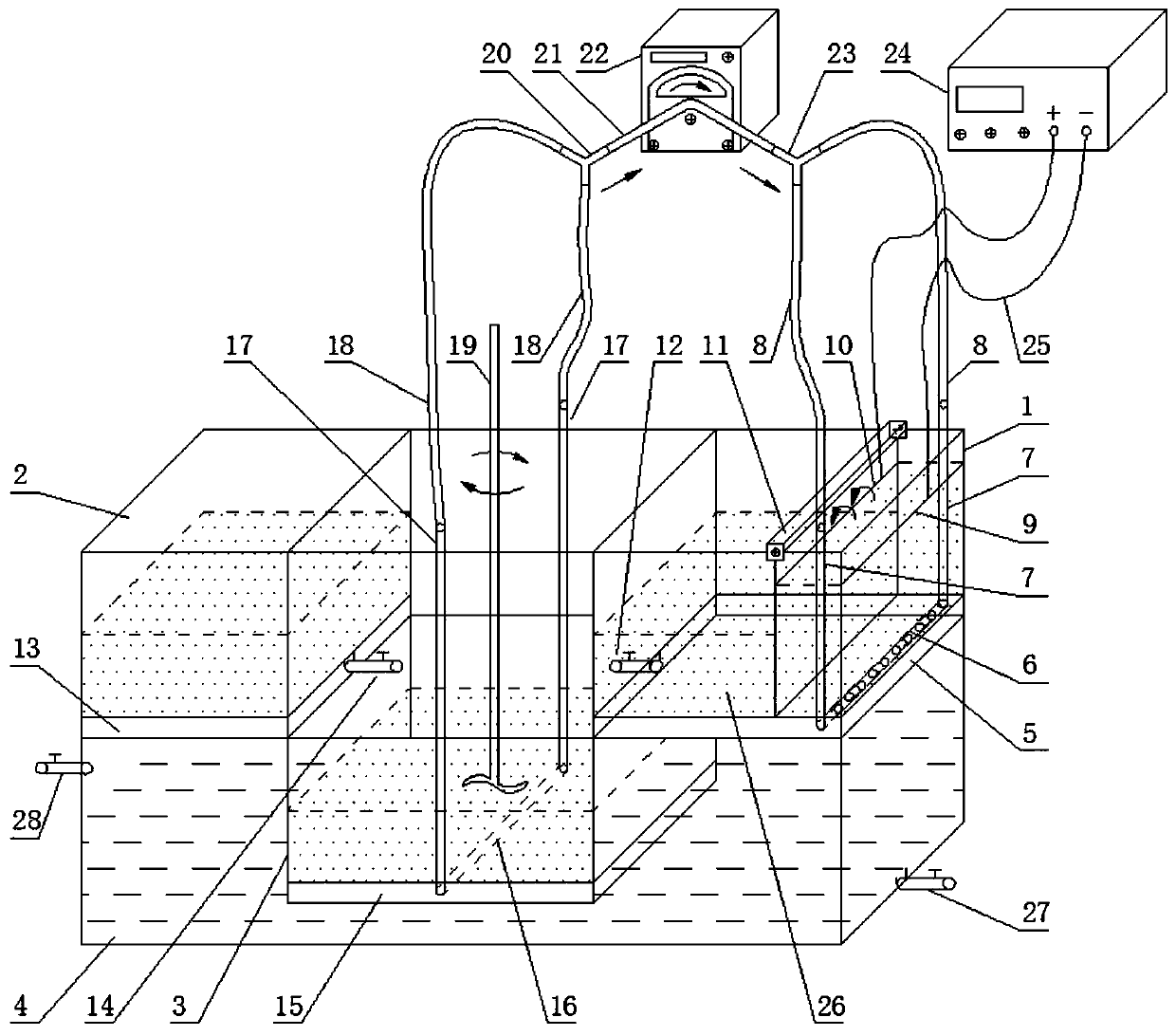

[0038] Such as figure 1 A system for electrolytic copper foil experimental research shown includes an electrolytic cell 1 and a constant current rectifier 24. The electrolytic cell 1 is provided with a vertical cathode plate 9 and an anode plate 10 arranged side by side. The cathode plate 9 It is a pure titanium plate, the anode plate 10 is an iridium-coated titanium plate, and the cathode plate 9 and the anode plate 10 are electrically connected to the positive pole and the negative pole of the constant current rectifier 24 respectively;

