Lithium battery cathode material with nitrogen-doped graphene and lithium molybdate and preparation method of lithium battery cathode material

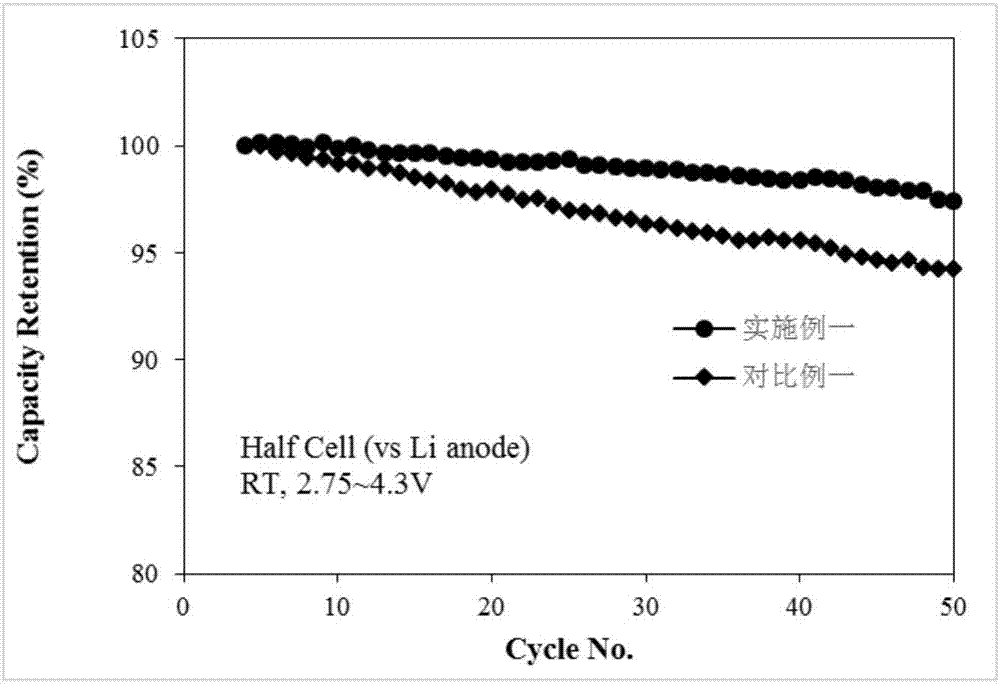

A technology of nitrogen-doped graphene and positive electrode materials, applied in battery electrodes, positive electrodes, secondary batteries, etc., can solve the problems of processing performance, charge-discharge cycle, and unsatisfactory rate performance, and achieve cycle stability and rate performance Effects of improved performance, improved electrochemical performance, and improved transport performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0019] The lithium battery cathode material preparation method of nitrogen-doped graphene and lithium molybdate provided by the invention comprises the following steps:

[0020] 1) Disperse graphite oxide and nitrogen source in water to form a dispersion, add ascorbic acid and heat to obtain a gel.

[0021] In the lithium battery cathode material finally prepared in the present invention, the amount of nitrogen-doped graphene added is calculated as graphite oxide, and the amount of graphite oxide added is 0.1% to 5% of the mass of the lithium battery cathode material. The graphite oxide and the nitrogen source are dispersed The concentration of the dispersion obtained in water is 0.1-5 mg / mL, and the nitrogen source is urea or thiourea.

[0022] 2) Add molybdenum source and lithium battery ternary material into the gel, stir and evaporate to dryness to obtain a mixed material.

[0023] The molybdenum source is molybdenum trioxide, wherein the molybdenum element is added in an...

Embodiment 1

[0029] Add 200mg of graphite oxide and 2g of urea to 100mL of water to form a dispersion, add 0.75g of ascorbic acid, stir at 90°C for 1.5h to form a semi-gel, then add 40mg of molybdenum trioxide and 20g of NCM622 positive electrode material, then at 80°C Stir and dry for 2h. The dried material was transferred to an argon atmosphere muffle furnace for heat treatment at 600° C. for 5 hours, and cooled to obtain a lithium battery cathode material co-coated with nitrogen-doped graphene and lithium molybdate.

Embodiment 2

[0031] Add 500mg of graphite oxide and 4g of urea to 100mL of water to form a dispersion, add 1.5g of ascorbic acid, stir at 80°C for 2h to form a semi-gel, then add 1.0g of molybdenum trioxide and 500g of NCM622 positive electrode material, and then stir at 70°C Dry for 5h. The dried material was transferred to an argon atmosphere muffle furnace for heat treatment at 700°C for 5 hours, and after cooling, a lithium battery positive electrode material co-coated with nitrogen-doped graphene and lithium molybdate was obtained.

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com