Preparation method of lithium-intercalated molybdenum trioxide electrode material

A technology of molybdenum trioxide and electrode materials, which is applied to battery electrodes, circuits, electrical components, etc., can solve the problems of electrode materials such as cumbersome steps, long time consumption, and high cost, and achieve excellent cycle performance, simple and easy raw materials, and uniform size distribution Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

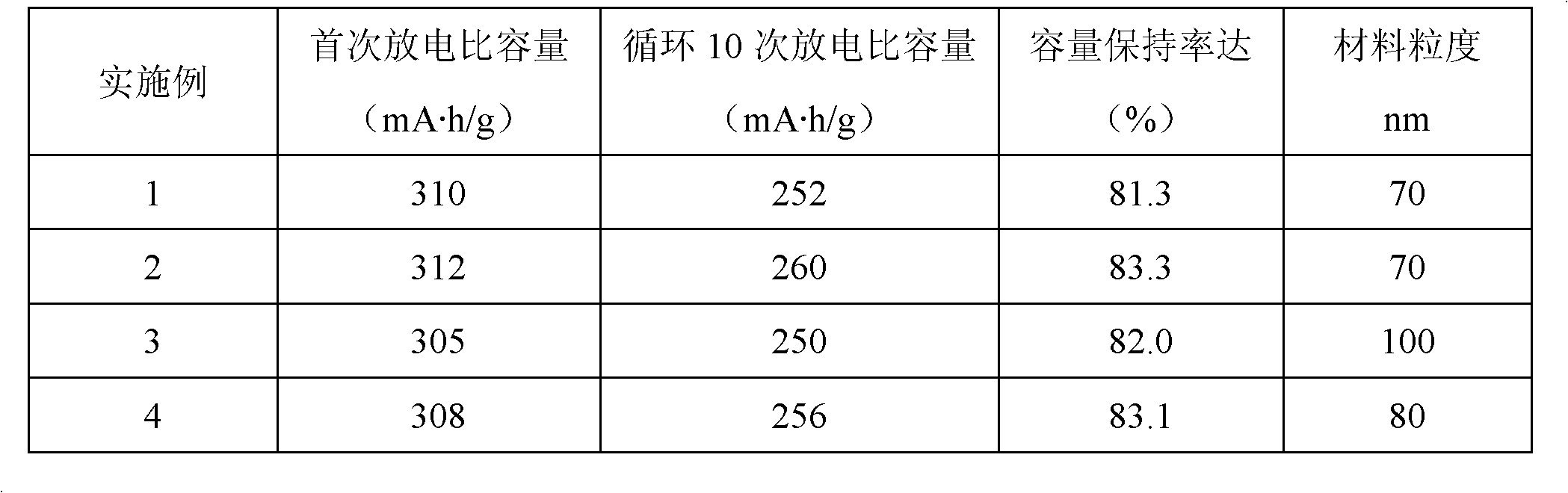

Embodiment 1

[0014] The preparation method of the lithium intercalation molybdenum trioxide electrode material of the present embodiment is as follows:

