Preparation method of nano-silver particle dispersed Li4Ti5O12 thin film lithium ion battery negative electrode

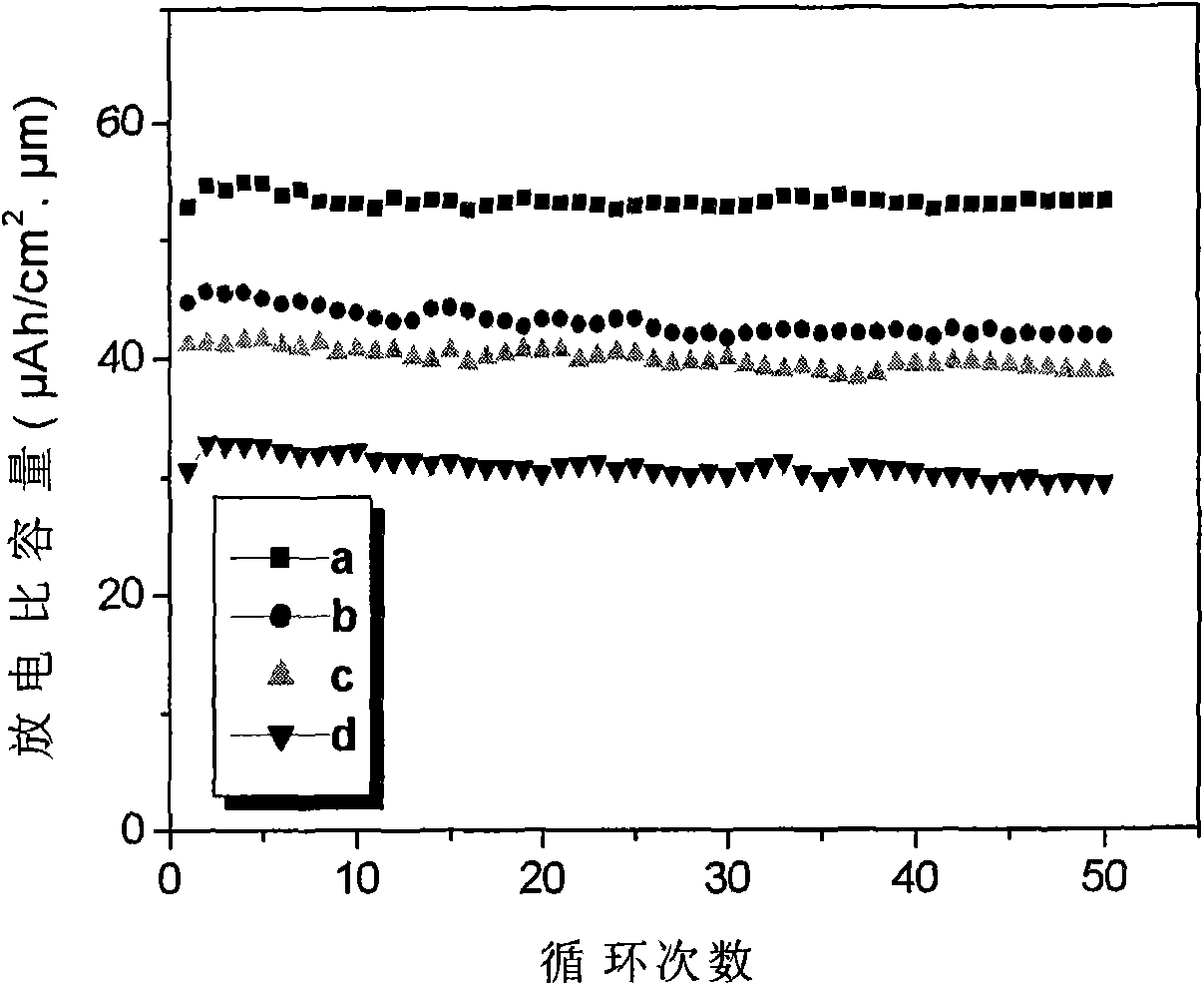

A technology of nano-silver particles and lithium-ion batteries, which is applied in the field of electrochemistry, can solve the problems of low electronic conductivity and poor high-current charge and discharge performance, and achieve improved electronic conductivity, dense film, and improved discharge area specific capacity and The effect of cycle performance

Inactive Publication Date: 2011-01-05

大连德润达实业有限公司

View PDF0 Cites 0 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

But Li4Ti5O12 is an insulator material, the electronic conductivity is very low, and the high current charge and discharge performance is very poor.

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

example 1

example 2

example 3

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

The invention discloses a preparation method of an all solid-state film lithium ion battery negative electrode-a nano-silver particle dispersed Li4Ti5O12 negative electrode thin film, which belongs to the technical field of electrochemistry. The process is as follows: material preparation: dissolving compounds of titanium and the compounds of lithium in an organic solvent for obtaining solution Aand mixing water, complexing agent and silver nitrate for obtaining solution B; preparation of precursor solution as follows: stirring and mixing the solution A and the solution B to a stable sol; and the preparation of the thin film: preparing a gel thin film on a substrate through the sol-gel method, carrying out preheating decomposition at 200-400 DEG C, annealing in an H2 atmosphere at 600-800 DEG C and further preparing the Ag / Li4Ti5O12 thin film. The thin film provided by the invention has the advantages of controllable stoichiometric composition, simple preparation method, process and equipment and easy preparation of the negative electrode thin film with large area. Compared with the traditional Li4Ti5O12 thin film negative electrode, the lithium ion battery negative electrode of the invention has high area specific capacity and excellent cycle performance in case of high multiplying power discharge.

Description

A kind of nano-silver particle dispersed Li4Ti5O12 thin film lithium-ion battery negative electrode preparation method technical field The invention discloses a method for preparing an Ag / Li4Ti5O12 thin film. The prepared thin film can be used as a negative electrode material in an all-solid thin film lithium ion battery, and belongs to the technical field of electrochemistry. Background technique Thin-film lithium battery is a kind of secondary battery with wide application prospects, which has the advantages of high discharge voltage, good charge and discharge performance, and high mass specific energy density. At present, research on thin-film lithium batteries has become a hot topic abroad, but there are not many researches on thin-film lithium batteries in China. In recent years, although some all-solid-state thin-film batteries have gradually appeared, their performance still needs to be further improved. The current research mainly focuses on the positive electrode...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Patents(China)

IPC IPC(8): H01M4/04H01M4/62

CPCY02E60/12Y02E60/10

Inventor 胡晨卢祥军汪浩潘山存

Owner 大连德润达实业有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com