Patents

Literature

69 results about "Lithium molybdate" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Lithium molybdate (Li₂MoO₄) is a chemical compound. It is mainly used as an inhibitor in some types of industrial air conditioning.

Multifunctional concrete structure endurance protective agent, preparation and application method thereof

The invention discloses a multifunctional concrete structure endurance protective agent as well as the preparation and application method thereof. The protective agent provided by the invention contains the following ingredients of: an organic / inorganic composite fluorosilicone-acrylate copolymer, lithium silicate, sodium silicate, lithium molybdate, sodium tetraborate, sal glauberi, 1,2-aminoazophenylene, nanometer titanium dioxide, anhydrous ethanol and water. The protective agent can penetrate inside concrete, wherein a densification ingredient can minimize internal holes and cracks to raise the compactness of concrete, and a rust-resistant ingredient can penetrate into concrete and be adsorbed on the surface of steel bar so as to passivate and protect the steel bar; the low-surface energy silicon fluoride ingredient can be solidified to form a cured film on the surface of concrete so as to endow the protective agent with the hydrophobic performance; a nanometer ingredient can endow the cured film layer with properties of resisting ultraviolet and ageing and improving the organic polymer performance as well as the self-cleaning performance. In addition, hydroxy generated from the hydrolysis of siloxane group can perform a condensation reaction with hydroxy on the surface of concrete to produce chemical bond, so as to raise the anchoring strength between the film and concrete and improve the interface combination. The protective agent provided by the invention can be widely applied in various concrete structure engineering protections to raise the service life of concrete.

Owner:CENT SOUTH UNIV +1

Multifunctional preparation for controlling biological corrosion and blockage of oilfield production system

ActiveCN101875839AEliminate pollutionEliminate cloggingDrilling compositionDisinfectantSulfate-reducing bacteria

The invention relates to a multifunctional preparation for controlling biological corrosion and blockage of an oilfield production system. The contents of functional preparations in the treating water are as follows: 20 to 200 ppm of disinfectant: glutaraldehyde, acrolein, dodecyldimethylbenzyl ammonium chloride or dodecyldimethylbenzyl ammonium bromide, 10 to 100 ppm of inhibitor: sodium nitrateor sodium nitrite; and / or 10 to 20 ppm of sodium molybdate, sodium tungstate or lithium molybdate; 10 to 20 ppm of corrosion inhibitor: imidazoline quaternary ammonium; or / and 20 to 50 ppm of desulphurizing reagent: trihydroxymethyl nitromethane; or / and 10 to 20 ppm of penetrating agent: alkylpheol ethoxylates. The components undergo synergistic action so that the concentration of the single component is reduced obviously and reaches 25 to 90%, and the efficiency of killing the SRB (Sulfate Reducing Bacteria) reaches more than 90%.

Owner:PETROCHINA CO LTD

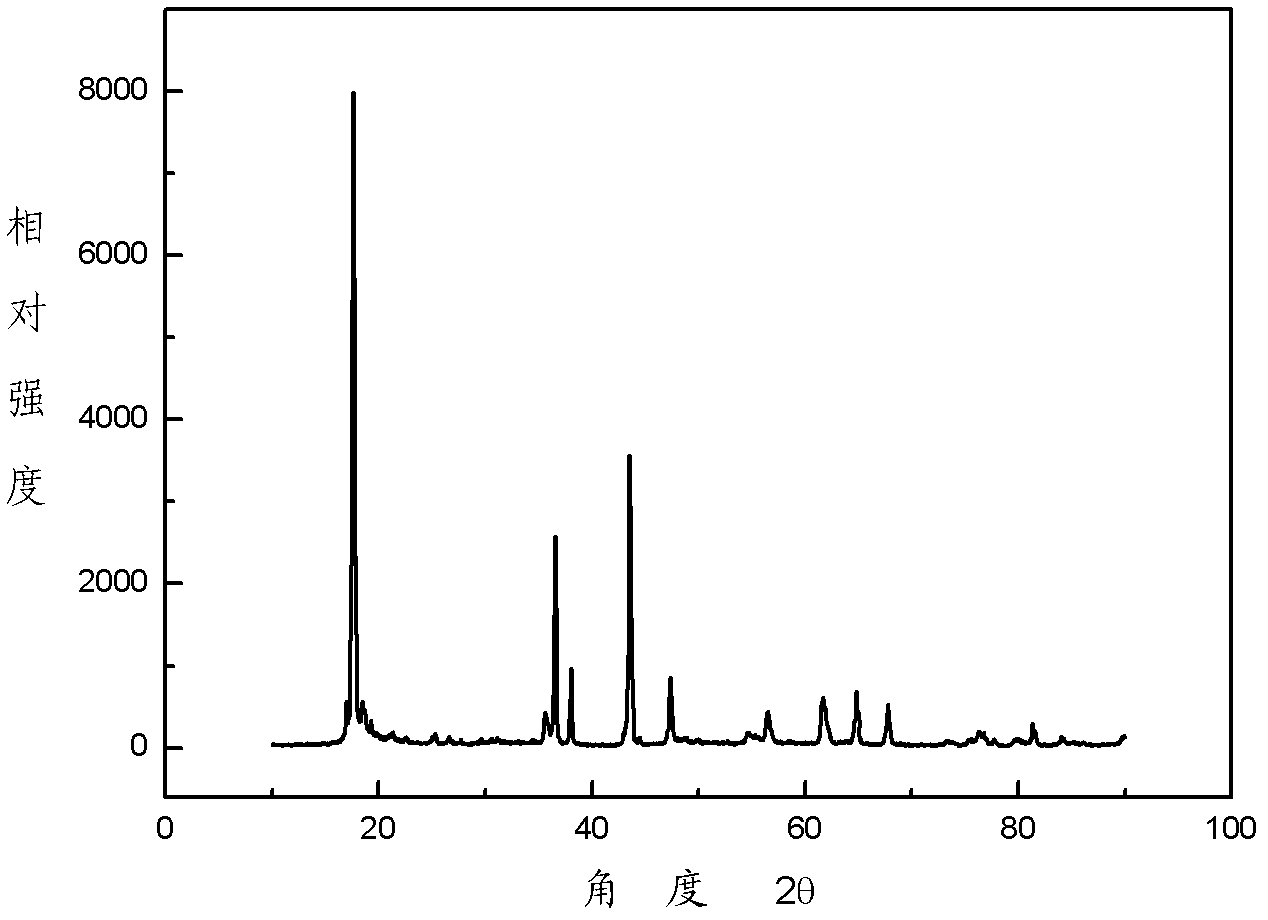

Lithium ion battery positive electrode material lithium-enriched doped lithium molybdate and preparation method thereof

InactiveCN102306779AInhibit side effectsImprove conductivityCell electrodesPower flowEconomic benefits

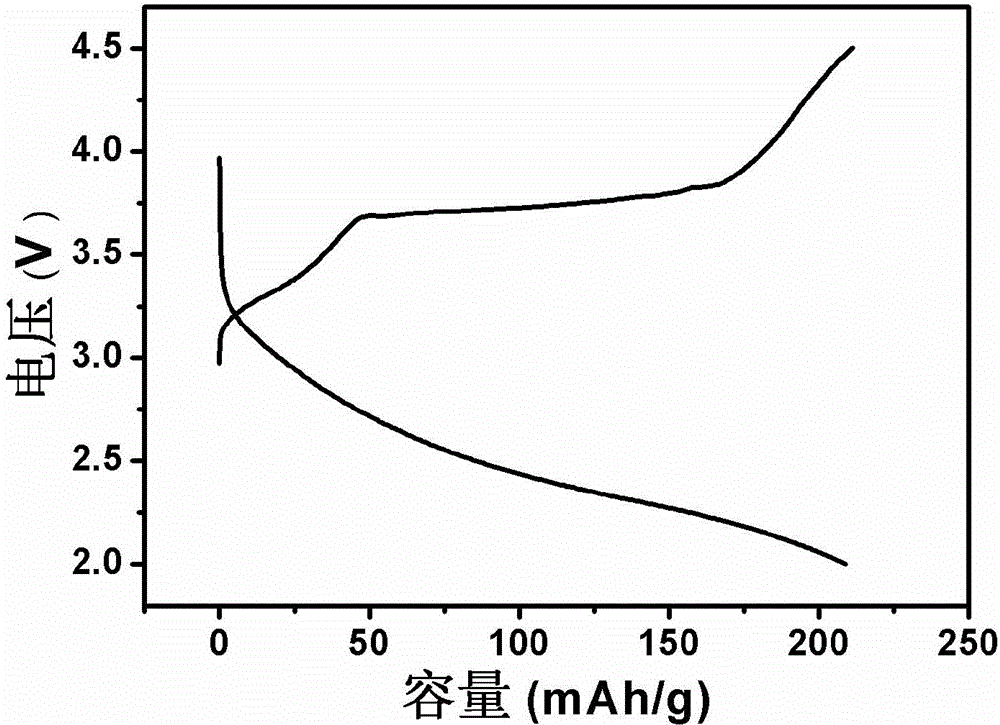

The invention discloses a positive electrode material lithium-enriched doped lithium molybdate of a lithium ion battery and a preparation method thereof. The chemical structural formula is Li2M1-xMoxO3; the lithium-enriched doped lithium molybdate has favorable electrochemical charge and discharge actions; the discharge capacity is 156mAh / g (the theoretical capacity is 85% of 169.8mAh / g) under the low-current charge and discharge condition (0.1C); the preparation method is simple and feasible, has low cost, has high specific capacity and excellent cycle reversible performance, and has obvious practical value and economic benefit.

Owner:SHANGHAI JIAO TONG UNIV

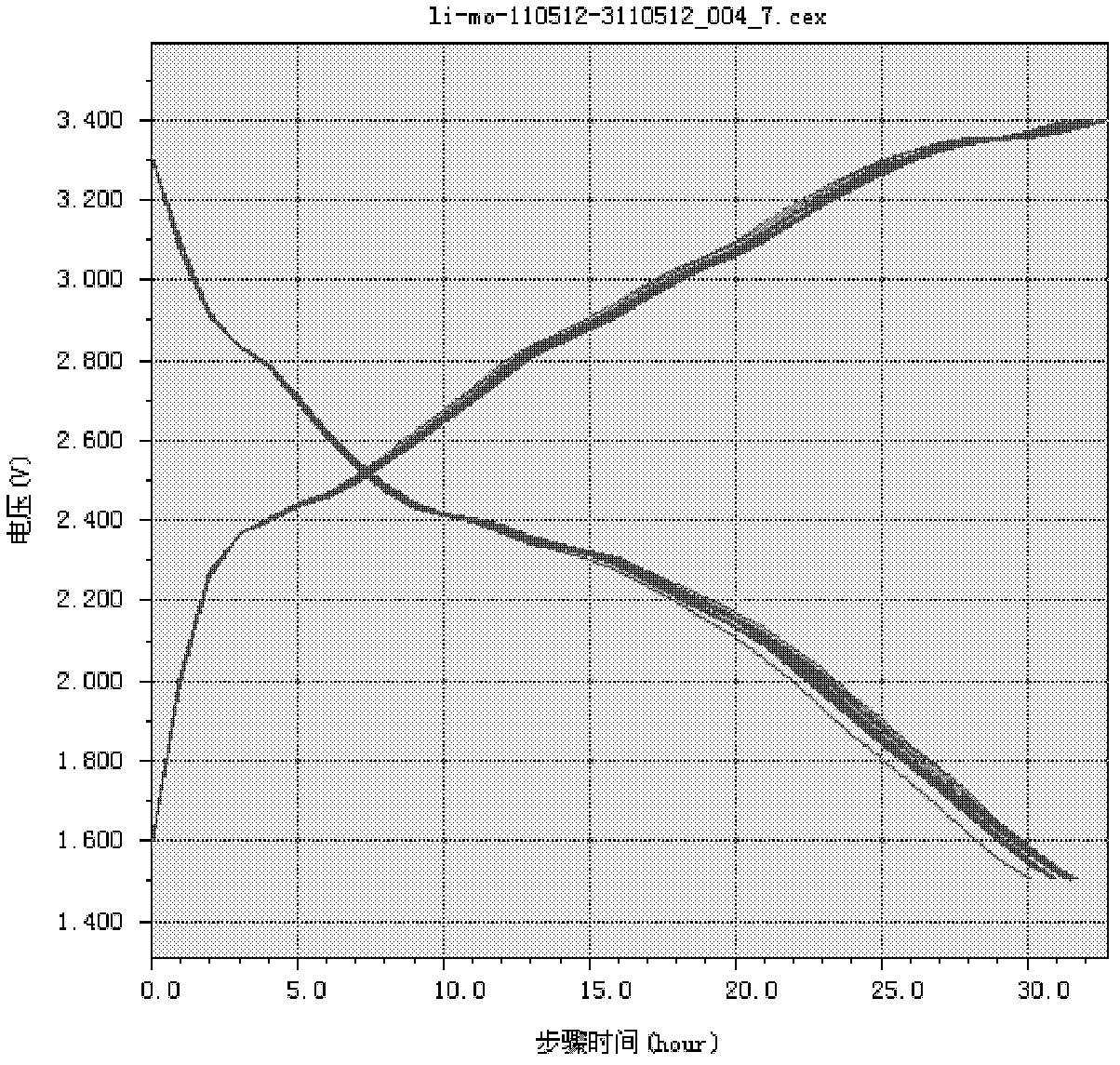

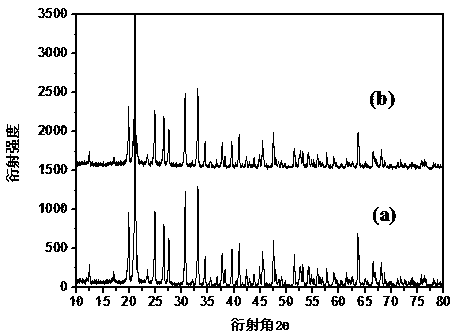

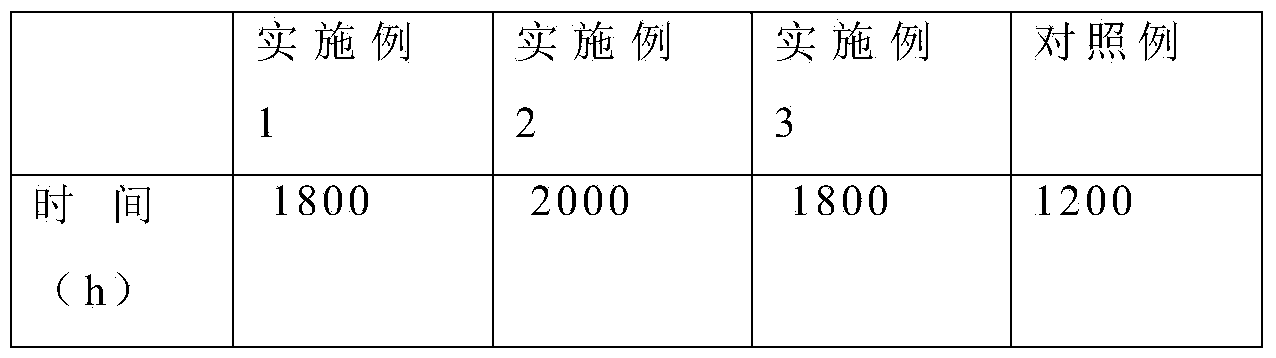

Lithium molybdate serving as secondary battery electrode material

InactiveCN104577088AImprove cycle performanceImprove securityCell electrodesSecondary cellsMetallurgyLithium molybdate

The invention discloses lithium molybdate serving as a secondary battery electrode material. In an execution mode, a chemical formula of the electrode material is Li (2-x)MoyMzO(3-u), wherein x is larger than or equal to minus 2 and smaller than or equal to 2, y is larger than 0 and smaller than or equal to 5, z is larger than or equal to 0 and smaller than or equal to 9, u is larger than or equal to minus 9 and smaller than or equal to 3, and M comprises one element selected from C, N, F, Na, Mg, Al, Si, P, S, Cl, K, Ca, Sc, Ti, V, Cr, Mn, Fe, Co, Ni, Cu, Zn, Ga, Ge, As, Se, Br, Rb, Sr, Y, Zr, Nb, Mo, Tc, Ru, Rh, Pd, Cd, In, Sn, Sb, Te, I, Cs, Ba, Ta, W, Re, Os, Ir, Pt, Au, Hg, Pb, Bi, Po, At, La, Ce, Pr, Nd, Pm, Sm, Eu, Gd, Tb, Dy, Ho, Er, Tm, Yb and Lu or combination of the elements. The electrode material is characterized by having very high specific capacity, excellent cycle performance, rate capability and safety.

Owner:INST OF PHYSICS - CHINESE ACAD OF SCI

Titanium composite, preparation method thereof and application thereof

ActiveCN101901905AImprove performanceEasy to preparePigmenting treatmentAlkali titanatesLithium chlorideHigh rate

