Preparation method of film lithium ion battery

A lithium-ion battery and thin-film technology, which is used in the manufacture of primary battery equipment, electrolyte battery manufacturing, and secondary batteries, etc., can solve the problem that metal materials are easily corroded, the quality of thin-film lithium-ion batteries is high, and the service life of thin-film lithium-ion batteries is affected. and other problems, to achieve the effect of high energy density, not easy to damage, and long service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The thin-film lithium-ion battery provided by the present invention and its preparation method will be further described in detail below with reference to the accompanying drawings and specific examples.

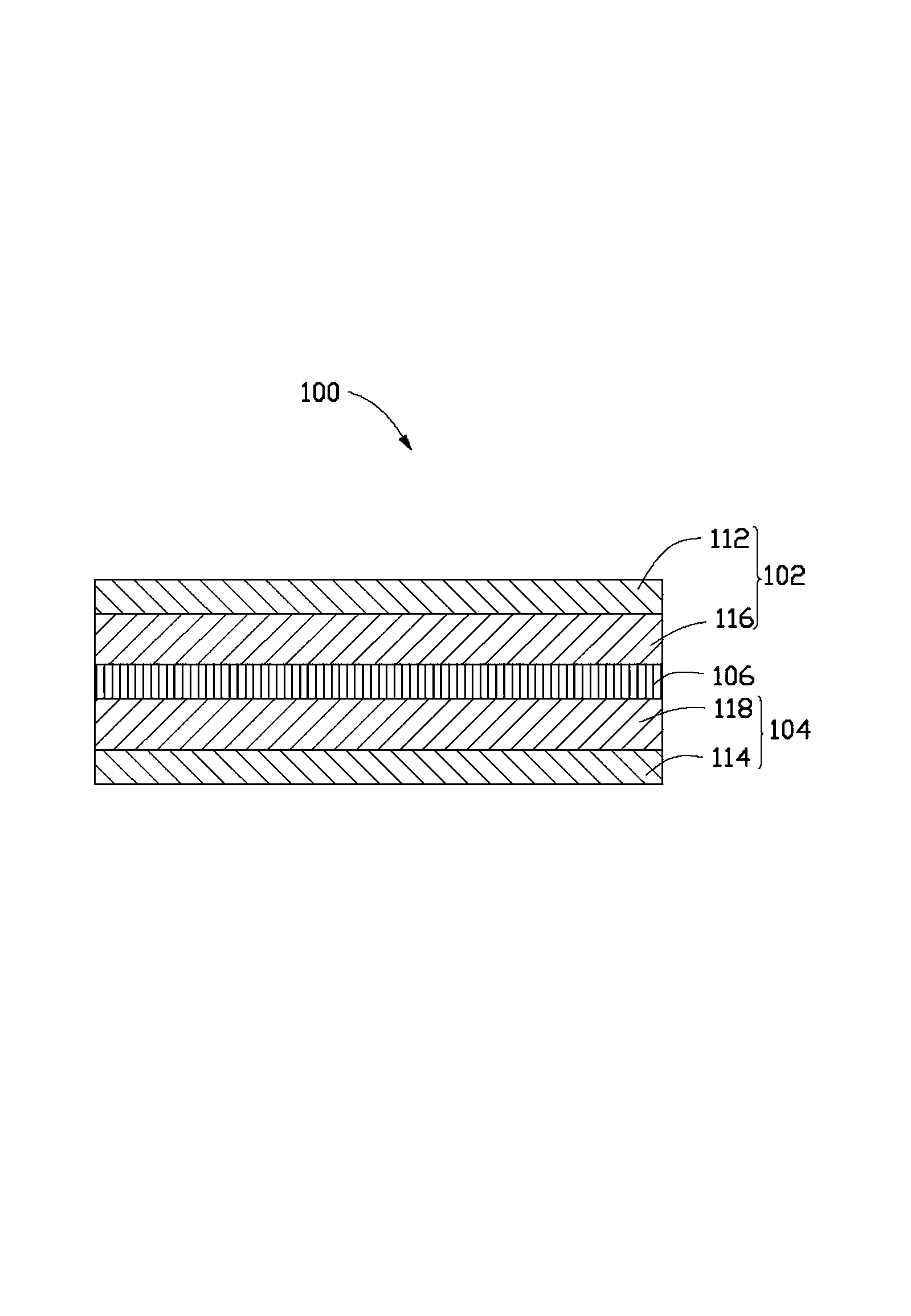

[0017] see figure 1 , The first embodiment of the present invention provides a thin film lithium ion battery 100, the thin film lithium ion battery 100 includes a positive electrode sheet 102, a negative electrode sheet 104, a solid electrolyte film 106 and an external packaging structure (not shown). The external packaging structure encapsulates the positive electrode sheet 102, the negative electrode sheet 104 and the solid electrolyte film 106 therebetween. The positive electrode sheet 102 and the negative electrode sheet 104 are stacked and separated from each other by a solid electrolyte film 106 . The positive electrode sheet 102 and the negative electrode sheet 104 are respectively located on both sides of the solid electrolyte film 106 and bonded to the solid...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| electrical conductivity | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com