A kind of nano-copper particle dispersed cobalt oxide composite optical film and its preparation method

A composite film, cobalt oxide technology, applied in optics, nonlinear optics, instruments, etc., to achieve the effects of simple operation, low price, and short preparation period

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

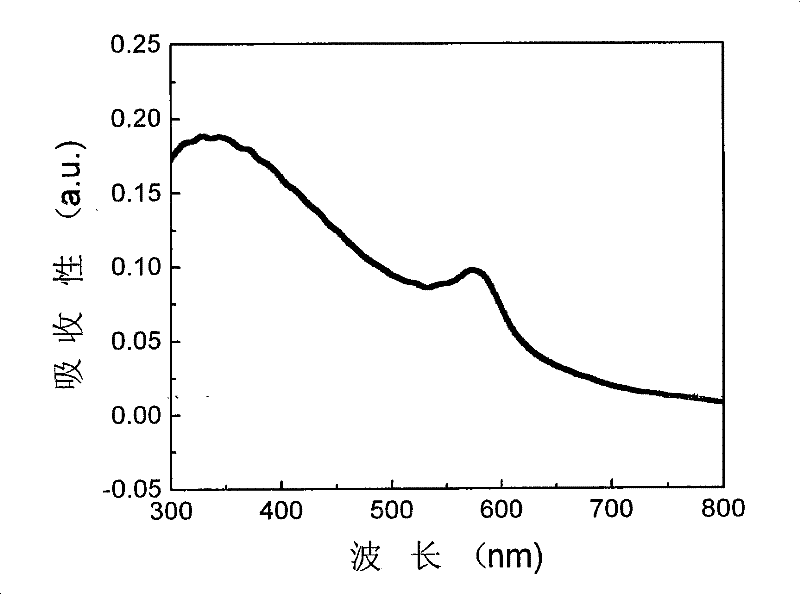

[0016] Dissolve 0.29397g (0.001mol) cobalt nitrate and 0.2428g (0.001mol) copper nitrate in 10ml ethylene glycol monomethyl ether respectively, and stir for 1 hour to obtain 0.1mol / L pink CoO precursor solution and blue copper nitrate solution , after aging for 2 hours, mix 1ml of CoO precursor solution and 9ml of copper nitrate solution and stir for 6 hours to obtain Cu / CoO precursor solution; Minutes, then drop the solution onto the substrate, first run at 300rpm for 20 seconds, then run at 1000rpm for 50 seconds. After homogenizing the glue, thermally decompose the film at 100°C for 2 seconds, shake the glue once, and finally place the sample in H 2 (5%)-Ar 2 (95%) annealed in a mixed atmosphere furnace for 10 minutes, the heating rate was 7°C / min, and the annealing temperature was 600°C, the prepared Cu 0.9 / (CoO) 0.1 Composite film.

Embodiment 2

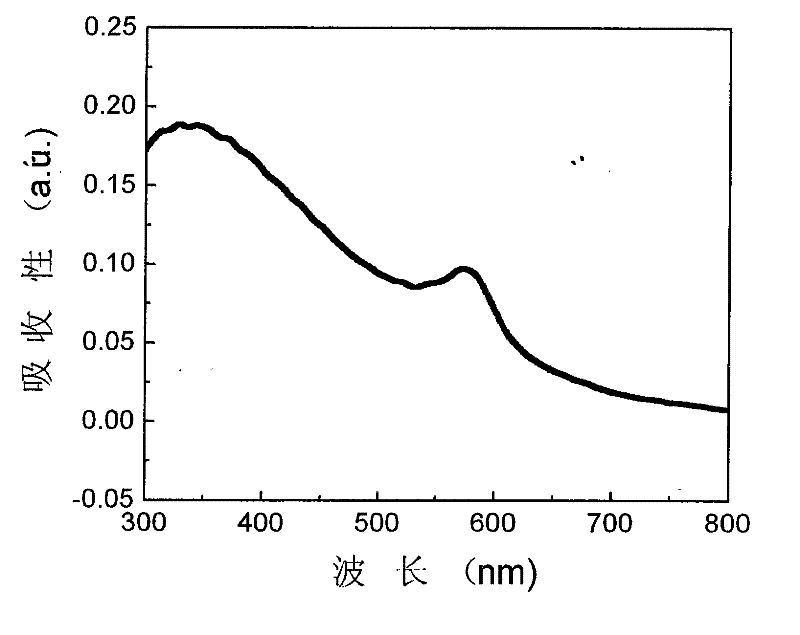

[0018] Dissolve 0.58794g (0.002mol) cobalt nitrate and 0.4856g (0.002mol) copper nitrate in 10ml ethylene glycol monomethyl ether respectively, and stir for 3 hours to obtain 0.2mol / L pink CoO precursor solution and blue copper nitrate solution , after aging for 4 hours, mix 3ml of CoO precursor solution and 7ml of copper nitrate solution and stir for 4 hours to obtain Cu / CoO precursor solution; Minutes, then drop the solution onto the substrate, first run at 500rpm for 15 seconds, then run at 1500rpm for 40 seconds. After homogenizing the glue, thermally decompose the film at 200°C for 10 seconds, repeat this 5 times, and finally place the sample in H 2 (10%)-Ar 2 (90%) annealed in a mixed atmosphere furnace for 30 minutes, the heating rate was 7°C / min, and the annealing temperature was 550°C, the prepared Cu 0.7 / (CoO) 0.3 Composite film.

Embodiment 3

[0020] Dissolve 0.88201g (0.003mol) cobalt nitrate and 0.7284g (0.003mol) copper nitrate in 10ml ethylene glycol monomethyl ether respectively, stir for 5 hours to obtain 0.3mol / L pink CoO precursor solution and blue copper nitrate solution , after aging for 5 hours, mix 5ml of CoO precursor solution and 5ml of copper nitrate solution and stir for 4 hours to obtain Cu / CoO precursor solution; Minutes, then drop the solution onto the substrate, first run at 700rpm for 15 seconds, then run at 2000rpm for 30 seconds. After homogenizing the glue, thermally decompose the film at 300°C for 100 seconds, repeat this 20 times, and finally place the sample in H 2 (30%)-Ar 2 (70%) annealed in a mixed atmosphere furnace for 120 minutes, the heating rate was 7°C / min, and the annealing temperature was 500°C to prepare Ag 0.5 / (CoO) 0.5 Composite film.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thermal decomposition temperature | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com