Owner:BYD CO LTD

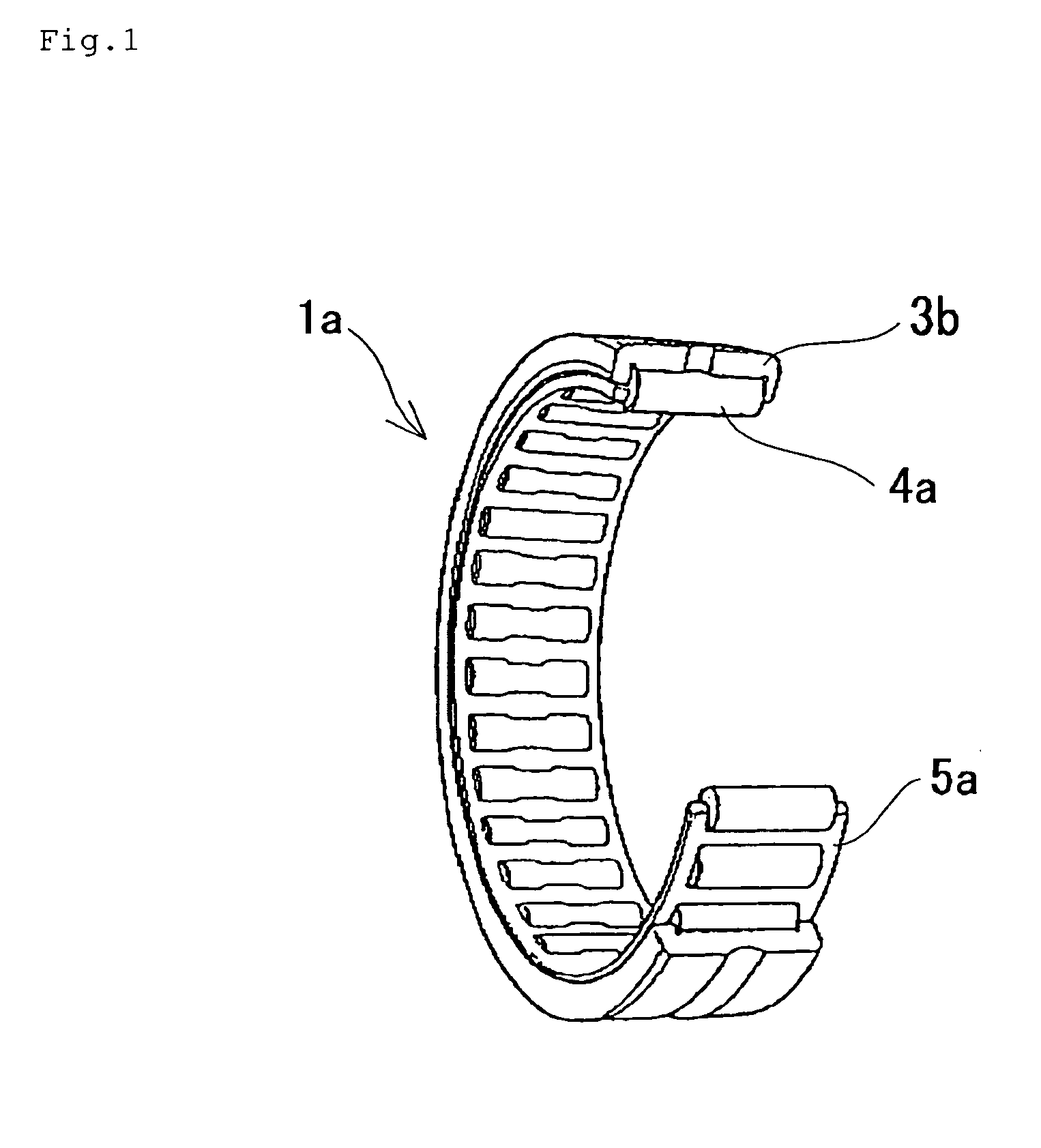

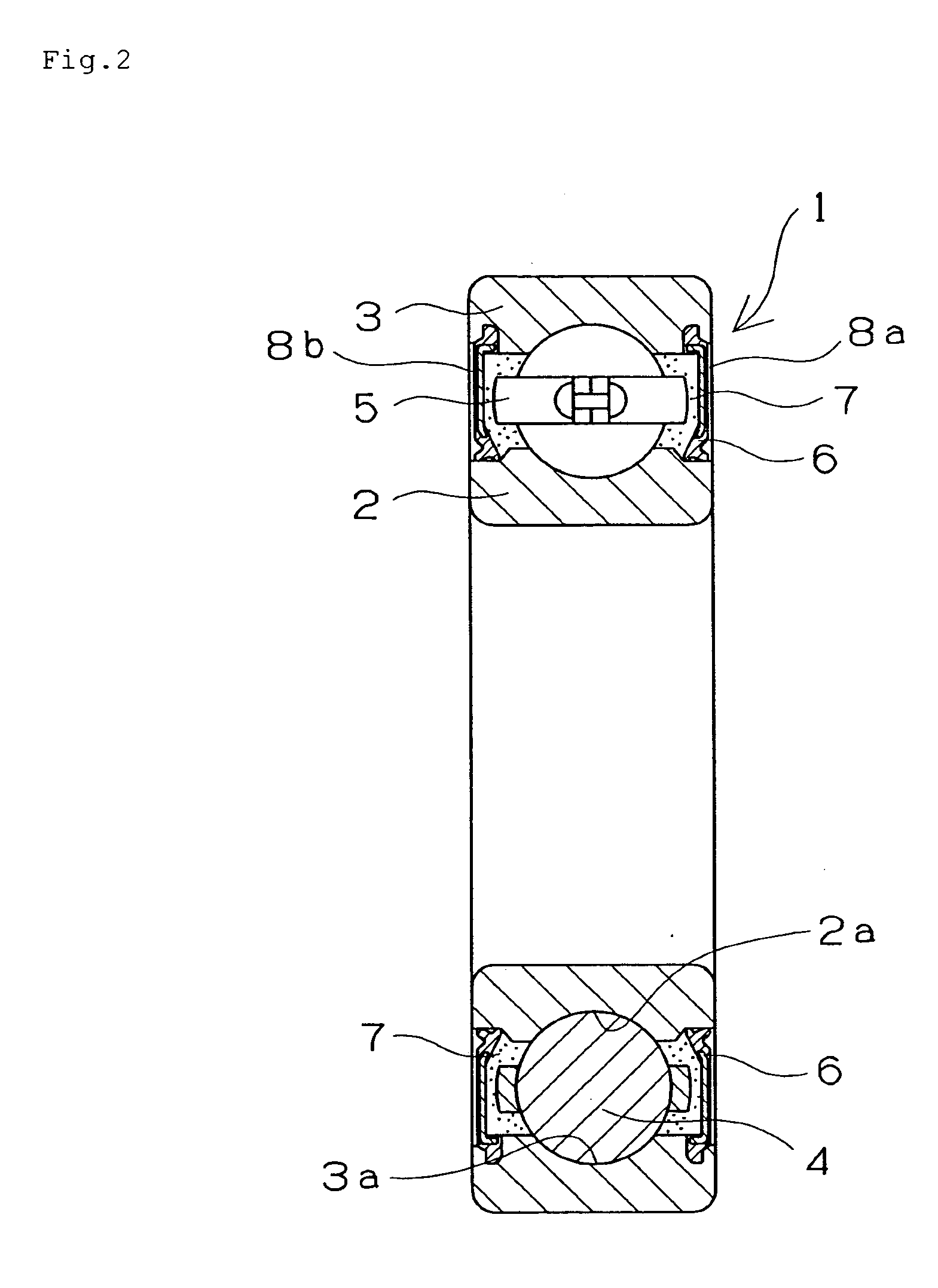

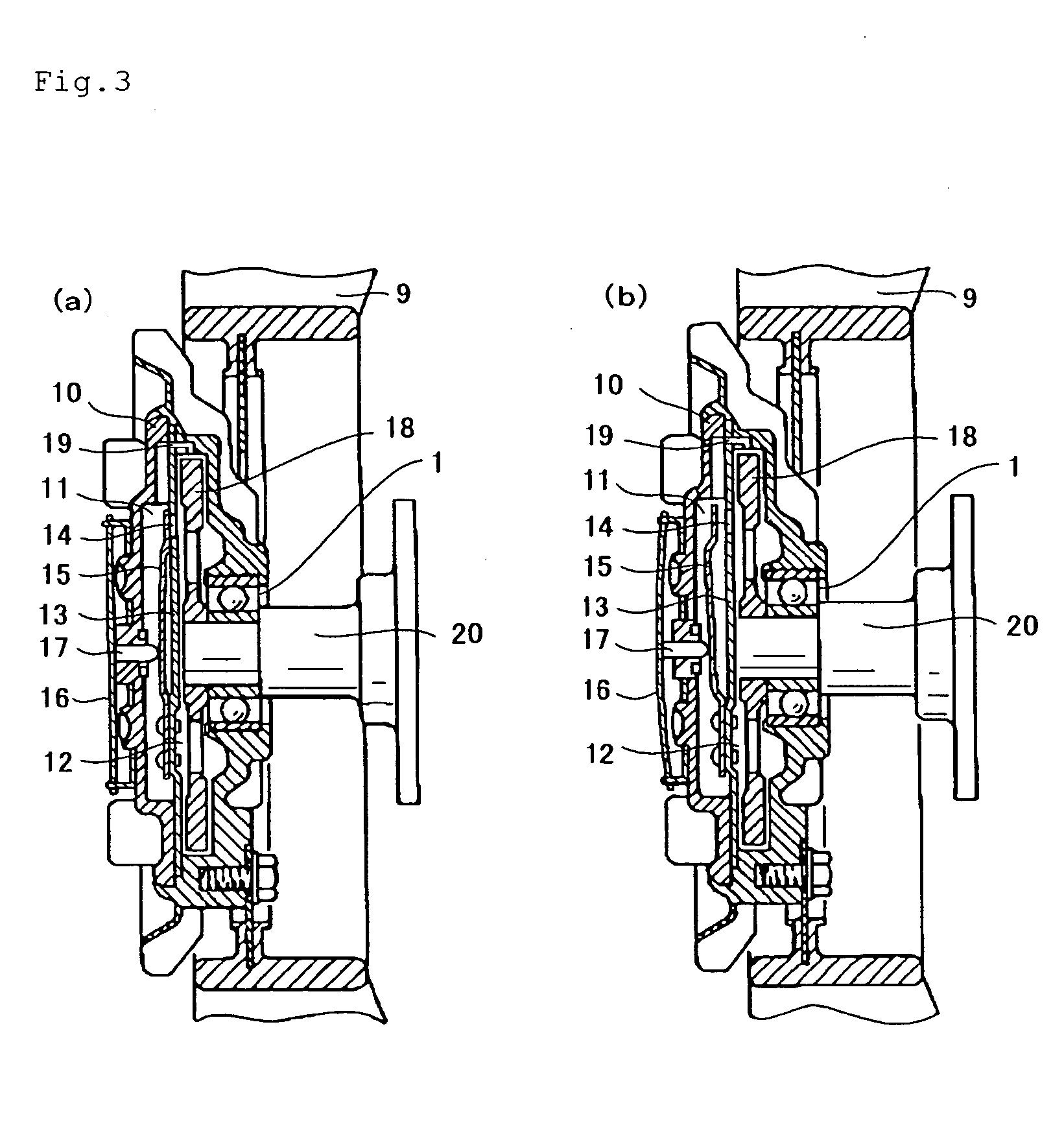

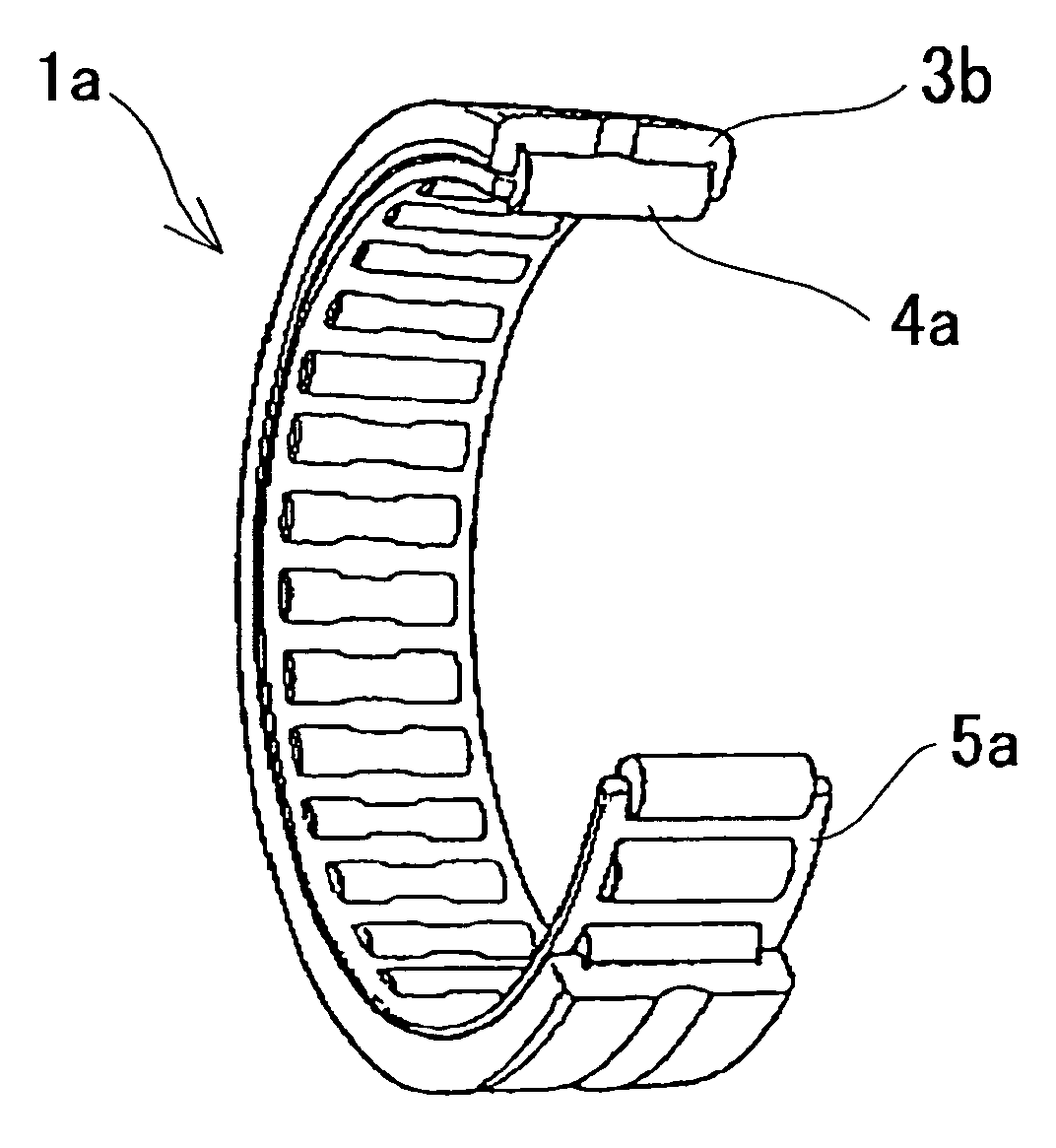

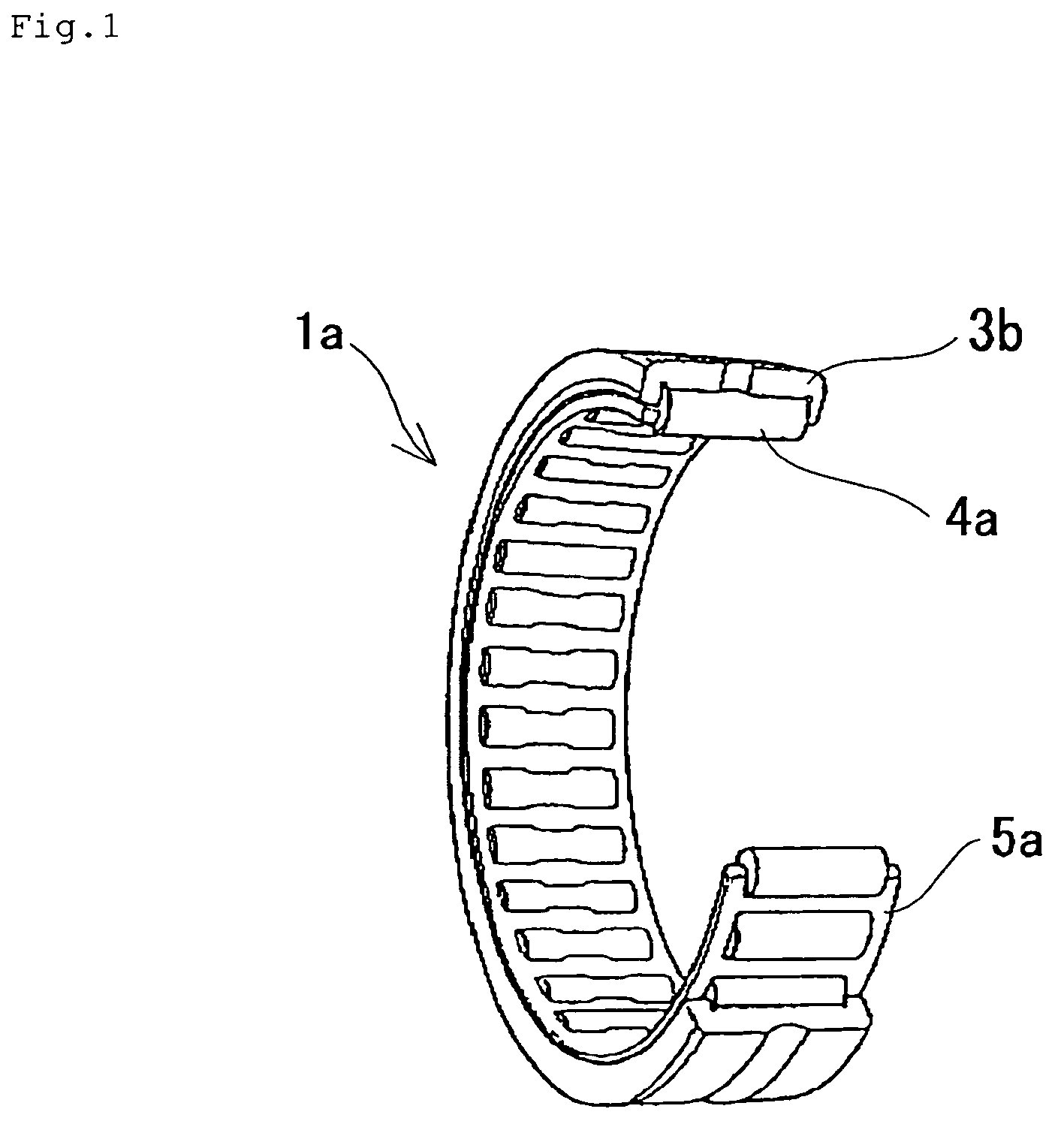

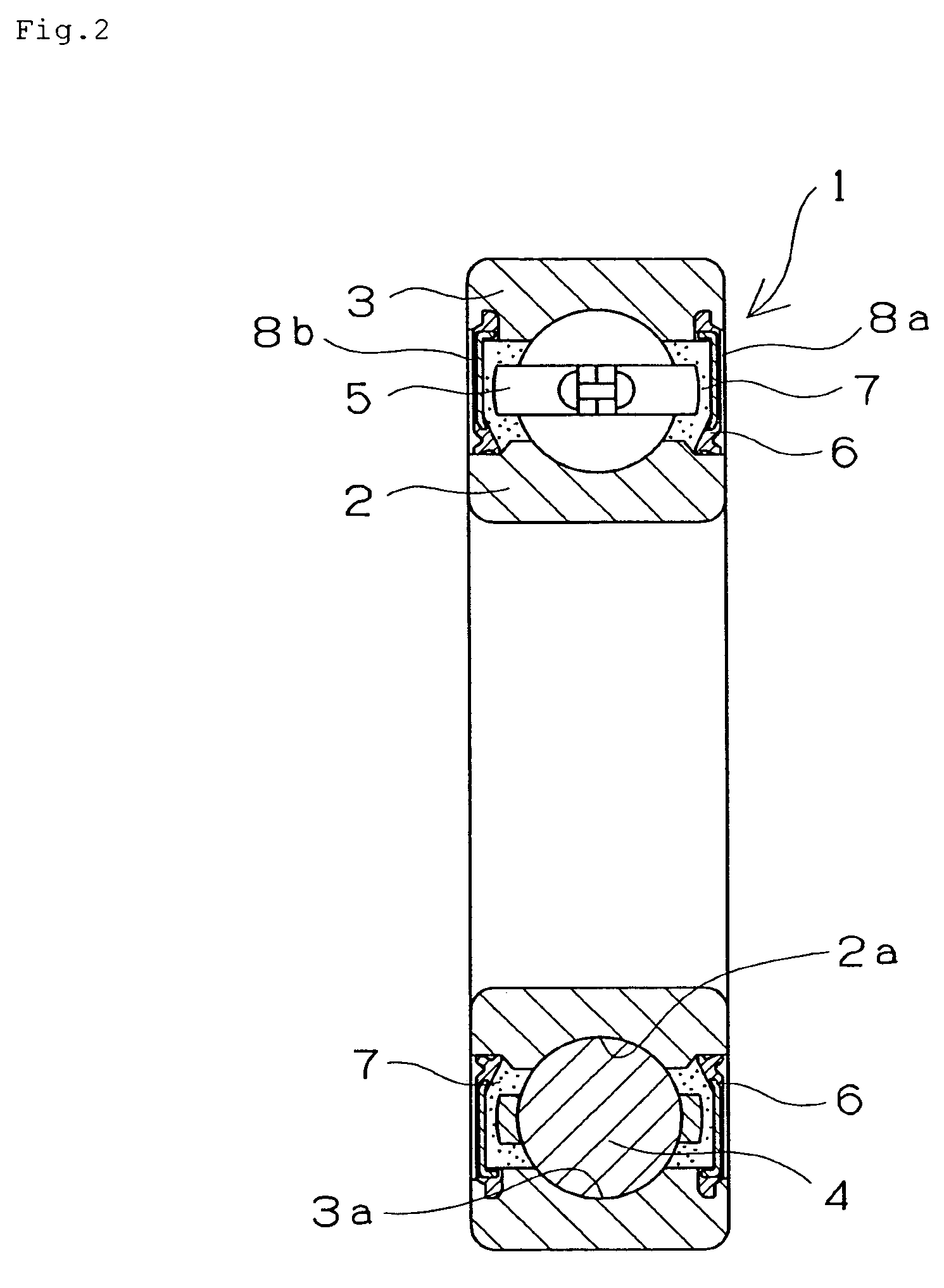

Lubricant composition and bearing using same

ActiveUS20050009713A1Prevent surfaceIncreased durabilityGroup 1/11 element organic compoundsMixingPotassiumSodium salt

A lubricant composition capable of effectively preventing a rolling surface of a bearing from flaking owing to hydrogen embrittlement. The bearing is lubricated with the lubricant composition. The lubricant composition is lubricating oil or grease. The lubricant composition contains a molybdate. The lubricant composition also contains an organic acid salt. At least one molybdate is selected from sodium molybdate, potassium molybdate, and lithium molybdate. The organic acid salt is a sodium salt of an organic acid having one to 20 carbon atoms. 0.01 to 5 wt % of the molybdate is added to the entirety of the lubricant composition. 5 wt % to 70 wt % of the organic acid salt is added to the addition amount of the molybdate. The lubricant composition has a function of forming a film containing a molybdenum compound in addition to an iron oxide film on a worn surface of the bearing or on a fresh surface of an iron-based metal generated by wear. The bearing is used as a rolling bearing for use in electric parts and auxiliary machines of a vehicle. The bearing is also used as a bearing, for a motor, in which the lubricant composition is sealed.