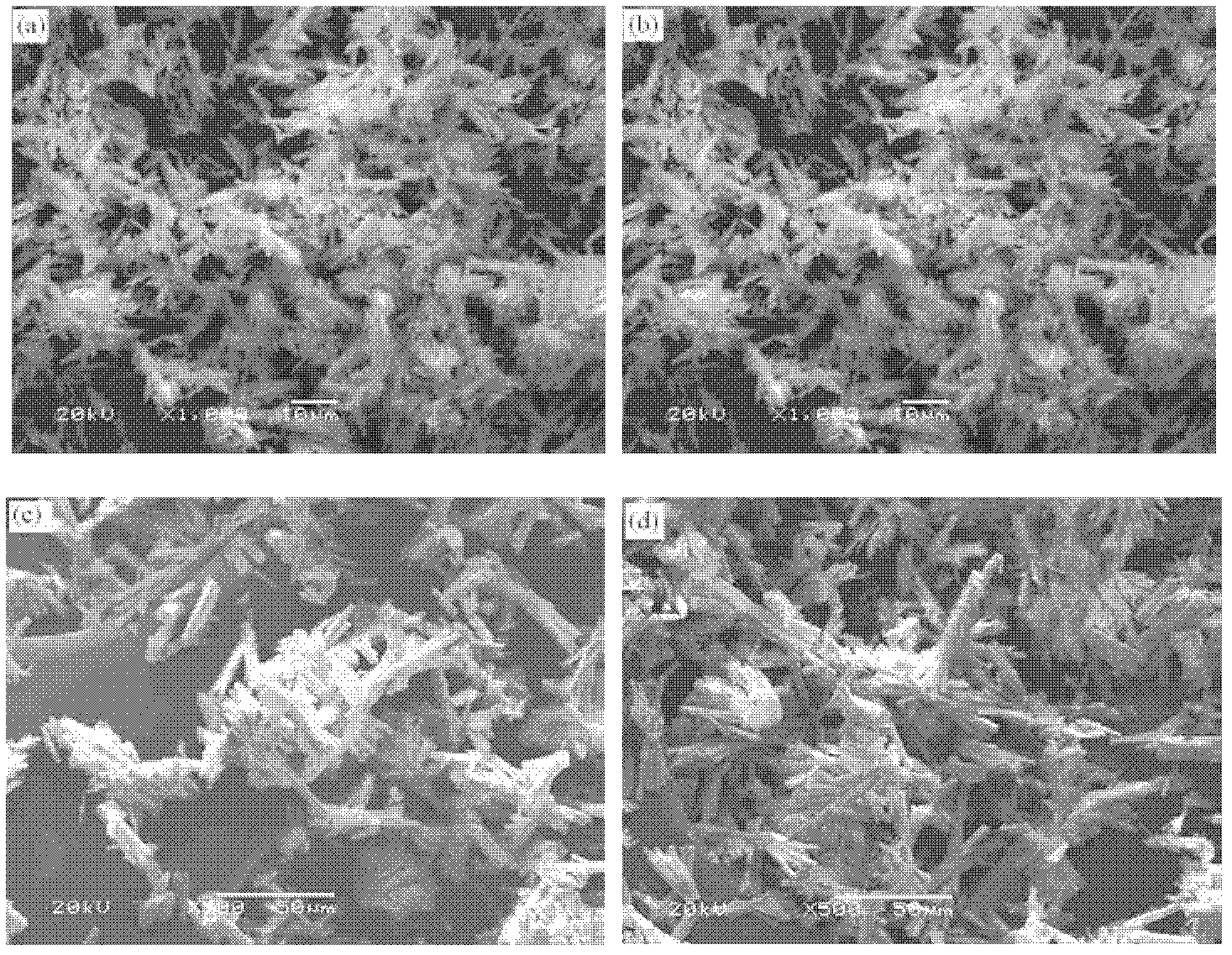

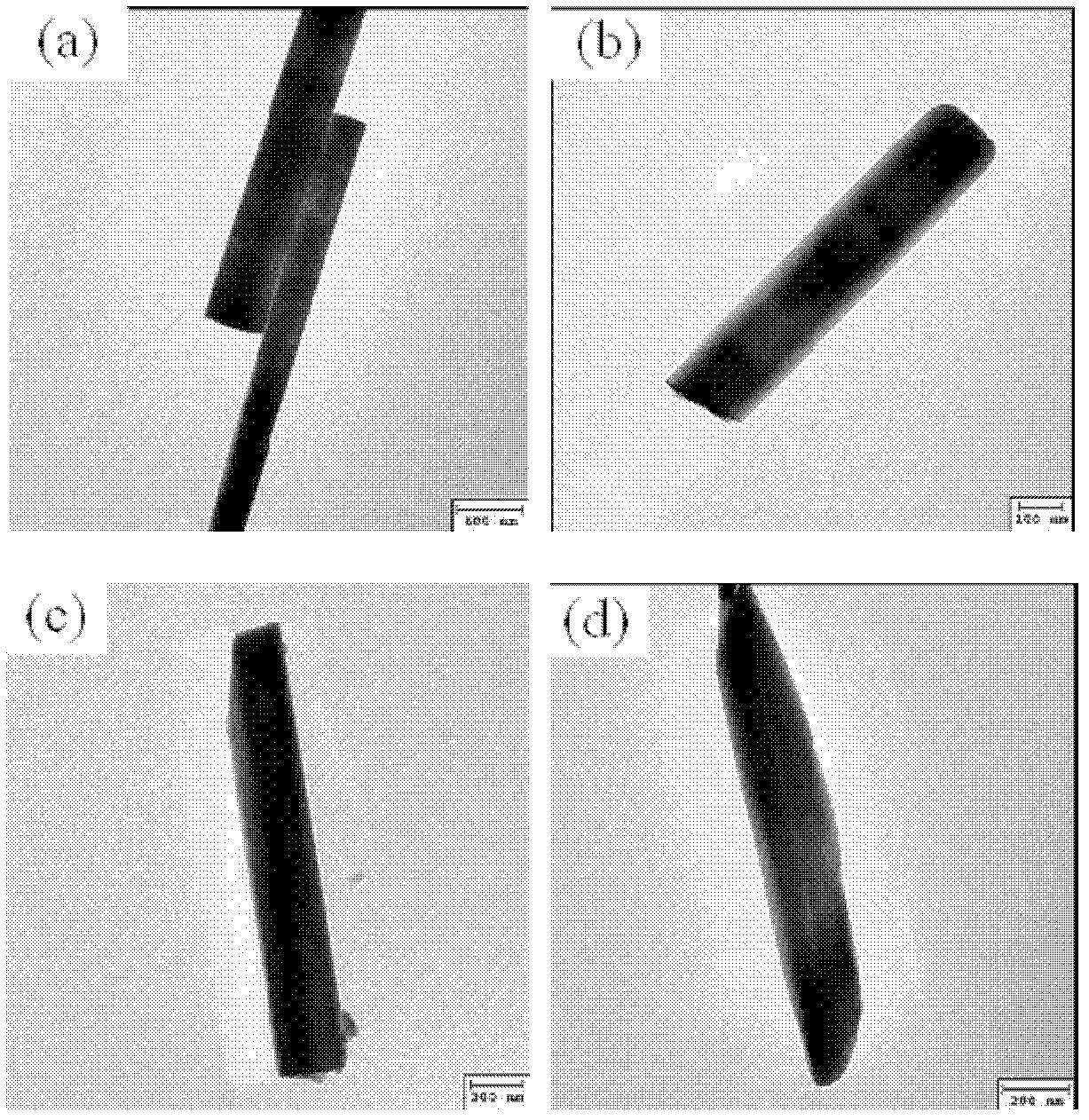

[0015] Weigh 36g of lithium molybdate and pour it into a beaker, add appropriate deionized water to prepare 180mL of a saturated solution of lithium molybdate; then put the beaker into an ultrasonic cleaner, ultrasonically clean it at 25°C for 10min, and use the prepared A good 2.2mol / L nitric acid solution adjusts the pH value of the saturated solution to 0.5, white precipitates appear, stir, then place it in the autoclave, then put the autoclave into the electric heating constant temperature blast drying box, set The temperature is 170°C, and the hydrothermal reaction time is 4h; after the constant temperature is over, let the reactor cool down naturally, and the obtained product is washed with 33wt% nitric acid, absolute ethanol and deionized water; the washed sample is heated at 60°C Dry at constant temperature for 6 hours to obtain n...

Embodiment 2

[0017] The preparation method of the lithium intercalation molybdenum trioxide electrode material of the present embodiment is as follows:

[0018] Weigh 40g of lithium molybdate and pour it into a beaker, add appropriate deionized water to prepare 200mL of a saturated solution of lithium molybdate; then put the beaker into an ultrasonic cleaner, ultrasonically clean it at 25°C for 10min, and use the prepared A good 2.2mol / L nitric acid solution adjusts the pH value of the saturated solution to 1.0, white precipitates appear, stir, then place it in the autoclave, then put the autoclave into the electric heating constant temperature blast drying box, set The temperature is 180°C, and the hydrothermal reaction time is 10h; after the constant temperature is over, let the reactor cool down naturally, and the obtained product is washed with 33wt% nitric acid, absolute ethanol and deionized water; the washed sample is heated at 60°C Dry at constant temperature for 6 hours to obtain ...

Embodiment 3

[0020] The preparation method of the lithium intercalation molybdenum trioxide electrode material of the present embodiment is as follows:

[0021] Weigh 50g of lithium molybdate and pour it into a beaker, add appropriate deionized water to prepare 250mL of a saturated solution of lithium molybdate; then put the beaker into an ultrasonic cleaner, ultrasonically clean it at 25°C for 10min, and use the prepared A good 2.2mol / L nitric acid solution adjusts the pH value of the saturated solution to 2.0, white precipitates appear, stir, then place it in the autoclave, then put the autoclave into the electric heating constant temperature blast drying box, set The temperature was 175°C, and the hydrothermal reaction time was 20h; after the constant temperature was over, the reactor was allowed to cool naturally, and the resulting product was washed with 33wt% nitric acid, absolute ethanol and deionized water; the washed samples were heated at 60°C Drying at a constant temperature for...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| retention rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com