Silicon-based composite material and preparation method thereof

A technology of silicon-based composite materials and composite materials, applied in the direction of active material electrodes, electrical components, electrochemical generators, etc., can solve the problems of inability to effectively improve cycle stability and rate performance, complex preparation process, and uneven coating thickness and other problems, to achieve the effect of improving the high charge transfer impedance, improving the low power output, and improving the rate performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0047]The present invention also provides a method for preparing the silicon-based composite material described in the above technical solution, comprising the following steps:

[0048] a) dissolving aluminum salt compound, lithium salt compound and silicon dioxide in a solvent and then sintering to obtain fast ion coating agent;

[0049] b) mixing the silicon-based substrate with the fast ion coating agent to obtain a precursor powder;

[0050] c) mixing the precursor powder, carbon source and liquid-phase coating agent, and sintering to obtain a silicon-based composite material.

[0051] Regarding step a):

[0052] In the present invention, the aluminum salt compound is preferably one or more of aluminum isopropoxide, aluminum sec-butoxide, aluminum sulfate and aluminum nitrate. The lithium salt compound is preferably one or more of lithium carbonate, lithium hydroxide, lithium acetate and lithium citrate. The particle size of the silica is preferably 0.5-2 μm, more prefe...

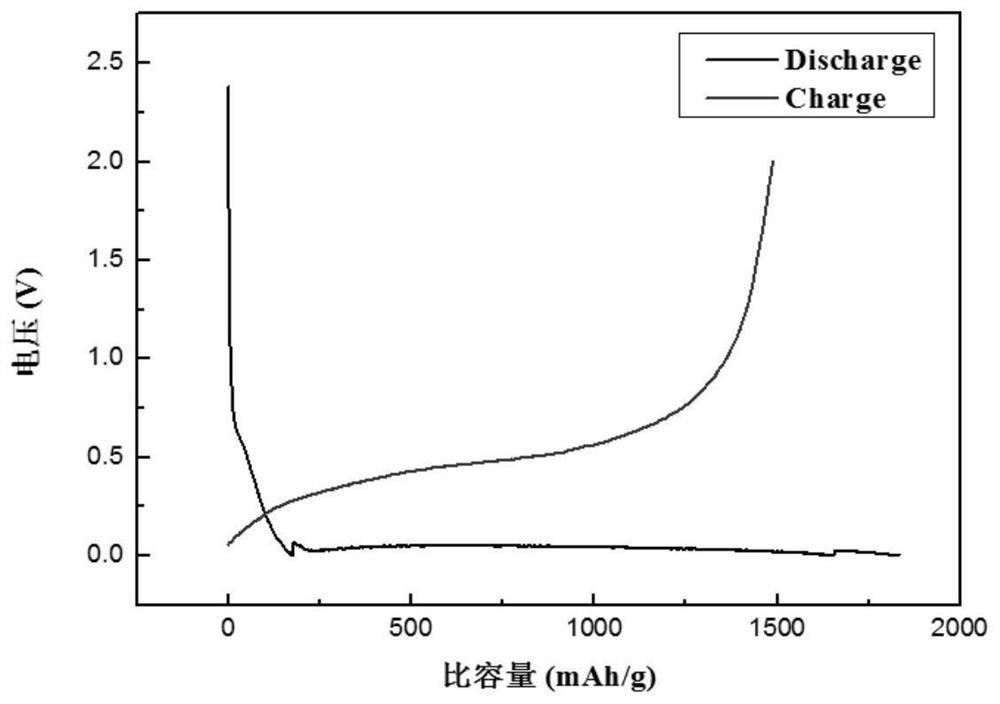

Embodiment 1

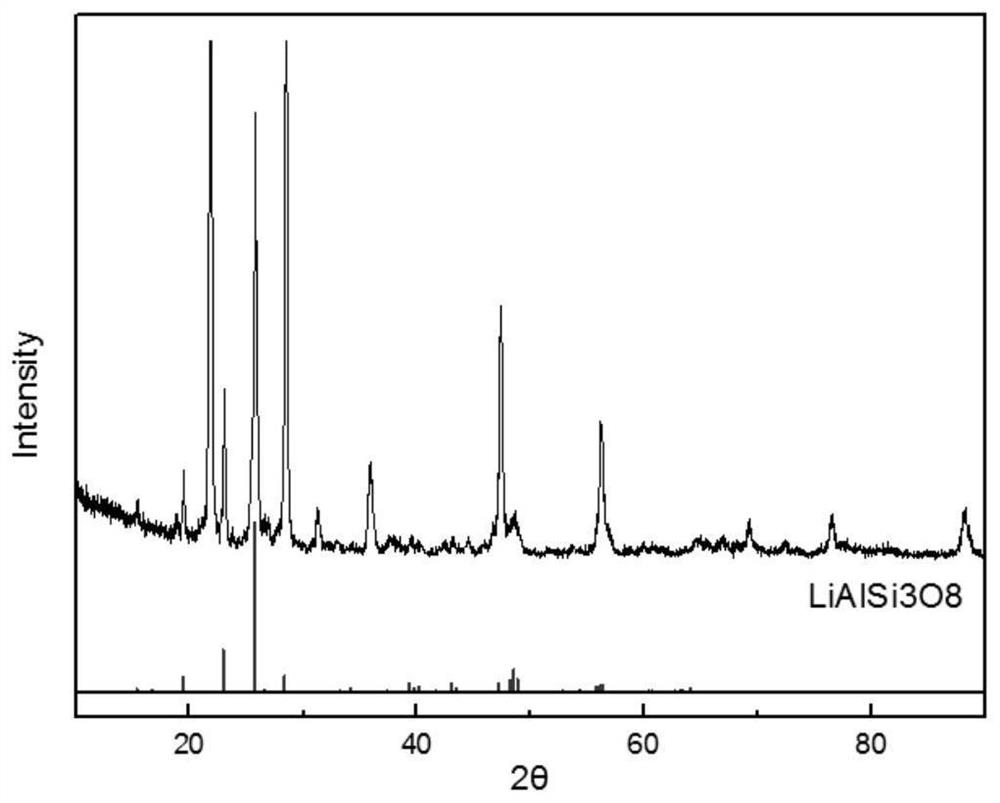