Owner:NTN CORP

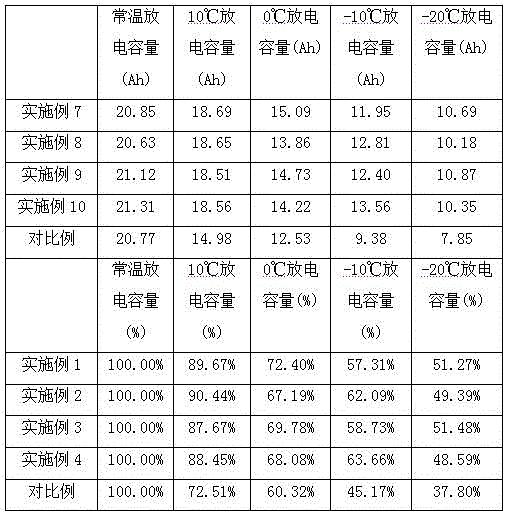

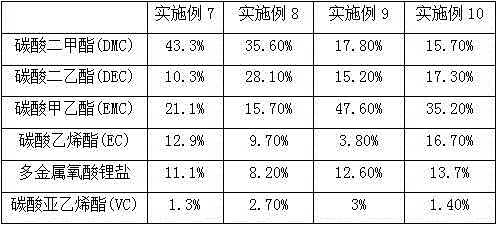

Low-temperature electrolyte for LiFePO4 (lithium iron phosphate) lithium-ion batteries

InactiveCN102983362AIncrease migration rateGood low temperature characteristicsSecondary cellsElectrolytic agentPhosphomolybdic acid

The invention relates to a low-temperature electrolyte for LiFePO4 (lithium iron phosphate) lithium-ion batteries, belonging to the technical field of low-temperature electrolytes for lithium batteries. The electrolyte comprises dimethyl carbonate, diethyl carbonate, ethyl methyl carbonate, ethylene carbonate, a film-forming additive and lithium polyoxometallate, wherein the lithium polyoxometallate refers to lithium phosphomolybdate Li3PMo12O40, lithium phosphotungstate Li3PW12O40, lithium silicotungstate Li4SiW12O40 or lithium silicomolybdenate Li4SiMo12O40. For solving the problems that in the prior art, the lithium ion transport of an electrolyte is blocked, slow in speed and low in efficiency and the electrolyte is poor in low-temperature performance, the invention provides a novel fluoride-free low-temperature electrolyte for LiFePO4 lithium-ion batteries; and by taking the non-fluoride lithium polyoxometallate with a three-dimensional skeleton structure as an electrolytic lithium salt and selectively adopting a low-viscosity carbonate solvent, through optimized proportioning, the migration rate of lithium ions is increased, and the low temperature properties of LiFePO4 batteries can be significantly improved.

Owner:中国东方电气集团有限公司

Lithium molybdate cathode material for lithium ion battery and preparation method thereof

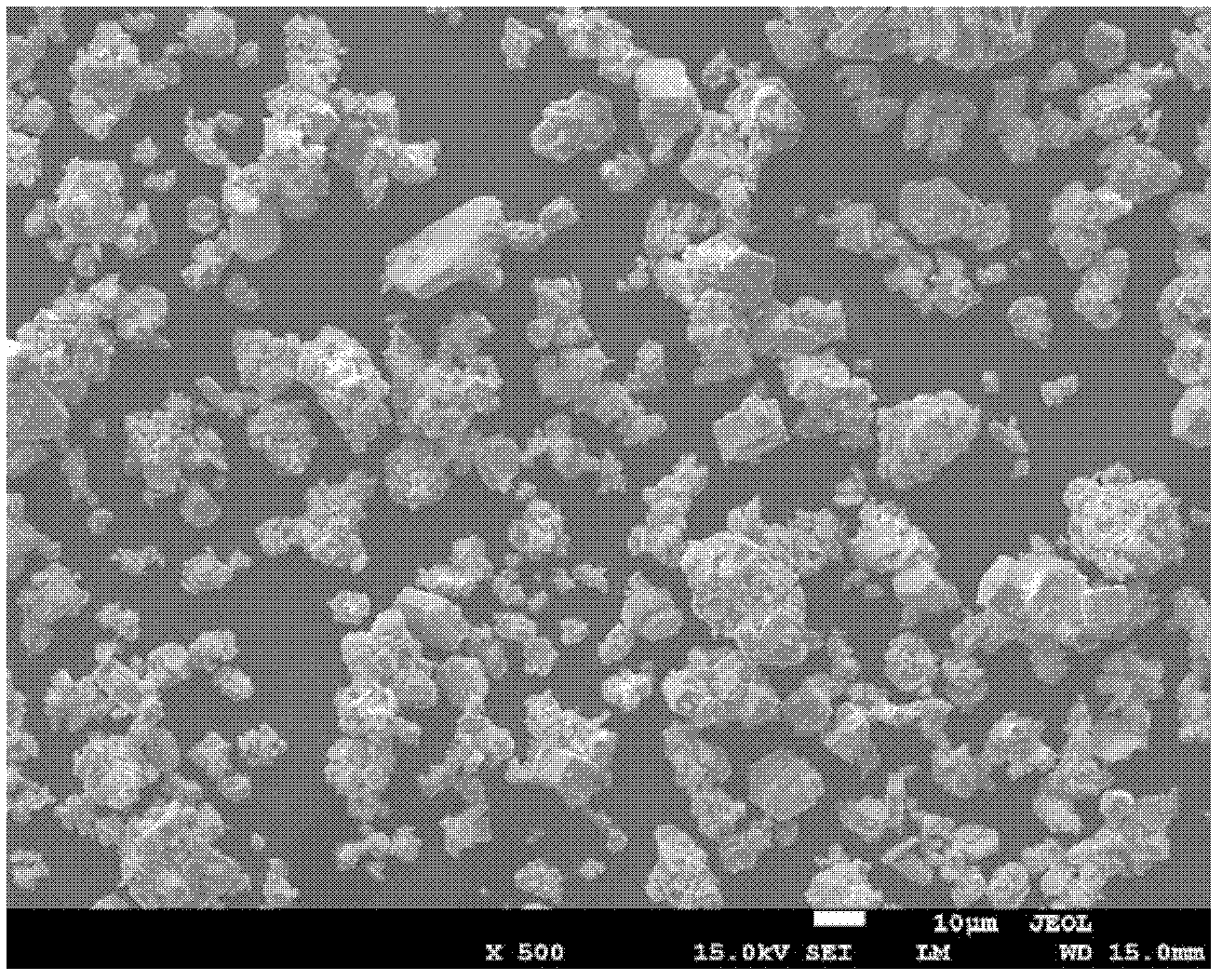

ActiveCN104241642AEasy to makeSuitable for industrial productionSecondary cellsNon-aqueous electrolyte accumulator electrodesNitrogen gasLithium-ion battery

