Special lithium bromide solution for adsorption refrigerator and preparation method thereof

An absorption refrigerator and lithium bromide technology, applied in chemical instruments and methods, heat exchange materials, etc., can solve problems such as peeling off shells, poor adhesion between oxide film and base layer, poor heat resistance stability of corrosion inhibitors, etc. , to achieve the effects of not easy to deteriorate, outstanding passivation characteristics, and good corrosion resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

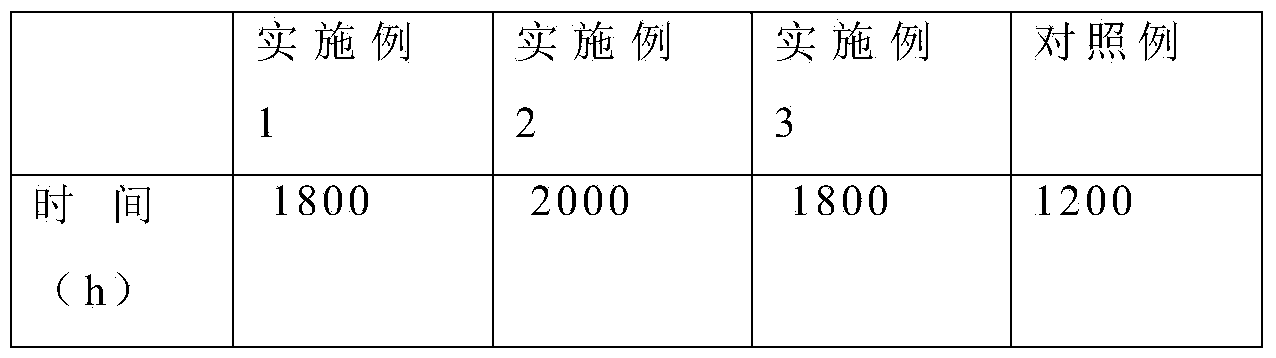

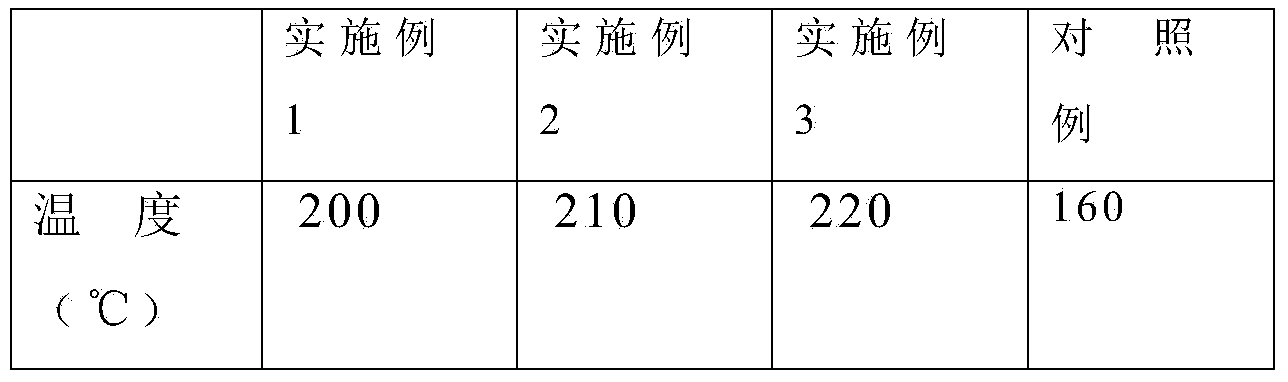

Embodiment 1

[0021] (1) Dissolve 4g of hydrobromic acid in 50g of deionized water to make a hydrobromic acid solution; use 25g, 22g, 7g, and 5g of the above-mentioned hydrobromic acid solution with 15g of lithium molybdate, 10g of lithium tungstate, and manganese nitrate 1g and 1g of lithium dihydrogen phosphate are mixed until dissolved to prepare lithium molybdate solution, lithium tungstate solution and lithium dihydrogen phosphate solution respectively;

[0022] (2) Add lithium tungstate solution into the reaction kettle, heat to 40°C, add lithium dihydrogen phosphate solution dropwise while stirring, mix well, and keep warm for 60 minutes;

[0023] (3) After completing step (2), add the remaining manganese nitrate solution dropwise while stirring, then add dilute nitric acid to adjust the pH value of the solution to 1-2; continue stirring for 15 minutes, add lithium molybdate solution dropwise, and stir for 60 minutes ;

[0024] (4) Place it for more than 24 hours, adjust the pH to 8...

Embodiment 2

[0028] (1) Dissolve 8g of hydrobromic acid in 60g of deionized water to make a hydrobromic acid solution; use 25g, 38g, 3g, and 2g of the above-mentioned hydrobromic acid solution with 20g of lithium molybdate, 30g of lithium tungstate, and 1g of nitric acid respectively Manganese and 2g lithium dihydrogen phosphate are mixed until dissolved, as lithium molybdate solution, lithium tungstate solution, manganese nitrate solution and lithium dihydrogen phosphate solution;

[0029] (2) Add lithium tungstate solution to the reaction kettle, heat to 60°C, add lithium dihydrogen phosphate solution dropwise while stirring, mix well, and keep warm for 75 minutes;

[0030] (3) After completing step (2), add the remaining manganese nitrate solution dropwise while stirring, then add dilute nitric acid to adjust the pH value of the solution to 1-2; continue stirring for 30 minutes, add lithium molybdate solution dropwise, and stir for 75 minutes ;

[0031] (4) Place it for more than 24 ho...

Embodiment 3

[0035] (1) Dissolve 15g of hydrobromic acid in 80g of deionized water to make a hydrobromic acid solution; use 45g, 30g, 10g, and 10g of the above-mentioned hydrobromic acid solution with 35g of lithium molybdate, 20g of lithium tungstate, and 3g of nitric acid respectively Manganese and 5g lithium dihydrogen phosphate are mixed until dissolved, as lithium molybdate solution, lithium tungstate solution, manganese nitrate solution and lithium dihydrogen phosphate solution;

[0036] (2) Add lithium tungstate solution to the reaction kettle, heat to 80°C, add lithium dihydrogen phosphate solution dropwise while stirring, mix well, and keep warm for 90 minutes;

[0037] (3) After completing step (2), add the remaining manganese nitrate solution dropwise while stirring, then add dilute nitric acid to adjust the pH value of the solution to 1-2; continue stirring for 45 minutes, add lithium molybdate solution dropwise, and stir for 90 minutes ;

[0038] (4) Place it for more than 24...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com