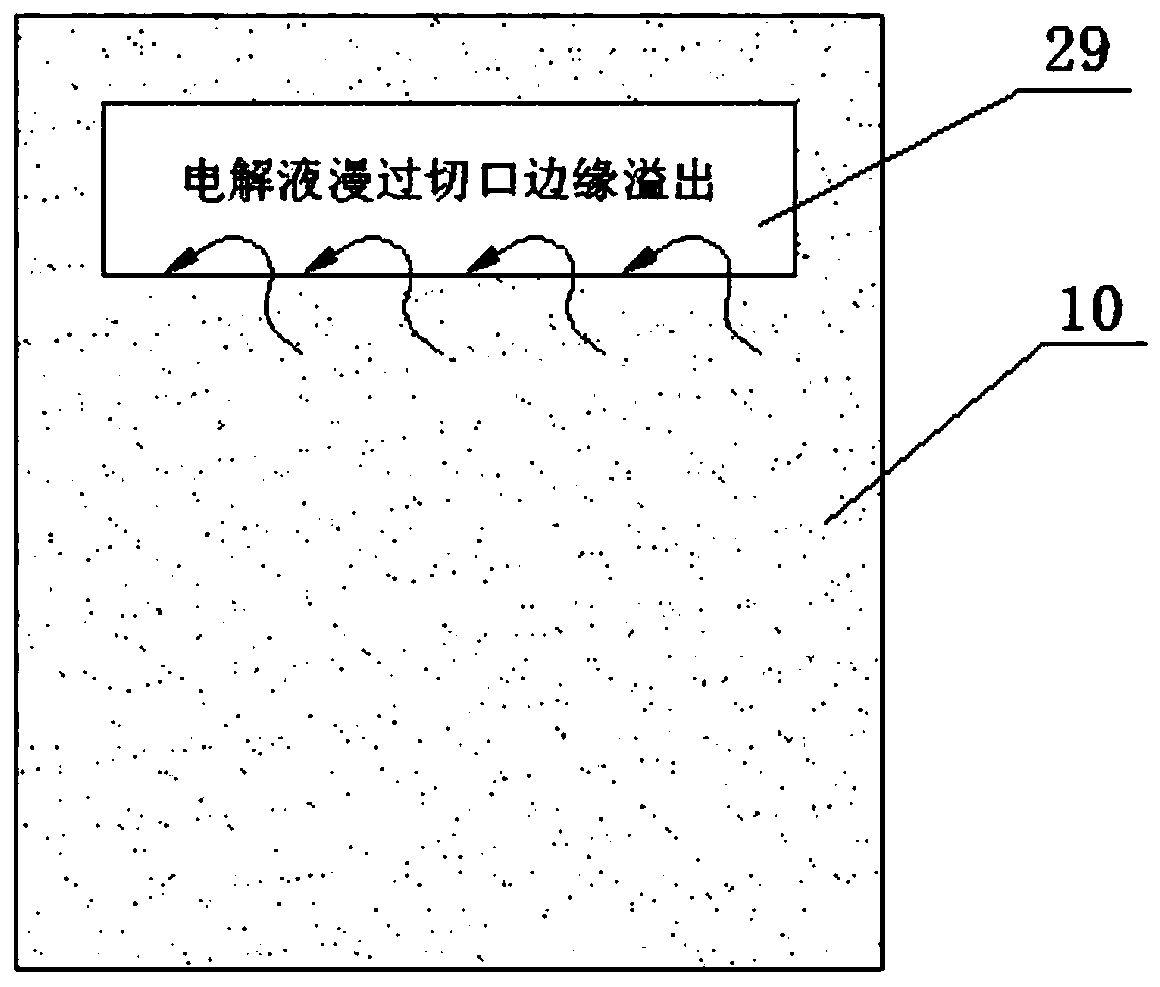

[0039]The width of the cathode plate 9 and the anode plate 10 is consistent with the internal width of the electrolytic cell 1, and the bottoms of the negative plate 9 and the anode plate 10 all extend to the bottom of the electrolytic cell 1, and the negative plate 9 is attached to the electrolytic cell 1 The side wall of one side of the electrolytic cell 1 corresponding to the cathode plate 9 is provided with a liquid inlet straight pipe ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com