P-type silicon microchannel based surface uniform nano modification method

A technology with a uniform surface and silicon microchannels, applied in the fields of nanotechnology, nanotechnology, nanotechnology, etc. for materials and surface science, can solve the problems of irregular shape, large particle size, complex process, etc., and achieve low production costs. , The effect of high particle purity and good dispersibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0041] 1) Configure electroless nickel plating solution, the composition of the solution includes 2mol / L NiCl 2 ·6H 2 O, 2mol / L Na 2 HPO 4 ·7H 2 O, 2mol / L NH 4 Cl.

[0042] 2) Drop the solution prepared in step 1) into a certain amount of ammonia water to adjust the pH value of the solution so that the pH value is 9.

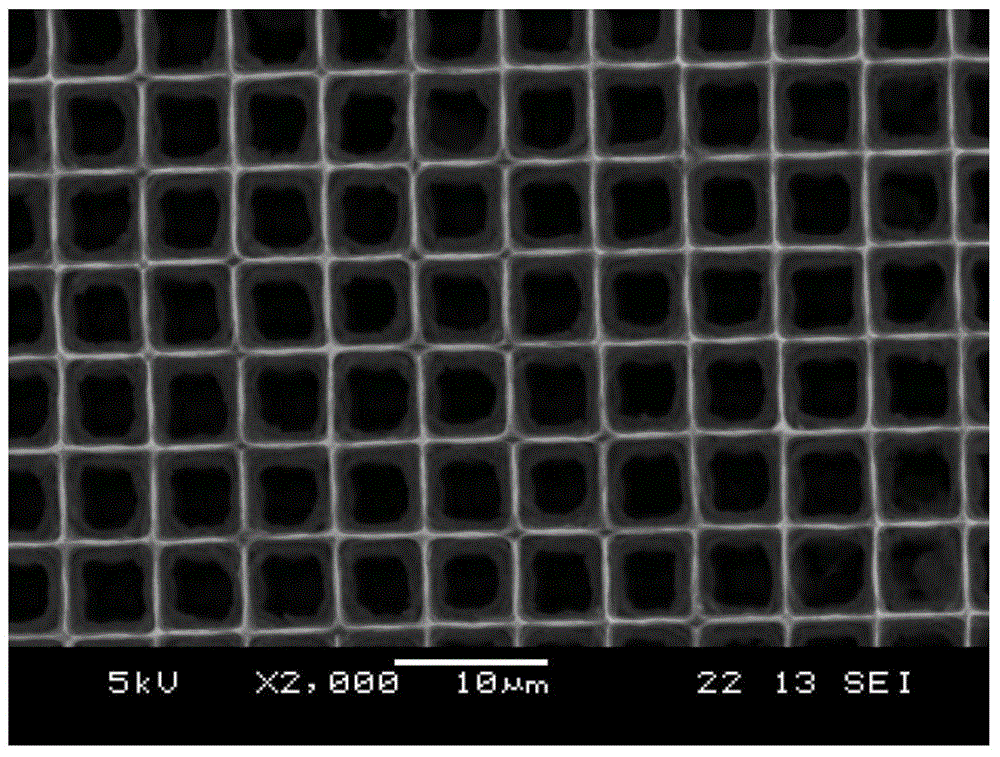

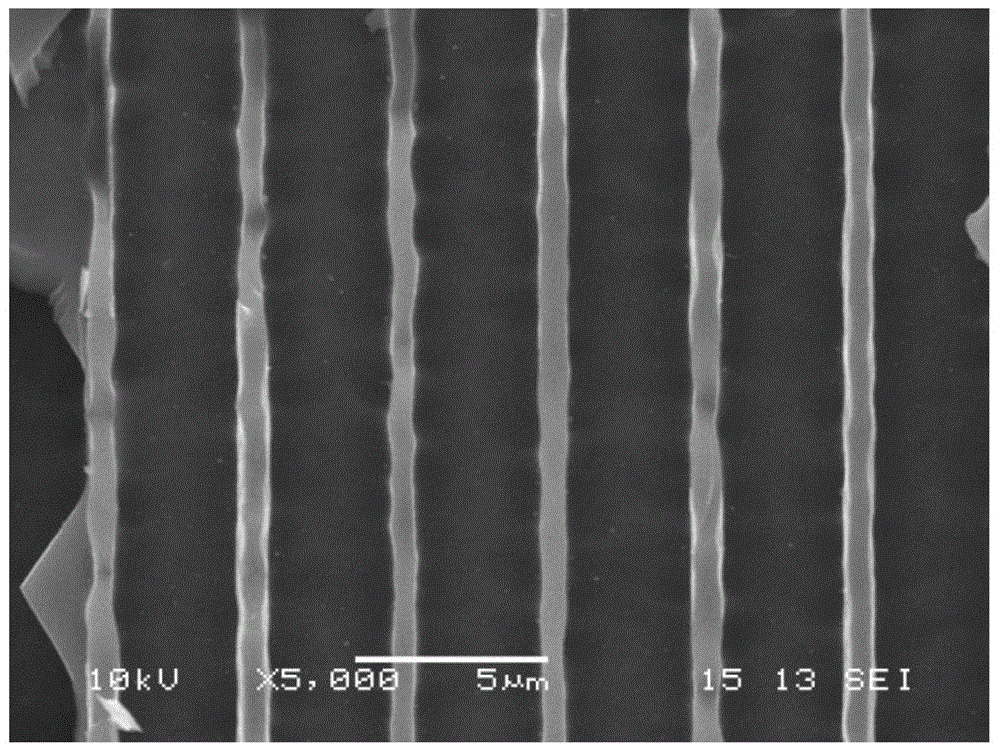

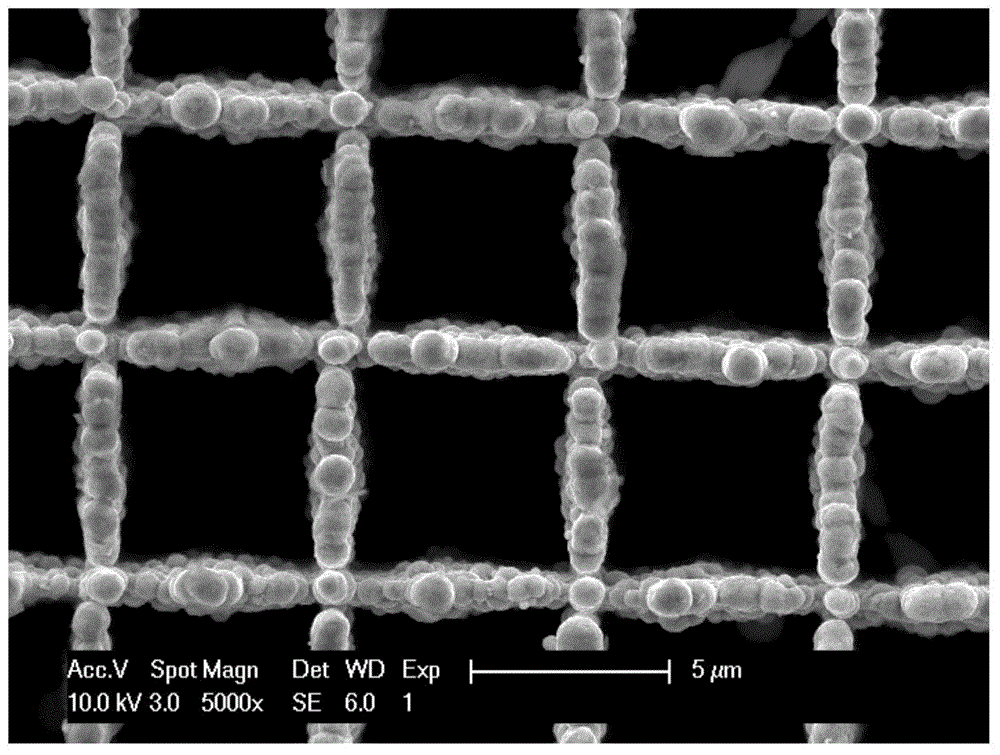

[0043] 3) Put the electroplating solution after adjusting the pH in step 2) into a water bath and heat it to 90°C, put the silicon microchannel plate cleaned in 1 into and keep it for 40 minutes. The surface morphology of the obtained sample is as Figure 2a , 2b ;by Figure 2a And it can be seen that nickel is uniformly covered on the surface of the microchannel; Figure 2b It can be seen that nickel is uniformly covered inside the microchannel.

[0044] 4) The sample of step 3) electrolessly deposited nickel is electrochemically deposited with a nickel layer to enhance the conductivity of the sample, and the deposition solution contains 2mol / L Ni(NO 3 ) 2 ·6H 2 Mixtu...

Embodiment 2

[0047] 1) Configure an electroless nickel plating solution, the composition of the solution includes 0.1mol / L NiCl 2 ·6H 2 O, 0.1mol / L Na 2 HPO 4 ·7H 2 O, 0.1mol / L NH 4 Cl.

