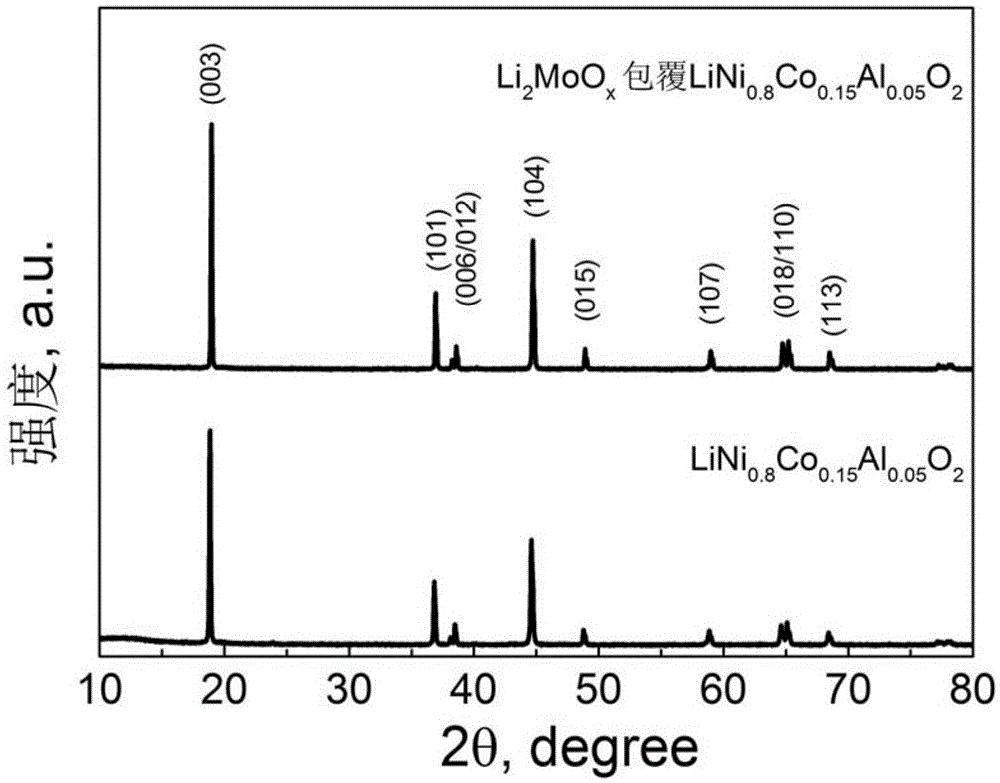

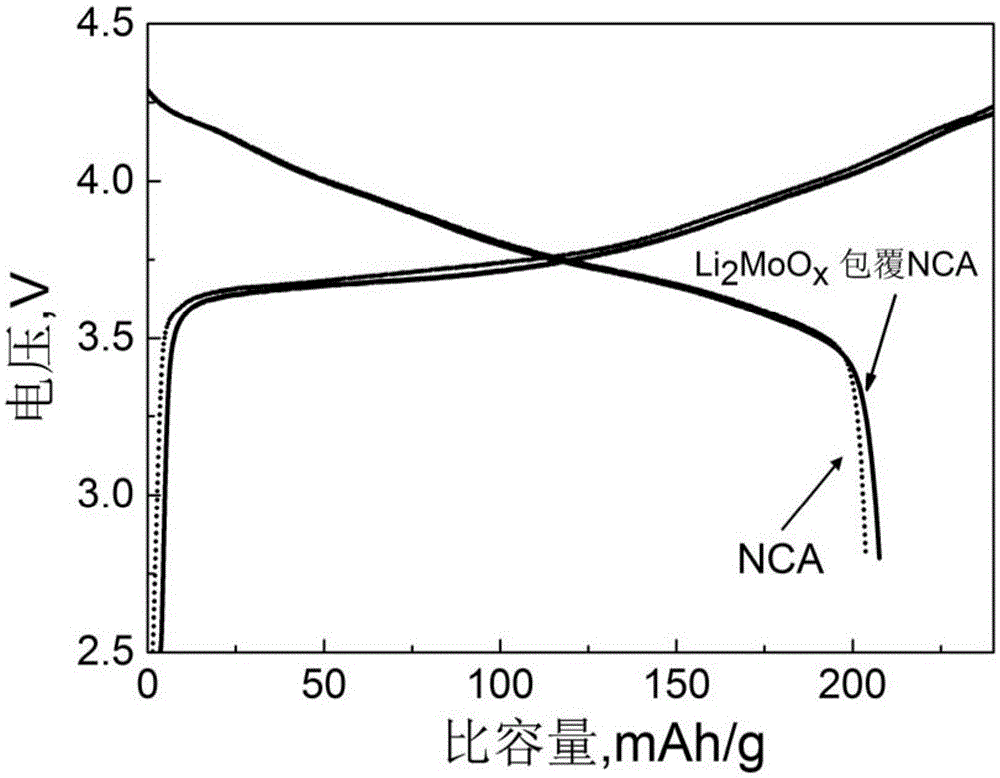

Lithium molybdate surface modified lithium ion battery nickel-rich positive pole material and preparation method thereof

A lithium-ion battery and surface modification technology, which is applied in battery electrodes, secondary batteries, circuits, etc., can solve problems such as charge and discharge and stability research, and achieve improved cycle stability and safety performance with high reproducibility , control the effect of convenience