Owner:SOUTH CHINA UNIV OF TECH

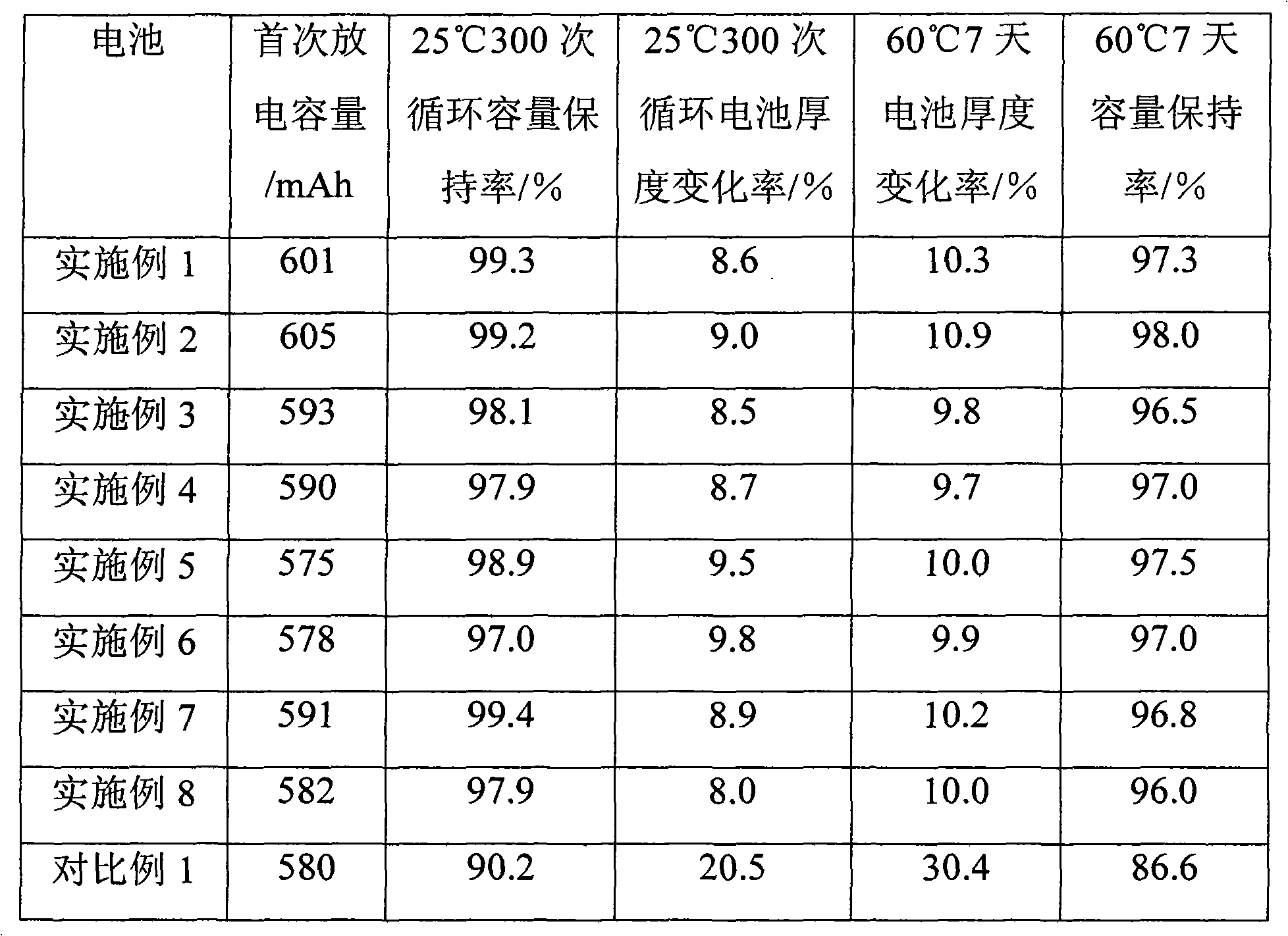

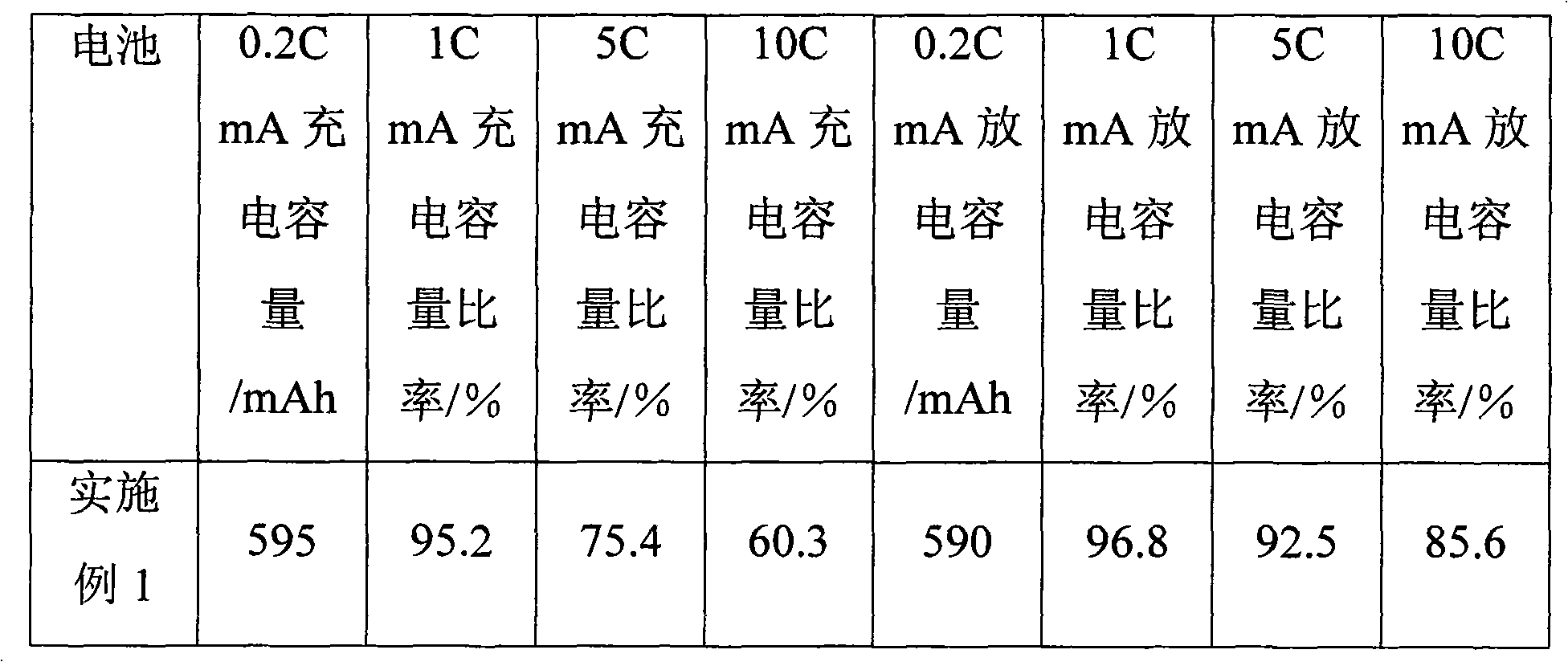

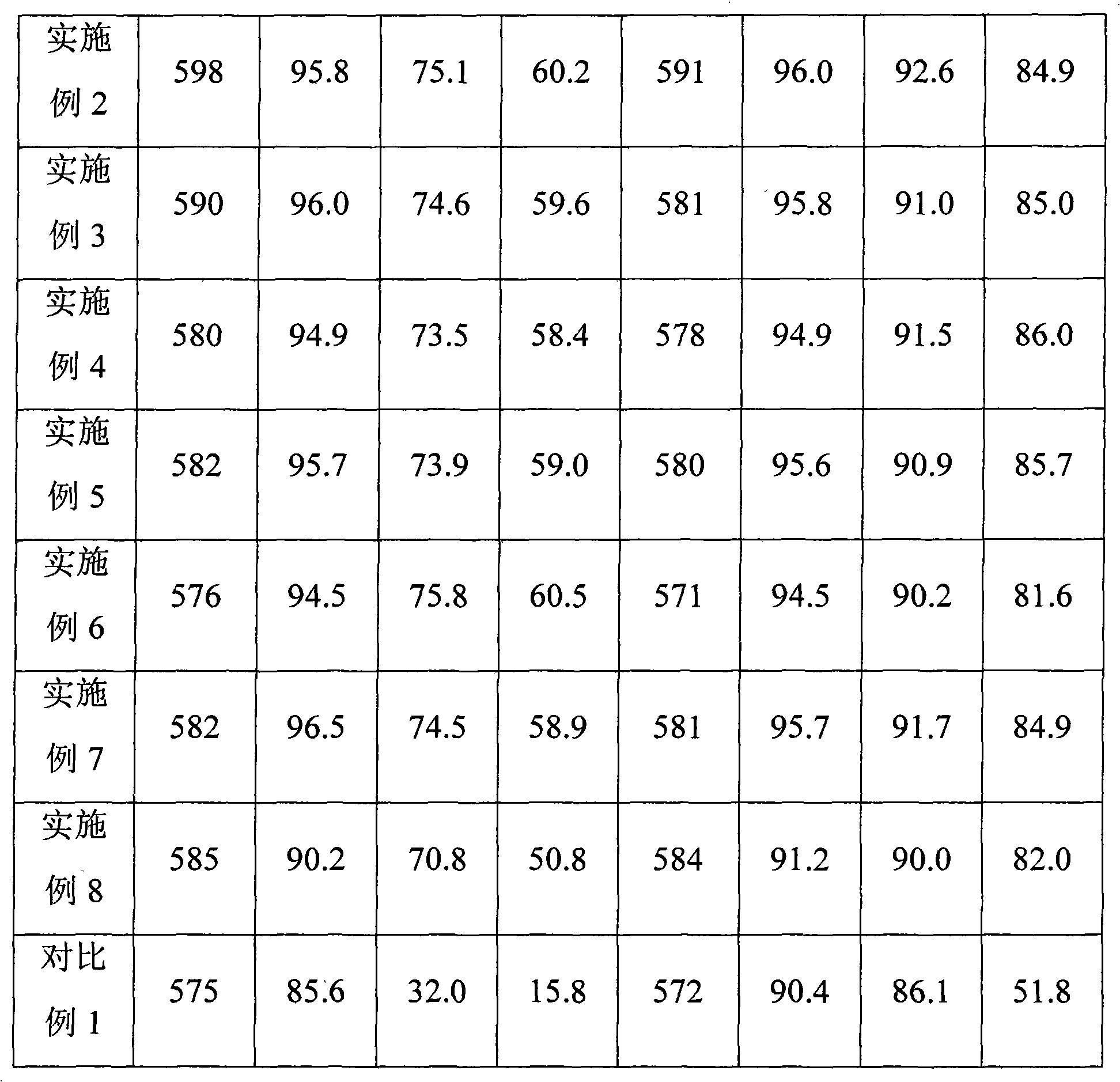

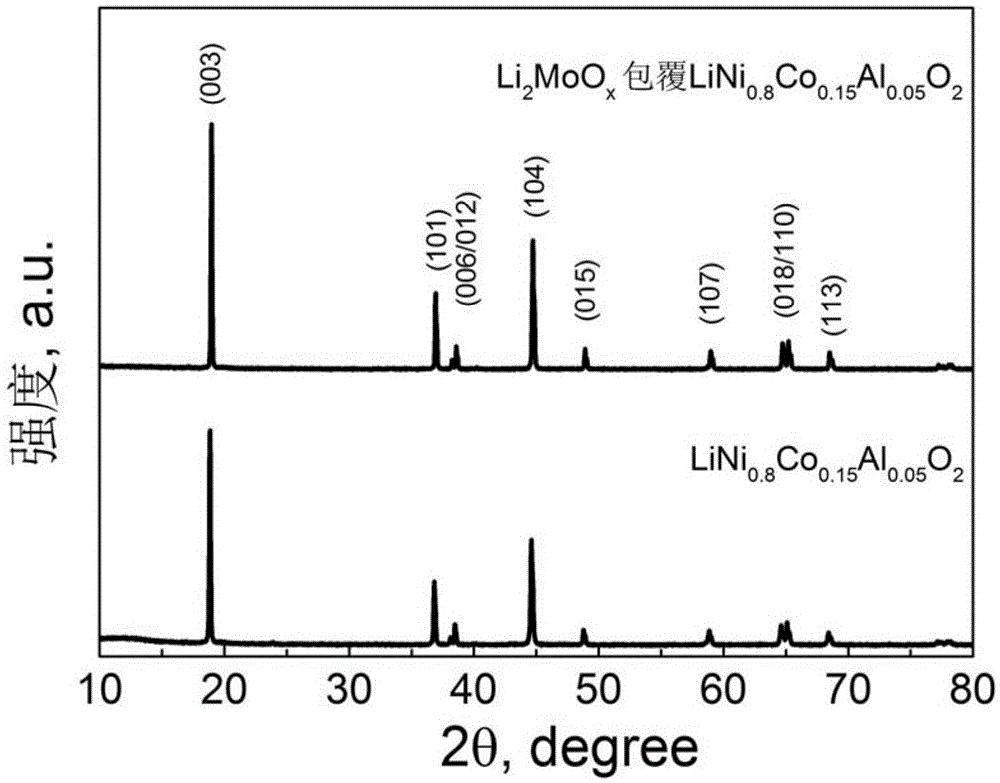

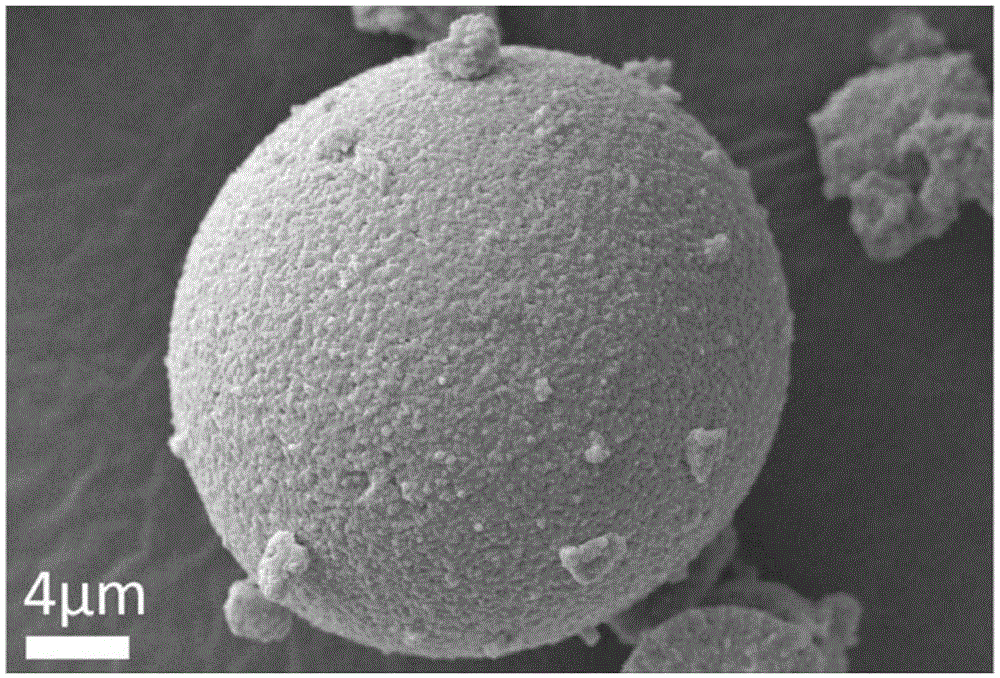

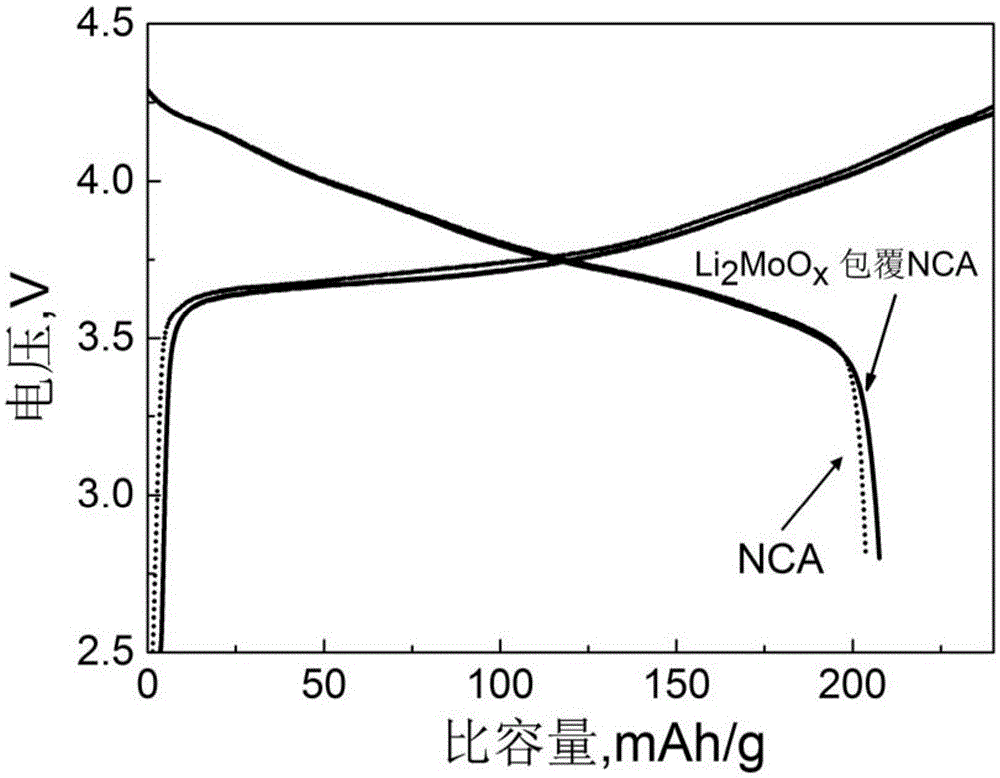

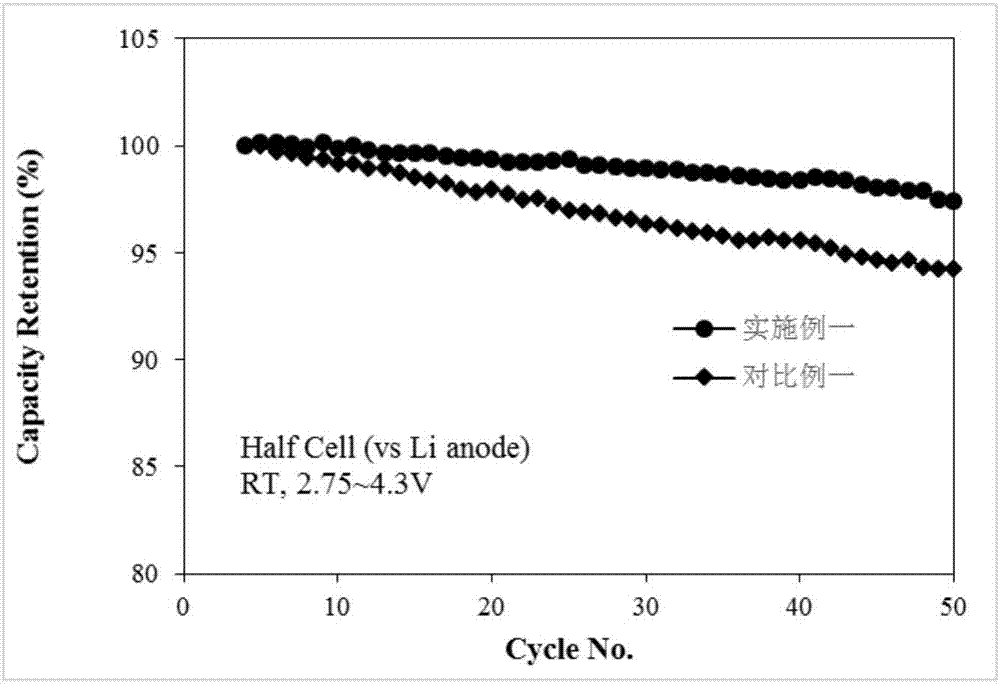

Lithium molybdate surface modified lithium ion battery nickel-rich positive pole material and preparation method thereof

InactiveCN105591099AFacilitate de-intercalationReduce absorptionCell electrodesSecondary cellsLithium-ion batterySurface modification

The invention discloses a lithium molybdate surface modified lithium ion battery nickel-rich positive pole material and a preparation method thereof. The chemical formula of the lithium ion battery nickel-rich material is LiNiaCobM1-a-bO2, wherein a and b are the mole number, a is larger than or equal to 0.5 and is smaller than or equal to 1, b is larger than or equal to 0 and is smaller than or equal to 0.2, M is one or more of Mn, Al and Fe, Li2MoOx is surface modified layer material lithium molybdate, and x is larger than or equal to 3 and is smaller than or equal to 4. The lithium molybdate surface modified lithium ion battery nickel-rich positive pole material is prepared through simple liquid phase precursor preparation, surface modification and high-temperature solid phase sintering reaction. The lithium molybdate surface modification layer has the good lithium ionic conductivity, and is beneficial to lithium ion de-intercalation. By means of the lithium molybdate surface modified lithium ion battery nickel-rich positive pole material, the rate capability, cycle performance and safety of the nickel-rich positive pole material can be greatly improved; according to the preparation method, raw materials are easy to obtain, operation is easy, the cost is low, and industrial large-scale production is easy to achieve.

