Lithium molybdate positive electrode material of high-temperature lithium battery and preparation method and positive electrode material of high temperature lithium battery and preparation method thereof

A high-temperature lithium battery and positive electrode material technology, which is applied in battery electrodes, secondary batteries, circuits, etc., can solve the problems of low discharge capacity, battery performance degradation, and poor discharge performance of positive electrode materials, and achieve high temperature resistance compatibility, High capacitance and superior discharge performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

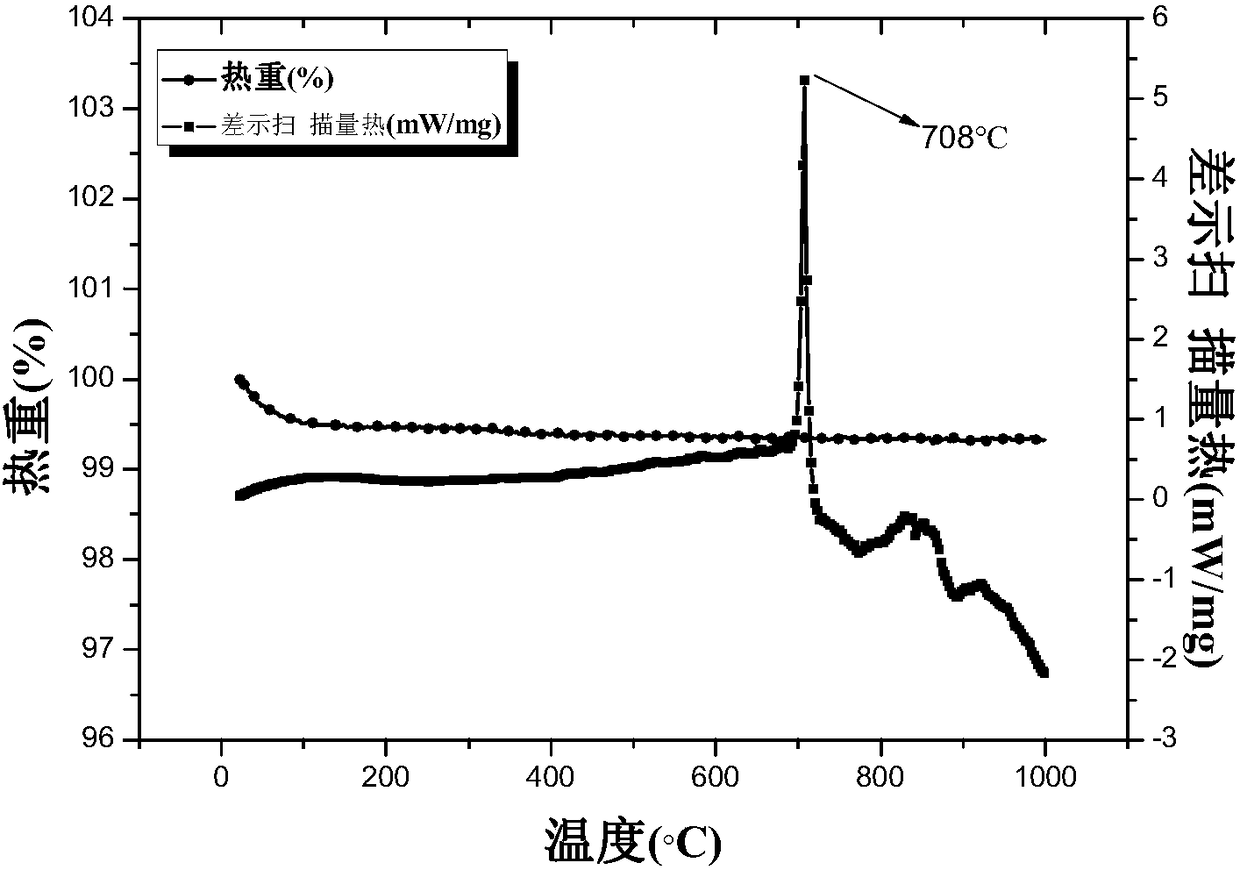

[0044] Example 2 Aqueous Synthesis and Preparation Method of Lithium Molybdate Cathode Material for High Temperature Lithium Battery and Preparation Method of Cathode Material for High Temperature Lithium Battery

[0045] The advantage of the aqueous solution synthesis preparation method is that its Li 2 MoO 4 The raw materials are uniformly mixed at the atomic level in the liquid phase environment, so that in the preparation of Li 2 MoO 4 While avoiding the generation of impurity phase, the prepared Li 2 MoO 4 Higher purity is conducive to improving the discharge performance of lithium molybdate cathode materials for high-temperature lithium batteries.

[0046] Step S1: According to the molar ratio of Li:Mo=2:1, weigh 1.6784g of LiOH and 2.8788g of MoO with an electronic balance 3 , Pour the weighed raw materials into a beaker, pour an appropriate amount of distilled water into the beaker, and stir on a magnetic stirrer until the raw materials are dissolved.

[0047] St...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com