[0074] S1. Weigh 20g of aluminum sec-butoxide, 10g of lithium carbonate, and SiO 2 30g of powder was dissolved in 50mL of ethanol solution, stirred with a magnetic stirrer for 4h, after stirring evenly, dried at 80°C for 5h, and then the dried material was ground to obtain mixture A. Sintering is then carried out in an argon atmosphere at a heating rate of 5° C. / min, raised to 1000° C. and kept for 5 hours to obtain a fast ion coating agent.

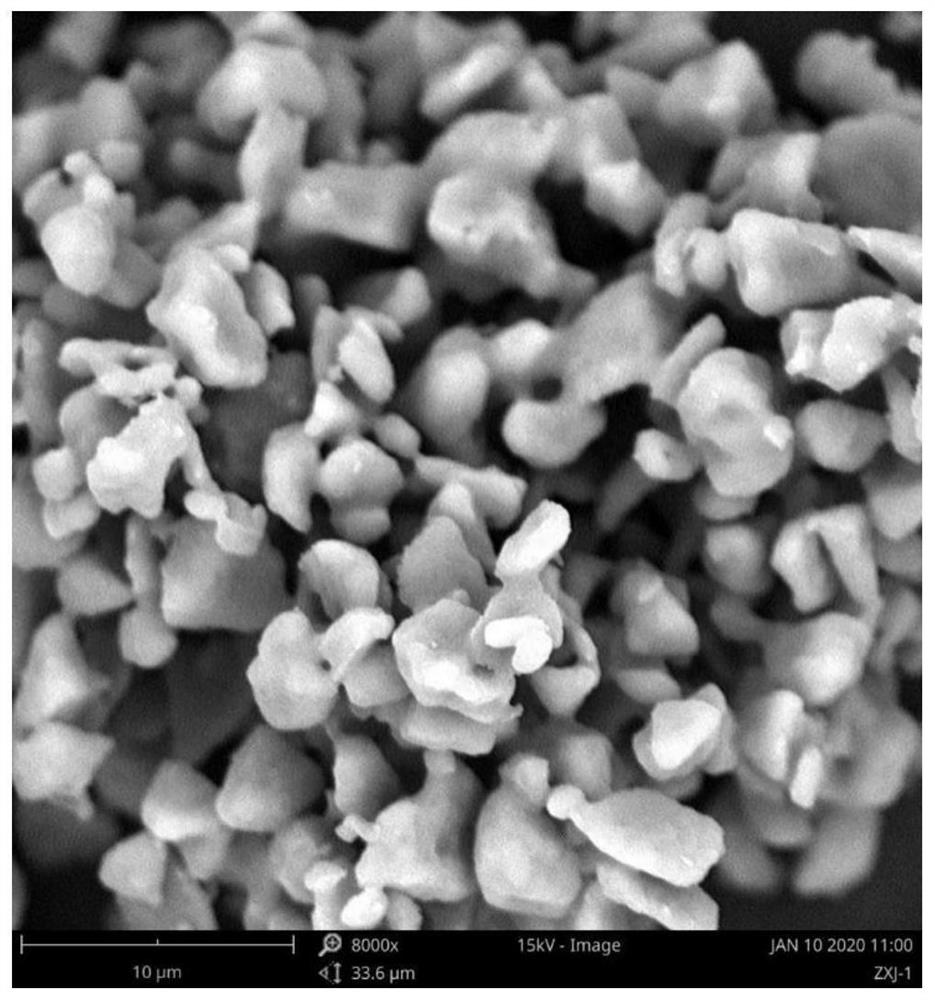

[0075] S2, weigh silicon oxide SiO z (z is 0.9, particle size is 3 μm) 200g, fast ion coating agent 10g, put into a ball mill jar for ball milling at a speed of 400r / min, and ball mill for 2h to obtain a precursor powder.

[0076] S3. Add the precursor powder, asphalt and liquid phenolic resin into the fusion machine at a mass ratio of 90:5:5, stir at room temperature at a speed of 300 r / min, and mix for 30 minutes to obtain a mixture.

[0077] S4. Put the mixed material into a crucible, and sinter in an argon atmosphere at a heating r...

Embodiment 2

[0081] S1. Weigh 20g of aluminum sec-butoxide, 10g of lithium carbonate, and SiO 2 30g of powder was dissolved in 50mL of ethanol solution, stirred with a magnetic stirrer for 4h, after stirring evenly, dried at 80°C for 5h, and then the dried material was ground to obtain mixture A. Sintering is then carried out in an argon atmosphere at a heating rate of 5° C. / min, raised to 1000° C. and kept for 5 hours to obtain a fast ion coating agent.

[0082] S2, weigh silicon oxide SiO z (z is 0.9, particle size is 3 μm) 100 g, fast ion coating agent 10 g, put into a ball mill jar for ball milling at a speed of 400 r / min, and ball mill for 2 hours to obtain a precursor powder.

[0083] S3. Add the precursor powder, asphalt and liquid phenolic resin into the fusion machine at a mass ratio of 90:5:5, stir at room temperature at a speed of 300 r / min, and mix for 30 minutes to obtain a mixture.

[0084] S4. Put the mixed material into a crucible, and sinter in an argon atmosphere at a h...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com