Owner:SOUTH CHINA UNIV OF TECH

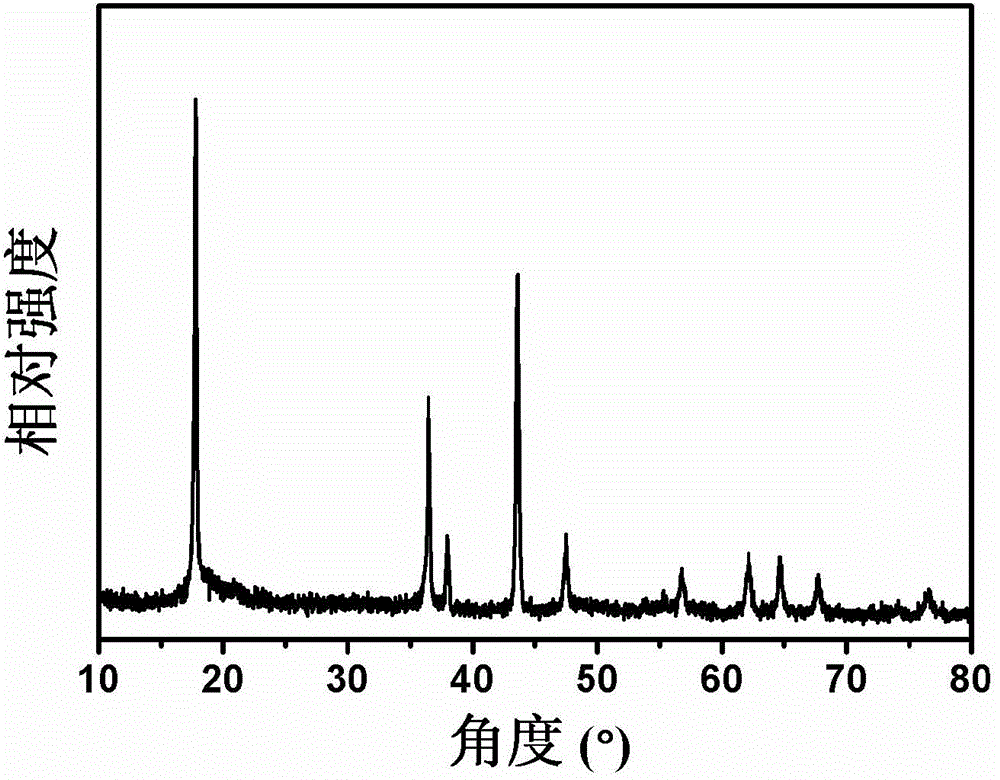

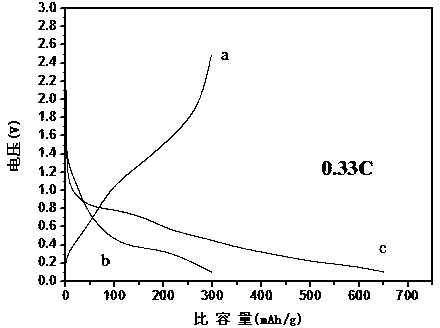

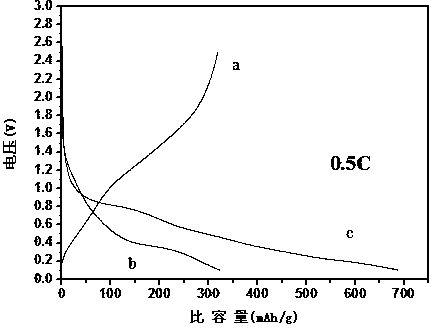

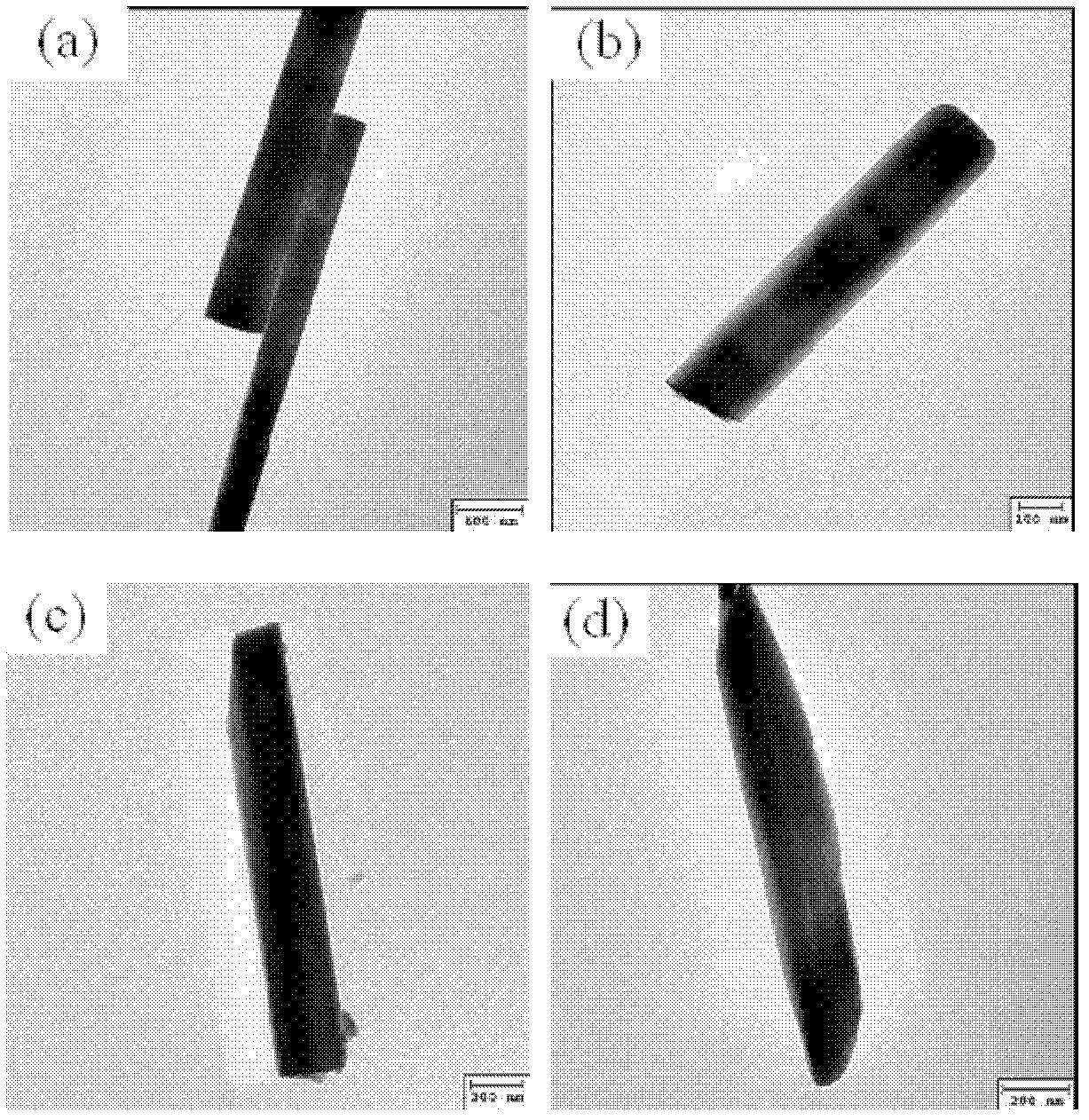

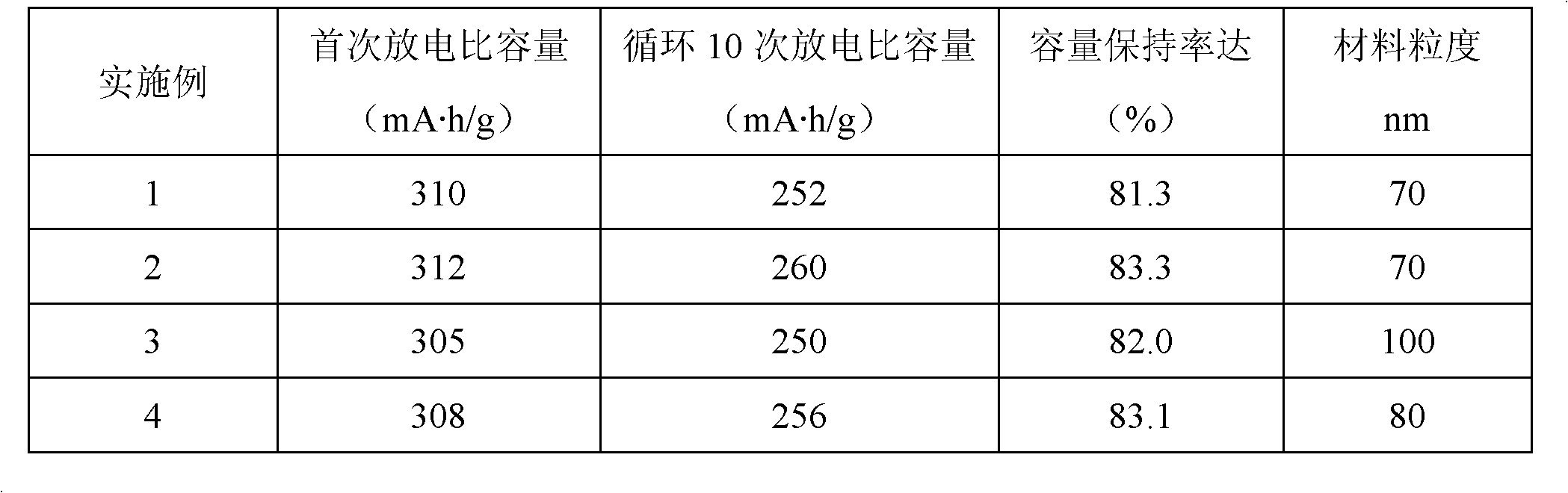

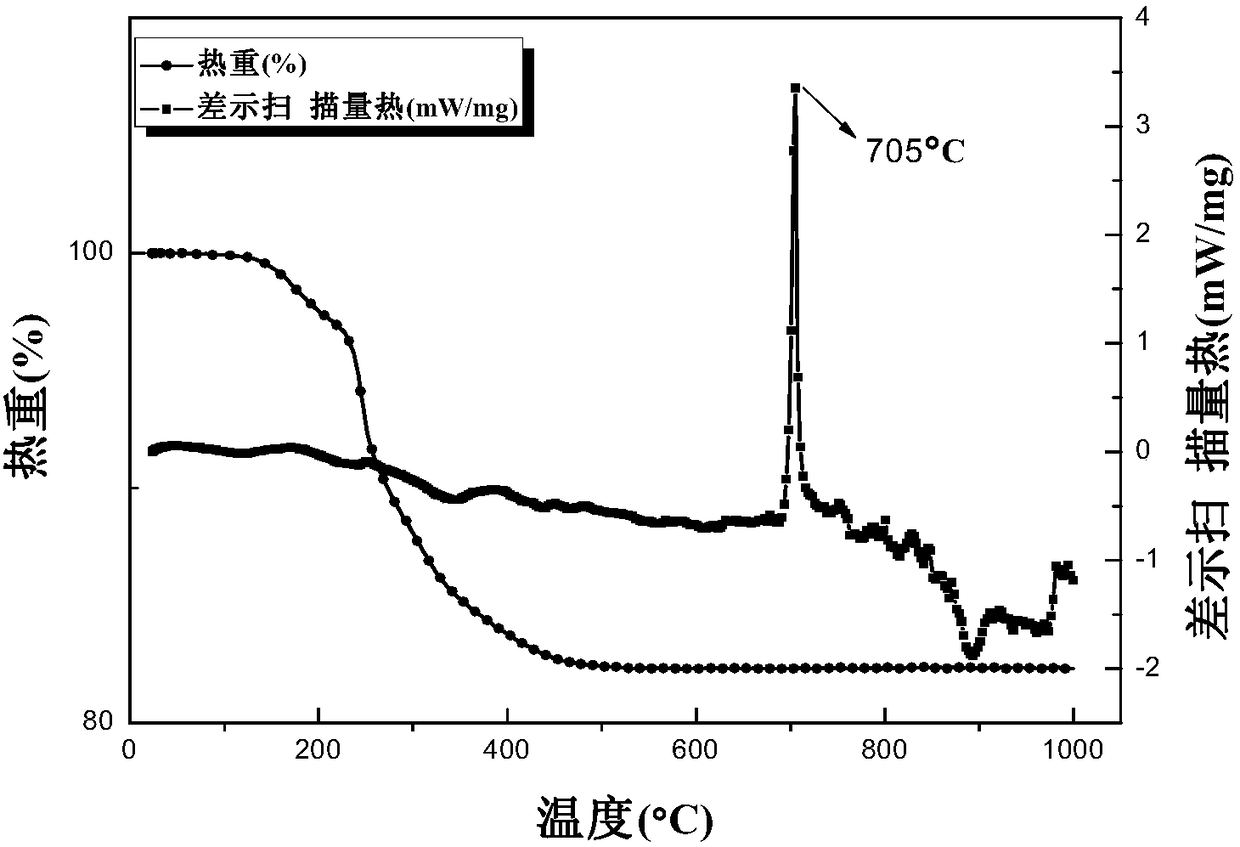

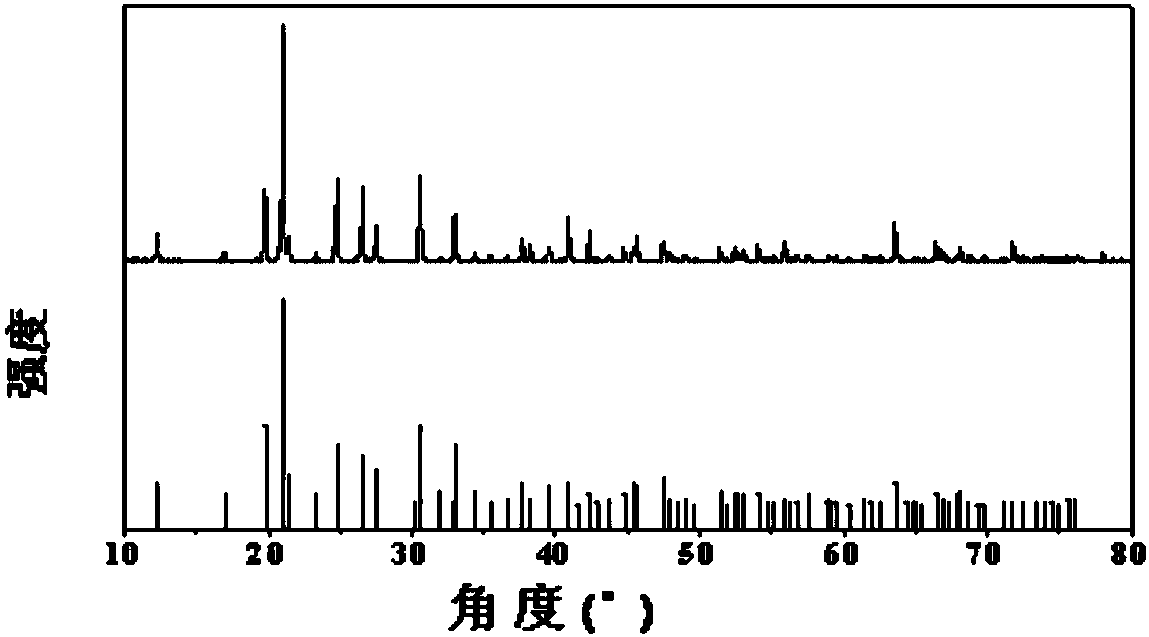

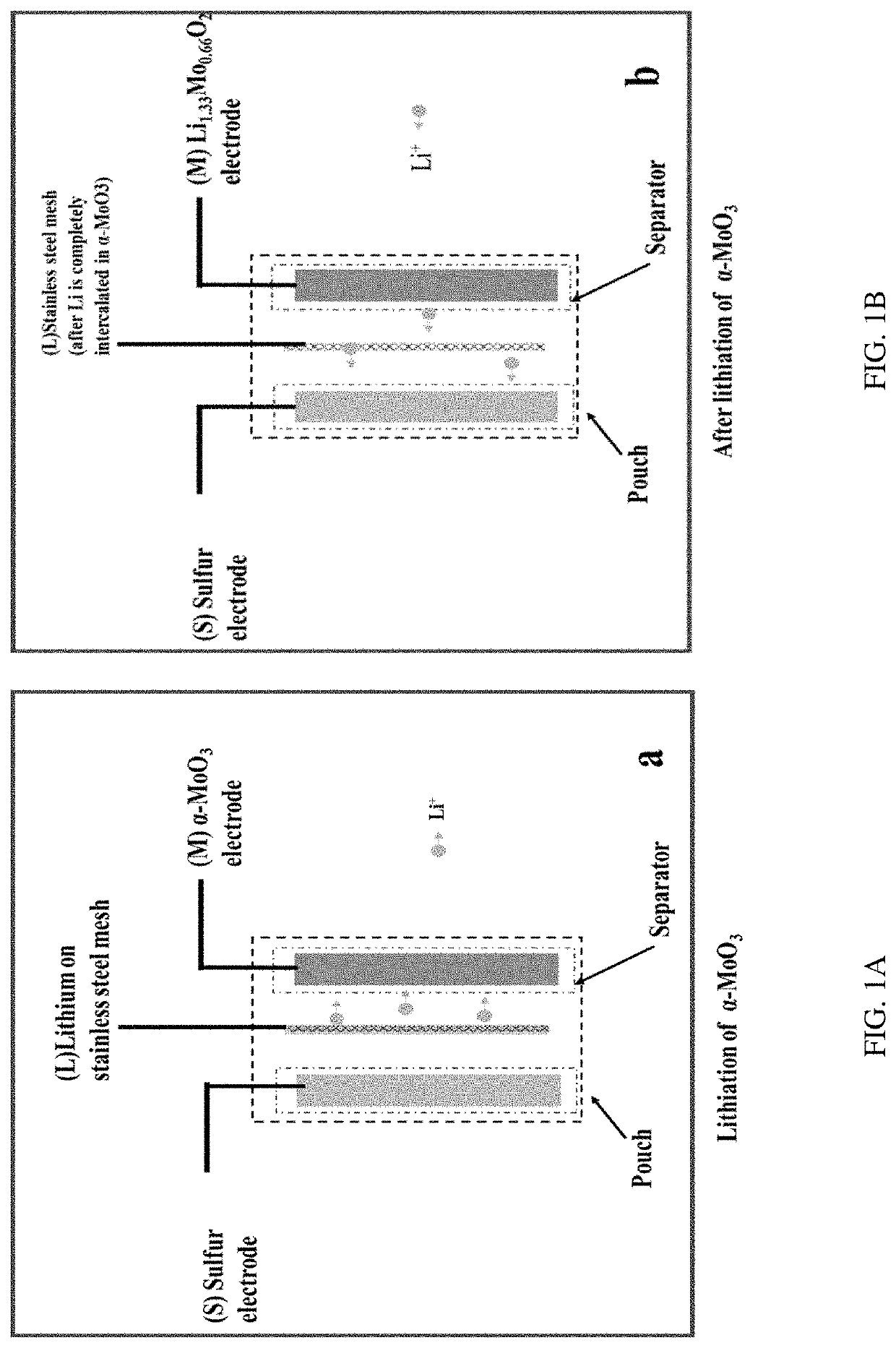

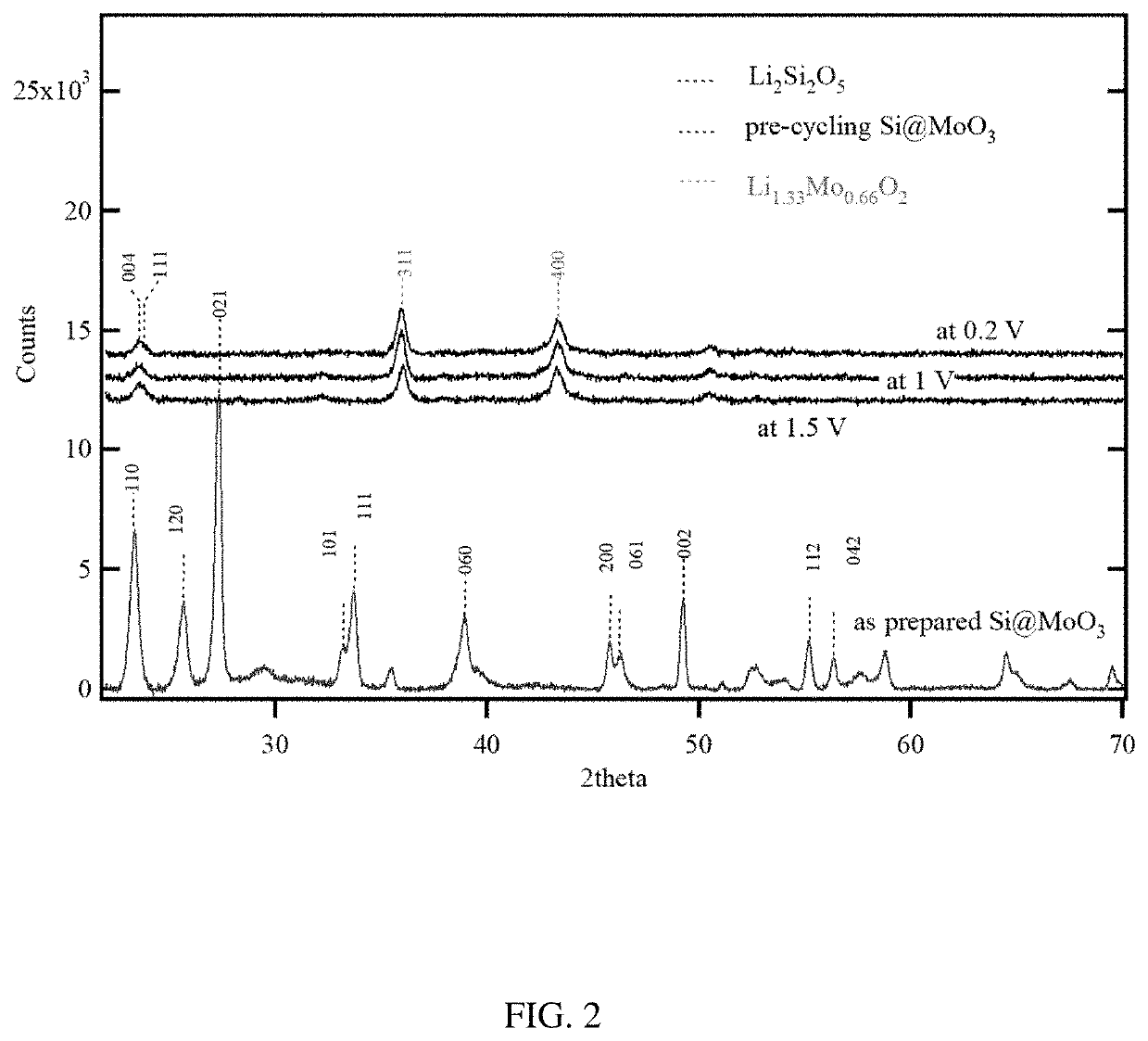

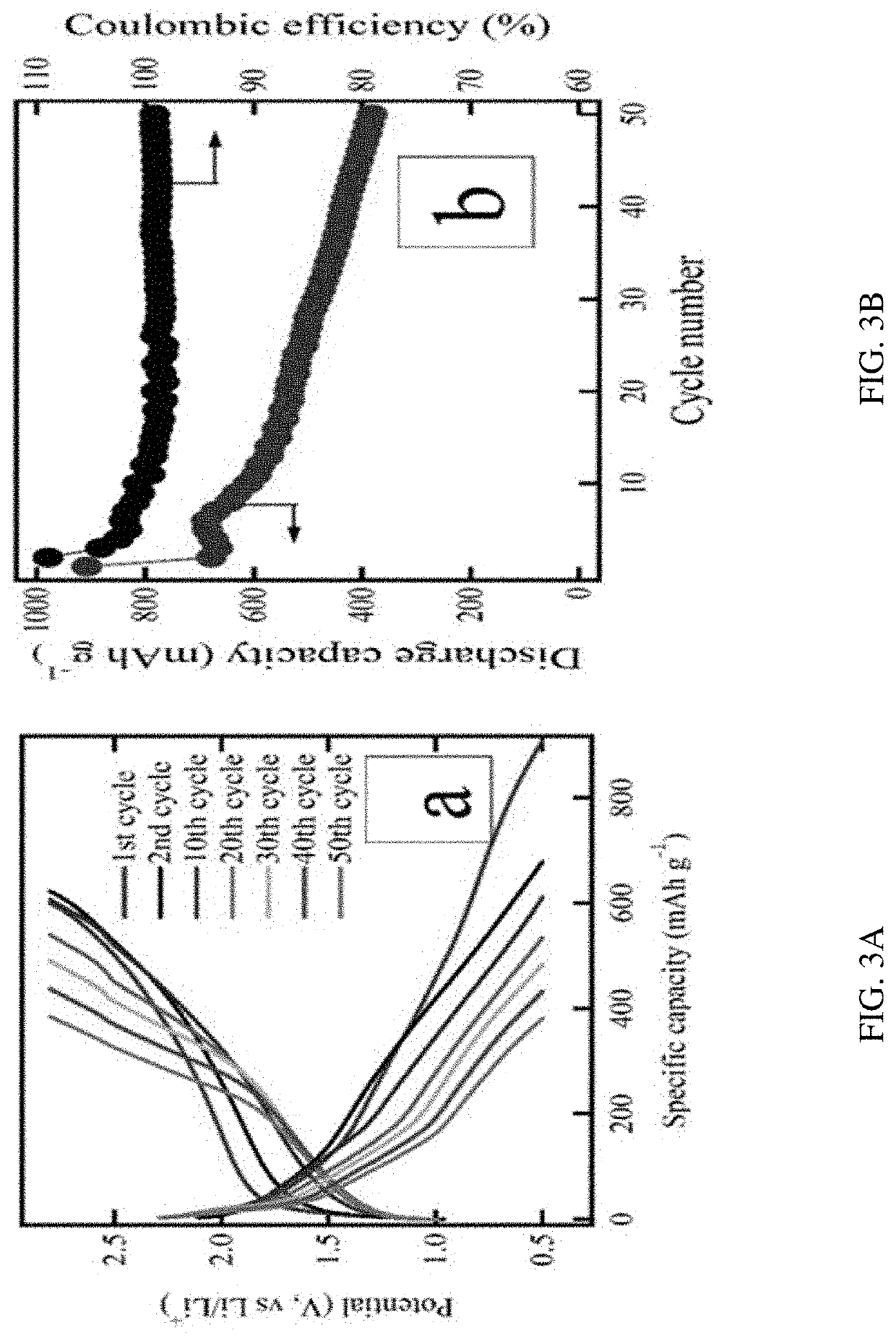

Preparation method of lithium-intercalated molybdenum trioxide electrode material

InactiveCN102694159AUniform particle size distributionSimple manufacturing methodCell electrodesMolybdenum trioxideDischarge current

The invention discloses a preparation method of a lithium-intercalated molybdenum trioxide electrode material, which comprises the following steps: adding de-ionized water to lithium molybdate to prepare a lithium molybdate water solution; regulating the pH value of the solution to 0.5-3.0 until white precipitates appear; then, carrying out hydrothermal reaction at 170-180 DEG C for 4-40 hours; and separating, and drying to obtain the lithium-intercalated molybdenum trioxide electrode material. By using the lithium molybdate (Li2MoO4) as the raw material to prepare the lithium-intercalated molybdenum trioxide electrode material through a one-step hydrothermal reaction method, the preparation method is simple and easy to implement, the used raw material is simple and easy to control, and the preparation cost is greatly lowered. By using the lithium-intercalated molybdenum trioxide battery material prepared by the invention in case of 100 mA / g discharging current, the first discharging specific capacity is more than or equal to 300 mA.h / g, and the discharging specific capacity is more than or equal to 250 mA.h / g after 10 weeks of cycling, there ensuring that the capacity conservation rate reaches 85.5% or above. Thus, the lithium-intercalated molybdenum trioxide battery material has fine cycle performance, thereby having wide application prospects.

Owner:HENAN UNIV OF SCI & TECH

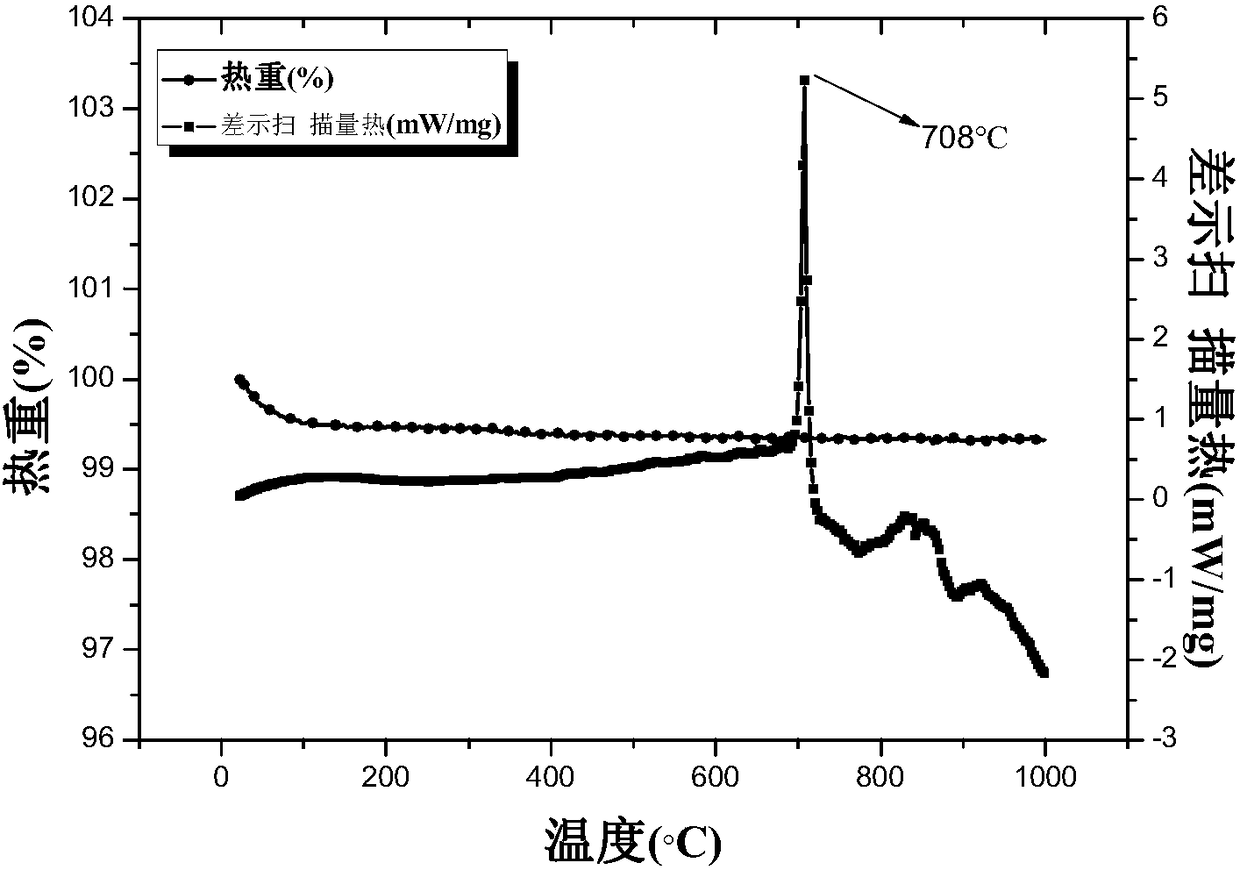

Lithium molybdate positive electrode material of high-temperature lithium battery and preparation method and positive electrode material of high temperature lithium battery and preparation method thereof

InactiveCN108493440AIncrease capacityGood compatibilityCell electrodesSecondary cellsAir atmosphereStructural formula

The invention provides a lithium molybdate positive electrode material of a high temperature lithium battery. A chemical structural formula is Li2MoO4. The invention also provides a preparation methodof a high temperature solid phase of the material, which comprises the following steps: weighing lithium salt and a molybdenum source according to a mol ratio, performing ball milling for 2-5 h and taking the material out, grinding the material and sieving the material, and sintering the material for 10-16 h under the air atmosphere at the temperature of 200-800 DEG C, and cooling the material toroom temperature. The invention also provides a preparation method of synthesis of its aqueous solution, and the difference is characterized in that the lithium salt and the molybdenum source are dumped in water for stirring and drying. In addition, the invention provides a preparation method of the positive electrode material of the high-temperature lithium battery, which comprises the followingsteps: grinding the above lithium molybdate positive electrode material of the high-temperature lithium battery and sieving the material; weighing the material, low melting point nitrate and an active carbon material, performing ball milling for 2-5 h, sintering the material under air atmosphere for 180 DEG C, taking the material out and grinding the material, and sieving the material. The lithium molybdate positive electrode material employs lithium molybdate, and has the advantages of high temperature resistance, good compatibility with nitric acid molten salt, high capacitance, and good discharge performance.

