Preparation method of ferric oxide/carbon nanotube lithium ion battery anode material

A lithium-ion battery, ferric oxide technology, applied in battery electrodes, circuits, electrical components, etc., can solve the problem of not being able to provide the conductive volume effect of iron oxide, difficult to obtain rate performance and cycle performance, and unable to achieve large-scale production. and other problems, to achieve the effect of improving cycle performance and stability, good rate performance and cycle performance, and electrical conductivity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] (1) Weigh 25g of ethanol as a carbon source and 0.25g of ferrocene as a catalyst, and add 0.2g of thiophene as a promotor, mix and sonicate for 30min; obtain a uniform precursor solution; wherein carbon source ethanol and catalyst ferrocene The mass ratio of iron is 100:1;

[0027] (2) A vertical furnace is used as the reactor. The reactor is heated to 1100°C under the protection of argon and then kept warm. The carrier gas is replaced by argon with hydrogen (the gas flow rate is 600 sccm), and then the prepared precursor solution is 8mL h -1 The rate is injected into the reactor;

[0028] (3) After the reaction starts, when the cylindrical composite film is formed at the tail end of the reactor, it is drawn to the rotating shaft, thereby obtaining a uniform and continuous composite film;

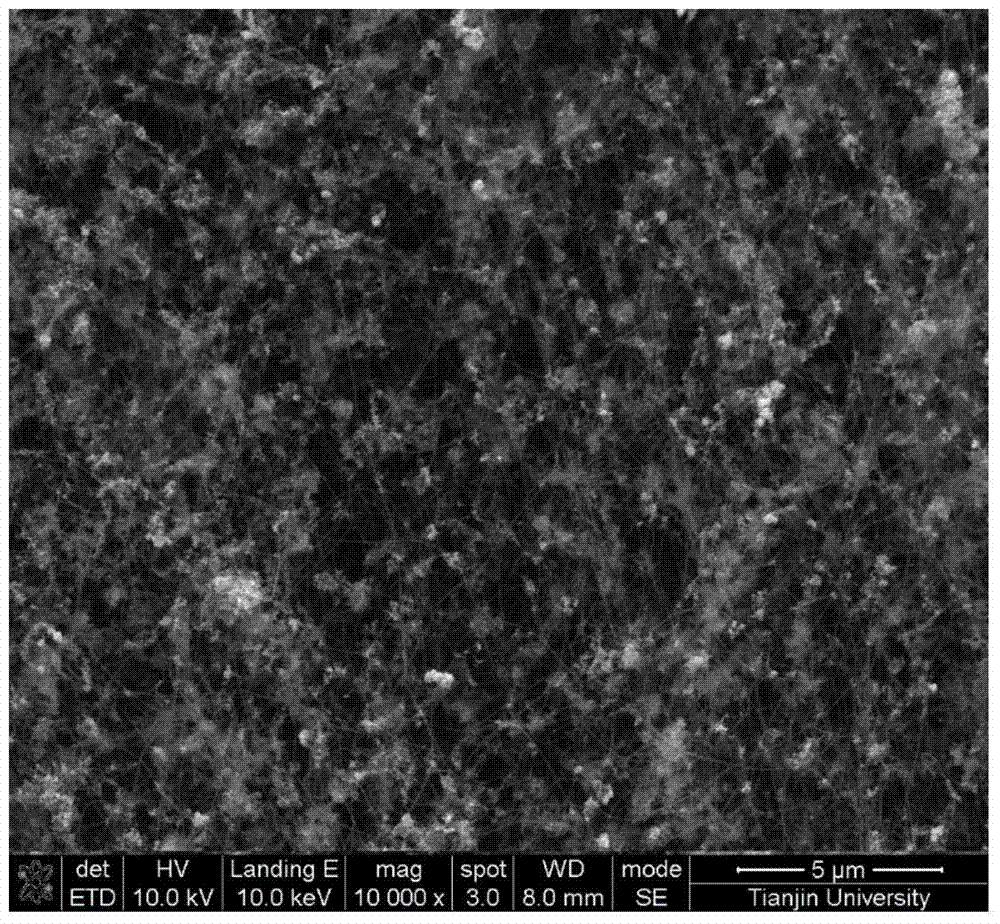

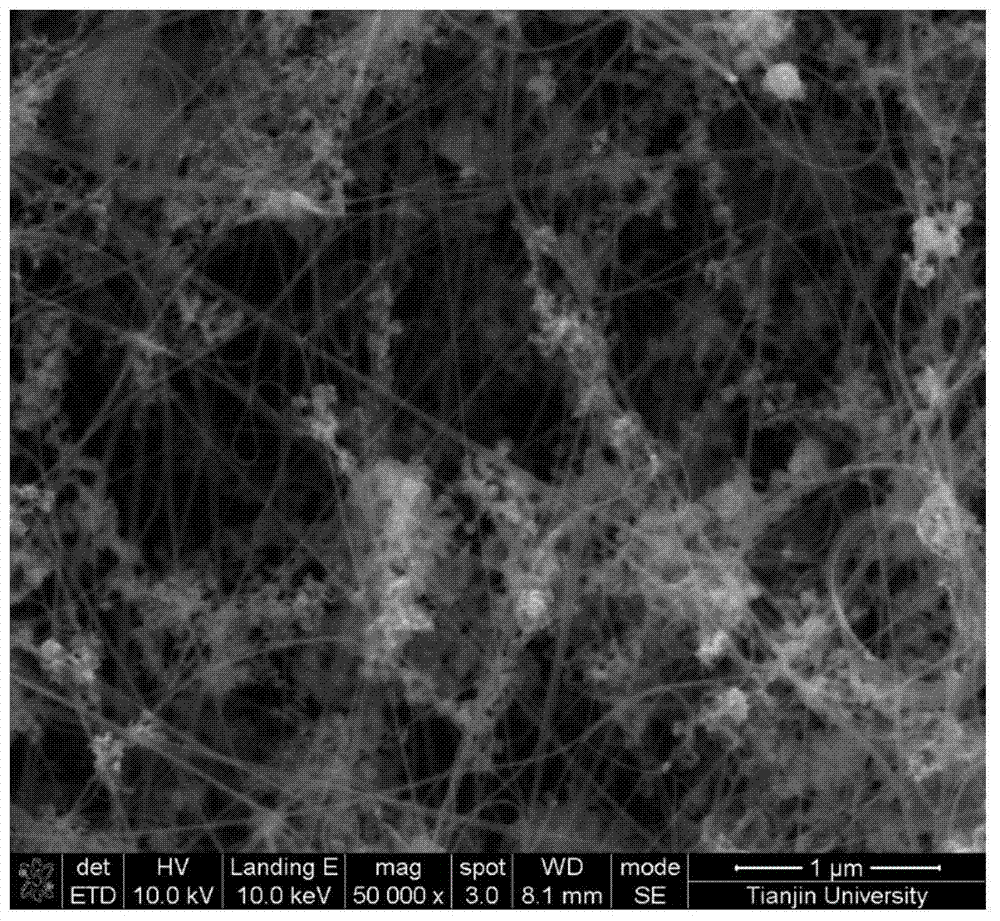

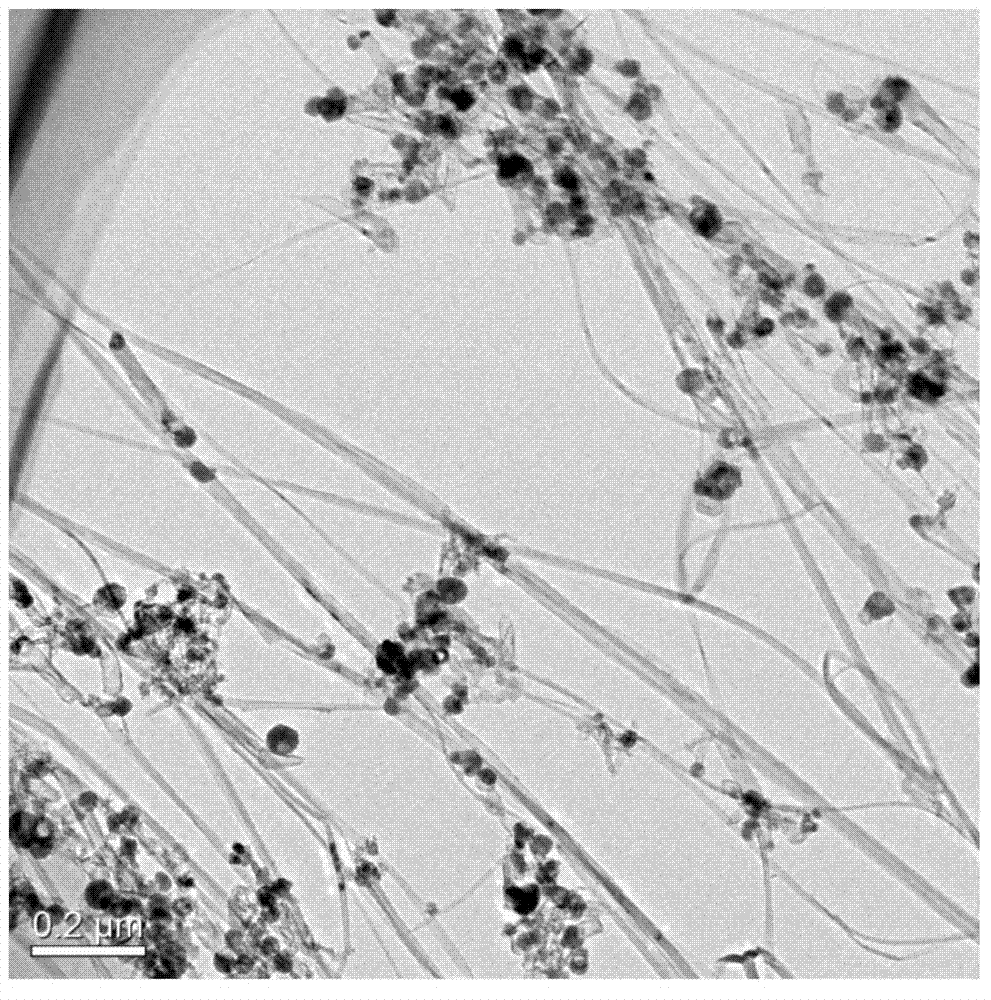

[0029] (4) After the reaction, the collected composite film was heat-treated at 500°C for 2 hours in air to obtain Fe 2 o 3 / Carbon nanotube composite thin film lithium ion batt...

Embodiment 2

[0032] (1) Take by weighing 25g ethanol as carbon source and 0.5 ferrocene as catalyst, and add 0.2g of thiophene as promotor, after mixing, ultrasonic 30min; Obtain uniform precursor solution; wherein carbon source ethanol and catalyst ferrocene The mass ratio is 50:1;

[0033] (2) A vertical furnace is used as a reactor, and the reactor is heated to 1100° C. under the protection of argon and then kept warm. Replace the carrier gas argon with hydrogen and argon mixed gas (gas flow rate is 800sccm), and prepare the precursor solution with 8mL h -1 rate into the reactor.

[0034] (3) After the reaction starts, when a cylindrical composite film is formed at the end of the reactor, it is drawn to the rotating shaft to obtain a uniform and continuous composite film;

[0035] (4) After the reaction, the collected composite film was heat-treated at 500°C for 2 hours in air to obtain Fe 2 o 3 / Carbon nanotube composite thin film lithium ion battery anode material.

[0036] Unde...

Embodiment 3

[0038] (1) Weigh 25g of toluene as a carbon source and 0.5g of ferrocene as a catalyst, and add 0.2g of thiophene as a promotor, mix and sonicate for 30min; obtain a uniform precursor solution; wherein the carbon source and catalyst ferrocene The mass ratio is 50:1;

[0039] (2) A vertical furnace is used as a reactor, and the reactor is heated to 1100° C. under the protection of argon and then kept warm. Replace the carrier gas argon with hydrogen (gas flow rate is 600sccm), and prepare the precursor solution with 8mL h -1 rate into the reactor.

[0040] (3) After the reaction starts, when a cylindrical composite film is formed at the end of the reactor, it is drawn to the rotating shaft to obtain a uniform and continuous composite film;

[0041] (4) After the reaction, the collected composite film was heat-treated at 500°C for 2 hours in air to obtain Fe 2 o 3 / Carbon nanotube composite thin film lithium ion battery anode material.

[0042] Fe obtained under this condi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Charge and discharge capacity | aaaaa | aaaaa |

| Charge and discharge capacity | aaaaa | aaaaa |

| Charge and discharge capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com