Preparation method of GaAs-based high-power semiconductor laser cavity surface passivation film based on AlxNy

A semiconductor and laser technology, applied in the field of high-power semiconductor laser cavity surface passivation, can solve the problems of large absorption of light in the near-infrared band, easy deliquescence, etc., to achieve enhanced passivation effect, good passivation characteristics, and avoid the introduction of impurities. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

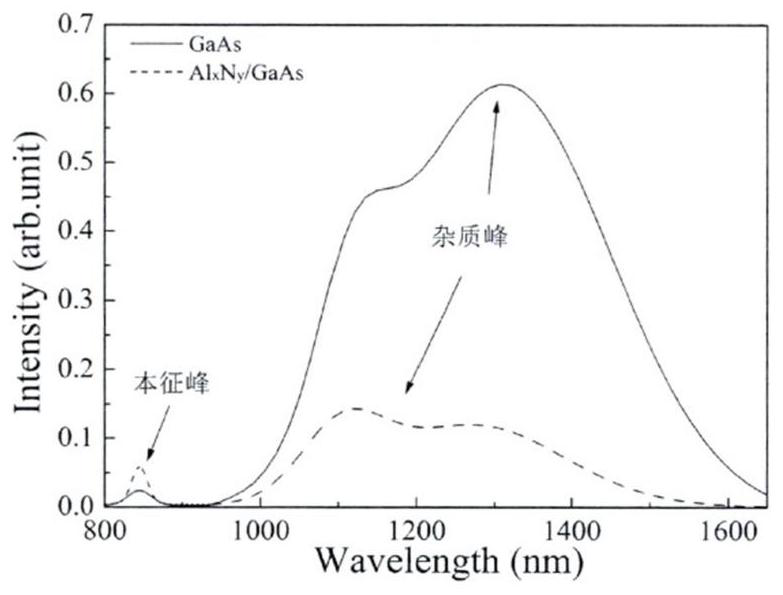

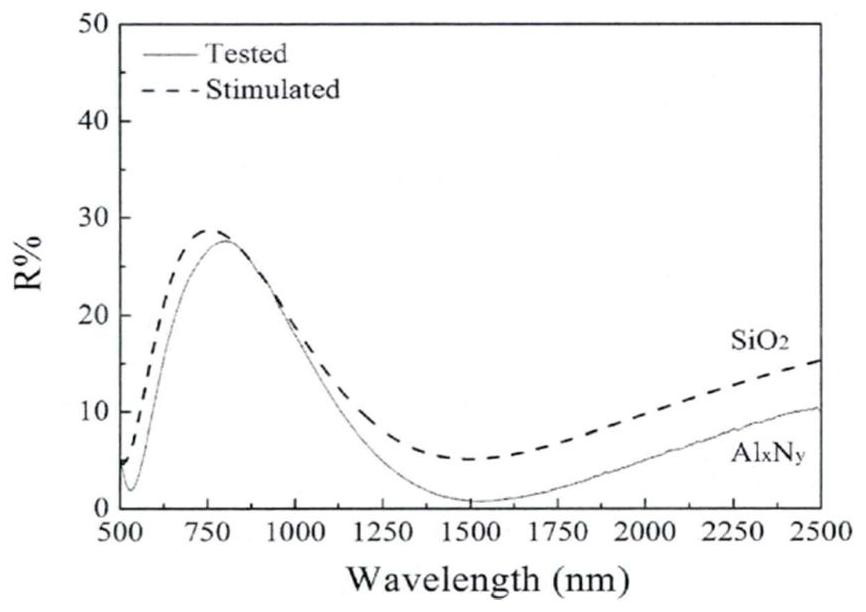

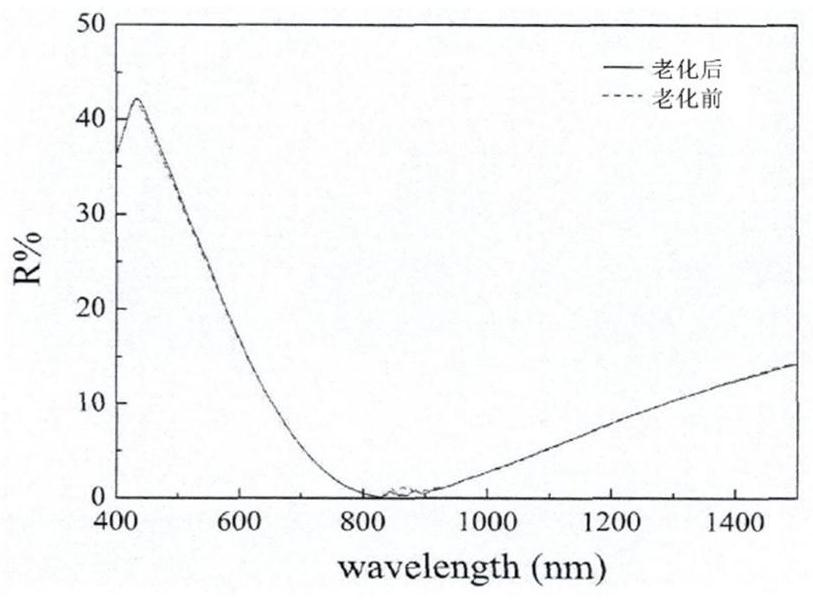

Embodiment 1

[0020] The present invention employs reaction magnetron sputtering techniques, using high pure aluminum (99.99%) target and high purity nitrogen and argon mixed gas plated in GaAS-based laser cavity surface x N y film. The process is to use acetate ratio of the semiconductor laser before 1: 1, acetone, ethanol mixed solution, ultrasonically; Ultrasound cleaning, the semiconductor laser cavity is removed, and the deionized water (Di) is rinsed, After cleaning, the semiconductor laser is placed in a magnetron sputter system vacuum chamber, and the laser is blown away by nitrogen; in order to minimize the residual oxygen content in the cavity, the magnetron sputtering system is required to be a vacuum cavity. It is repeated multiple times of inflation and deflation of nitrogen, and the glow-discharged nitrogen plasma in the magnetron sputtering system is used as the cleaning source, and the laser is cleaned for nitrogen plasma; in order to further improve the semiconductor laser perf...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com