Owner:SHANGHAI INST OF MICROSYSTEM & INFORMATION TECH CHINESE ACAD OF SCI

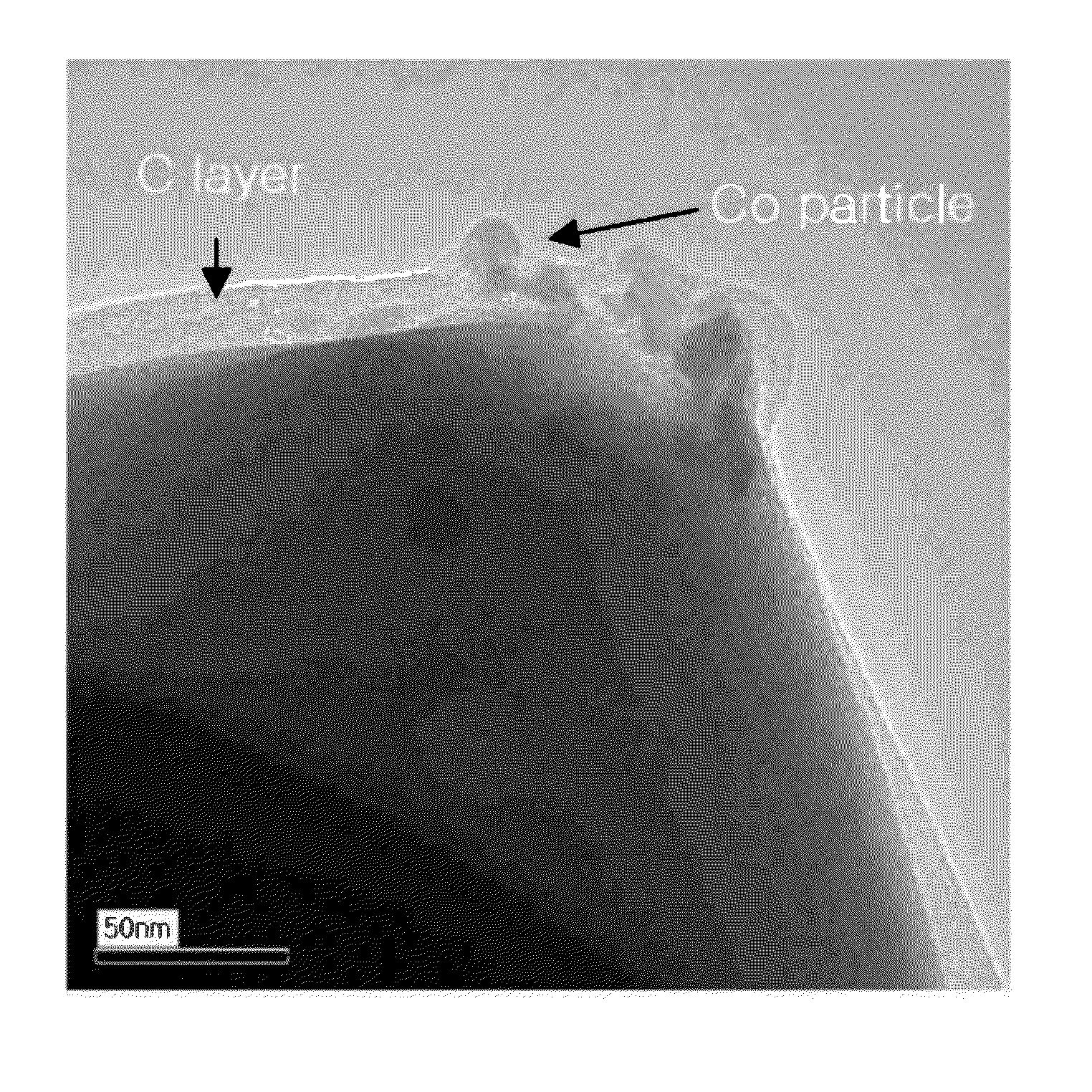

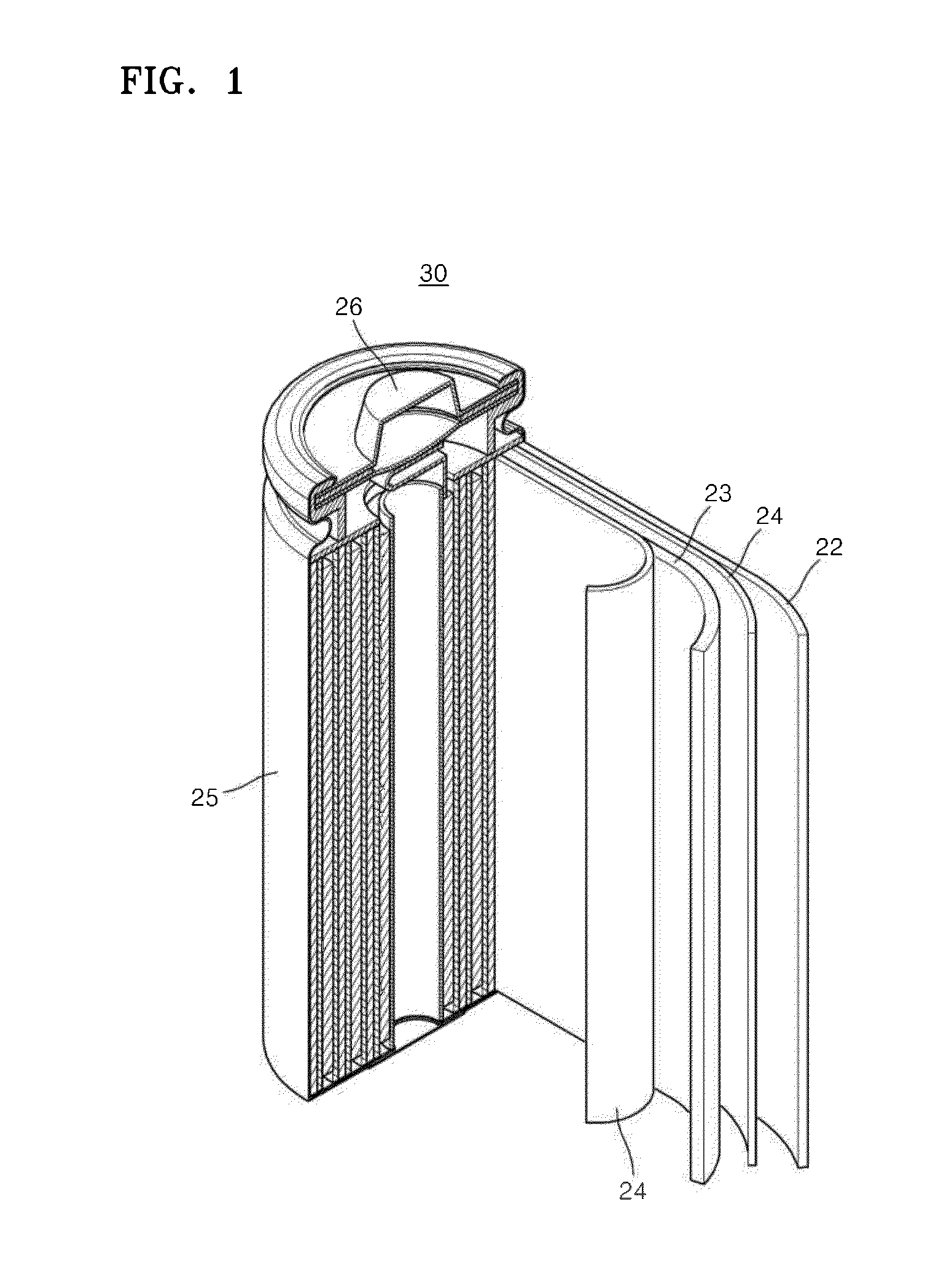

Positive active material, lithium battery including the same, and method of manufacturing the positive active material

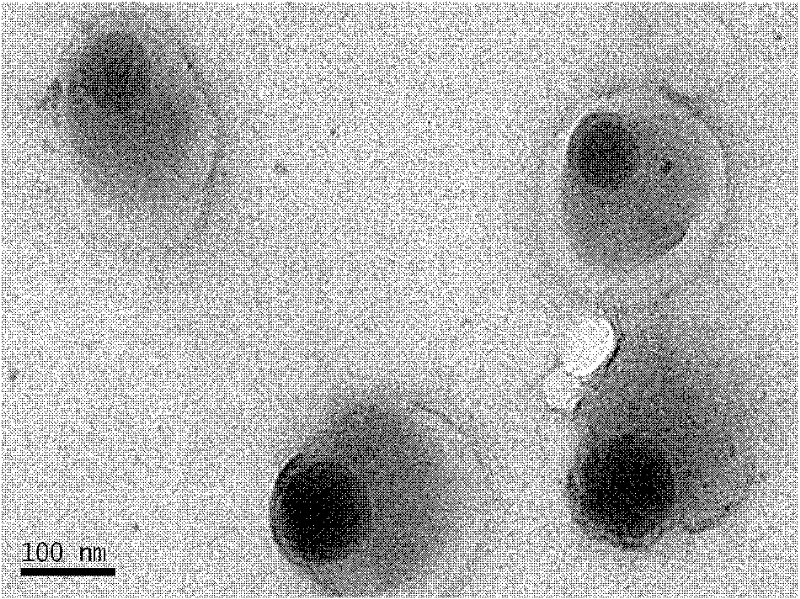

ActiveUS20150214543A1Increase capacityImproved lifetime propertyMolybdeum compoundsLi-accumulatorsEngineeringCore shell

Provided are a positive active material, a lithium battery including the positive active material, and a method of manufacturing the positive active material. The positive active material includes a lithium molybdate composite having a core-shell structure. The lithium molybdate composite acts as a sacrificial positive electrode in a positive electrode of a battery. The positive active material is able to increase charge capacity of a lithium battery, and accordingly is able to improve lifetime properties of a lithium battery.

Owner:SAMSUNG SDI CO LTD

Neodymium doped LiGd(MoO4)2 laser crystal, its preparation method and use

Disclosed is neodymium-doped gadolinium lithium molybdate laser crystal, its preparation process and use thereof, wherein the crystal is prepared through a Czochralski method conducted at 1035 deg C at a crystal rotational speed of 20-55 rpm, the obtained high quality large scale Nd3+:LiGd(MoO4)2 crystal can be applied into the fields of optical spectroscopy, biological medicine and military purpose.

Owner:FUJIAN INST OF RES ON THE STRUCTURE OF MATTER CHINESE ACAD OF SCI

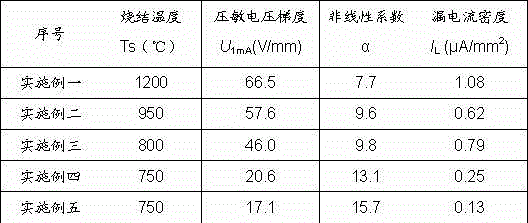

Zinc oxide voltage-sensitive ceramic and preparation method thereof, as well as zinc oxide voltage-sensitive resistor and preparation method thereof

InactiveCN104557018ALower sintering temperaturePromote growthResistor manufactureVaristor coresCeramic sinteringGrain boundary

The invention provides zinc oxide voltage-sensitive ceramic and a preparation method thereof, as well as a zinc oxide voltage-sensitive resistor and a preparation method thereof. The matrix ingredients comprise zinc oxide, bismuth trioxide and cobaltic oxide. By adding cosolvents vanadic oxide and calcium fluoride, as well as a vitrification agent nitrate barium, the sintering temperature of the ceramic is reduced, the grain growth in the sintering process is effectively promoted, and the voltage-sensitive voltage threshold is reduced; by adding interface optimization agents sodium tungstate dihydrate and lithium molybdate, the grain boundary component and structure are optimized, the voltage-sensitive coefficient and performance of the material are improved, the nonlinear coefficient is improved, and the leakage current density is reduced.

Owner:HUBEI UNIV +1

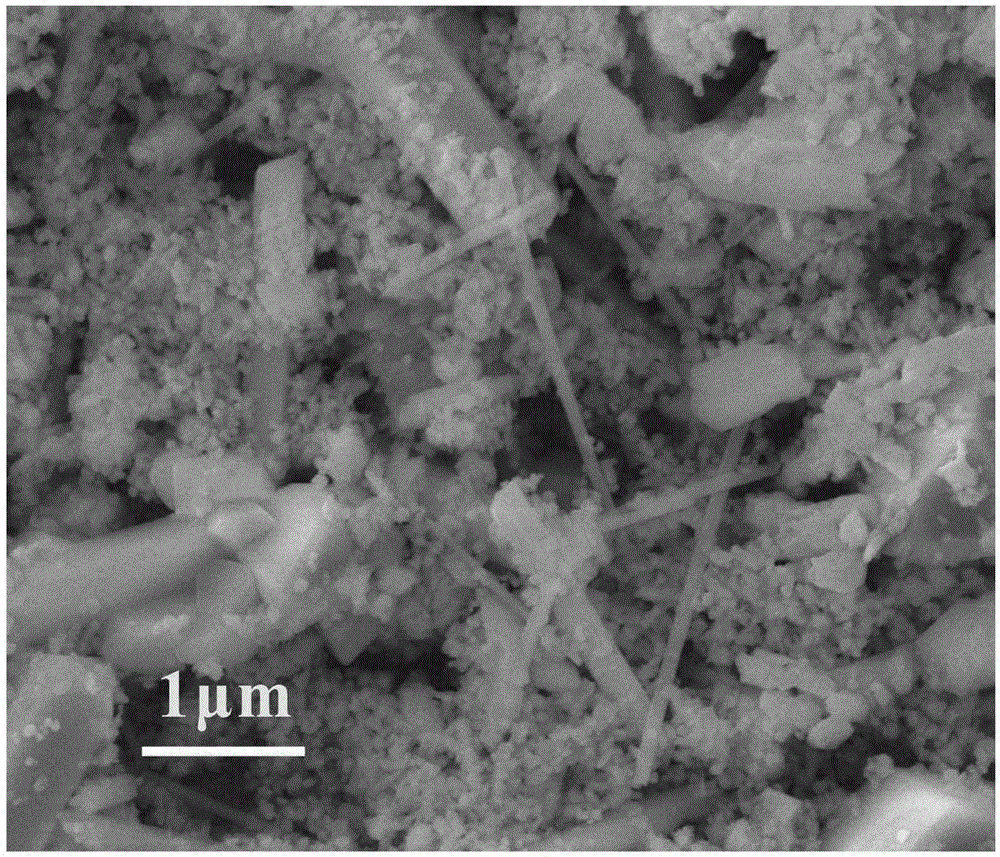

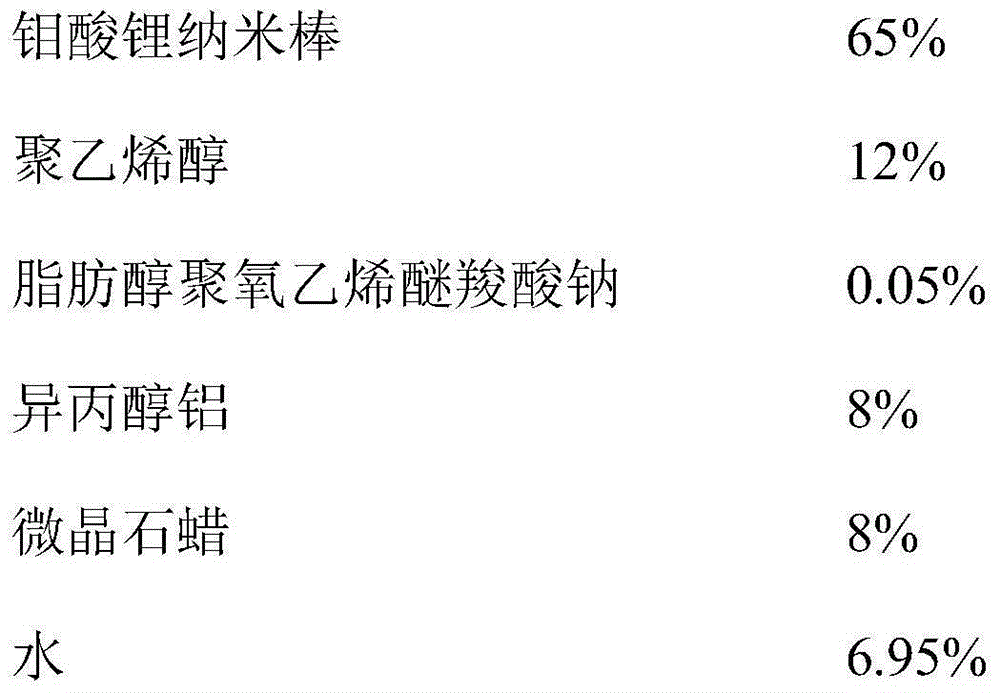

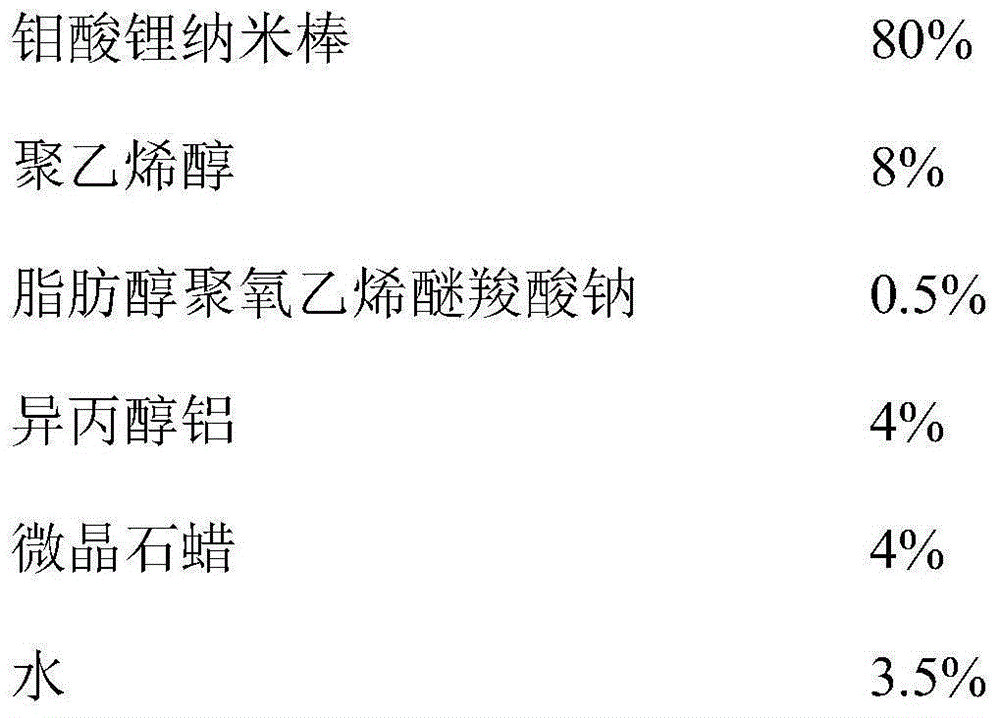

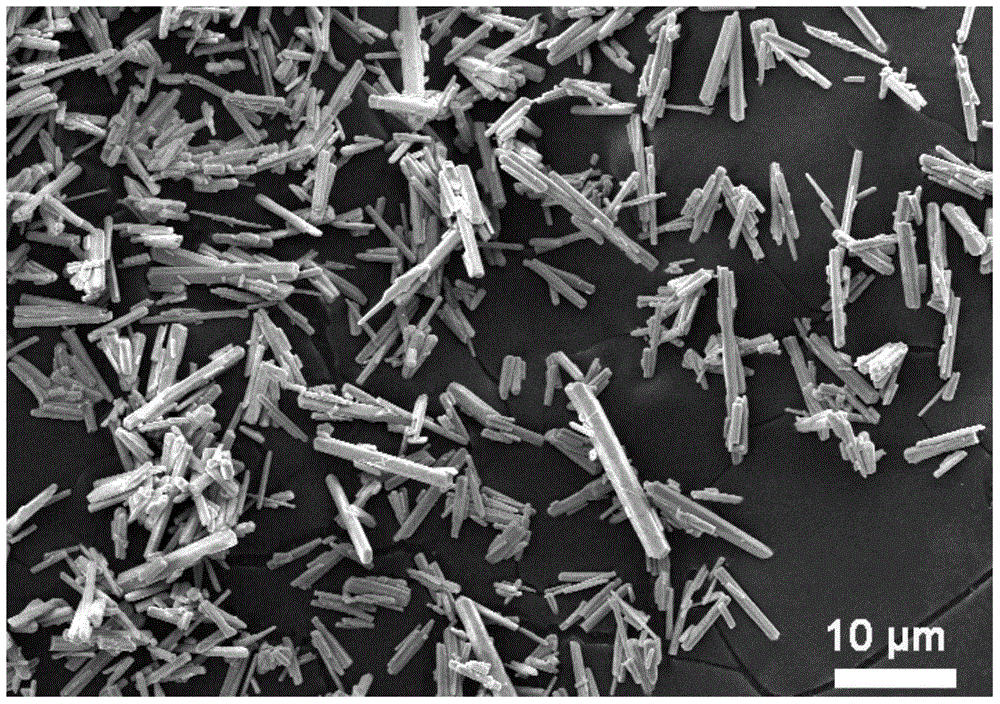

Lithium molybdate nano-rod electronic packaging material

ActiveCN105175965AImprove thermal conductivitySmall coefficient of thermal expansionPolyvinyl alcoholFatty alcohol

The invention discloses a lithium molybdate nano-rod electronic packaging material, and belongs to the technical field of electronic packaging materials. The lithium molybdate nano-rod electronic packaging material comprises, by mass, 65-80% of lithium molybdate nano-rods, 8-12% of polyvinyl alcohol, 0.05-0.5% of sodium fatty alcohol polyoxyethylene ether carboxylate, 4-8% of aluminum isopropoxide, 4-8% of microcrystalline paraffin and 3-7% of water, the diameter of the lithium molybdate nano-rods is 50-100nm, and the length of the lithium molybdate nano-rods is 1-3[mu]m. The lithium molybdate nano-rod electronic packaging material has the characteristics of good insulation property, excellent ageing and corrosion resistance, high heat conduction coefficient, small heat expansion coefficient, good workability, simple preparation process and low preparation temperature, and has good application prospect in the field of electronic packaging materials.

