Method for preparing nano silver particle dispersion silicon dioxide optical film

A technology of nano silver particles and silicon dioxide, which is applied in optics, optical components, nonlinear optics, etc., can solve the problem of no absorption peaks being observed, and achieve the effects of excellent nonlinear optical characteristics, low reaction temperature, and energy saving.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

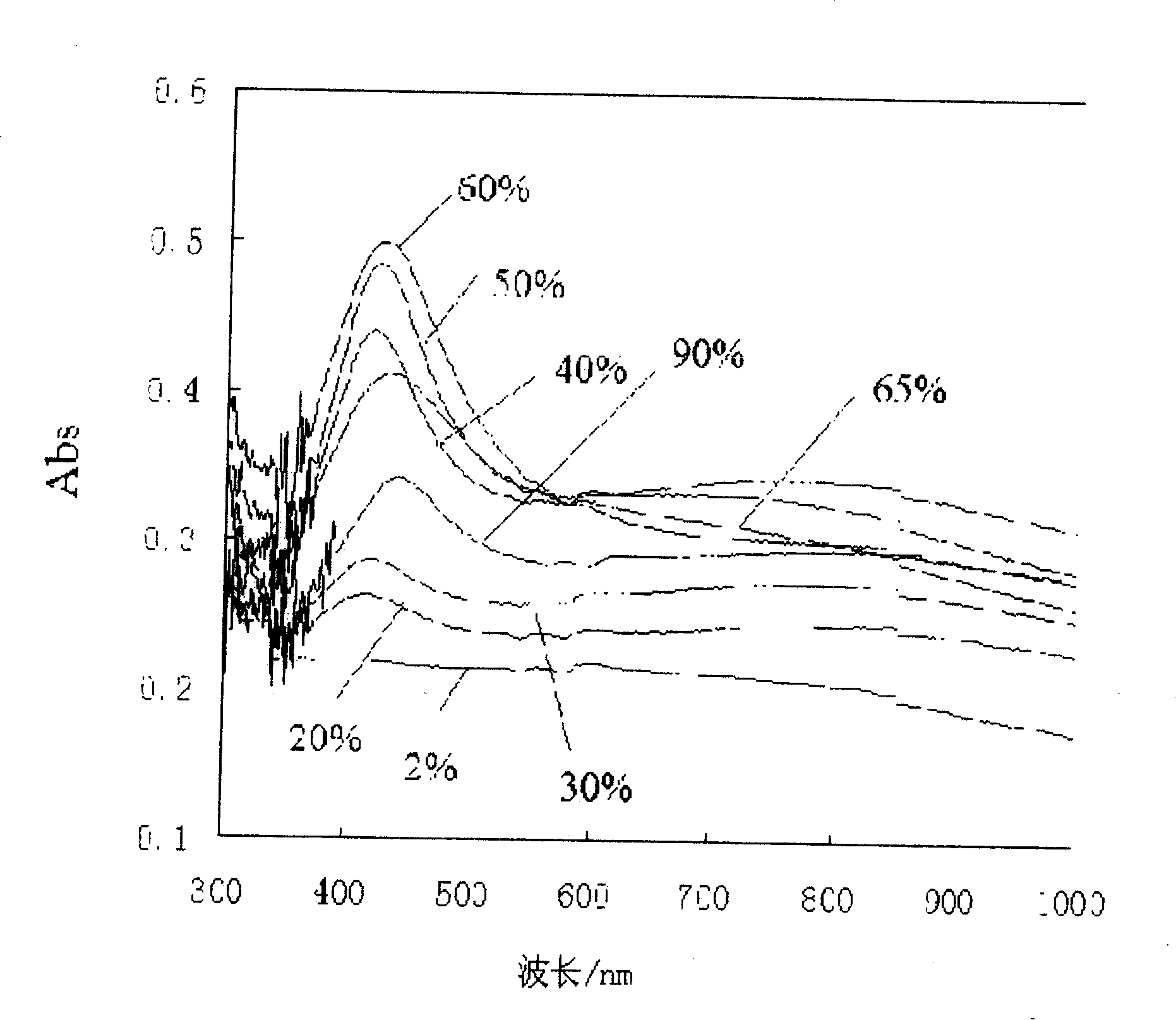

Embodiment 1

[0016] Dissolve 2ml TEOS in 1ml H 2 O and 8mlCH 3 OCH 2 CH 2 OH solvent, and stir in an ultrasonic cleaner for 1 minute, add 1 drop of concentrated nitric acid, and stir for 1 hour for hydrolysis and polycondensation, add 0.017g AgNO 3 , and stirred again for 0.5 h to obtain Ag / SiO 2 Precursor solution; when uniform film, drop the solution onto the substrate. First run at 200rpm for 5 seconds, then run at 1000rpm for 10 seconds. Every time the glue is uniformed, the film is thermally decomposed at 100°C for 2 seconds. After the glue is glued once, the sample is placed in a rapid heat treatment furnace for annealing treatment for 0.5 minutes. The annealing temperature is 600°C, and the Ag content is 2wt% Ag. / SiO 2 Composite film.

Embodiment 2

[0018] Dissolve 0.23ml TEOS in 2ml H 2 O and 8mlCH 3 OCH 2 CH 2 OH solvent, and stirred in an ultrasonic cleaner for 10 minutes, added 10 drops of concentrated nitric acid, and stirred for 4 hours for hydrolysis and polycondensation, added 0.0256g AgNO 3 , and stirred again for 2 hours, the Ag / SiO 2 Precursor solution; when uniforming the film, drop the solution onto the substrate, first run at 300rpm for 6 seconds, then run at 2000rpm for 30 seconds. Every time the glue is glued, the film is thermally decomposed at 150°C for 200 seconds. After being glued 5 times, the sample is placed in a rapid heat treatment furnace for annealing treatment for 30 minutes. The annealing temperature is 600°C, and the Ag content is 30wt% Ag. / SiO 2 Composite film.

Embodiment 3

[0020] Dissolve 2.5ml TEOS in 0.5ml H 2 O and 9.5ml CH 3 OCH 2 CH 2 OH solvent, and stirred in an ultrasonic cleaner for 15 minutes, added 15 drops of concentrated nitric acid, and stirred for 6 hours for hydrolysis and polycondensation, added 1.004g AgNO 3 , and stirred again for 2.5 hours to obtain Ag / SiO 2 Precursor solution; when uniforming the film, drop the solution onto the substrate, first run at 500rpm for 6 seconds, then run at 4000rpm for 40 seconds. Every time the glue is uniformed, the film is thermally decomposed at 150°C for 300 seconds. After 50 times of glueing, the sample is placed in a rapid heat treatment furnace for annealing treatment for 30 minutes. The annealing temperature is 300°C, and the Ag content is 60wt% Ag. / SiO 2 Composite film.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com