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

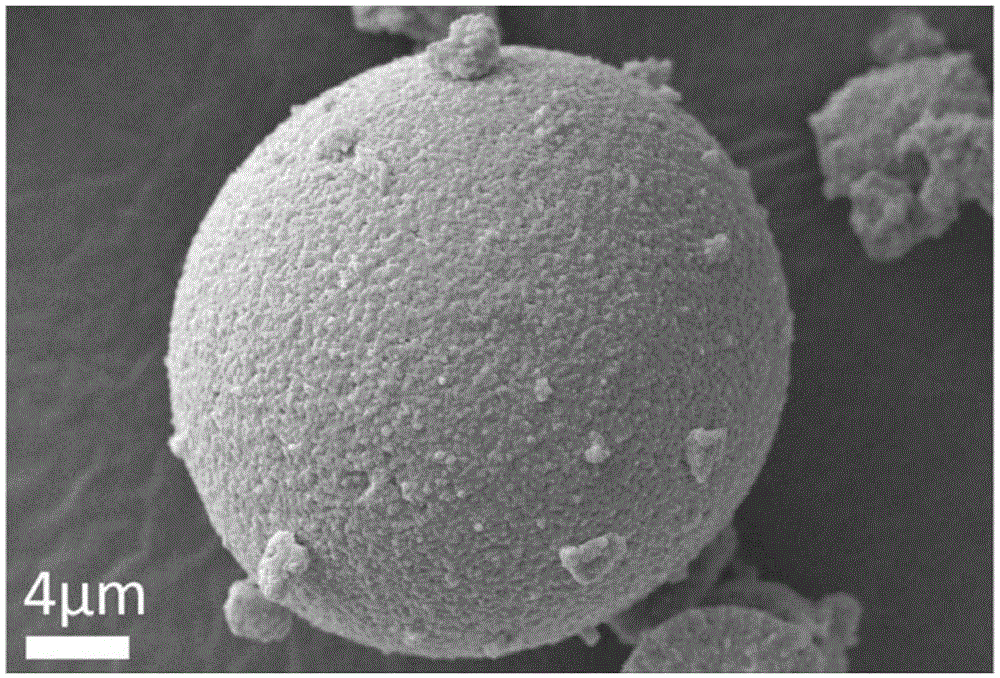

[0028] (1) Weigh 0.1mol of (Ni 0.8 co 0.15 Al 0.05 )(OH) 2 For the precursor material, disperse it in 200ml deionized water, and sonicate it for 1 hour. Then, take 0.1g of ammonium molybdate and add it into deionized water to form a molybdenum source solution of 0.01mol / L, and add the configured molybdenum source solution dropwise to the solution containing the precursor material under stirring conditions simultaneously. Stir evenly at 80°C and evaporate to dryness, then dry at 120°C for 12 hours.

[0029] (2) Weigh 0.105 mol of lithium hydroxide and mix it with the materials prepared in the above step (1), add 50 mL of absolute ethanol as a dispersant, and after ball milling for 8 hours, dry and press into tablets to obtain precursor tablets. First put the precursor sheet into a tube furnace, heat treatment at 500°C for 4 hours in an oxygen atmosphere, then continue to heat up to 750°C for sintering for 12 hours, and naturally cool to room temperature to obtain Li 2 MoO ...

Embodiment 2

[0032] (1) Weigh 0.2mol of (Ni 0.8 co 0.15 mn 0.05 )(OH) 2 Precursor materials were dispersed in 800ml deionized water and ultrasonicated for 0.5 hours. Then, the molybdenum acid that takes 0.2g is added into the deionized water and is made into the molybdenum source solution of 0.02mol / L, and the molybdenum source solution that will configure is added dropwise to (Ni 0.8 co 0.15 mn 0.05 )(OH) 2 The solution of the precursor material was uniformly stirred at 100°C and evaporated to dryness, and then dried at 110°C for 20 hours.

[0033] (2) Weigh 0.105 mol of lithium carbonate and mix it with the materials prepared in the above step (1), add 100 mL of absolute ethanol as a dispersant, ball mill for 8 hours, dry and press into tablets to obtain precursor tablets. First put the precursor sheet into a tube furnace, heat treatment at 600°C for 6 hours in an oxygen atmosphere, then continue to heat up to 800°C for sintering for 15 hours, and naturally cool to room temperatur...

Embodiment 3

[0036] (1) Weigh 0.05mol of (Ni 0.7 co 0.2 Fe 0.1 )(OH) 2 For the precursor material, disperse it in 400ml deionized water, and sonicate it for 1 hour. Then, weigh 0.2g of molybdenum acetylacetonate and add it into deionized water to form a 0.05mol / L molybdenum source solution, add the prepared molybdenum source solution dropwise into the solution containing the precursor material, and evenly stir and evaporate at 80°C. After drying, it was dried at 100° C. for 20 hours.

[0037] (2) Weigh 0.0524mol of lithium nitrate and mix it with the material prepared in the above step (1), add 50mL of absolute ethanol as a dispersant, ball mill for 10 hours, dry and press into tablets to obtain precursor tablets. First put the precursor sheet into a tube furnace, heat treatment at 550°C for 6 hours in an oxygen atmosphere, then continue to heat up to 700°C for 24 hours, and cool naturally to room temperature to obtain the finished Li 2 MoO 4 Surface Modified LiNi 0.8 co 0.15 al 0...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com