Owner:ANHUI UNIVERSITY OF TECHNOLOGY

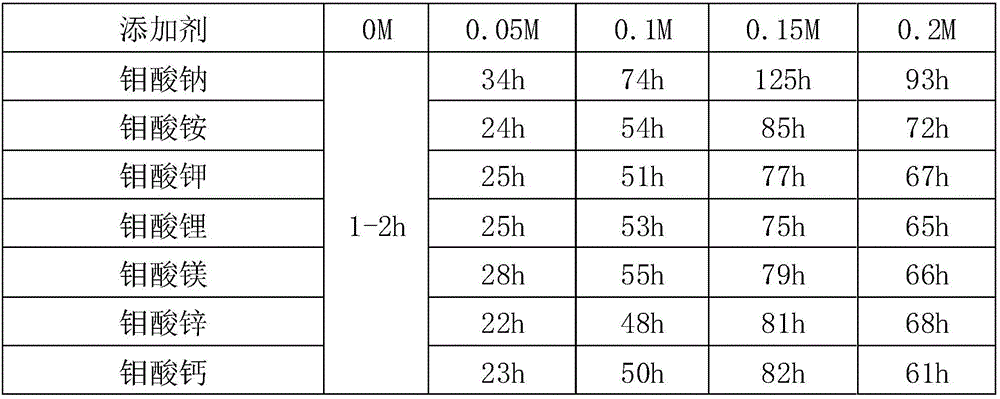

Vanadium battery electrolyte containing inorganic molybdate and vanadium battery

InactiveCN106299434AImprove stabilityExtended operating temperature rangeRegenerative fuel cellsPotassiumMaterials science

The invention provides a vanadium battery electrolyte containing inorganic molybdate. The vanadium battery electrolyte contains vanadium ion, sulfuric acid and an inorganic molybdate additive, wherein the concentration of the inorganic molybdate additive is 0.01M-0.25M and the inorganic molybdate is selected from one or more than two of sodium molybdate, ammonium molybdate, potassium molybdate, lithium molybdate, magnesium molybdate, zinc molybdate and calcium molybdate. The vanadium battery electrolyte containing inorganic molybdate can be taken as a cathode electrolyte of the vanadium battery. According to the invention, the inorganic molybdate is taken as the cathode electrolyte additive, so that the stability of the cathode electrolyte is increased and the running temperature scope of the vanadium battery is widened. The vanadium battery electrolyte containing inorganic molybdate has the advantages that the preparation technique is simple in operation, the cost is low and the high-temperature stable running of the vanadium battery can be easily realized.

Owner:PANZHIHUA IRON & STEEL RES INST OF PANGANG GROUP

Neodymium-doped lanthanum barium lithium molybdate laser crystal and preparation method and application thereof

The invention relates to a neodymium-doped lanthanum barium lithium molybdate laser crystal and a preparation method and application thereof. The high-quality Nd<3+>:Li3Ba2La3(MoO4)8 crystal with large size is grown by using 60-80at% Li2MoO4 as a fluxing agent under the conditions that the cooling rate is 0.5-2 DEG C / day and the rotating speed is 5-30r / min. The crystal belongs to the monoclinic system and has C2 / c space group structure. The crystal is a novel laser crystal and can generate and output lasers with wavelength being about 1.06mu m. The solid lasers prepared by the crystal can be applied to such fields as spectroscopy, biomedicine, military affairs and the like.

Owner:FUJIAN INST OF RES ON THE STRUCTURE OF MATTER CHINESE ACAD OF SCI

Method for retarding corrosion of metals in lithium halide solutions

InactiveUS20070031280A1Growth inhibitionLow corrosion rateOther chemical processesHeat-exchange elementsCrystal habitAqueous solution

Owner:ITZHAK DAVID

Lubricant composition and bearing using same

ActiveUS8188016B2Prevent surfaceIncreased durabilityGroup 1/11 element organic compoundsBearing componentsPotassiumSodium salt

Owner:NTN CORP

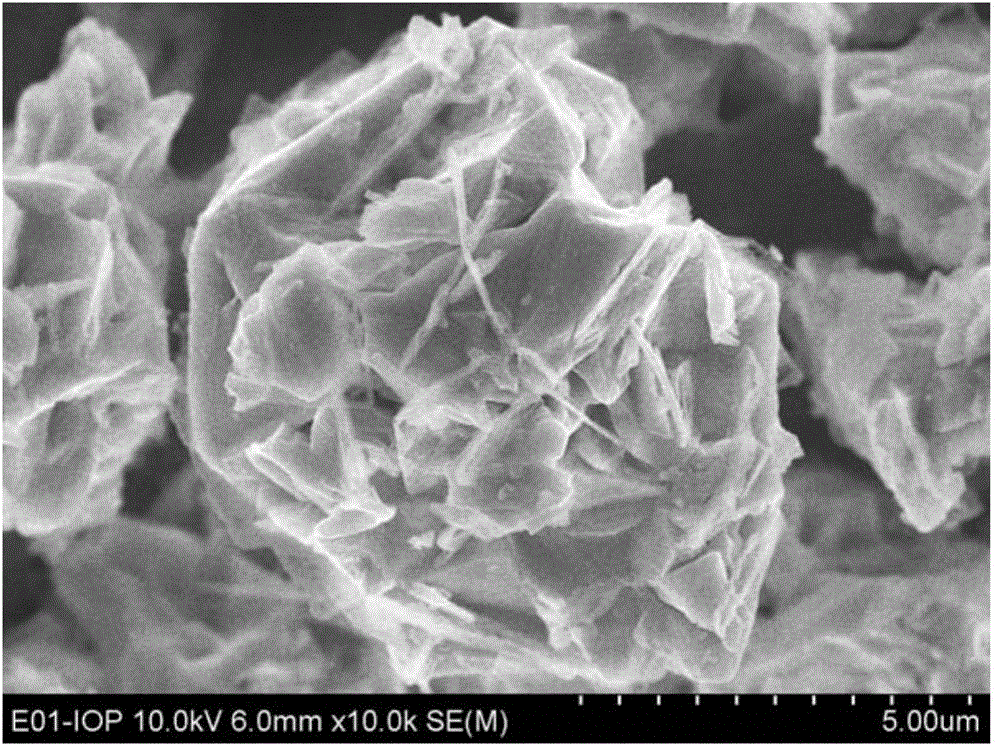

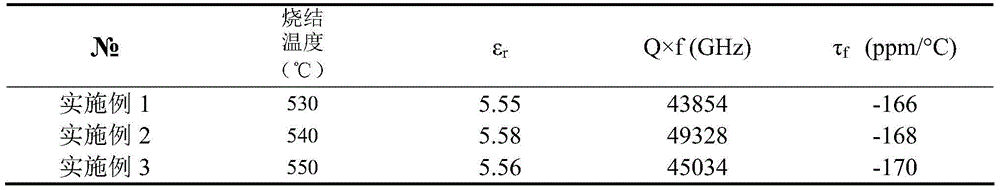

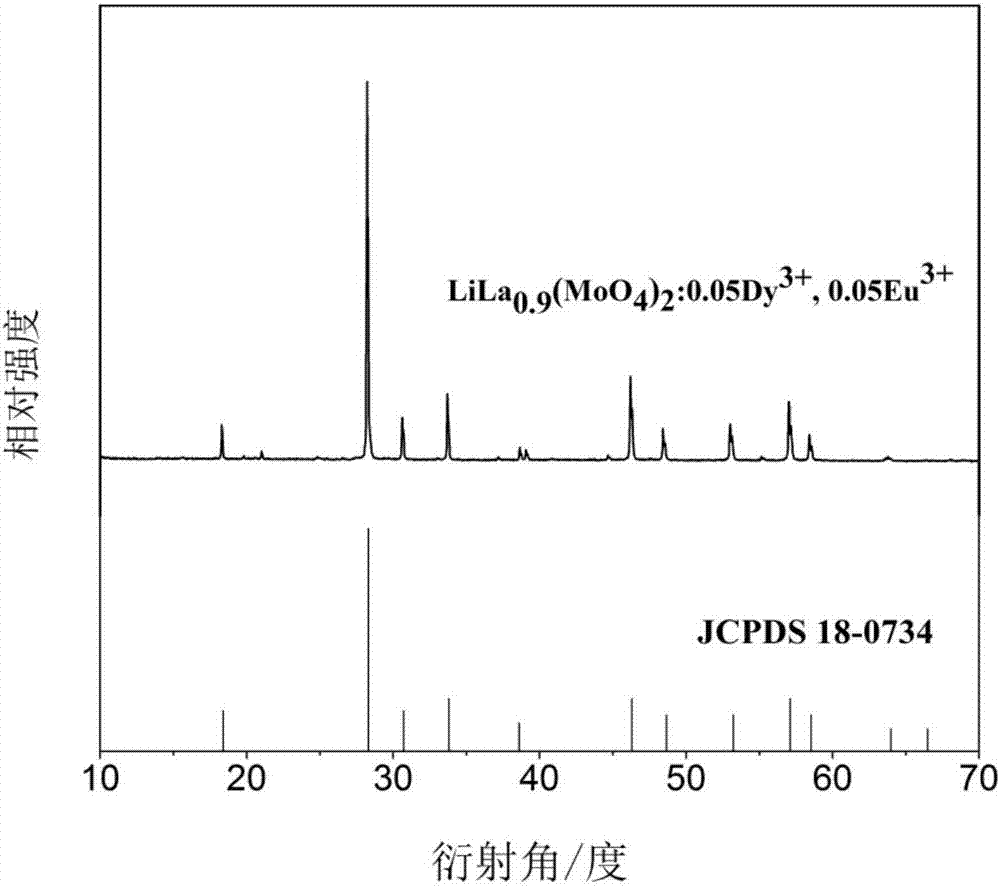

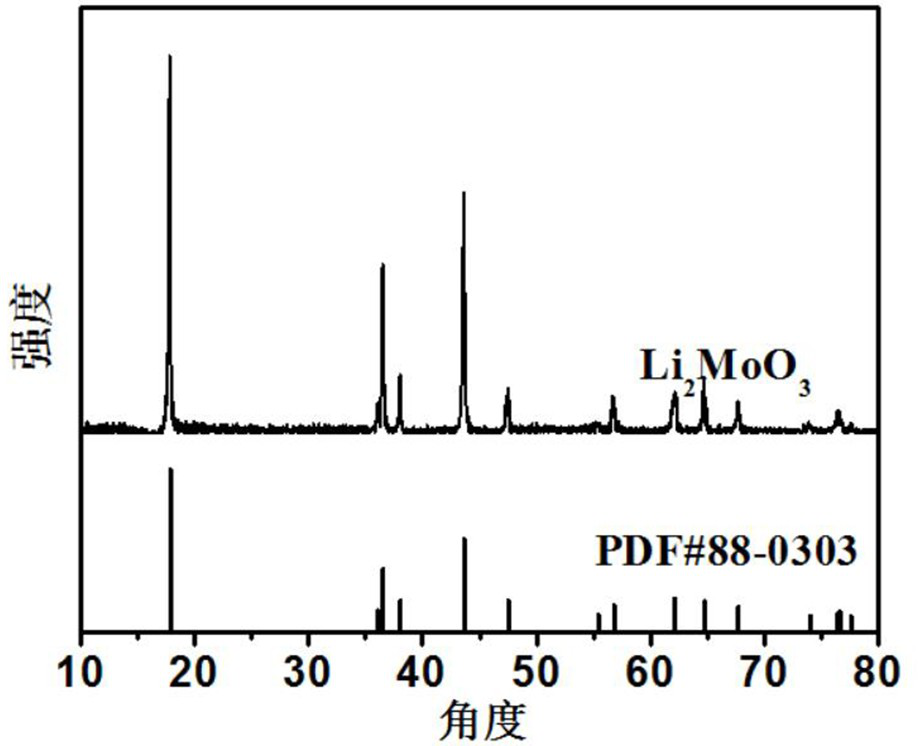

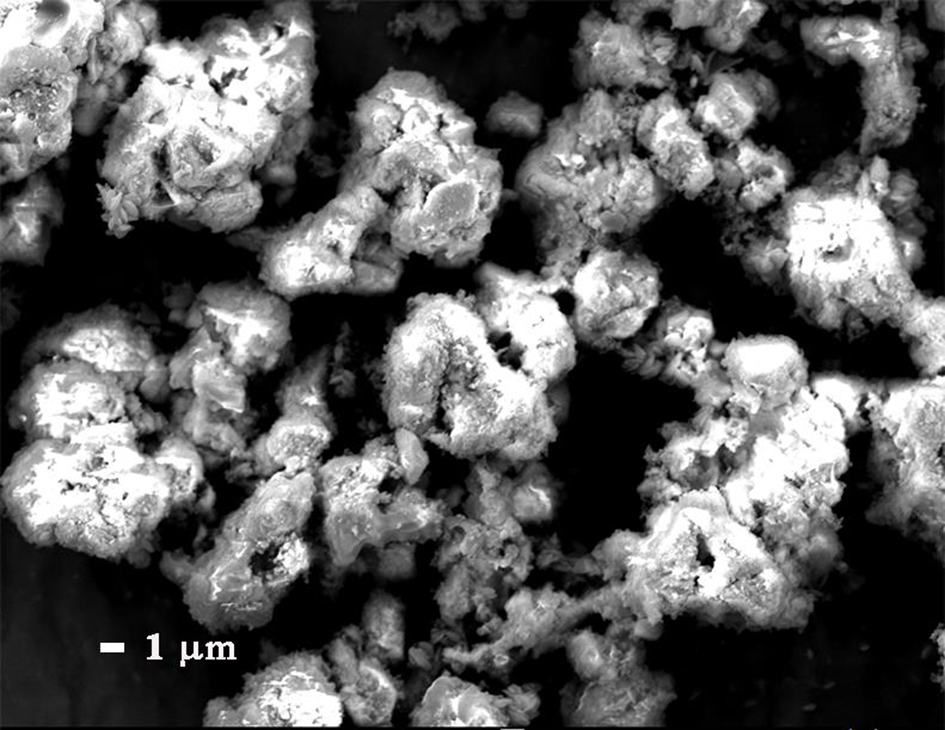

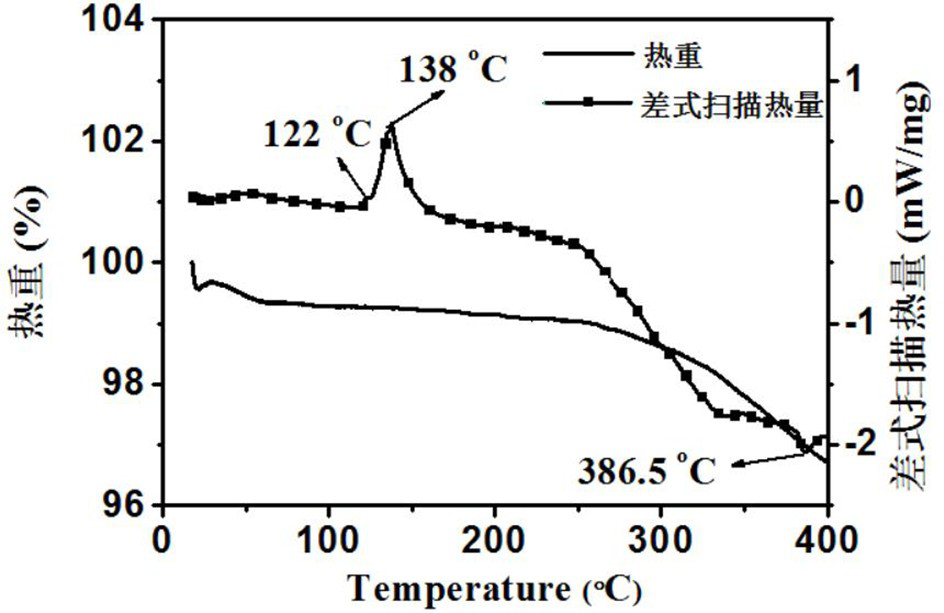

Preparation method for improving quality factor of lithium molybdate microwave dielectric ceramic

The invention discloses a preparation method for improving a quality factor of a lithium molybdate microwave dielectric ceramic. The preparation method comprises the following steps of first weighing raw materials (NH4)6Mo7O24.4H2O and LiOH.H2O according to a molar ratio of 1:14 for feed proportioning, and adding deionized water into an obtained mixture, so as to obtain a clear solution; afterwards, transferring the solution into a mortar, and heating the solution to 60 DEG C at a constant temperature, thereby completely evaporating moister, so as to obtain white powder; subsequently, using anhydrous alcohol as a dispersing agent, and grinding and drying the white powder to obtain a powder lot which is uniform in particles; after that, granulating the powder lot, and then carrying out compression molding on the granulated powder lot to become a green compact; first carrying out heat preservation on the green compact for 1 hour at 120 DEG C, and then sintering the green compact at 530 DEG C to 550 DEG C, so as to prepare the lithium molybdate microwave dielectric ceramic. According to the preparation method, in comparison with a conventional solid phase method, water is used as a reaction environment; the raw materials can react with one another sufficiently; high-purity lithium molybdate powder is obtained; presintering and ball milling processes are excluded; an impure phase is prevented from being introduced due to an insufficient reaction in the presintering process and the ball milling; therefore, the quality factor is improved; the microwave dielectric property of the ceramic is effectively improved; the preparation method has a better application prospect.

Owner:TIANJIN UNIV

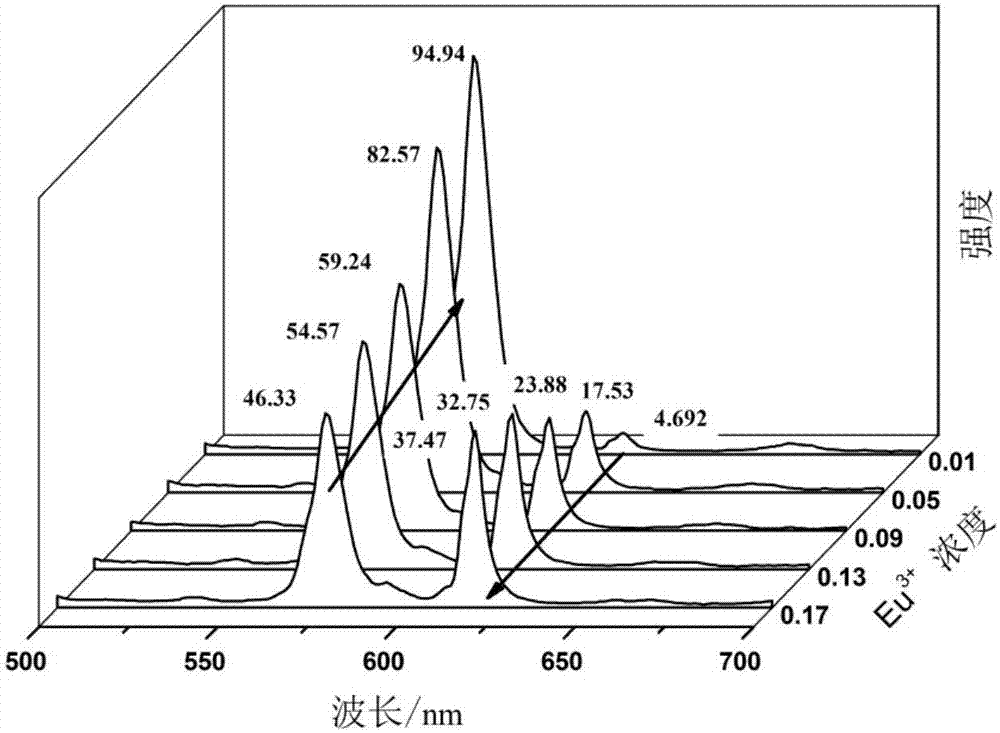

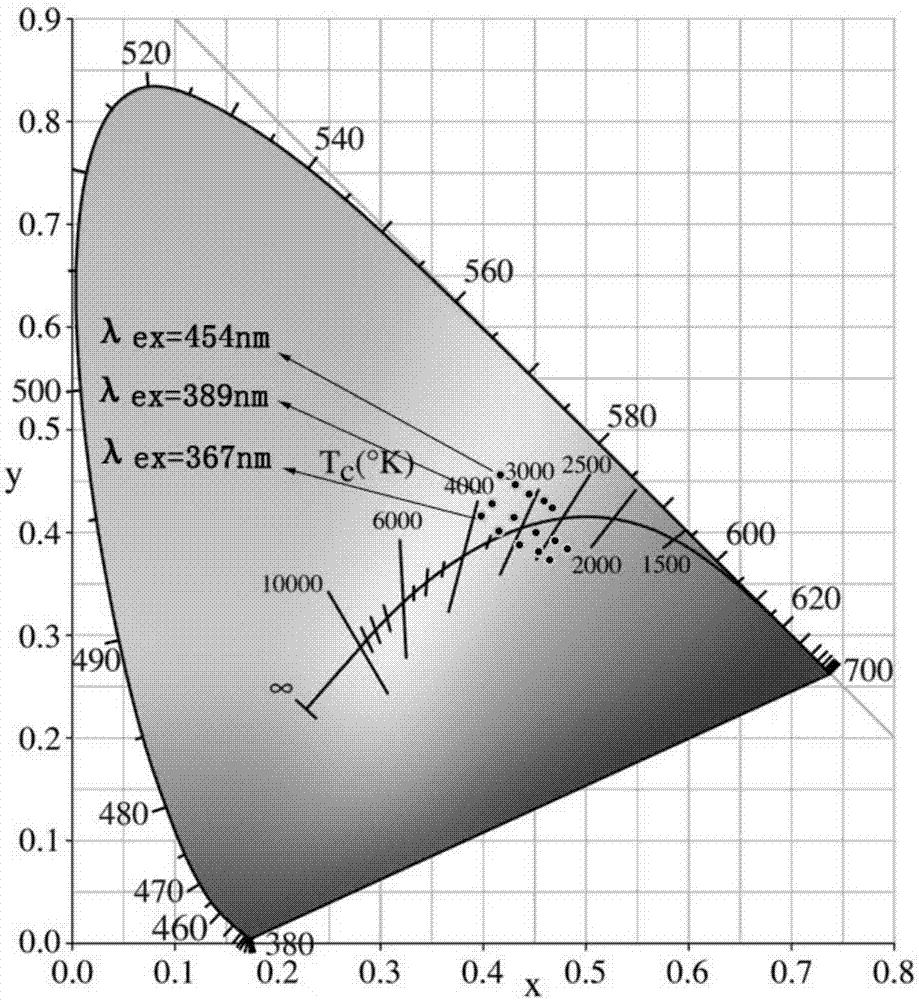

Dimmable rare earth doped lanthanum lithium molybdate fluorescent powder and preparation method thereof

The invention relates to dimmable rare earth doped lanthanum lithium molybdate fluorescent powder and a preparation method thereof. Li2CO3 powder, La2O3 powder, MoO3 powder, Dy2O3 powder and Eu2O3 powder are weighed in the mole rate being 1:(1-x):4:0.05:x, ground and stirred uniformly, and a reactant material is obtained, wherein x ranges from 0.01 to 0.17; the reactant material is calcined at 750-850 DEG C for 4-6 hours, and a reaction product is obtained; after the reaction product is cooled, the reaction product is taken out, ground and sieved, and the dimmable rare earth doped lanthanum lithium molybdate fluorescent powder is obtained. The fluorescent powder adopting a pure-phase substance structure is formed with a high-temperature solid phase method, raw materials are more widely sourced, the cost is lower, and no toxic organic matter is produced; under excitation of fixed wavelength, the developing range of the fluorescent powder can change in red and yellow light areas in a color coordinate graph by changing the doping concentration of Eu<3+> and using the energy transfer function between Dy<3+> and Eu<3+>, and the dimmable performance of the fluorescent powder is realized.

