Preparation method of nano-silver particle dispersed Li*Ti*O* thin film lithium ion battery negative electrode

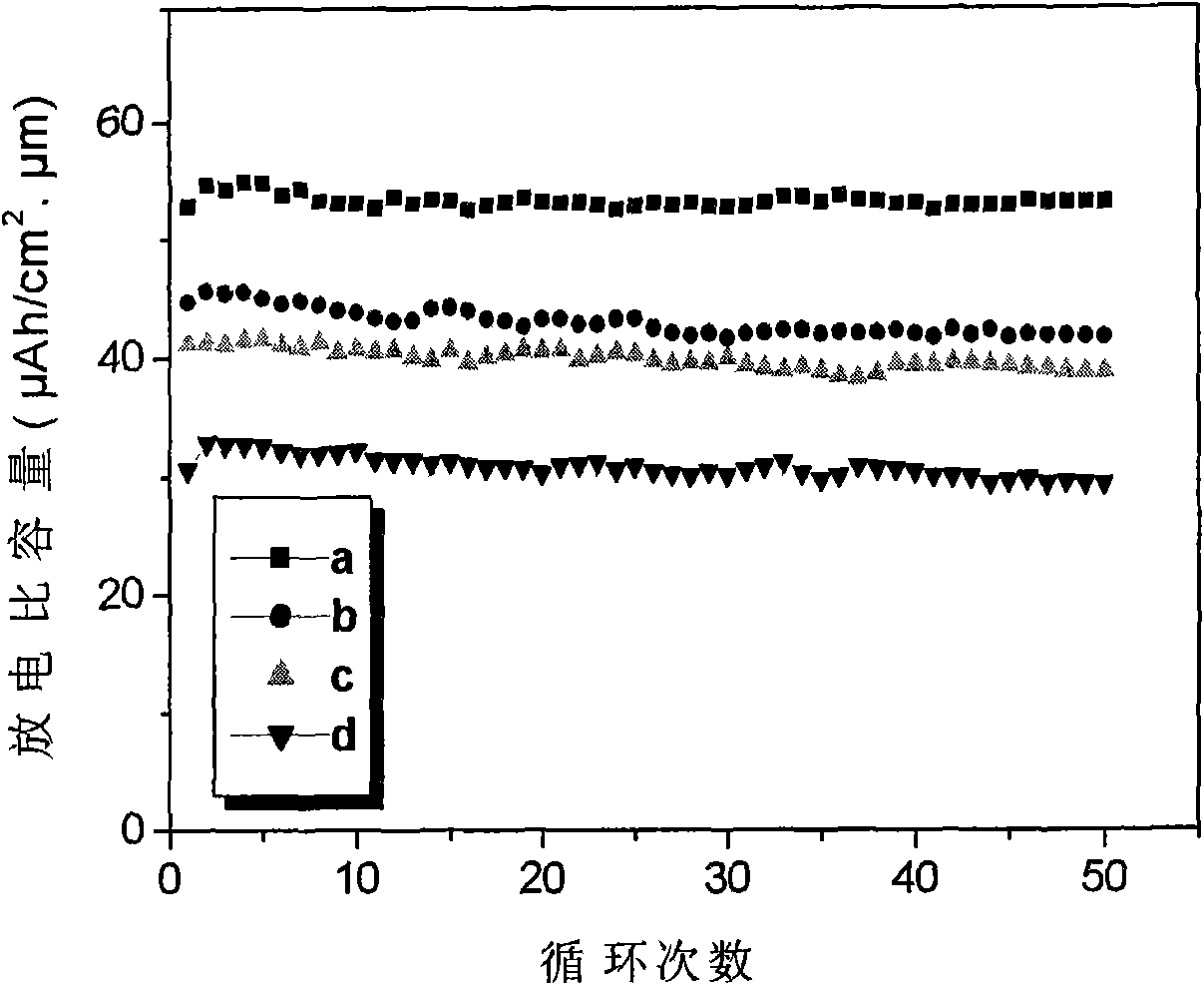

A lithium-ion battery and nano-silver particle technology, which is applied in the field of electrochemistry, can solve the problems of low electronic conductivity performance, poor high current charge and discharge performance, etc., and achieve the effects of improving electronic conductivity, dense film and excellent cycle performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

[0016] Weigh a certain amount of lithium acetylacetonate and isopropyl titanate, dissolve them in the organic solvent butanol, stir the mixture evenly to obtain liquid A; then weigh a certain amount of deionized water, glacial acetic acid and silver nitrate powder, mix Stir constantly afterward, until silver nitrate and complexing agent are all dissolved, obtain B liquid, wherein isopropyl titanate: lithium acetylacetonate: propanol: deionized water: glacial acetic acid: silver nitrate (molar ratio)=1: 0.9: 15:60:1.9:0.0103; Mix liquid A and liquid B and continue to stir until the color-stable precursor sol is obtained, and then age the sol at room temperature for use; when uniforming the film, drop the solution onto the substrate. First run at 1000rpm for 5 seconds, then run at 2000rpm for 50 seconds. After each glue leveling, the film was thermally decomposed at 200°C for 300 seconds, after 15 times of glue leveling, the sample was placed in H 2 Annealing treatment was carr...

example 2

[0019] Weigh a certain amount of n-butyl titanate and lithium acetylacetonate, dissolve them in the organic solvent butanol, stir the mixture evenly to obtain liquid A; then weigh a certain amount of deionized water, glacial acetic acid and silver nitrate powder, mix After that, stir continuously until silver nitrate and complexing agent are all dissolved to obtain liquid B, wherein n-butyl titanate: lithium acetylacetonate: butanol: deionized water: polyvinylpyrrolidone (PVP): silver nitrate (molar ratio) = 1: 0.9: 30: 40: 1.9: 0.032; Mix liquid A and liquid B and continue to stir until the precursor sol with stable color is obtained, then age the sol at room temperature for use; onto the substrate. First run at 300rpm for 20 seconds, then at 3000rpm for 40 seconds. After each glue leveling, the film was thermally decomposed at 280°C for 200 seconds, and after 40 times of glue leveling, the sample was placed in H 2 Annealing treatment was carried out in the atmosphere for 6...

example 3

[0022] Weigh a certain amount of n-butyl titanate and lithium acetate, dissolve them in the organic solvent isopropanol, stir the mixture evenly to obtain liquid A; then weigh a certain amount of deionized water, glacial acetic acid and silver nitrate powder, mix Stir constantly afterward, until silver nitrate and complexing agent are all dissolved, obtain B liquid, wherein n-butyl titanate: lithium acetate: ethylene glycol methyl ether: deionized water: glacial acetic acid: silver nitrate (molar ratio)=1: 0.9∶60∶15∶1.9∶0.114; Mix liquid A and liquid B and continue to stir until the precursor sol with stable color is obtained, then age the sol at room temperature for use; when uniforming the film, drop the solution onto the substrate superior. First run at 500rpm for 15 seconds, then run at 5000rpm for 20 seconds. After each gluing, the film was thermally decomposed at 400°C for 60 seconds. After 30 times of gluing, the sample was placed in H 2 Annealing treatment was carrie...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com