Preparation method of aqueous sodium ion battery cathode composite material

A technology for sodium ion batteries and composite materials is applied in the field of preparation of positive electrode composite materials for aqueous sodium ion batteries, which can solve the problems of poor safety performance, complex production process and high cost, and achieve the effects of enhancing electrical conductivity and improving rate capability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

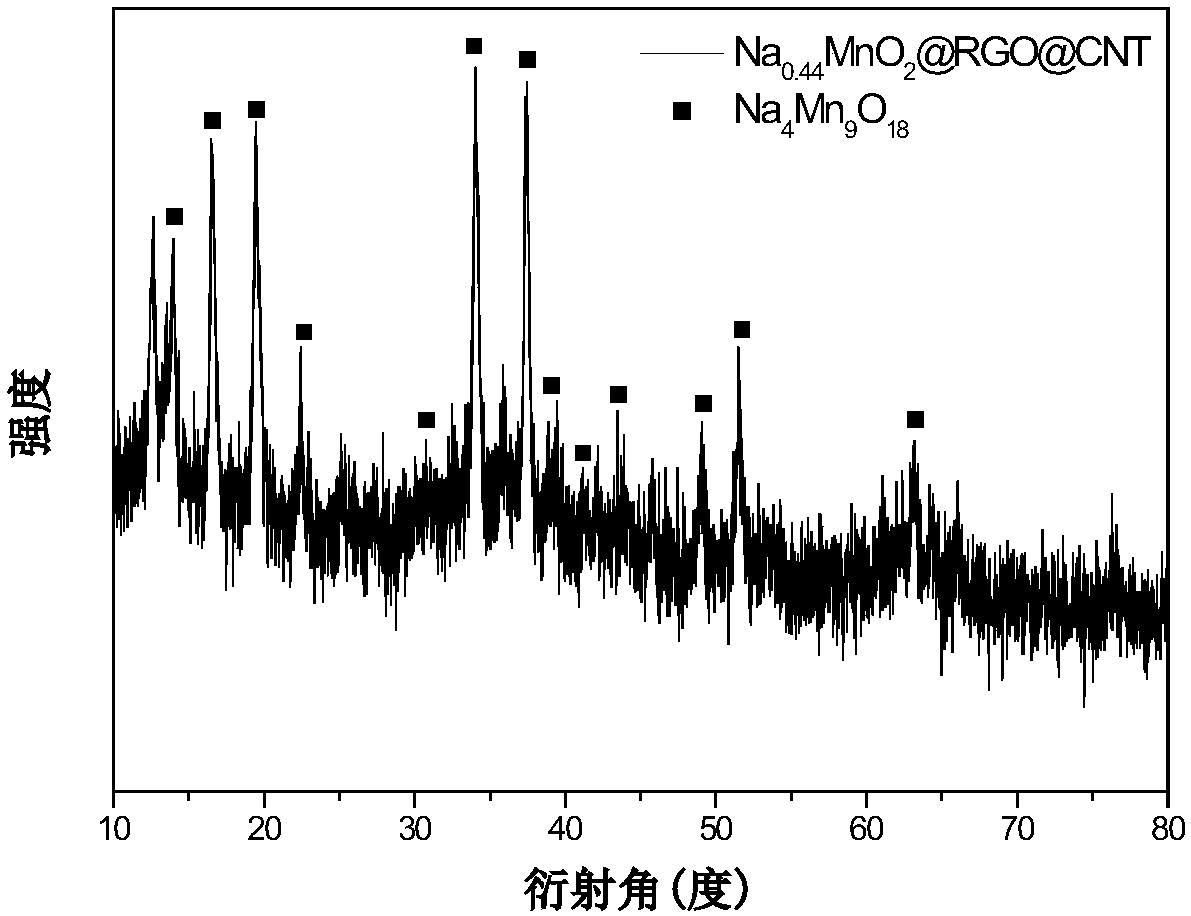

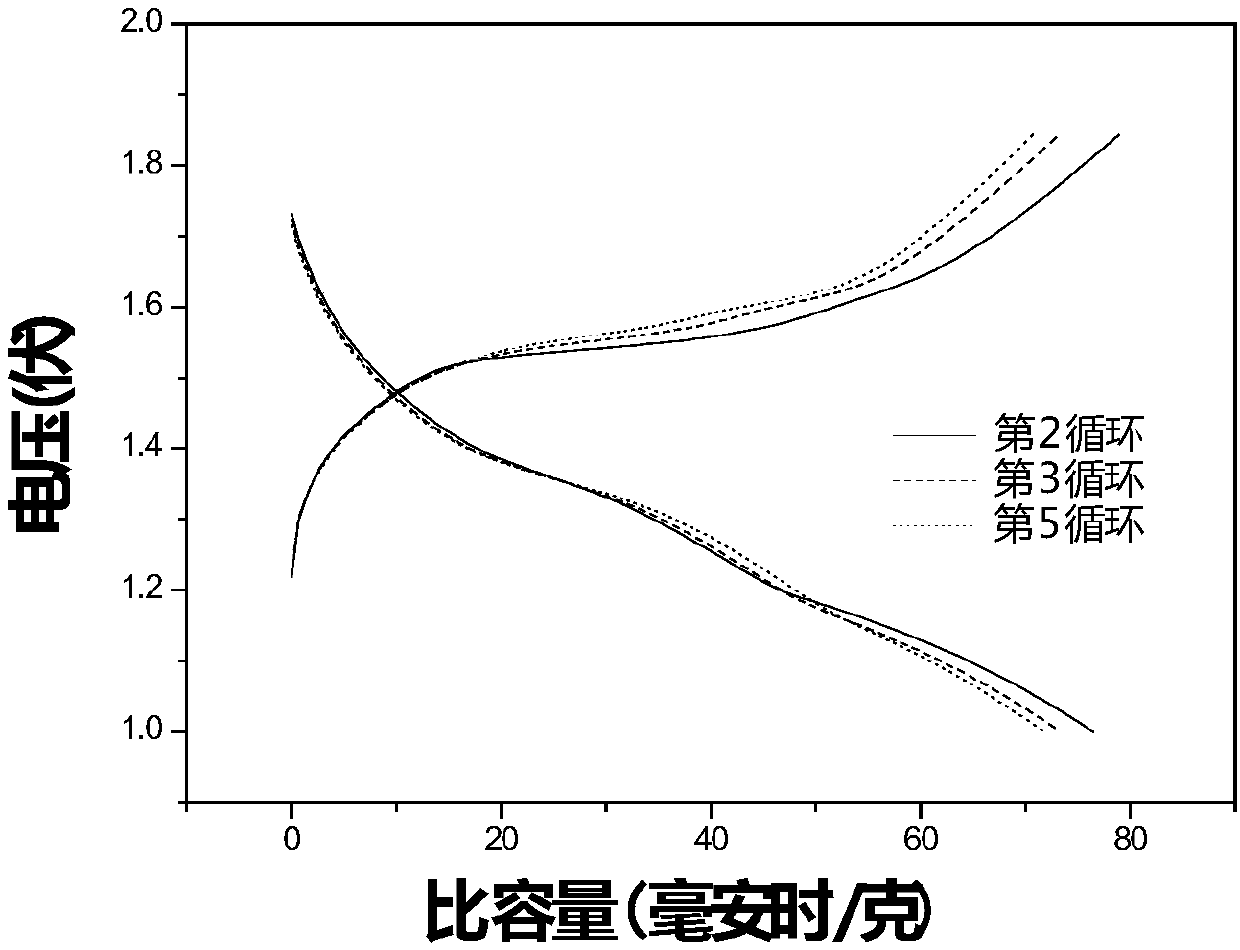

[0027] The first step is to prepare the cathode composite material (NMO-CNT-RGO composite material) for aqueous sodium ion battery:

[0028] Measure 25mL of 0.28mol / L MnSO 4 , stirred for 30min, and then weighed 25mL of NaOH with a concentration of 3mol / L and KMnO with a concentration of 0.1mol / L 4 The mixed solution was stirred for 30min, and the MnSO 4 Add NaOH and KMnO to the solution 4 In the mixed solution, stir for 30min, then introduce the mixed solution into a test tube and centrifuge to obtain a black precipitate, pour out the water in the test tube, and let the test tube stand for 24 hours to obtain Na 0.44 MnO 2 Precursor.