Owner:SHAANXI UNIV OF SCI & TECH

Erbium-doped yttrium barium lithium molybdate laser crystal and preparation method and application thereof

InactiveCN101676448APromote growthExcellent optical propertiesPolycrystalline material growthFrom melt solutionsSpace groupErbium doping

The invention relates to an erbium-doped yttrium barium lithium molybdate laser crystal and a preparation method and application thereof. The high-quality Er<3+>:Li3Ba2Y3(MoO4)8 crystal with large size is grown by using 60-80at% Li2MoO4 as a fluxing agent under the conditions that the cooling rate is 0.5-2 DEG C / day and the rotating speed is 5-30r / min. The crystal belongs to the monoclinic systemand has C2 / c space group structure. The crystal is a novel laser crystal and can generate and output lasers with wavelength being about 1500nm.

Owner:FUJIAN INST OF RES ON THE STRUCTURE OF MATTER CHINESE ACAD OF SCI

High-temperature lithium battery cathode material, preparation method thereof and high-temperature lithium battery

ActiveCN112510183AExcellent discharge capacity performanceDeferred-action cellsCell electrodesActivated carbonElectrical battery

The invention provides a preparation method of a high-temperature lithium battery positive electrode material. The preparation method comprises the following steps: preparing lithium molybdate; grinding and sieving the lithium molybdate; weighing 70-90 parts by mass of ground and sieved lithium molybdate, 5-20 parts by mass of eutectic salt with the melting point lower than 300 DEG C and 5-10 parts by mass of activated carbon, grounding and evenly mixing, and obtaining a mixture A; and sintering the mixture A in a vacuum atmosphere to obtain a high-temperature lithium battery positive electrode material. The invention also provides a high-temperature lithium battery positive electrode material and a high-temperature lithium battery. The high-temperature lithium battery positive electrode material and the preparation method thereof provided by the invention can be applied to the field of high-temperature batteries, and the high-temperature lithium battery prepared from the high-temperature lithium battery positive electrode material has excellent discharge capacity performance.

Owner:太仓市华盈电子材料有限公司

Lithium bromide absorption refrigerator high-efficiency corrosion inhibitor and preparation method thereof

The invention provides a lithium bromide absorption refrigerator high-efficiency corrosion inhibitor and a preparation method thereof and in particular relates to a polyoxometalate composite inorganic high polymer material. The lithium bromide absorption refrigerator high-efficiency corrosion inhibitor provided by the invention is prepared from the following raw materials in parts by weight: 15-35 parts of lithium molybdate, 10-50 parts of lithium tungstate, 1-5 parts of lithium dihydrogen phosphate, 50-75 parts of deionized water, 4-15 parts of hydrobromic acid and 0.5-2 parts of zinc dihydrogen phosphate. The preparation method comprises the following steps of: firstly preparing hydrobromic acid solution, dissolving lithium molybdate, lithium tungstate and lithium dihydrogen phosphate, heating lithium tungstate solution and lithium dihydrogen phosphate solution in a reaction kettle, regulating the pH value, then dropwise adding lithium molybdate solution, and finally regulating the pH value and adding zinc dihydrogen phosphate, so that the lithium bromide absorption refrigerator high-efficiency corrosion inhibitor is obtained. Compared with the prior art, the lithium bromide absorption refrigerator high-efficiency corrosion inhibitor provided by the invention has the characteristics that inner cavity material of the lithium bromide refrigerator is obviously passivated, a passivated film is excellently bonded with the inner cavity material and has high corrosion resistance, and the corrosion inhibitor has good temperature resistance and stability and is low in additive amount.

Owner:镇江市富来尔制冷工程技术有限公司

Special lithium bromide solution for adsorption refrigerator and preparation method thereof

InactiveCN103509521AGood passivation propertiesImprove the shortcoming of easily generating hydrogenHeat-exchange elementsPhosphateLithium bromide

The invention belongs to the technical field of air conditioning refrigeration and particularly relates to a special lithium bromide solution for an adsorption refrigerator and a preparation method thereof. The special lithium bromide solution for the adsorption refrigerator comprises a corrosion inhibitor which accounts for 1 to 3.5 percent of the total mass of the lithium bromide solution. The corrosion inhibitor comprises the following raw material components in parts by mass: 15 to 35 parts of lithium molybdate, 10 to 50 parts of lithium tungstate, 1 to 5 parts of lithium dihydrogen phosphate, 4 to 15 parts of hydrobromic acid, 0.5 to 2 parts of zinc dihydrogen phosphate and 0.5 to 2 parts of manganous nitrate. The special lithium bromide solution for the adsorption refrigerator is excellent in combination of a passive film layer and an inner cavity material, has more excellent corrosion resistance and good temperature resistance and stability.

Owner:昆山市周市溴化锂溶液厂

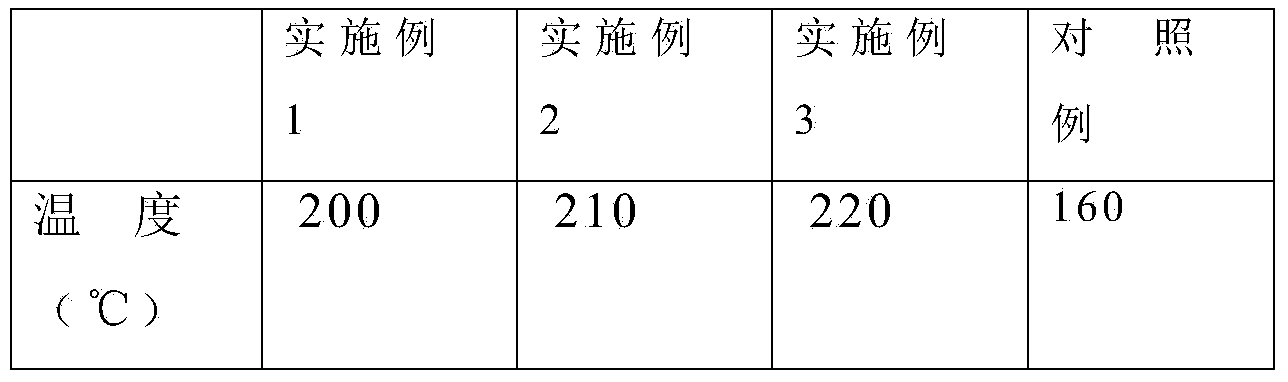

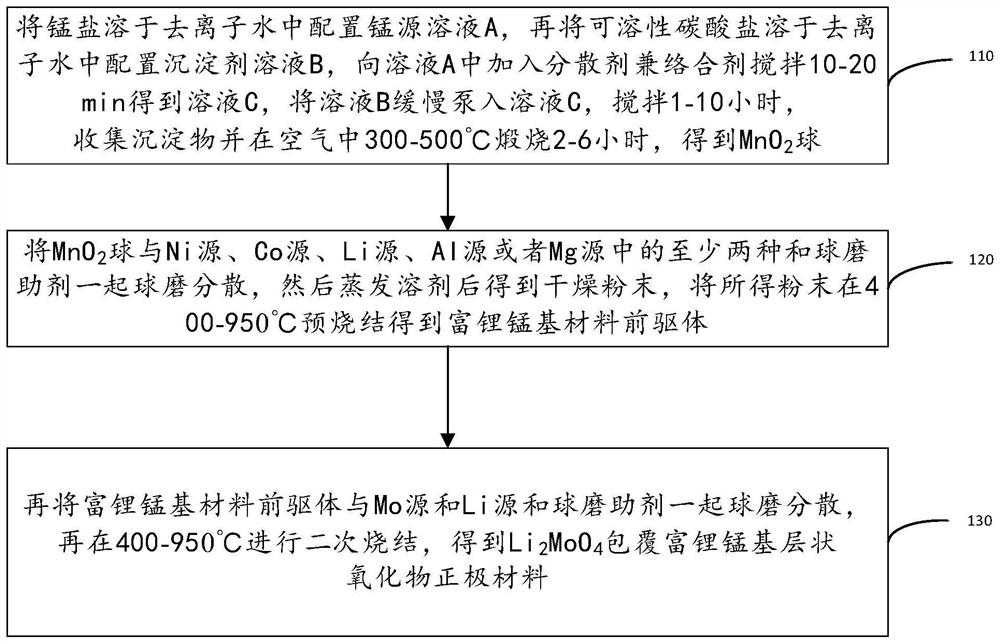

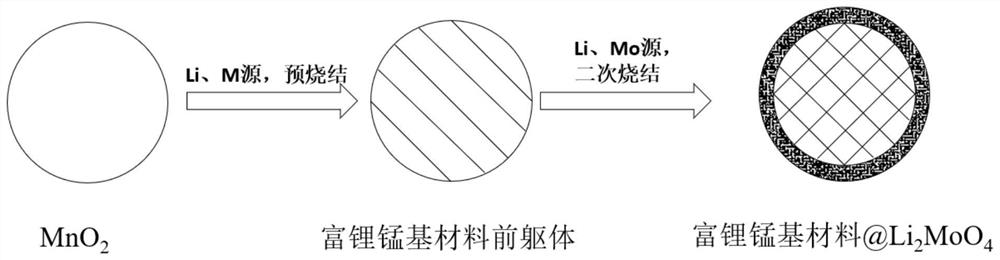

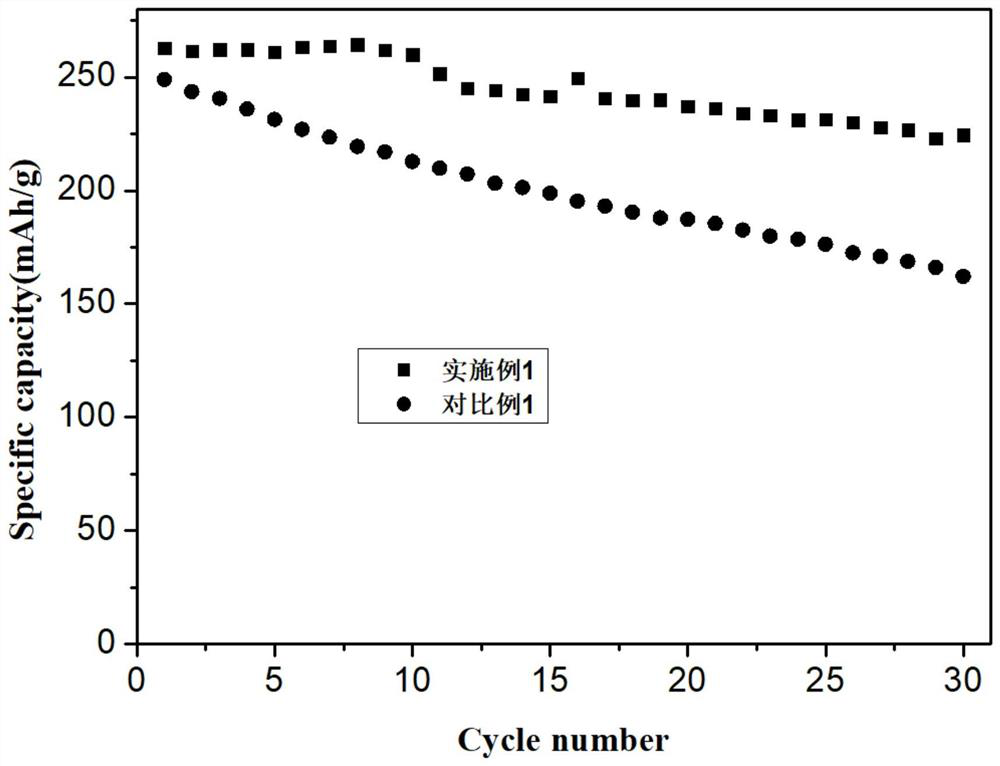

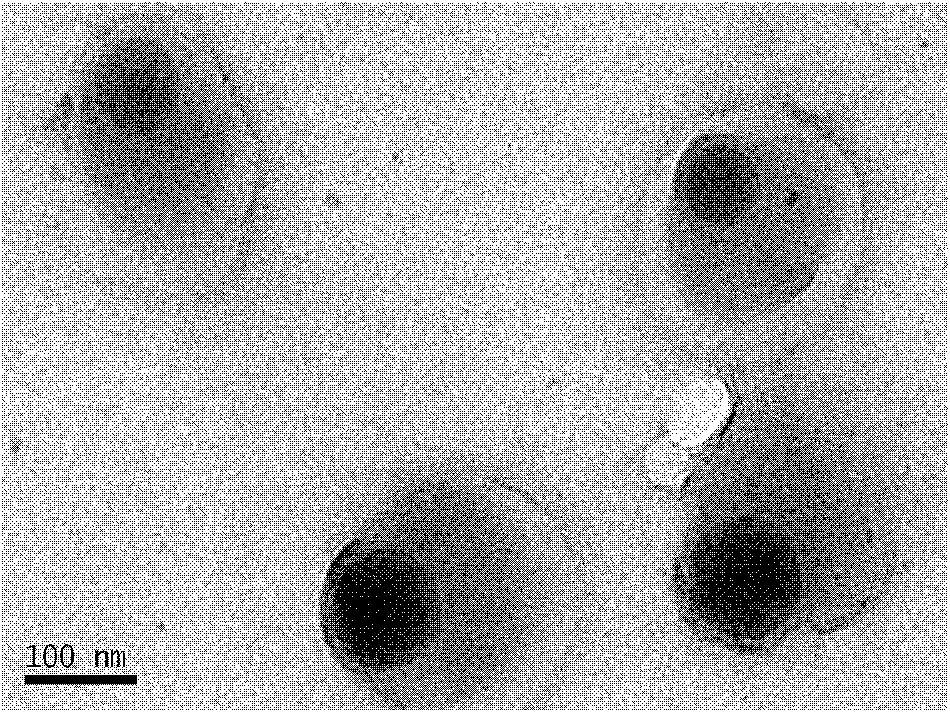

Lithium molybdate coated lithium-rich manganese-based positive electrode material as well as preparation method and application thereof

ActiveCN113078316AElectrochemically activeReduce oxygen evolutionMolybdeum compoundsCell electrodesPhysical chemistryManganese

The invention relates to a lithium molybdate coated lithium-rich manganese-based positive electrode material as well as a preparation method and application thereof. The structure of the lithium molybdate coated lithium-rich manganese-based positive electrode material comprises a lithium-rich manganese-based layered oxide inner core and a Li2MoO4 coating layer, and a Mo6+ concentration gradient transition layer exists between the lithium-rich manganese-based layered oxide inner core and the Li2MoO4 coating layer; in the transition layer, the concentration of Mo6+ is gradually reduced from one side of the coating layer to one side of the inner core, and the thickness of the transition layer is 0.1-10 nm; the chemical expression of the Li2MoO4 coated lithium-rich manganese-based layered oxide positive electrode material is xLi[Li0.33Mn0.67]O2.(1-x)LiMO2@Li2MoO4, 0<x<1, wherein M at least comprises two elements of Mn, Ni, Co, Al and Mg.

Owner:江苏蓝固新能源科技有限公司

Lithium battery cathode material with nitrogen-doped graphene and lithium molybdate and preparation method of lithium battery cathode material

InactiveCN107959004AImprove electrochemical performanceImprove cycle stabilitySecondary cellsPositive electrodesElectrical conductorDistillation

The invention is suitable for the technical field of lithium batteries, and provides a lithium battery cathode material with nitrogen-doped graphene and lithium molybdate and a preparation method of the lithium battery cathode material. The preparation method comprises the following steps: dispersing graphite oxide and a nitrogen source in water to form dispersion liquid, adding ascorbic acid, andheating to form gel; and adding a proper amount of molybdenum trioxide and a lithium ternary material in mixed gel, stirring and drying by distillation, calcining in an inert gas atmosphere, and cooling to obtain nitrogen-doped graphene and lithium molybdate co-coated lithium battery ternary cathode material. A nitrogen-doped graphene and lithium molybdate lithium-ion conductor co-coated layer isformed on the surface of the material by molybdenum trioxide and graphene gel, the electrochemical performance of the material can be improved by good conductive property of nitrogen-doped graphene,by use of the ascorbic acid, part of residual alkali is reduced favorably, the processing performance of the cathode material is improved, moreover, by the coated layer in a lithium salt mode, the diffusion path of lithium ions in an electrode material can be greatly expanded, the lithium ion conveying rate is increased, and therefore, the rate capability of the material is improved. The method issimple in process, and the electrochemical performance improving effect is remarkable.

Owner:GEM WUXI ENERGY MATERIAL CO LTD +1

Laser crystal of lithium lanthanum molybdate with neodymium being doped, preparation method and usage

This invention discloses Czochralski method for preparing Nd-doped lanthanum lithium molybdate laser crystal (Nd3+ : LiLa(MoO4)2) and its application. The method comprises growing high-quality and large-size Nd3+: LiLa (MoO4)2 crystal at a temperature of 977 deg.C, a rotation speed of 20-55 rpm and a drawing speed of 0.5-1 mm / h. The crystal can produce laser output with wavelengths of 1.06 mum and 0.9 mum. Solid laser devices produced from the laser crystal can be used in such fields as spectroscopy, biomedicine and military.

Owner:FUJIAN INST OF RES ON THE STRUCTURE OF MATTER CHINESE ACAD OF SCI

Multifunctional concrete structure endurance protective agent, preparation and application method thereof

The invention discloses a multifunctional concrete structure endurance protective agent as well as the preparation and application method thereof. The protective agent provided by the invention contains the following ingredients of: an organic / inorganic composite fluorosilicone-acrylate copolymer, lithium silicate, sodium silicate, lithium molybdate, sodium tetraborate, sal glauberi, 1,2-aminoazophenylene, nanometer titanium dioxide, anhydrous ethanol and water. The protective agent can penetrate inside concrete, wherein a densification ingredient can minimize internal holes and cracks to raise the compactness of concrete, and a rust-resistant ingredient can penetrate into concrete and be adsorbed on the surface of steel bar so as to passivate and protect the steel bar; the low-surface energy silicon fluoride ingredient can be solidified to form a cured film on the surface of concrete so as to endow the protective agent with the hydrophobic performance; a nanometer ingredient can endow the cured film layer with properties of resisting ultraviolet and ageing and improving the organic polymer performance as well as the self-cleaning performance. In addition, hydroxy generated from the hydrolysis of siloxane group can perform a condensation reaction with hydroxy on the surface of concrete to produce chemical bond, so as to raise the anchoring strength between the film and concrete and improve the interface combination. The protective agent provided by the invention can be widely applied in various concrete structure engineering protections to raise the service life of concrete.

Owner:CENT SOUTH UNIV +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com