[0048] 2) Drop the solution prepared in step 1) into a certain amount of ammonia water to adjust the pH value of the solution so that the pH value is 7.

[0049] 3) Put the electroplating solution whose pH value has been adjusted in step 2) into a water bath and heat it to 50°C, put the silicon microchannel plate cleaned in 1 into and keep it for 10 minutes. The surface morphology of the obtained sample is as Figure 2a , 2b ;by Figure 2a And it can be seen that nickel is uniformly covered on the surface of the microchannel; Figure 2b It can be seen that nickel is uniformly covered inside the microchannel.

[0050] 4) The sample of step 3) electrolessly deposited nickel is electrochemically deposited with a nickel layer to enhance the conductivity of the sample. The deposition solution contains 0.05mol / L Ni(NO...

Embodiment 3

[0053] 1) Configure an electroless nickel plating solution, the composition of the solution includes 1mol / L NiCl 2 ·6H 2 O, 1mol / L Na 2 HPO 4 ·7H 2 O, 1.5mol / L NH 4 Cl.

[0054] 2) Drop the solution prepared in step 1) into a certain amount of ammonia water to adjust the pH value of the solution to make its pH value 8.

[0055] 3) Put the electroplating solution whose pH value has been adjusted in step 2) into a water bath and heat it to 70°C, put the silicon microchannel plate cleaned in 1 into and keep it for 30 minutes. The surface morphology of the obtained sample is as Figure 2a , 2b ;by Figure 2a And it can be seen that nickel is uniformly covered on the surface of the microchannel; Figure 2b It can be seen that nickel is uniformly covered inside the microchannel.

[0056] 4) Electrochemically deposit a nickel layer on the sample of step 3) electrolessly deposited nickel to enhance the conductivity of the sample. The deposition solution is containing 1mol / L Ni(NO 3 ) 2 ·6H 2...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com