Lithium molybdate cathode material for lithium ion battery and preparation method thereof

A technology of lithium ion battery and negative electrode material, which is applied to battery electrodes, non-aqueous electrolyte battery electrodes, secondary batteries, etc., to achieve the effect of simple preparation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0043] Will Li 2 CO 3 and MoO 2 Weigh it according to the stoichiometric ratio (molar ratio) of Li:Mo=2:1, grind it in an agate mortar for 30min, and mix well;

[0044] Then in the air atmosphere, heat up to 200 ° C for 4 hours of heat preservation pretreatment, and then grind again after natural cooling;

[0045] Then sinter in air at 500°C for 24h to obtain lithium molybdate (Li 2 MoO 4 ) anode material.

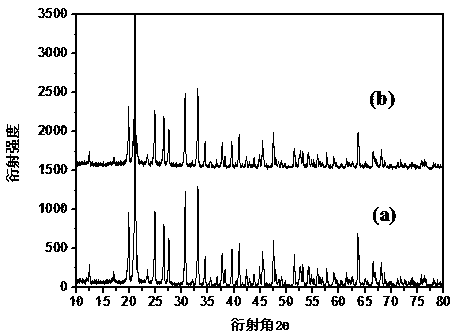

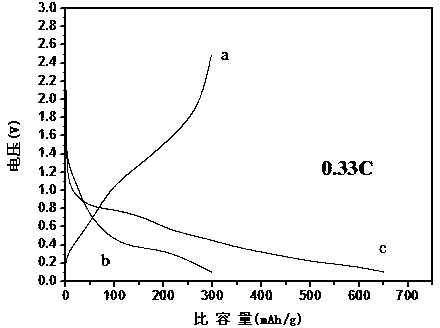

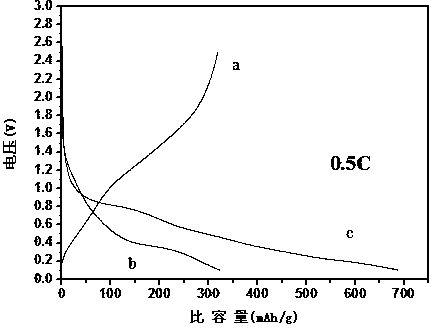

[0046] The XRD pattern of the product is shown in figure 1 (a), as can be seen from the figure, using this solid-state sintering method, a pure-phase trigonal lithium molybdate (Li 2 MoO 4 ) negative electrode material, there is no impurity peak in the spectrum, and the product has high purity. The lithium molybdate (Li 2 MoO 4 ) The negative electrode material is in the voltage range of 0.1~2.5V, and the rate is 0.33C and 0.5C respectively. The first charge and discharge and the second discharge curve are as follows figure 2 , image 3 As shown, the cycle per...

Embodiment 2

[0049] Will Li 2 CO 3 and MoO 3 Weigh according to the stoichiometric ratio of Li:Mo=2:1, add Li 2 CO 3 and MoO 3 The total mass of the precursor is 10wt% citric acid as a carbon source, and the raw material is ball milled in a planetary ball mill for 5 hours;

[0050] Under Ar gas atmosphere, heat up to 250°C for 5 hours of heat preservation pretreatment, after natural cooling, ball mill again;

[0051] Sintering was carried out at 550 °C for 15 h under Ar gas atmosphere to obtain carbon-coated lithium molybdate (Li 2 MoO 4 ) anode material.

[0052] The XRD pattern of the product is shown in figure 1 (b), as can be seen from the figure, using this solid-state sintering method, a pure-phase trigonal lithium molybdate (Li 2 MoO 4 ) negative electrode material, there is no impurity peak in the spectrum, and the product has high purity. The lithium molybdate (Li 2 MoO 4 ) The negative electrode material is within the voltage range of 0.1~2.5V, and the rate is 0.25C...

Embodiment 3

[0054] CH 3 COOLi and (NH 4 ) 2 MoO 4 Weigh according to the stoichiometric (molar ratio) ratio of Li:Mo=2:1, ball mill the raw materials in a planetary ball mill for 10 hours, and mix well;

[0055] Then, in an air atmosphere, heat preservation pretreatment was carried out at 300 ° C for 6 hours, after natural cooling, acetylene black accounting for 5 wt% of the sample mass after cooling was added, and ball milled again;

[0056] in N 2 sintering at 650°C for 12 h in an air atmosphere to obtain carbon-coated lithium molybdate (Li 2 MoO 4 ) anode material.

[0057] The XRD pattern of the product is shown in Figure 7 (a), as can be seen from the figure, using this solid-state sintering method, a pure-phase trigonal lithium molybdate (Li 2 MoO 4 ) negative electrode material, there is no impurity peak in the spectrum, and the product has high purity. The lithium molybdate (Li 2 MoO 4 ) The negative electrode material is within the voltage range of 0.1~2.5V, and the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com