[0029] Weigh 4.38g of precursor and add it to 15mol / L NaOH solution, stir for 20min, pour it into the reaction kettle for 24h hydrothermal reaction at 180°C, after cooling down to room temperature, centrifuge with deionized water and place in a vacuum oven Dry at 70°C for 24h to obtain Na 0.44 MnO 2 .

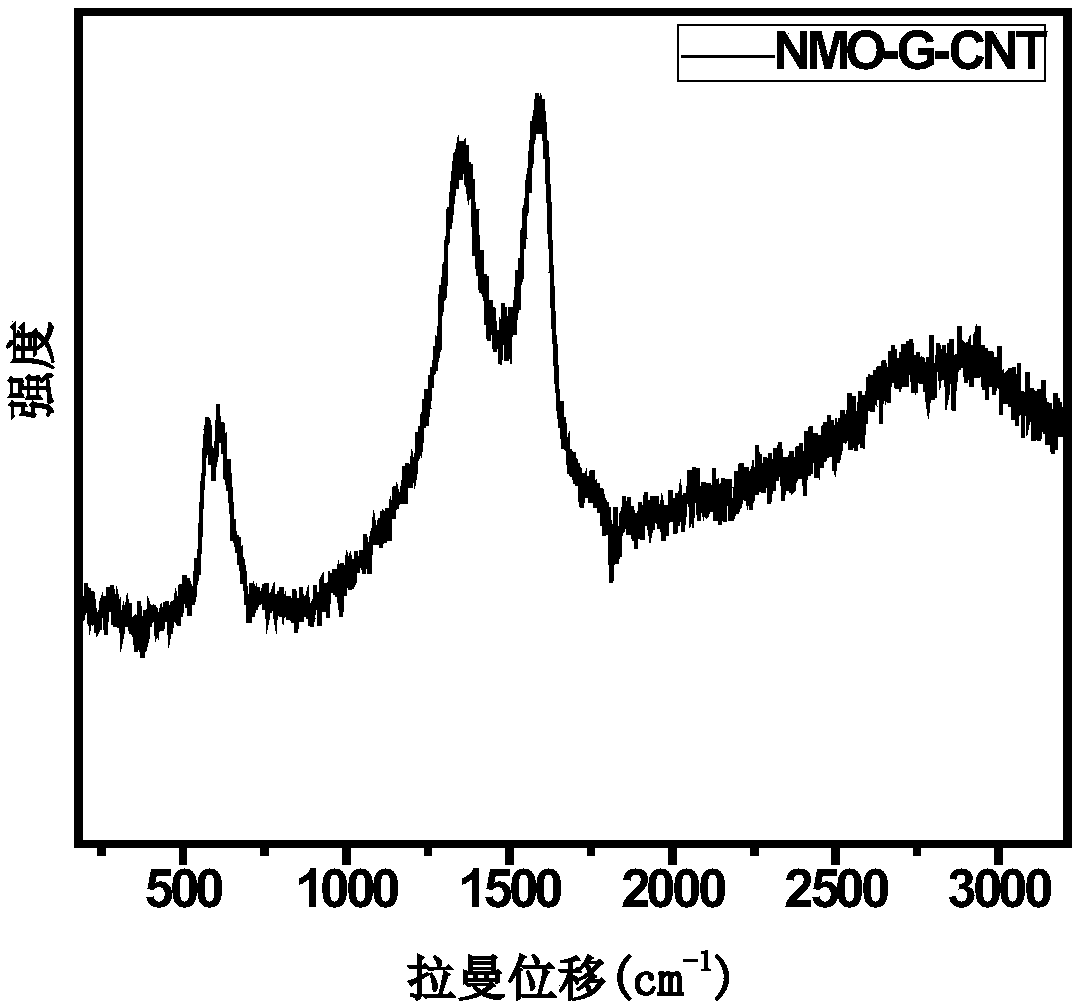

[0030] Weigh 22.32mg of GO, 248mg ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com